-

Posts

1,612 -

Joined

-

Last visited

-

Days Won

13

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Bryan

-

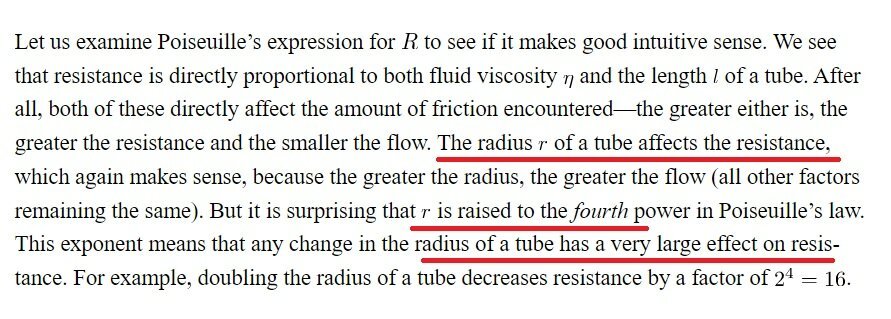

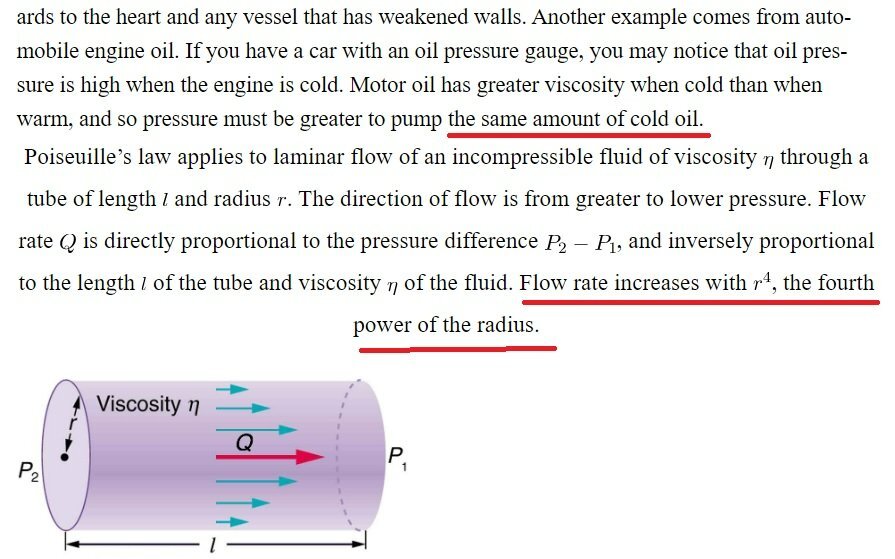

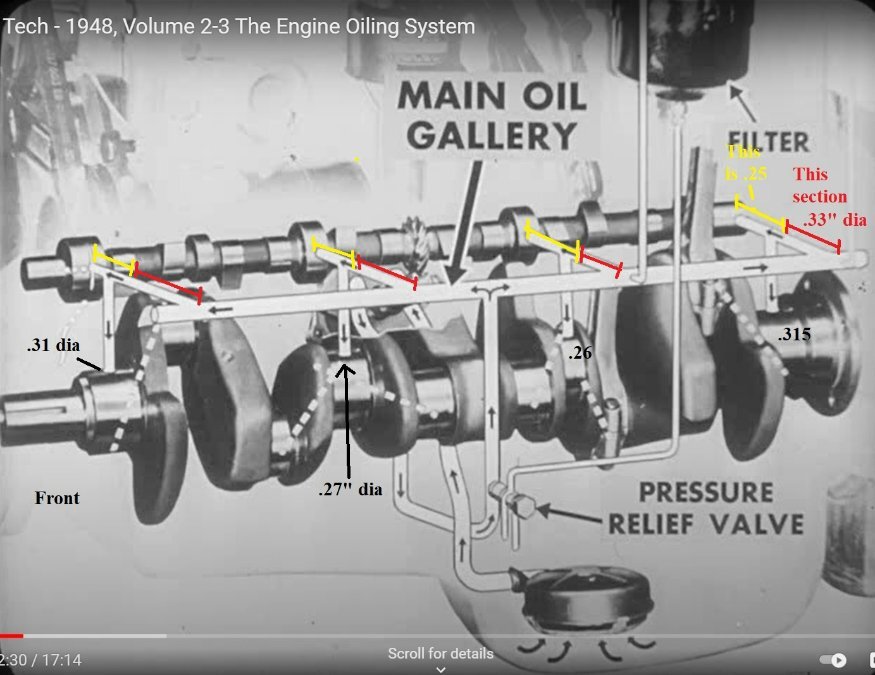

Best explanation of laminar flow I've come across.. Viscosity and Laminar Flow; Poiseuille’s Law – College Physics (opentextbc.ca) Radius of the tube DOES matter. Engineering doesn't change. In the factory, boring holes, like getting rid of casting sand, is left to the workers and quality control.

