-

Posts

470 -

Joined

-

Last visited

-

Days Won

1

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by FarmerJon

-

-

I am building a r10 Od, so will need a 10 spline disk. Looks like 61-62 and 65-69 C10 pickups with 6 cylinders have a 10", 10 spline clutch. I have to work of finding more info and cross references, but if they will work, there will be cheap and mild performance options... I know that the pedal pressure is reduced,but are the diaphragm pressure plates physically lighter than the lever type?

-

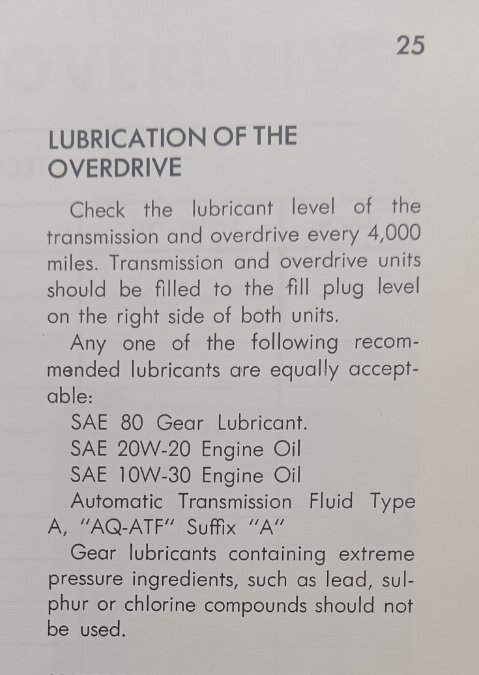

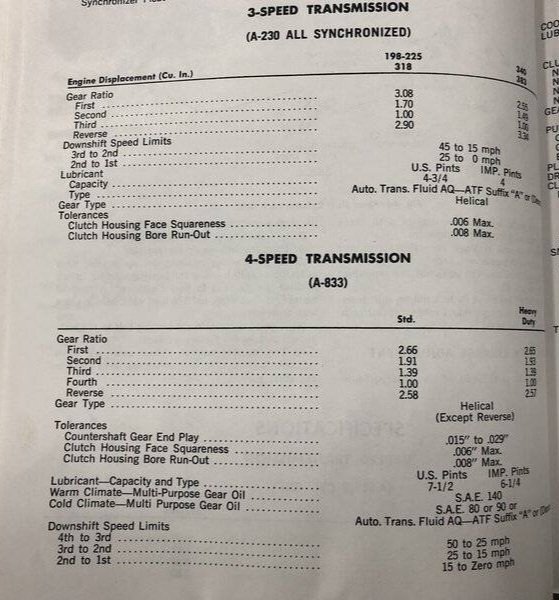

There will be some disagreement on this, as is the case of all oil discussions, but Mopar in the '40s recommend GL1 80w. Hypoid lubricant is not recommend, although some modern versions have removed the componests that were thought to effect the bronze synchro rings. I will try to look at my late '50s mopar books to see what they recommend by the end of the '50s, but the early '60s-80s they called for Dexron ATF. The Mopar 3 speed shares its general architecture with many of its peers, so much so that many Ford, Studebaker, Jeep, Nash/AMC BW transmissions share the same part number synchro rings. It also is the direct ancester of the 833, and it shows. Here is what Nash recommend in its version, in the mid '50s Ignore the Overdrive, that recommendation is the same as the non-OD transmission section, but that one is on a page split. So, what works? Most Oil. 75w-80 GL4 GM Synchromesh oil (what I currently run) Amsoil/Redline Manual Transmission oil Motor oil-some people who run this use the motorcycle type oil, that is wet clutch compatible. Dexron ATF. What to consider avoiding: Hypoid gear oil Ultra heavy oil in cold climates Synthetics that cause gear clash or excessive leaking. Good luck!

-

Did you ever figure out what clutch this was? Do you notice a big difference going from the lever style to the diagram type?

-

Have you looked at the Tony Smith guide to oil pumps? I belive there is a PDF in the tech archives here. He details what to check and modify on new and used pumps.

