-

Posts

2,435 -

Joined

-

Last visited

-

Days Won

24

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by DonaldSmith

-

Here's the heater valve on my '47 DeSoto: The bellcrank pulls the valve open as the knob is pulled. The two little holes in the bellcrank assembly correspond to the two little holes in the body of the valve.

-

typo: primed, not rimed

-

There are metal strips with teeth on the hidden side, to catch the headliner material. This photo shows the metal strips, which I removed, rimed and reinstalled (back in 2007). It's a bit tricky to disengage the existing headliner from these teeth. The bottom of the metal strips can be bent out a bit, and something used to push the edges of the headliner free from the points of the teeth.

-

Was the engine at TDC when the dizzy was removed? If not, "7:00" doesn't apply. Before removing the dizzy, keep track of where the rotor points, and put the dizzy back the same. Too late? Don't know? Then the fun begins. Find TDC of the compression stroke (Thumb over the spark plug hole works well). The rotor should point to the corresponding plug wire for No. 1 cylinder. If no one screwed up, that will be at the 7:00 position. People have lived with unorthodox arrangements, just so the rotor points to the No. 1 plug wire when that cylinder is at the top of its compression stroke. That's all I have to say about that.

-

ANSWERED My First Car -- P15 1947 Plymouth Deluxe

DonaldSmith replied to NickPickToo's topic in P15-D24 Forum

The must have had a real powerful stapler that pierced the metal in the process. I used real small screws to put in my fuzzies. But that was in distant memory, and before I had a digital camera to memorialize processes. -

Jiffy Jet - these are posted somewhere else, but here goes: (The thicker hose goes to the foot-operated pump under the floor. The thinner hose goes to the tubing at the dashboard.

-

-

Yesterday was not too bad, cool but dry. We raked and blew some leaves to the street, and I thought I would sneak in one last drive of the year. Slow cranking; loose cable clamp. Battery charger. Shot of starter fluid. Car started, but quit when I let off the gas. More battery charger, another shot. Kept foot on the gas for a while. Headed down the drive, giving it gas to keep it running. Let it idle and warm up. Took a photo, saved photo under "Glamour shots" folder. Headed out. Not running right; using the clutch at stops, afraid to the Fluid Drive would stall it. Went around the block, and back to the garage. This isn't fun anymore. Maybe the loss of car shows this year, and an abbreviated, unofficial. Woodward DreamCruise. Maybe too many chronic aches and pains. Recently replaced the manifold gaskets, a major job for me, to no apparent audible difference. Wondering what it takes to get this car running sweet again, for the rare times it would run sweet. Too many bad memories of flatbed returns home. I'm editing documents on History of my Ownership, Maintenance, and Improvements to My DeSoto. Maybe you can see where I'm going. Someday, I or my survivors will sell the car. We'll see how I feel, come Spring. Meantime, I can lurk on the forum, and vicariously participate in all the wonderful adventures with these old Mopars.

-

The oil filler cap has an opening with mesh filter, to let air into the crankcase. The opening faces away from the front of the car, so as not to force the air into the crankcase. The draft tube, hanging down on the other side of the engine, allows air and fumes to get out of the crankcase. The end of the tube is beveled, so that the passing wind will suck, or draw, the fumes out.

-

To RNR: My mother's folks lived near Welland, Ontario, and once a year we visited them. As a kid, I had little exposure to the exchange rate, but the Imperial Gallon of milk was one U.S. quart larger than the U.S. gallon. The paper jugs were cone-shaped. Nabisco Shredded Wheat boxes were squat, and had an image of the Niagara Falls on them. Crystal Beach: Yes, we would get there, too.

-

I'm so old, that if I see a penny dime on the ground, I'll pick it up. (They got rid of pennies in Canada. They should sell them all to us. We used to circulate Canadian pennies with our 'Merican change, without regard to the exchange rate. That's when we used to handle cash. Now everything is hand sanitizer and credit card. )

-

ANSWERED Possible issue with IAP type distributor

DonaldSmith replied to 49WINDS's topic in P15-D24 Forum

Pertronix - No dreaded points, condenser, etc. Running fine for 5 years. Lingering fear of sudden Pertronix failure, perhaps rare but sometimes reported. But with these cars, anything can bite us. Then there's lightning, meteors, etc. Tools for an extended cruise - cell phone, contact number for tow truck service, and credit card. -

