-

Posts

470 -

Joined

-

Last visited

-

Days Won

1

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by FarmerJon

-

Homebrew brake fluid, now that is a good one! The master cylinder is under the floor, not much paint to ruin there. Usually when I have spilled DOT 3-4-5.1 I wipe it up right away, ideally with a damp rag. I have not had any major issues with paint loss. Yes it absolutely will turn paint to soft goo, but it takes more than a few seconds, and there is plenty of time to clean it up. Just run silicone DOT 5 if you are worried about it. At least it has a known boiling point and tested properties. I have always flushed Drum brake cars with DOT 4 or 5.1 and have enjoyed having less brake fade in the rolling hills and country roads of my area. I just flush it every 2 years or so. Not much work, and a cheap upgrade.

-

You have a hemi powered Desoto fire truck? Either I am confused, or really want to see a picture of this beast! What is the current engine doing or not doing that makes it a poor driver?

-

Will 1951 DeSoto car A arms bolt up to my 1940 Plymouth Coupe?

FarmerJon replied to Noonan's topic in P15-D24 Forum

I can't fully answer this, BUT I have a pair of '52 desoto uprights I plan to install on my '48 in order to add the 12" Desoto brakes in place of the factory 10" plymouth ones. I havent finished the project, but what I have found is this: The uprights are bolt in. The Plymouth steering arms might need to be used. The Desoto kingpins use a needle bearing for the top bushing, so it must be tracked down NOS. But is supposed to greatly reduce steering effort, so not all bad. The 12" drums may not fit inside stock Plymouth 15" wheels. You likely have 16" wheels, so try and see if they fit. I was able to use my old bearings and seals from the Desoto to track down replacements, as part stores are pretty slim on listings, BUT everything was available affordablly and USA made. Hope this helps -

Bore and stroke work out to 220.73 CI. I would say that it is a .020 over 218.

-

Options to modernize the front suspension of a 41 Dodge 3 window coupe

FarmerJon replied to AZmopar's topic in P15-D24 Forum

" Precision Springs" are made in USA # SP08160 Also available from MOoG, but are more $ and like all mOOg parts now, are made of Chinesium. May drop stance a little, I cut 1 coil before installing them, so I dont know. I like the stance and ride, but they are a bit too short of a spring and bang around over larger dips. (Once cut) Went from this: to this: -

Looks like you got it figured out. The Mopar part you posted IS the correct number for '32-48 plymouth (my parts list only goes to '48) Plan on cleaning the old, hard grease out of that bearing. Lots of solvent and compressed air is usually enough (although dont free spin the bearing with the air) but if you have access to an ultrasonic cleaner, they do a nice job on bearings.

-

I will be home in an hour and will check my parts book

-

I am hoping to reduce the force needed to hold the clutch down, and have better feel of the clutch action, since most likely I will be also getting rid of the overcenter spring. The 10" clutch can hold more power and take a little more abuse, not that important with a stock 217, but I am still playing with the idea of swapping in a hot 251. More importantly, the 9.25" clutch isn't available as a diaphragm time (that I can find) Finally, the lower cost vs the aftermarket stock types (even though both are certainly West Taiwan made)

-

Edit to add:the below pressure plate did not fit inside my passenger car bellhousing. Proceed with caution. I am planning on trying this diaphragm type clutch from DC truck parts. I never managed to track down a OEM one that had the right size input shaft. As a side note, I belive that the 6 bolt flange on your crank indicates that it is a 230, not a 217.