-

Looking back at your previous trials and tribulations with this engine, it sounds like you already tried the running engine swap, only to be burned by a dishonest/lazy/ignorant shop. These are simple machines, but the last 3 (or more) generations of "professional " mechanics have NO experience with them. Honestly, it is getting hard to find an honest/competent mechanic even for easy Late Model car work. Numerous guys at my work have cars that shops wont fix. Several have cars that have waited many months just for basic collision repairs. Engine Machine shops are no better: the old guys are closing up shop, and the newer shops only want to do basic stuff on SBC and late model quick jobs... It sucks. I get the lack of time, I am close to the same age, with a job that wants me there 50-65 hours a week, and a wife and kids at home, (rightfully) wanting my attention during the few hours I am there. Your Coronet is a nice looking car. If the only thing holding it back is an engine, lets take the time to rediagnose, make a plan, and make it happen. Once you have a plan, taking a day or two once a month to implement it will have you feeling better and will get it back together faster than you think. Depending on the policies and realitys of your work, could you use the fact that you travel the USA to get the machine/engine work done outside of your home state?

-

Cool car! I would give French Lake Auto salvage a call, they will know what interchanges and likely have it to sell.

-

Mounting a lockout cable for the r10g overdrive

FarmerJon replied to comedtech63's topic in P15-D24 Forum

I was wondering what that bracket was! Thanks!! -

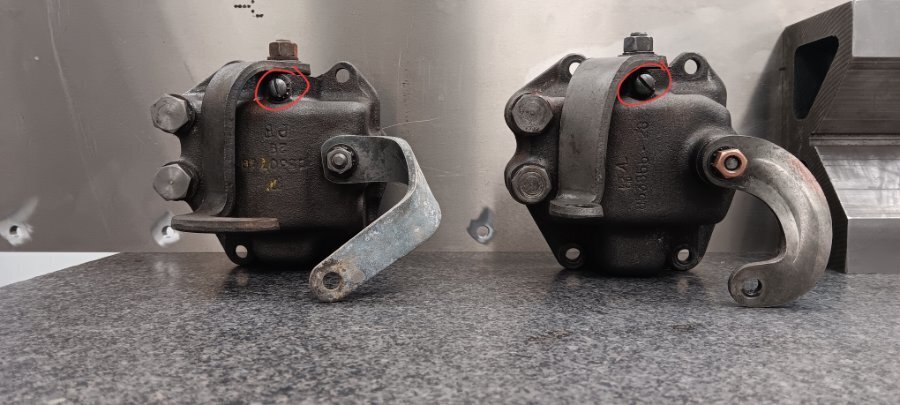

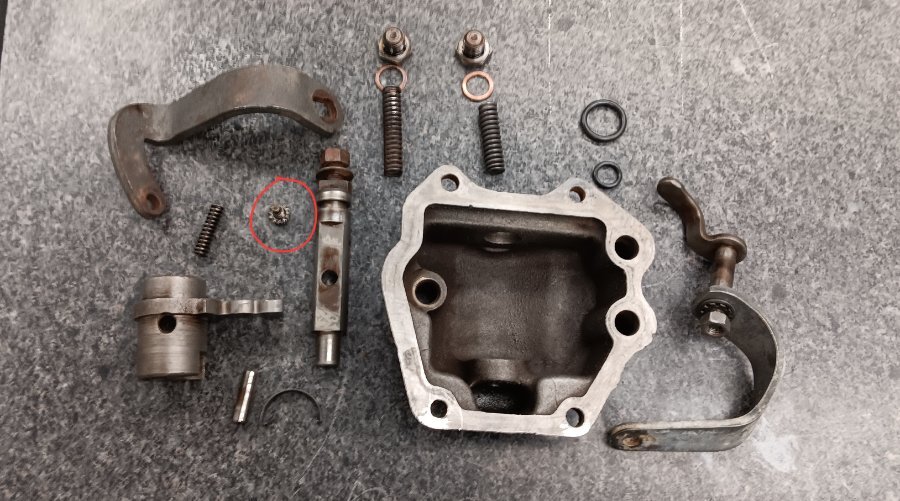

It is just a 1/4-20 screw, .396 long (from under the head) with the threads turned off .160 of it, down to .150, and a lock washer.

- 3 replies

-

- transmission

- shifter

-

(and 2 more)

Tagged with:

-

It happens on my '48 fustratingly often. I was able to remove the pans that go from bumper to nose, and reach up in the gap with a flathead screwdriver. I think I have it adjusted to not stick now, but it still doesn't latch consistently, and I bet it will stick again at the worst possible time.

