-

Posts

2,058 -

Joined

-

Last visited

-

Days Won

17

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Mark D

-

The convertible top on the plumber has one Oakbow just before the Klopf waterfalls towards the back of the car. Just above the rear window this bow served as a tack surface for the rear curtain and the top fabric, as well as the padding which runs above the left shoulder of the driver in the right shoulder of the passenger. This bow is visible from the inside of the car. As such it is wrapped in fabric to make it less noticeable. As mentioned prior there were two other pieces of wood that are wrapped in fabric, these 12 inch sections of oak or shaped to fit into steel C channels at the rearmost sections of the driver and passenger door windows. These identical sections of wood service tech services for the side curtains, as well as for surfaces to receive the weatherstripping that the chrome encased window seals against when shut..

-

Someone asked this very same question on the POC facebook page...

-

Last Monday I visited the trimmers shop. He's been plugging away at the interior rear well liner and has been slowed waiting for materials to arrive. However I was able to help him reinstall the top mechanism and the paint job I gave it got a good cure while I was in Australia last couple weeks. In addition to the well liner, he has also made repairs to the oka bow, filled all old staple holes with epoxy and wrapped it and the side window jambs all in Hartz fabric. New rubber door window seals and baric tape has arrived from Steele and that was completed yesterday. Today the top goes on the bows and the tacking begins. He is taking photos of the entire process and I will have all of these delivered to me with the car. My plan is to put them together in a document with full descriptions on each photo that I will make available.

-

My floor rubber is cracked in several places. Carefully removing the rubber allowed me to replace the jute with modern carpet pad, (using the old one as a template) and to also apply 3" wide gorilla tape to the underside of the rubber thus repairing and closing the cracks. I hope to part of your pit crew when the OD arrives, and will bring the gorilla tape with me.

-

I did nothing more than to remove the factory floor panel. A dozen bolts and it was out of my way. Several here have given that advice in prior threads. mark d

-

Hey paul, thanks for the suggestion. When and if I do get around to it, it won't be my first time. That happened a few years back when I bought an OD from Paul Flaming, tore it down to a pile of parts, rebuilt and replaced all bearings and seals, then swapped it for the three speed in my sedan. The secret to the game is pulling the floor out of the car. Makes it 100% more easy to see what you're doing and to literally lift the tranny into position and then thread the bolts into the bell housing. Cheers Mark D

-

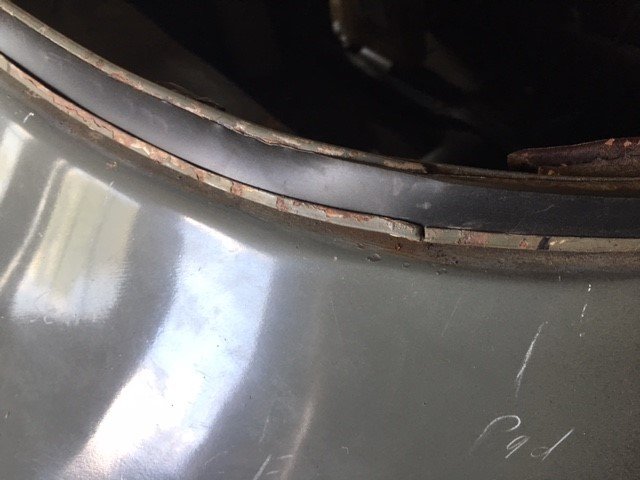

Getting back to Wards original question, attached are a few pictures of the tack strip replacement on my car. Here you can see the new PVC tacking strip installed. This requires opening the bead slightly and removing the old pressed board strip. Once complete the new PVC needs to be warmed and it will slide in place. Then the bead is closed again. White marks on the body are grease pencil recorded reference marks that my trimmer made in order to have everything line up again. A close up showing the new bead being worked into place. The header rail in the front of the also has a tack strip, however it is thicker and requires a little more patience to put in place. Rather than a full bead, the head has small tabs which need to be very gently opened and closed to prevent breaking.

-

I've always had a problem with this as well, and with the exception of one show that uses the money for charitable purposes, and another that gives good value for the fee (food, entertainment, etc..) I don't feel it's fair. There's another local show that collects only from the cars and spectators are free, which I feel is quite upside down. Seven years ago when I bought my first p15 I attended a lot of shows. Nowadays I'm happy to take the odd tour with likeminded car friends, wrench on my cars, and drink beer or two in the Garage with my buddies.