-

ANSWERED Possible issue with IAP type distributor

DonaldSmith replied to 49WINDS's topic in P15-D24 Forum

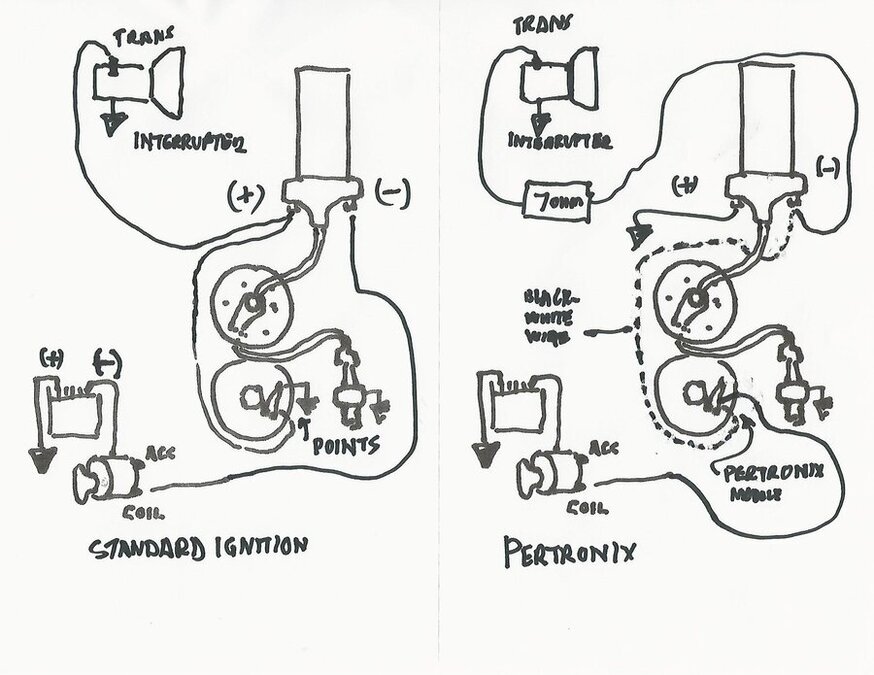

The resistor did not come with the Pertronix stuff. I will have to look into my records for a source. Maybe tomorrow. Yes, run the ground wire from the coil to any good ground. 8-26-2020: Breaking news: I checked my records from 5 years ago, when I installed the Pertronix ignition module. Pertronix called for a 7-ohm, 5-watt resistor. I called their technical gurus and asked if 12.5-watt would be OK. Yes. (I got resister RH0107R000FC02, 12.5 watt, 7 ohm, 1%, from Mouser Electronics. Less than 10 bucks, including shipping. -

ANSWERED Possible issue with IAP type distributor

DonaldSmith replied to 49WINDS's topic in P15-D24 Forum

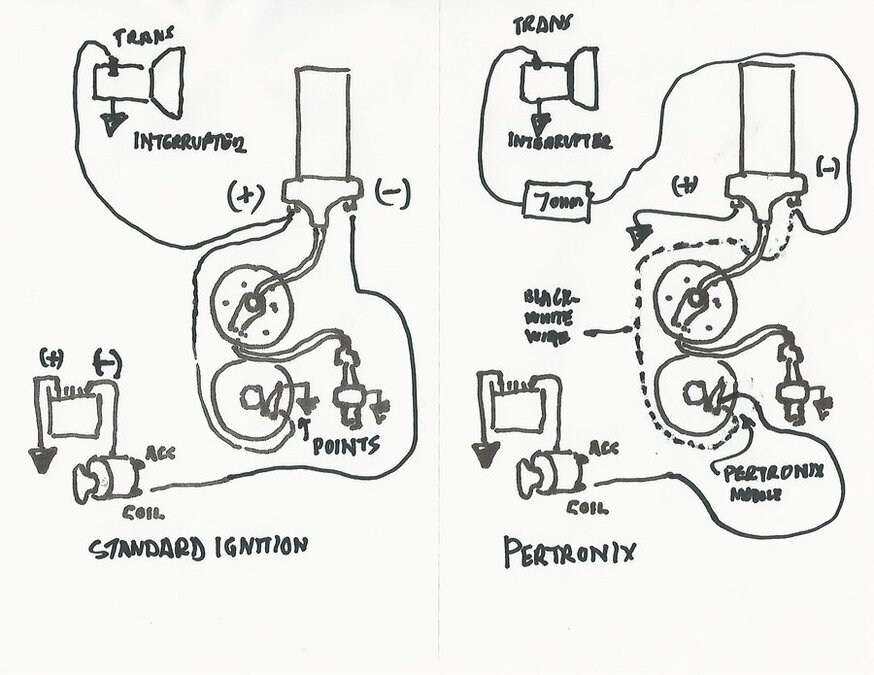

The Pertronix is wired opposite the standard system. I made a sketch of the two systems. The standard system uses the points to ground the primary circuit of the coil, while the ignition circuit keeps "live" power to the coil. The Pertronix system controls the current to the "live" side of the coil, and the coil is always grounded. If you have the semi-automatic transmission, the interrupter circuit briefly kills the engine to allow for the shifting. The standard system uses grounds the points, so no spark. The Pertronix system grounds the live side of the circuit, so it needs a 7 ohm resister in the interrupter circuit to keep from frying anything. -

