-

Posts

2,554 -

Joined

-

Last visited

-

Days Won

83

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Sam Buchanan

-

What tire pressure do you run in G78-15 tires?

Sam Buchanan replied to BobinBC's topic in P15-D24 Forum

Bob, I have Coker H78-15 bias ply on my '48 P15 which is oversize compared to the original tires. However the speedometer is spot on so the diameter must be very close to original. The tires work fine at 26-28 psi, these large tires would probably be happy with less pressure but lower pressure would require a bit more effort when parking. -

41' Dodge Coupe window vent removal question

Sam Buchanan replied to 41RogueCoupe's topic in P15-D24 Forum

Excellent. And seems I recall the washer can be installed two ways but only one way will provide proper operation of the vent. -

What tire pressure do you run in G78-15 tires?

Sam Buchanan replied to BobinBC's topic in P15-D24 Forum

The '48 P15 has 15" tires. But without knowing for sure if the OP is running bias or radial tires on the stock rims we are kinda in the dark. -

What tire pressure do you run in G78-15 tires?

Sam Buchanan replied to BobinBC's topic in P15-D24 Forum

Beautiful car! According to the manual 6.70x15 bias-ply tires are to be inflated to 24 psi. This may sound low for those accustomed to running radials, but keep in mind the P15 is not a heavy car, about 3200 lbs, the same as an old Chevy S-10 pickup. You do have a service manual, right? Well, in case you don't: https://www.rockauto.com/en/moreinfo.php?pk=10593924&cc=1486874&pt=10335&jsn=385 -

Ok, you had us thinking "Whaaaat??" when you stated "The bearings actually pretty good, other than staining from long storage with acid containing oil in it." Some of us took that to mean you thought the bearings were good to use. We are all on the same page now.

-

I mentioned that earlier and I agree that is a likely issue. Wouldn't have to be misaligned much to bind up everything.

-

Ken, are you sure about your assessment of the bearings? They look pretty bad to me, lots of erosion of the surface if I am interpreting the photos correctly. The second photo seems to show bearing material wiped across the oil hole.

-

Trying to think of everything that could possibly bind. Splines not aligned with the clutch disc? Nose of shaft not going into the pilot bearing? Could the release bearing get dislodged somehow and prevent the bearing cover from going though it? Trans and engine not precisely aligned? Trans tunnel not allowing proper alignment? Do you have the floor pan out of the car? The transmission is much easier to maneuver when working from above. That's about all I can come up with. The last time I installed the trans in my P15 it fought me for awhile but finally went into place. I don't know exactly what I did, just kept messing with it.....................

-

Sometimes you have to sprinkle chicken blood around the shop and offer up certain incantations to get the final fit. But if no chicken blood is available keep raising and lowering the tranny a little at a time, most likely you have not yet inserted the shaft into the pilot bearing. It has to be just right. With new mounts the tranny will probably be a tighter fit up against the transmission tunnel than before. Patience. New mounts can sometimes alter the shifter geometry enough to make it impossible to engage all gears. Just go through the shifter adjustment procedure in the service manual to restore proper shifting if this is a problem.

-

Gloss can also be very temperature-dependent. The paint has to be applied wet enough to flow out before the solvents begin to flash off. That is why high-end paint has various reducers available for a wide range of application temps. Don't get us started on orange peel........or fish-eyes......

