bkahler

Members-

Posts

1,951 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

A while back I was looking for some shock mounting washers. I spent several evenings googling and ended up finding several sources. Part # 1319554. My original washer is in the middle. They were used on 70-74 Mopars. The 1-1/2" wheel adapters also arrived today. Now if I just had the axle done so I could try them out Brad -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

If for whatever reason I do end up going with a remote reservoir this is the one I would likely use, or something similar anyway. It has the nostalgic look that I would want and provides decent mounting points. And like TJ said I'd make my own parts to fit onto the MC. For a little while I considered the idea of 3D printing my own reservoir but I'm not really up to the skill level yet to do something like that. Brad -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Ok, thanks. If I put a pedal stop in it's going to be set so the pedal is just shy of touching the plastic reservoir. It would do me no good to get full pedal stroke and take out the reservoir in the process -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Welding in a breeze can make for interesting welds I think my first MIG was either a 125 or 150 which covered just about anything I wanted to do on the vehicles I worked on. -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

I'm not sure I follow what you're trying to say? -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Good info on the pedal stroke. It should be pretty easy to fabricate an add on bracket as part of the MC adapter. Possibly even something TIG welded to the top of the adapter that would stop the pedal just before it contacted the reservoir. Definitely something to think about. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Today was cold but the only day for the next week or so where I could work outside. Rain and snow the rest of the week. I kinda like welding when it's cold much more so than when I'm hot and sweaty What kind of welder? -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Well.....you just have to build an engine that really sucks.......! -

B-Series Trucks Represented in Auto Museums....

bkahler replied to 48Dodger's topic in Mopar Flathead Truck Forum

But it has a dent in the fender!! ? Seriously though, nice choice. Other than surface rust most of your trucks seem to be rust free. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I finally got around to welding the perches onto the Cherokee axle. This is the first decent day we've had in a while so why not take advantage of it For others that might be interested in using a Cherokee diff in their B3B the one I used came from a 1997 Jeep Grand Cherokee. It is a Dana 44 with the aluminum center section and C-clip axles. It is a disc brake rear axle. It measures 1" shorter per side at 60-1/4" wms to wms. The original axle in my truck measured 62-1/4" wms to wms. The Dana 44 measured 55-1/16" from outside to outside of the flanges. The leaf springs on my truck are 44-1/4" apart centerline to centerline of the springs. On the Dana 44 diff I ended up measuring in from the outer flange 4-1/2" and placed the edge of the perch at that point. Using 4-1/2" places the centerline of the perches at 44-1/4". Next up is temporarily mounting the disc brakes so I can see where to mount a couple of brackets to hold the rubber brake lines for the calipers. They need some sort of mounting bracket so they don't just flap in the breeze while driving. Brad -

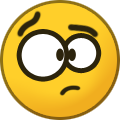

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

I think I found a winner! The Dorman M390378 that I bought from Amazon for the 97-06 Wrangler looks like it's going to work. As luck would have it needed a slightly modified adapter plate so I fabricated one this afternoon. Currently it's made from 3/8" aluminum plate but I think I'll use 1/2" for the final version. I'd like the extra thickness for the 5/16-18 bolts that hold the MC to the plate. More depth means more thread engagement. The reservoir doesn't come close to the steering column or the pedal. There are some definite differences between the Wrangler MC and the Cherokee MC. The Cherokee reservoir is 5-1/4" tall from the centerline to the top of the high part of the reservoir and 4-1/2" at the low end. The Wrangler is only 3-1/2" from centerline to the top of the reservoir. That difference right there was all I needed to get a lot more pedal travel. The pedal actually runs into the firewall pad on the right edge where it angles inward. At rest the pedal is about 10" above the firewall. Fully depressed it gets to within 1-1/4" of the firewall. That equates to about 1-3/16" piston travel. I think full piston travel is about 1-5/8". I have no idea if not getting full stroke of the piston will matter but there's nothing I can do about that. The pedal arm does contact the the top of the reservoir at full pedal travel but my guess is if the pedal travels that far I probably have other problems to worry about at that point ? I will have to use socket head cap screws to mount the adapter plate to the bell housing or else countersink the holes and use flatheads. SOHC will definitely work for the top two holes but the bottom one will likely need to be countersunk. I'm still in the mode where I don't want to alter a new MC to make it work if I don't have too and I think even a SOHC will interfere with the bottom of the MC. One other thing. The depth of the Wrangler MC bore is deeper than the Cherokee so the end of my pushrod that I cut off will need to be welded back on ? Brad -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