-

Which WA-1 did you get? Most are the smaller base flange, but 413/414 are "universal" and fit both patterns. They also have an adjustable main jet and can be switched from vacuum controlled metering rods to mechanical metering rods. Jon (CarbKing) warned me against using these carbs as a pair due to the difficulty in tuning them, but I am going to try anyway. My plan is to run them as singles, getting both adjusted to the same vacuum, speed and air fuel ratio, then put them on my manifold. I just installed one, and am very impressed with its performance vs the B&B. However, despite the throttle shaft being fairly tight, it does seem to take in a littlle too much air, so I am going to go back and make bushings and maybe Oring it on both.

-

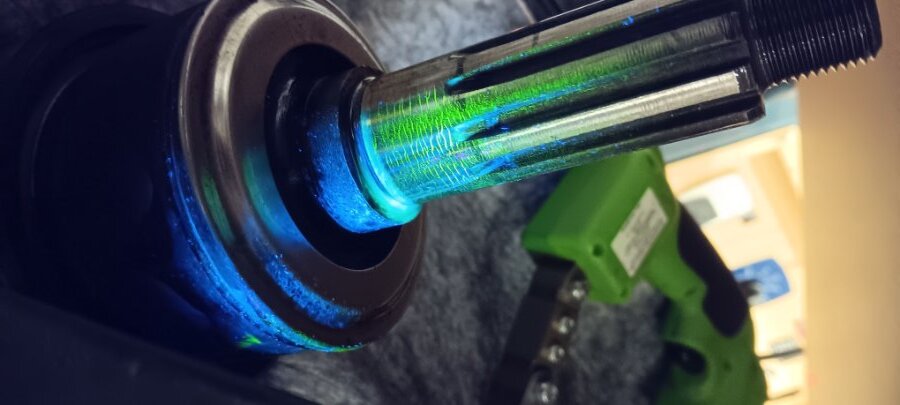

Been a while since a real update, spent most of last year working an average of 60 hours a week, so getting work done on the car has been slow going. I did manage to drive the Plymouth 1-2 days a week most of the year. That really got me thinking about all the work I need to get done on it! First priority is getting this BW OD rebuilt and installed. Mid December I started my "One piece at a time" plan, and rebuilt the selector mechanism. With some machine work and welding, I managed to take .015" of slop out of a couple places, and polished all of the rubbing surfaces. I also found earlier selector levers that are much shorter, hopefully they will work to reduce lever travel. I have now started on the rest of the trans. It is a little slow, between only working on it during my lunch breaks, and tracking down the parts to switch to the stronger "strut" synchros. Last week I got sick of the gas smell that has plagued the car for a couple months, so I swapped the leaky Carter Ball and Ball for the Carter WA-1 I rebuilt over a year ago. Went surprisingly well, and with a little tuning runs quite well. Seems much smoother than the previous carb, with less of a "wet sucking sound". While tuning, I noticed that it was producing fuel mist like a smoke machine, vs the slightly broken up drip of the B&B. https://imgdump5.novarata.net/7l0i97.jpg Only down side is that it doesnt seem to like cold starts, so yesterday I finally installed a choke cable. The B&B went 2 years of chokeless cold starts. I think it could use a little more tuning, Idle is a little too rich, but leaned out it acts like it needs more accelerator pump. I took a couple vacation days for my anniversary and birthday, so I finally took it to a tire shop and had the wheels balanced. All were a little bent, so we put the best on the front. 3 out of 4 were out of balance. Now no more vibration above 60. https://imgdump5.novarata.net/xbx1v4.jpg This allowed me to hit a new top speed on the expressway: 86 mph. Power was -just- starting to break up, maybe a little valve float? Keep in mind this is with 3.9 rear gears and the standard 3 speed still. I do not understand why so many people think these cars can't run 65...I run 70 with traffic routinely, with power to spare. Next up I am going to make a second try to get my dual point distributor installed, hopefully I can get a condenser to survive this time....

-

I am a big fan of using actual sound deadening products. I would NOT lay them on a raw steel floor pan though. Clean, paint, clean, heat, apply deadener. If done correctly there should be no air bubbles. POR 15 is a great product. There are also phosphoric acid based wash primers that can be used to make bare, clean steel more corrosion resistant AND help paint stick better. If you look at floor pans that have rusted out, you will find that most are from moisture being trapped in the carpet/padding, usually from a leaking windshield, not from moisture trapped under the actual sound deadening (jap cars will usually rust out around the bonded ruber deadening, but not under it, since the metal is protected there) So if you are going to be paranoid about stuff causing rust, avoid carpet!