-

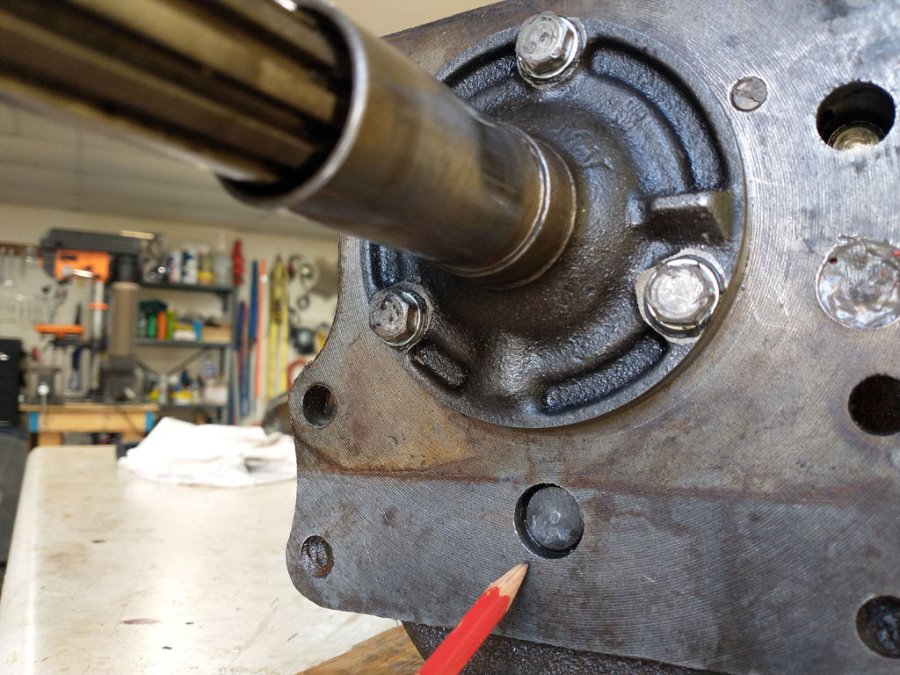

Your tranny is lying on its right side so that makes it a little harder to explain. Below is my tranny right-side-up, the hole you are referencing is upper right in my photo and is for the top shift rail. It doesn't need a plug because it is above the level of the oil in the tranny. The hole being pointed to in my photo is for the counter shaft which is a press fit in the case. But it can wear and allow leakage if not sealed. That may or may not be a problem in your case. There is a paper gasket between the tranny and bellhousing, see bottom photo.

-

A sealant I've used for a long time both automotive and aviation is Permatex #2. Yes, apply a very THIN film on both sides of the gasket after you have determined both sealing surfaces are flat and true. Silicone sealants (RTV, etc) are not recommended because a tiny glob of it might get into a jet and not dissolve.

-

Keep your leftover paint and a couple of brushes and touch-up as necessary.

-

I can absolutely assure you the new paint processes are not cheaper!! The cost of modern, cross-linked auto finishes is staggering, often many hundreds of $$$'s per gallon when you include the necessary reducers and hardeners. Then you add several coats of extremely expensive clear. But the resulting finish is much more durable and flexible (and environmentally friendly) than the old systems such as lacquer and acrylic enamel. To call modern auto finishes "paint" is a misnomer, they should be regarded more as a plastic coating.

-

My response was in regard to the original post about painting floor pans. These are parts of the car that aren't visible once the vehicle is assembled and can accept finishes that you wouldn't apply to the exterior of a hood. One of the common treatments for floor pans is POR which is a relatively thick "paint" that is applied with a brush so the pans will have a durable, rust and chip resistant finish. Rustoleum and similar exterior paints are an inexpensive alternative to the higher-$$$ stuff like POR or multi-stage epoxy and well suited to our old buggies. https://por15.com/products/rust-preventive-coating

-

I've used Rustoleum and Tractor Supply's implement paint for rust "proofing" on many projects over the years. No paint will kill rust that isn't addressed but it can inhibit surface corrosion on clean surfaces. Two VW Beetle floor pans (inside and out) and running gear received the Rustoleum satin and gloss finishes and both have held up well for over twenty years. I usually use a brush because the paint can be applied thicker and the cost and mess is much less than spray cans. I've also bought quarts, thinned with mineral spirits and shot it with a spray gun when that was the best option.

-

My P15 had developed a habit of occasionally going dark between high-beam and low-beam switching which made me wonder if the switch was going to totally die soon. A really dark road and the proximity of deer meant the car was more likely to pull this little trick. I replaced the dimmer switch and now the lights are reliable. I was pleased to see Rock Auto carries the switch in the Standard brand which is usually a good bet for aftermarket. I had to replace the old bullet connectors on the harness with ring terminals but that was a minor blip to get a new switch. https://www.rockauto.com/en/moreinfo.php?pk=445771&cc=1486874&pt=4340&jsn=390

-

That's the tank in my P15, it fits and functions just fine. It doesn't have a pickup filter, I installed a filter in the fuel line just forward of the tank. My tank doesn't use the little brass ferrule from the old tank, it has NPT pipe threads.

-

Carefully check the junction between the intake and exhaust manifold at the heat riser. That gasket can go bad and the sealing surfaces can erode making sealing difficult. Be sure you use the procedure outlined in the service manual when you reassemble the manifolds.

-

There is no rational reason for having a plastic filter in proximity to the exhaust manifold. I don't even like having a metal filter in that location because it can absorb heat which is transferred to the fuel (vapor lock). There are locations that are much better suited for a filter.

-

I recently replaced the windshield in the '69 Beetle. A bottle of KY Lube from the local drug store turned out to be a superb windshield molding lube. It also triggered several off-topic comments from bystanders......

-

Ok. Here is the Summit Racing listing of electric fuel pumps (2000+ hits related to fuel pumps): https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=electric fuel pump Most of the pumps have fewer than ten reviews except the......wait for it.......Carter pumps, the most common which have hundreds of reviews averaging at least 4.5 stars. Here is the search return for just Carter pumps and related stuff: https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=carter electric fuel pump If you want to look elsewhere you might check into Bosch, AC Delco, Airtex and Walbro but I have no personal experience with them. I've run Carter rotary pumps on two vehicles over the past 15 years with no failures. But the one on the Plymouth might die tomorrow.....

-

83% four and five star reviews. Who you gonna believe?

-

Our small town has Lowes, Harbor Freight, Tractor Supply, Fastenal, and a family-run auto parts store. I like Tractor Supply, especially for their hardware-by-the-pound and their work pants (wear them nearly every day). Life is good.

-

Best source of info is the manufacturer: https://carterengineered.com/electric-fuel-pump-p4594 According to their specs......diesel or gas.