-

Optional Gear Ratio for 3 speed or Overdrive Transmission

FarmerJon replied to Loren's topic in P15-D24 Forum

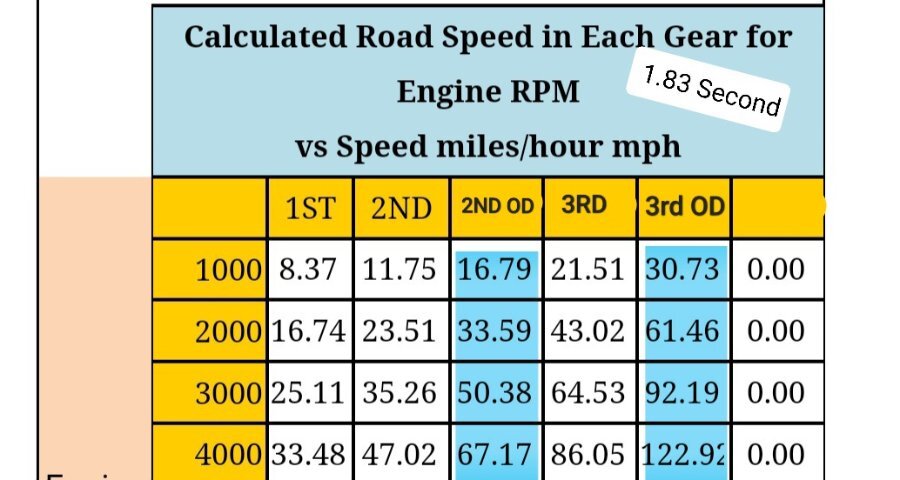

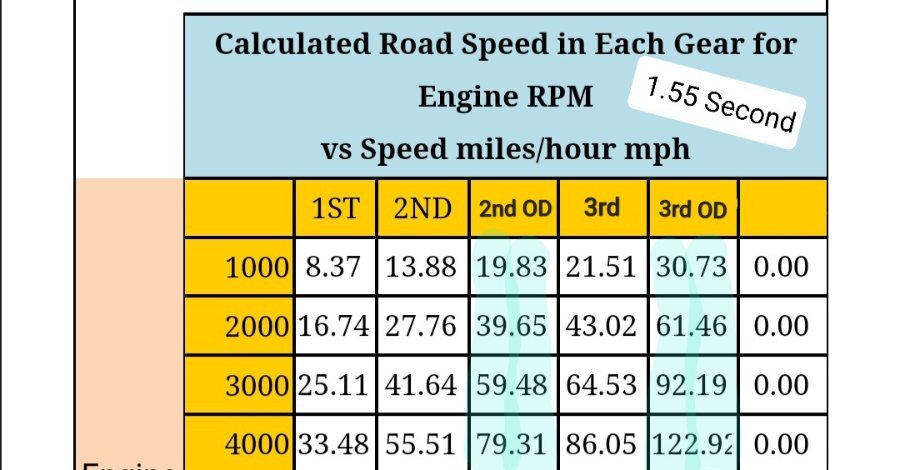

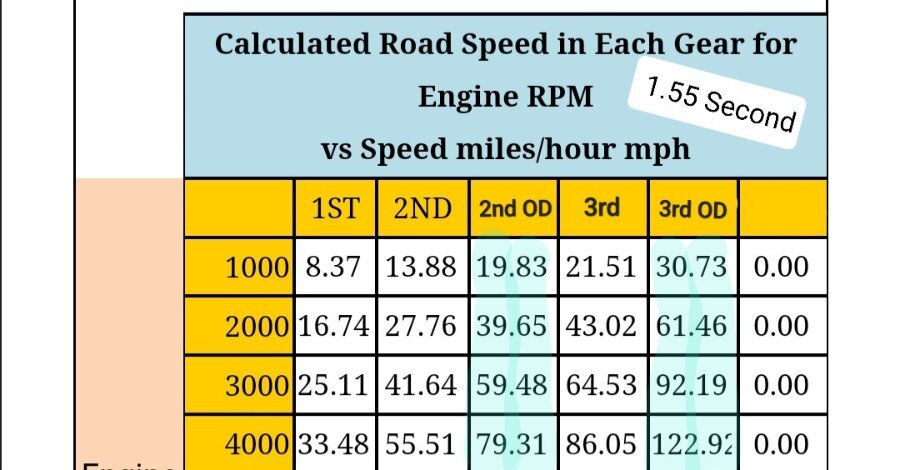

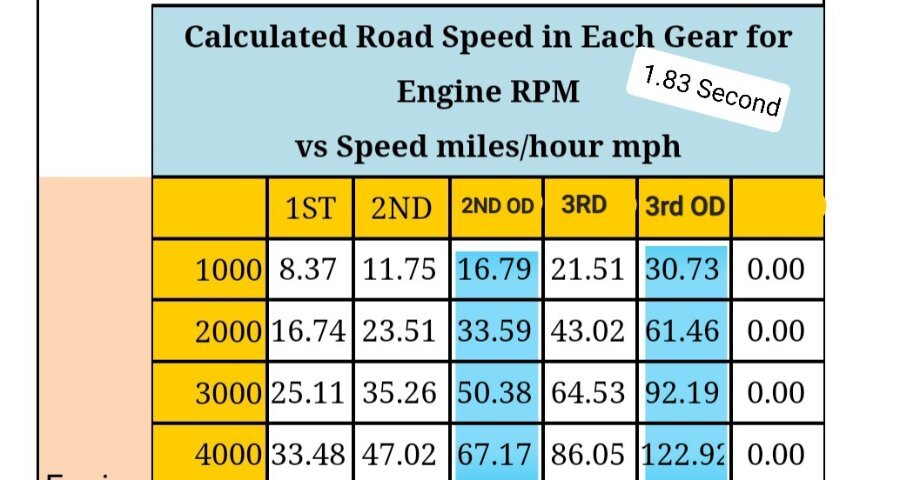

I am interested in what @Loren has to say, but if you look at the charts I worked up, "Fast second" in an OD doesnt make much sense, because 2nd OD is SO close to straight 3rd. At 3000rpm in 2nd OD, a shift to 3rd is only gives you 5mph and maybe 100 rpm before you are right back to 3000rpm. Now if your driving style is to treat it as a 4 speed, shifting from 1-2-2od-3od, sure, that will work. But I plan to wire mine up with the standard kickdown and a shifter mounted kickdown switch, so I can shift 1-2-2Od-3-3od, so I like the standard second better. I think either way, you are better off with an R10, especially if you have one on hand. Dropping to lower numerical rear gears doesn't gain much on the highway, and numbs low speed performance. I drive my '48 with standard 3speed and 3.9 gears in traffic and on the highway (70 is no problem, other than loud). While I have enough power to generally keep up, I wouldn't want less! Now if you do not have a OD, the Fast Second makes great sense. I often find that if I upshift to 3rd too soon (below 40) while merging onto the highway, it is a total dog untill RPM come above 2100 or so. -

Optional Gear Ratio for 3 speed or Overdrive Transmission

FarmerJon replied to Loren's topic in P15-D24 Forum