-

I am interested in how it goes and, more importantly, how it drives once completed. Just last night I had 3 other adults in my coupe and had to take off from a stop, up a hill. I personally wouldn't want less gear than the stock 3.9, unless I had a fair bit more power.

-

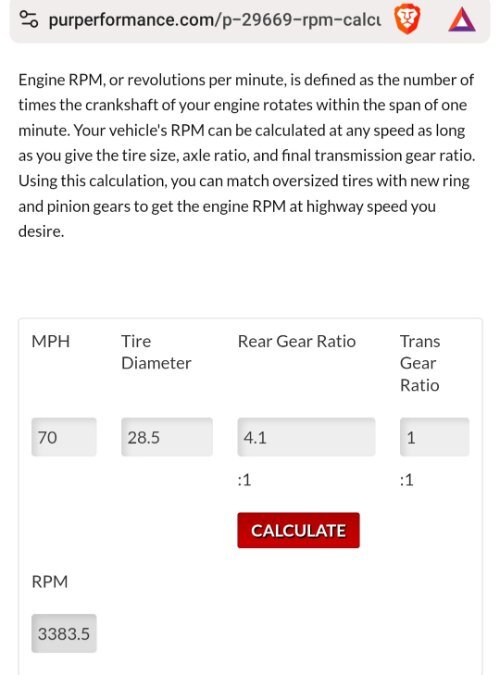

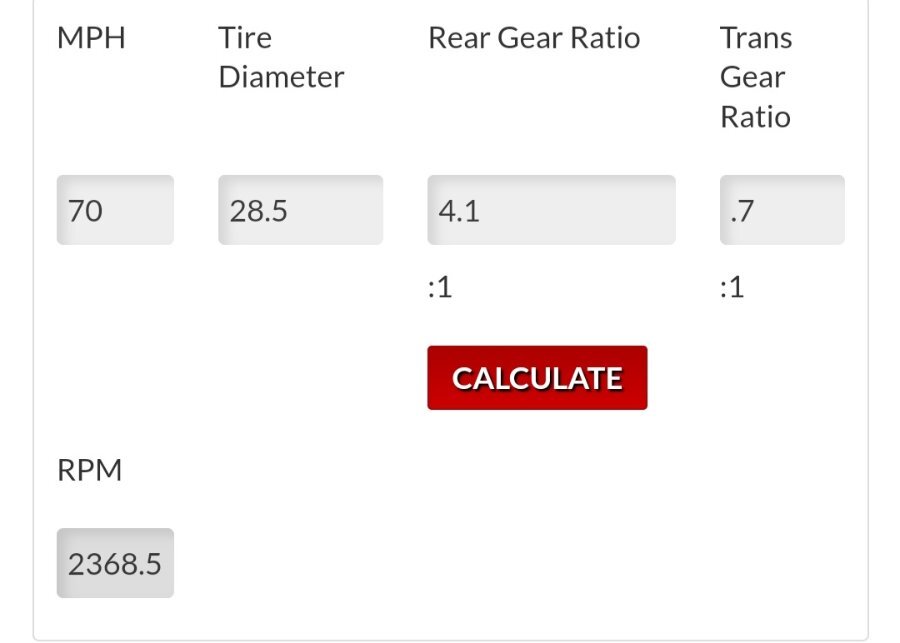

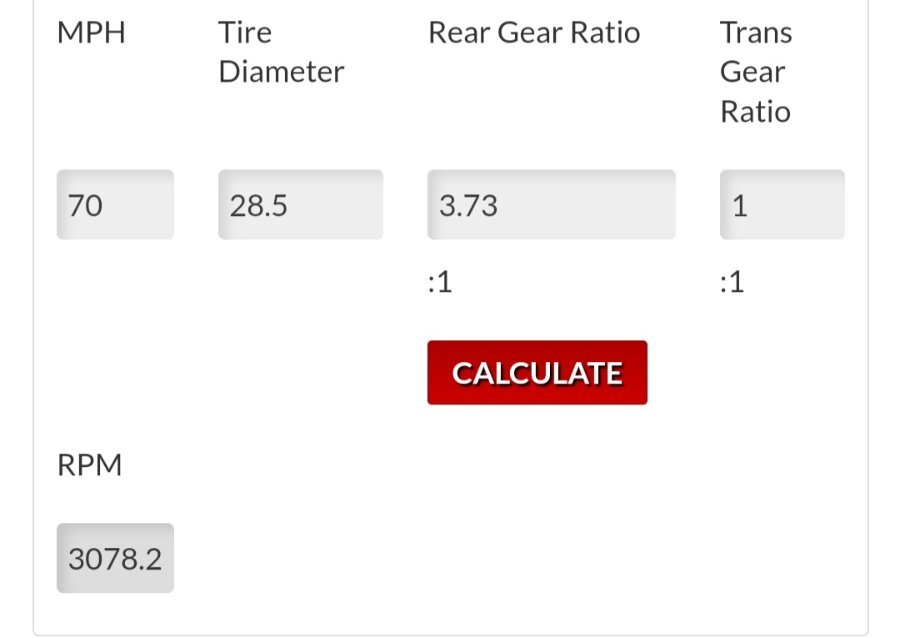

So changing ratio, from 4.1 to 3.73 is around a 300 rpm drop at highway speed. I assume the R6 has the same .7 od ratio as the r10 (I dont know much about the R6) It would drop your rpm by 1000. To me, that is much more worth it, especially if the R6 is the same length as your stock transmission ( the R10 is)