-

Good question... are they OEM? Still 6v? Wonder if the throw is the same as my vacuum cylinders.

-

Unfortunately and for posteritys sake, dean bennett supply wasn't able to deliver the leather cups in the correct diameter. Onward now with the search.

-

Met him last year when I attended. He did know about the forum.

-

P15 OEM Gas Pedal & Napa Ball Stud fitment

Mark D replied to 3046moparcoupe's topic in P15-D24 Forum

Thanks for publishing the ball stud part number! Appreciate that.- 8 replies

-

- 1

-

-

- ball stud

- accelerator pedal

-

(and 1 more)

Tagged with:

-

Maybe by Sep 2018 I will have freed myself from the bonds of employment and can laugh heartily at sight of the druggery in the rear view mirror. If the good lords allows, I will be there.

-

The bracket in the middle resembles a piece that I recall as being mounted to the transmission. I'll take another look when I'm back at the garage.

-

This event takes place four an a half miles from my house. The president of the ty-rods club is a personal friend of mine. I've been attending for the past four or five years with my P 15 sedan, and this year I registered my P 15 convertible. I had intended to be there, but an impending business trip down under, and many things left to do around the house prevented that..

-

Cleaned primed and painted the folding top mechanics last week. Delivered to the trimmer yesterday. Wednesday I'm off to Sydney Australia for a week. When i return the new top will be finished, and I will pick the car up on 9/24. Unfortunately the leather cup supplier here in the states that Greg G found did not pan out. They cannot get the cups in the 5.125" diameter. However since I will be in Sydney I will check with a supplier just outside of town that a fellow p15 convertible owner down there gave me reference to. A hydro/electric system may end up being the way to go, but avoiding the chase because others found no option is not the way I like to do things.

-

Hey Mike, welcome aboard. Let's see a picture of the car! I sold a couple plymouths in Luxembourg last year. Love to see if it's one of them. cheers, mark

-

Awesome - just beautiful.

-

Hey Bob - I called them and they don't have parts anymore.

-

P15 convertibles also have a spring assist. It is mounted horizontally behind the cylinder and attached to a lever on the B pillar top bow. Mine are present and in good shape. Nice car by the way!

-

From what I know, vacuum powered tops were only mopar, and only offered late 30's to early 49. The facebook group intention was to collect P15 owners, to try and figure out how many p15's were left, we may open it to the sister marques. Hoping to hear back that they can make up the cups, before I make too many promises there's a few more calls and research that I have to do for the vendor in order for them to be certain they can make the molds for these.

-

Greg - Thanks to you for this lead. I made a call and talked to them this morning. The cups I require are indeed special order, but they are willing to make new. Since we are in contact with a dozen p15 convertible owners now via the facebook page Robin and I are admin-ing, I will see if there is interest in having a few more sets made for these guys. Next step is for me to pull the cylinders from the car and take some pretty detailed photos of specific parts of the interior, they will then try to match spec at the factory.

-

YESIREEBOB! (or Greg...) #711 probably the closest fit, but the edges are not thickened or flared. Cheap enough to order and give it a go. Got an email from the guys downunder moments ago. Will see how these do before I go knock on their door.

-

Thanks for the response. My cylinders and chrome shafts were also in great shape. Tolerances between the shaft and bronze (i stand corrected, and it was what I meant to type) bushings is fantastic, with zero end play fully extended. Like your car my car was stored with the top down for most of its life, but the dry storage was not kind to the leathers. Ive been in contact with a company in Florida (http://www.hydroe.com) used to make replacement parts for these systems, however in my last conversation with them the old timer that had the skills passed on and they no longer offer the service. The do 100% hydraulic now and make systems for 50's through modern cars. Much of the stuff they sell is OEM direct replacement for 50's cars. They quoted me $700 for a complete hydraulic system which I have given thought to. Before I commit, i am waiting for a return call from a company in Australia the makes replacement rubber cups for pumps. The cups are $45AUS each, and since I will be in Australia for business next month I am going to stop by and see what I can get from them. I'd really like to keep the original system in the car, but I also want to have a functioning top for the car, and since most of this gear isn't seen, I am willing to acquiesce on an item like this.

-

Got a few questions for you; 1.) why did you decide to go with new shafts. Wouldn't it be easy to press out and insert new brass bushings? 2.) did you find a replacement for the leather seals and if so what was the material and where did you source them? 3.) does the top go up and down satisfactorily now? your work looks excellent. mark d