I am mid-build of a R10 as well. Have you already gotten yours done with the "fast second" 1940 gear set? My OD was from '55 and had pin type synchros, making the '40 second not a direct drop in. The gear has a different spline size than the gear for pin synchros. You can switch to the earlier strut synchros, but you will also need to swap in the matching input shaft, clutch gear, and shift fork. Here is the difference in the two ratios vs rpm & speed, based on a 28" tire and 3.9 rear gears. The countershaft is just a few thousandths larger than .750 -

I have an IAT distributor I rebuilt (and had vacuum can rebuilt) to swap into my '48 in place of the stock IAP distributor. The caps are different, so it is inconvenient to swap back and forth. Maybe not a big deal if everything goes smoothly, but I had condensers fight me, and had to get it back running before the end of a weekend, so switched back and forth a few times. If you want to go back and forth, compare the caps, it is much easier if you can leave it in place.

-

Engine rebuild on 39 Desoto not getting any oil pressure or fuel

FarmerJon replied to desoto1939's topic in P15-D24 Forum

Check out the write up that Tony Smith did about these oil pumps. -

55 V8 overdrive, any interchangeability with our flat sixes?

FarmerJon replied to p15-1948's topic in P15-D24 Forum

My OD is out of a '55 (6cyl) and is 6V. Not sure when they switched. Rumor is that the 6v solinoids can survive 12v. -

55 V8 overdrive, any interchangeability with our flat sixes?

FarmerJon replied to p15-1948's topic in P15-D24 Forum

I don't know much about the V8 cars, but the overdrive will most likely be an R10, but may be an R11. My parts catalog doesn't go up to '55. If it is an R10, I would bet it is a direct swap onto a 6 cyl bellhouse. If they are reasonable on price, I would gamble on it! Make sure you get the cable, relay, kickdown switch, and as much of the original wire harness while you are harvesting it. -

Rebuilding the Mopar 3 speed: synchro choices Resolved!