20,000 miles in a pilot house is impressive I don't know that I'll live long enough to be able to accomplish that feat! If I remember right the pedals are different between a 4-speed and a fluid drive. That might explain some of the difference. Thanks! Brad -

Its amazing how fast you can get something done when the right tool is at hand. Glad to hear you're past that hurdle. On to the next

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I've done similar in the past when I used to stick weld. I mostly mig weld now so I'll just have to build up a couple of layers. -

Timing Gears and chain info needed please

bkahler replied to Dodgefran's topic in Mopar Flathead Truck Forum

Vintage Power Wagons in Iowa. I bought most of my engine components from them -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Spent part of today dismantling the rear leaf springs and adding plastic liners that I bought from Speedway Motors. It actually ended up being easier than I was expecting. Of course the springs had been previously dismantled which obviously helped I didn't add the liner to the upper set of overload springs. I don't figure I'll be doing much heavy hauling in the truck so I figured it wasn't worth the effort or material. I did find the part number stamped on the bottom of the smallest spring leaf. 1271888. I was somewhat surprised that I couldn't find the number in my parts book. I'm not sure what to make of that. Brad -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Jeff, Thanks for the info and picture. That's the same MC I've been trying to fit. Do you happen to know how close your brake pedal gets to the top of the plastic reservoir when you have the fully depressed the brake pedal? Thanks! Brad -

Which rear end to swap in 1946 WD15

bkahler replied to lostviking's topic in Mopar Flathead Truck Forum

The axle in the picture is my original axle. I haven't as yet installed the Cherokee axle. -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Just finished trying TJ's idea of reversing the reservoir. I did gain about 1/2" of travel at the top of the pedal but still not enough to fully stroke the MC. This time I took a measurement of actual piston travel in the MC and came up with 15/16" of travel. I believe the Cherokee MC has about 1-1/2" of piston travel so there is still a fair amount of travel left. With the pedal depressed and the arm just touching the reservoir there is about 4-1/2" of travel before the pedal hits the floorboard. It starts at about 10" of travel so 5-1/2" of travel equates to about 15/16" of piston movement. This means the pedal will be just a little above the floorboard before the piston bottoms out. I believe the original MC has about 1-1/2" of piston travel as well. I get the Wrangler MC tomorrow and I hope to fabricate an adapter before the end of the day. Hopefully I'll be able to post more info tomorrow night. -