To DJ194950: Will do. I'll separate the manifolds and check each for true surfaces; and also the face of the block.

-

OK, OK, I just ordered the manifold-to-manifold gasket, and also the exhaust flange gasket, from the folks at Andy Bernbaum's. It'll take maybe a week for the gaskets to arrive. In the meantime there are other to-do items to do. I remember the drill. Assemble the two manifolds loosely, attach the manifolds to the block, and then tighten the bolts connecting the two manifolds together. That way each manifold will be happily snuggled to the block.

-

Manifolds off. I used all-thread and ratchet straps to raise the manifolds to a 2 x 4 across the fenders, and plumbing strap to secure the manifolds to the 2 x 4. My son took the heavy end of the 2 x 4, and I took the light end, to remove the manifolds from the engine bay. The photo shows the manifold faces. Some soot paths at the two "owl-face" duplex exhaust ports. I suppose a scraper and straightedge are next. I'll inspect the joint between the two manifolds. The end of the heat riser flap seems reasonably tight. So maybe I don't have to disconnect the two manifolds.

-

Manifold hung from a 2x4, and moved back from the block. Inspected gasket surfaces. Leakage pictured, Exhaust 4 and 3, and deterioration at Exhaust 2: Gasket on engine block. (The oily intake is from an attempt to generate smoke.) Manifold face of gasket. Engine block face of gasket. What to do: Scrape the surfaces, check surfaces with straight-edge. Chase all the threads of the studs and nuts. The long studs backed out; i captured the coolant. The short studs are still in the block. Will thread-lock seal the stud threads in the block? Any dope on gaskets? Exhaust pipe flange gasket: do they make a doughnut shape, instead of flat? Any other recommendations?

-

I got the exhaust flange bolts off. (Soot on one side of the gasket! Was this the leak?) I should have replaced that gasket first. But now I might as well keep going, to remove the manifolds and inspect them for exhaust leaks. The two underside "bolts" are studs. The nuts didn't come off; the studs came out. Yes, they went into a water passage. I had drained the radiator, but not the block. I quickly put a pan under the two stud locations. How heavy are the manifolds? I guess they are too heavy for me at my age. I devised a lifter, as shown, attached to the carburetor bolts, so that two people could lift the ends. Now I'm thinking that the pole that I would use is two frail. Maybe a 2 x 2 would be better.

-

Jacked up the car, left the jack in place, placed a jackstand under the frame, took the wheel off, and slid it under the frame by the jack. Took the inner fender panel off. Reached the hidden nut from the wheel well, and removed the nut (and washer). At the exhaust pipe flange, one stubborn bolt and nut remain . Heat? Wax? PB Blaster? Take a long break? The manifold nuts on the topside are loose. Started to remove one of the two bolts on the under side, one each side of the heat riser. Question: Do these bolts go into a water passage? Will I have to drain out the coolant? Photo looking up at the hidden nut and the two long bolts. (I don't know why the underside of the manifold is so red - rust?)

-

Doddggeb4ya said: "Looks like a lot of black soot at the header pipe blowing back to the tappet cover." It's a real old photo, but I will check it out. But lately I couldn't feel or hear any leakage at that gasket. The sound seems to be coming from the middle of the manifold. Steady sound, not pulsed. (Maybe the bushing on the heat riser shaft?) Lots of fun ahead.

-

Point well taken. The photo does not show that the floor jack is still in position. Always more than one means to hold the car up. It's an old photo, before the jack stand problem came to light. And usually, the jack stand is at at near its lowest position, so the ratchet does not come into play . Also, if I remove a wheel, I'll put the wheel under the car. as an additional safeguard.

-

Sam Buchanan says: " I suggest you go ahead and remove the wheel and liner, it just gives you a lot more options."" Thanks, Sam. Better to lean into machinery than to look up at it. Thanks guys for sharing your thoughts. Stay tuned.