FarmerJon replied to FarmerJon's topic in P15-D24 Forum

There are a number of potential leak points, I am planning on taking some pictures that show them all, and note which can be fixed with transmission in the car, out of the car, and at rebuild time. I will make a dedicated post so it isn't buried in this one. -

I had Porterfield line a set of shoes for me, although I haven't installed them yet. They have 3 different compounds to choose from, and will talk to you about which fits your needs. If you can give am accurate measurement for your drums, they will arch them to match. No need to choose if they should be bonded or riveted, they will do either or both.

-

Rebuilding the Mopar 3 speed: synchro choices Resolved!

FarmerJon replied to FarmerJon's topic in P15-D24 Forum

Thanks for putting those part numbers in! How do you like the "Fast Second"? Do you use 2nd OD much? I chose to go with the standard 1.83 second, so that 2nd OD would be a better split between 2nd and 3rd. Here is the difference in a 1940 "Fast" second transmission and a 1941-1956 "standard" second. The blue highlighted columns are BW overdrive gears, for standard 3 speed, ignore them. Calculated with 3.91 rear and 28" tires. As far as leakage, I have seen many of the posts about it. I belive this is caused by a few factors. 1: many of the bolts, in bearing retainer and tailhousing, are open to the transmissions oil resevoir. My '55 OD has these holes counter sunk and filled with rubber so the bolt heads act as a seal. This will take some care to duplicate on rebuild, but thread sealant should also be used. 2: lack of vent/breather. There is no dedicated vent on these transmissions, just the opening for the input shaft. This has no seal, just a threaded portion in the bearing retainer to wipe off the oil that is trying to work its way out. So hot, expanding air is pushing out in the same place that oil is already barely contained. A filtered breather plug added to the top of the case might help, especially if a custom bearing retainer was made, that would fit a lip seal. The last versions of these transmissions had this treatment from the factory. -

Rebuilding the Mopar 3 speed: synchro choices Resolved!

FarmerJon replied to FarmerJon's topic in P15-D24 Forum

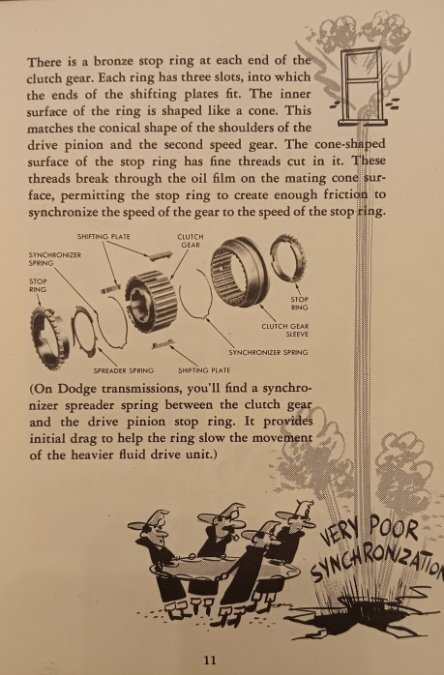

To give some closure to this, and consolidate what I have learned, here Is what I have come up with: I tracked everything down to convert to the '40s early '50s conventional blocker ring synchronizer assembly. To do so I needed: main drive pinion(853864), clutch gear assembly(1115595) synchronizer stop rings (853867), second gear (852456), and the correct shift fork (1138246). I also did the factory recommended upgrade and replaced my stamped synchro struts (detent plates) with the later solid ones. They most likely are directly interchange with early a-833 ones. If you have a spare 833 one floating around your shop, I would love to confirm this. I also got a synchro spreader spring intended for Fluid Drive cars, it preloads the blocker ring to help the 2-3 shift be more efficient. It is part number 1115576 I found that the blocker rings (WT243-14F) are shared by many different makers, including ford (B5A-7107A, Studebaker (1555429) AMC and Jeep(640397) This lead me to see that Studebaker rings were made slightly different- they often have grooves that cut perpendicular to the inner threads, just like more modern rings. Apparently this is referred to as an 'oil bleed' and helps evacuate the oil that gets between the gear and the ring. Makes sense. Again, this helps the synchro be more efficient, which should give smoother, quicker shifts. Of course, the rings I got did not have this feature, but were at least forged. I considered doing it right and making a drill fixture to add my own, but after talking to the engineer at my work (also a car guy) I ended up just cutting grooves carefully with a die grinder. After spending so much time reading about blocker rings, I really wanted to play with cutting teeth off the rings to further improve shifting, but I couldnt pin down what would give reasonable longevity, so I just mimicked the stock T5 rings, but cut 6 teeth less off. I ended up having to have my heat pump repaired, so I am not able to send everything out for REM polishing, but I belive I have all my parts together. Hopefully I can get this thing back together and give yall a report on how it shifts in the next month or two. -