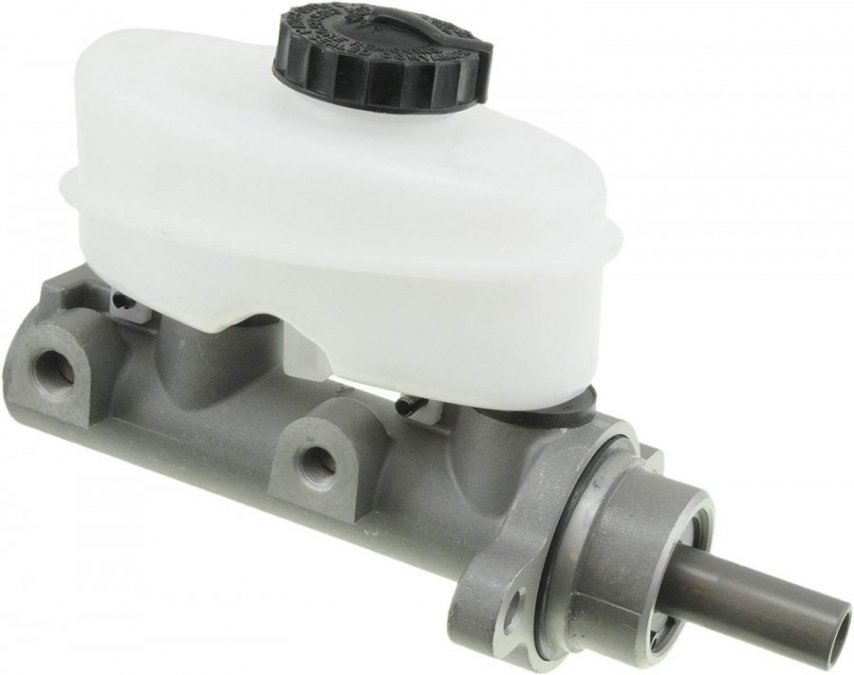

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Actually I misspoke, I do need two 2 lb residual valves installed along with the proportioning/combination valve. Maybe Jeff Balazs will chime in here, I seem to recall reading a post from him about having removed his residual valves after using his truck for a while. Then again I could be wrong about this! My memory isn't all that great anymore...... Found Jeff's post about the residual valves. He removed the front one. This post has even more info on the residual valves. Brad -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Just did it and it does lower the top where the pedal travels by about 1/2". However I will need to do some grinding on my adapter plate to provide some clearance for the reservoir. I'll do that tomorrow. If I remember right I needed about 1" or slightly more to provide full pedal travel. Surprisingly it was symmetrical About an hour ago I ordered this Dorman M290378 MC from Amazon. Should be here Sunday. It appears to be considerably narrower due to its oval shape. The brake pedal only needed about 1/8" to 3/16" clearance on the one corner for clearance. I think the mounting holes are slightly different which is no biggy. This MC is from a 97-06 Jeep Wrangler. After discussion with Eric he thinks most Wranglers had rear disc brakes so it should be appropriate. I bought a GM disc/disc proportional valve from Amazon as well. From what I've read it should do the job of eliminating the separate brake residual valves. The information came from a company called MDM. -

TRUCK MASTER CYLINDER UPGRADE ADVICE

bkahler replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Had a few inches of snow last night but I still decided to spend the morning sloshing through a couple of junk yards in the area but had zero luck finding any MC or reservoir that would be reasonably close to fitting. It didn't help that all the vehicles were covered in snow which made it difficult to find Jeeps. I'm pretty much convinced this style of MC will interfere with the brake pedal when the pedal is depressed just like the style of reservoir that I have now. The pedal interferes with the section of reservoir that is closest to the mounting point of the MC and this MC appears to be just as tall in that area. This style of MC might have a better chance of clearing due to its oval shape but I don't have any clue what model vehicle this MC came from. It also appears shorter than the Grand Cherokee MC which is a plus as the complete MC could be moved farther forward which might help with pedal clearance. I'm also now considering some sort of remote mount arrangement but so far my searches haven't been to productive. I'll keep looking though. What master cylinders have others used in the B3 series of trucks that actually fit and didn't interfere with the full stroke of the brake pedal? I'm even considering just using my original (brand new) MC. I've never experienced a MC failure which is one of the reasons I'm considering this approach. Brad -

Which rear end to swap in 1946 WD15

bkahler replied to lostviking's topic in Mopar Flathead Truck Forum

I'm not sure how the WC is configured but on the B3B the lower shock mounts are part of a plate that is located on the bottom of the axle. The spring perch is on top of the axle. The U bolts clamp the bottom shock plate to the axle and the leaf springs to the spring perch. -

Which rear end to swap in 1946 WD15

bkahler replied to lostviking's topic in Mopar Flathead Truck Forum

Wheel mounting surface. An example would be my original B3B axle has a WMS of 62-1/4". The new Dana 44 from the 97 Grand Cherokee has a WMS of 60-1/4". I'm buyint wheel spacers to make up the 1" difference on each side. -

Which rear end to swap in 1946 WD15

bkahler replied to lostviking's topic in Mopar Flathead Truck Forum

It will be interesting to seem what the WMS ends up being on the 2000 axle. I measured a 2002 and a 2003 in the junkyard and they were something like 65" or 66" for the WMS. The WMS is not the same as seal to seal measurement.

.jpg.c52bf729481a2c2837afa81b799fceab.jpg)