-

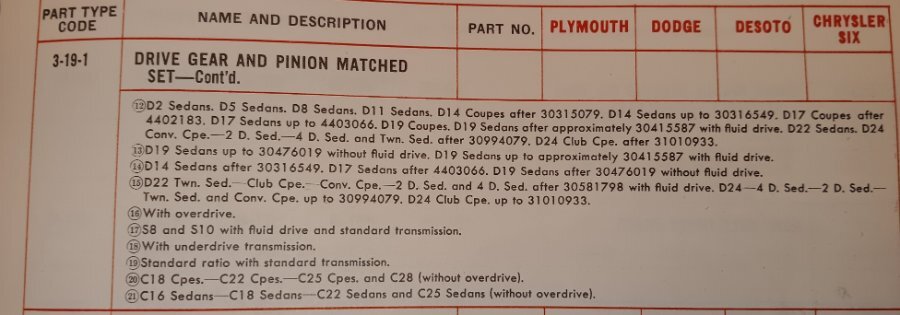

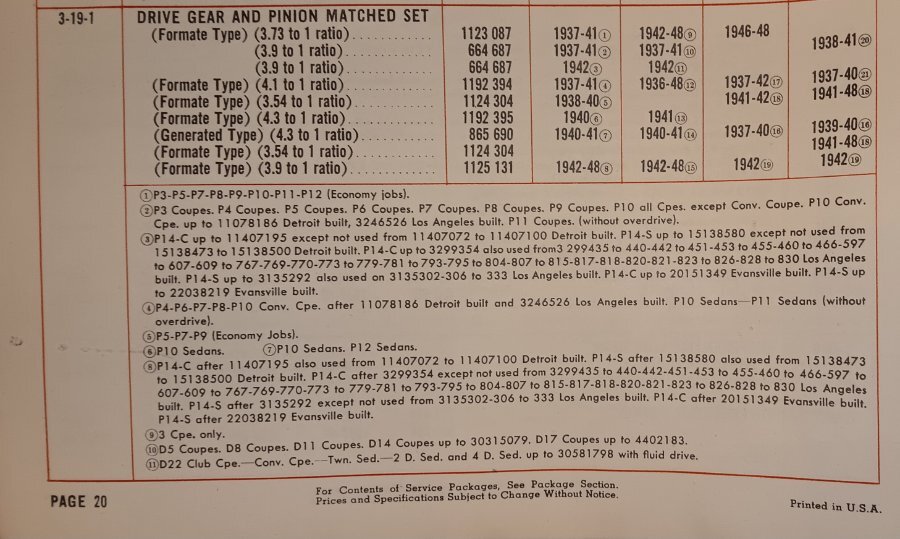

Beautiful Dodge! I will look up the part numbers when I get home, but your options are : 3.91 from most plymouths, definitely '46-48 3.73 from early '50s plymouths and Dodges, 3.54 late 40s chryslers and some early '50s V8 dodges I have 3.9 gears in my Plym, while it can and does run 70+ with traffic, it is not really a 'comfortable cruise' 3.73 gears would be a little better. 3.54 gears might be a little bit of a dog around town, unless you have hopped up the stock engine. Another option would be to find a R6 or other early BW Overdrive transmission to swap in, and keep your 4.1 gears.