By any chance, does the car have/ had an overdrive transmission? That switch with the 4 wires looks like a kickdown switch, and the box on the coil looks just like the OD relay. If you arent sure, take a look (or picture so we can look) of the driver side of your transmission.

-

What pistons are you running that takes the modern sized rings? What size is your bore currently?

-

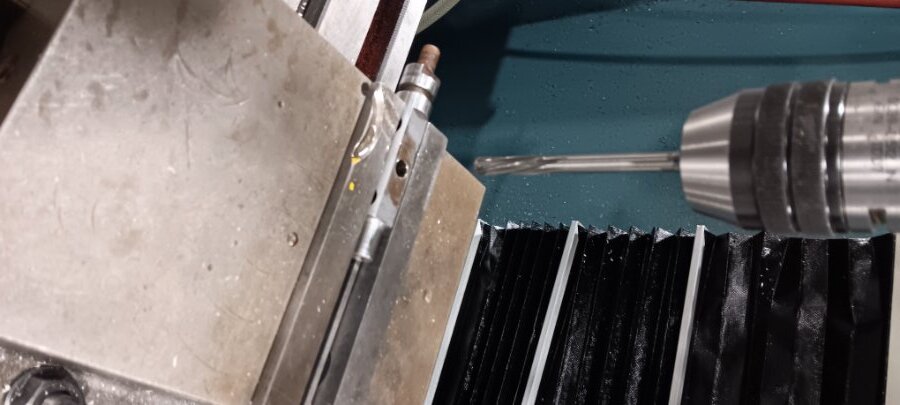

I am lucky to work at a place that lets guys like me to use the tools that arent in use. This little prototrack mill, and its fellow lathe makes for quick work of most minor mods I want to make. Does a really slick job of engraving and hole patterns too. Having a Magnuflux horseshoe and light at my beck and call is sweet too. But I also get dibs on the "Trash" like this little old machine, some 20k+ pieces of nuts, bolts and washers, as well as some height stands and other random goods

-

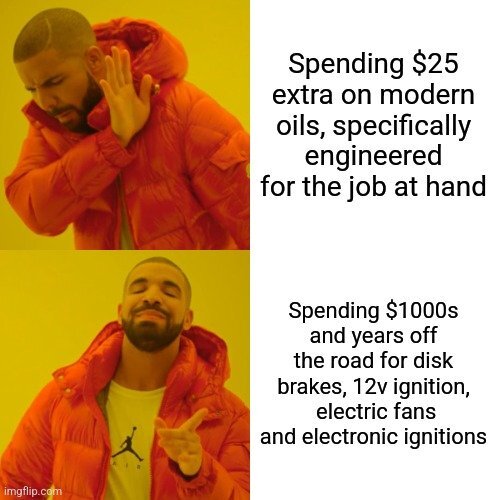

This publication is generally aimed at 745 and 903 transmission but the standard 3 speed, derived from our old '40s jalopys, was still in use in the Valiant and Dart for another year, so it got the same fluid update. The 745 and 903 have very similar bronze parts, roller bearings, and general architecture to our old boxes. Per Chrysler, ATF is compatible and interchangeable with the 80w oil previously recommended. In the '40s there were no better options, 10 years later Chrysler (and other makers) knew this, and took advantage of the cheap, easy improvements of better fluid. If these guys had access to the dedicated manual transmission lubes, like GM Synchromesh, Redline and Amsoil MTL, they would likely use that. If you are bringing a car or truck back from the dead, sure- use whatever is cheapest to get the old tar out of the box. But for a decent driver, the added $10-25 is trivial, and as @Sam Buchanan, myself, and others have found, can really breath new life into an old transmission.