-

-

Both of mine had a minor flat worn in them. unless yours is broken off or endplay is excessive (no spec i can find, but .050 or more would be suspicious, my two were .007 and .020.) I would hunt for trouble else where. Have you adjusted your clutch pedal? What happens when you shift into reverse? Does it grind and prevent you from going into gear? Does it go into gear but no movement?

-

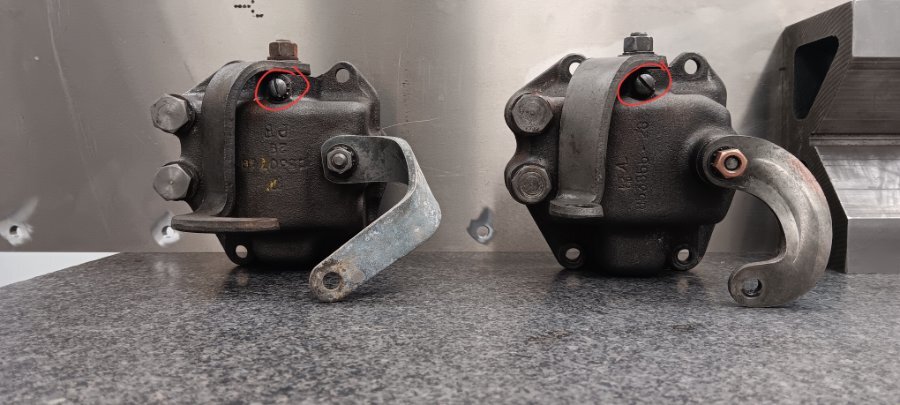

Are you talking about the screw that retains the selector shaft? (Circled in red) It is just a 1/4-20 screw, .396 long (from under the head) with the threads turned off .160 of it, down to .150, and a lock washer.

-

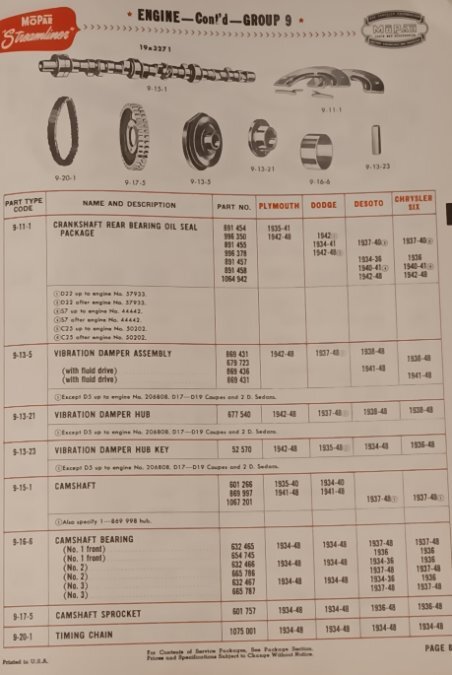

I have been focused on rebuilding the r10g1 I picked up for my '48. Finally got everything apart and clean enough to magnuflux. Most everything so far has looked good, until I got to the output shaft. I still have some research to do, so there may still be hope for the one I have, but If I can find a reasonable NOS one, it would be valuable in guiding my course of action. None of my parts catalogs have a number for it. Can anyone help me? Thanks guys!

-

Low buck, middle of the road option is to deck for good quench of the highest piston/rod/cylinder. Yes some will not be perfect, but nothing will hit, and all will be better than leaving them way down in the hole.

-

-

Check out this engine build guide, from Tony Smith. He recommends having .040 from the piston crown to flat of cylinder head. Due to the availability of gaskets, this usually ends up with the pistons OUT of the block around .020 Quench is often neglected by rebuilders, but it plays an important role in an efficient combustion process. Tight quench both keeps your compression up AND reduces preignition. https://p15-d24.com/topic/59234-engine-build-recommendations-mopar-flathead-6pdf/

-

Rebuilding the Mopar 3 speed: synchro choices Resolved!

FarmerJon replied to FarmerJon's topic in P15-D24 Forum

My '49 Mopar Parts interchange book shows '39 transmissions as being available with both styles, with the P7 having the early style synchro, and the P8 having the later strut type one.