-

The down side. No news on camshaft yet. Never made it to Delta. Mailed off 26 May. I contacted USPS and registered a search. Good news: I'm sure my 48 Dodge crankshaft fits in the D-46 1953 block. I cleaned the crank up and deburred it, and put the main bearings for the 48 in, and set the crank in the block. Going to tighten it down another day. It fit in the bearings well and turned easily, so I don't think I bent it. Reason for this was to make sure it fits. And I'm going to recheck the deck height using one cleaned up piston & rod (without rings). Probably odd # for 1,3 and 5. Need to also figure out how much thrust surfaces on the crank can be worn.

-

It's a D46 which I think is 53. On my original 48/49 it had dirt stirred up in it so everythings worn. The older block does have the same size holes in the main journals. .31 front and rear, about .26 for #s 2 & 3.

-

The 48 Dodge (49 Plymouth replacement block) has large .330 holes going all the way to the camshaft for all main bearings. The 2 middle cam bearings were turned slightly so the holes were 2/3 open. Somebody knew back then. Sorry I keep calling it a 48 Dodge, that's my car. The guy cracked the block (pure water) after owning it a year and had the block replaced. Story my father told me. Okay, NOW WHAT? It has the same dished out galley sides (from the cylinder bore) on the 2 middle cylinders. Probably safe to bore but still would like to know the logic.

-

Don't know, but there would be a small bracket with a screw hole, and a matching place on the side of the switch if there was. Some locks just have a very short section of threaded part on them, that you stick out of the dash front and screw a ring onto them. Doesn't take much to hold them. The main force on them is a twisting motion when you're turning the key.

-

Forgot about that. Let me crawl out there in the old wood shed and see. Been burning a brush pile this morning.

-

-

I would think the switch part is enough, look for the slot to match the dash hole. The flat piece definitely does not go on the curved dash.

-

I was studying last night fluid flow at T junctions to no avail. At least in water flow there can be stagnant areas near the junction. Oil flow don't know. Adding a step to a smaller size would cause turbulence. With water the velocity would increase. Plus still don't know if this is unique to my block or standard.

-

I'm talking about the front and rear mains, drilling 1/2" further on each to reach the vertical passage going to the mains. Difference between .33" and .25" diameter. .02 cubic inch volume difference total.

-

If it is engineered that way, then somebody here would have the knowledge why it was done that way. Should be based on some kind of science, right? Fluid mechanics? Flow of viscous fluids? Maybe the engineers that we trust lost out to the economics majors..

-

I have faith in the engineers. I've worked in a factory before and knows how that goes. The passages are drilled. I know because you can see the spiral markings. If some new guy bored the .33 part too short..then oops. As of yet nobody has confirmed this is how it is designed, and is the same on all 230 Dodge engines.

-

I know from other posts about using the small holes on the two middle cam bearings. If they figured the front and rear were getting less they would set it up to feed less rods. My main question is about why they bore from the side galley .33" diameter passages but stop right before the vertical passage to the mains, and change it to .25" diameter abruptly with a step.

-

That's the only thing that making me hesitant from boring the front and rear ones out. Just usually a step in pipe size messes with flow. Even wonder why they didn't taper the bore down gradually? Trying to understand the reasoning behind it.

-

Changed pictures to make it more clear.

-

That would make sense but why did they decrease the last 1/2" to .25 before the vertical junction to the mains on the front and rear? Oversight?

-

Confirmed what I was seeing last night. The horizontal passage from the main oil galley to the main bearings are about .33", but this stops before it gets to the main bearings vertical passage. It has a step and decreases to about .25. On the front and rear mains, why didn't they continue .33 to the vertical going to the main, and decrease it to .25 starting the passage to the cam bearings? On # 2 & 3, since the vertical passages are smaller, why not just make the entire horizontal passage about .25" diameter? Was thinking, oh I could drill all of them out to the vertical passages, BUT look at the engine block pictures of # 2 and #3. The cylinder bore is cut up into the oil galley passage. Might not be a good idea drilling those out unless you knew the wall was plenty thick. Still I could maybe drill the front and rear out to .33, but hesitant to do that. Edited: Pictures made it confusing. ALL passages are like that Front, 2nd, 3rd and rear mains. .33" to about 1/2" before vertical junction, then .25" to cam bearings on all.

-

New? You already have it filled up. ?

-

Been having a few health problems but did manage to look at the block and take a few measurements. Had the block upside down. The oil holes from the main bearings downwards measured Front .310, 2nd .27 , 3rd .26, and rear .315". Was hard to get to the holes from the cam bearings but they all looked the same size, and the tip I stuck in them (to pullout and measure) was .265". Funny, the front holes from the main oil galley to the main bearings were larger, but got smaller deeper in, in a sharp step. It got dark on me and had to stop. Imagine the smaller section is the same as the cam holes from the rear, BUT IT LOOKS LIKE THE LARGER SECTION STOPPED SOMETIMES BEFORE THE MAIN BEARINGS. Need to confirm. Hope some new worker did not drill short of the mains. You would think the larger section would go all the way to the mains, and past that to the cam bearings it would be smaller. Will confirm tomorrow, ran out of light.

-

Try the simple stuff first. If you sit in the car outside and hold the engine at a higher RPM, does it overheat? How hot like Sniper said? Pegging the gauge? Is this a gradual thing or did it start all of a sudden? Simple things first - is fan/generator belt tight enough? Does car roll easily down an incline in neutral - brakes not sticking? Anything changed recently on the car like timing or mixture? Bryan

-

Hope USPS didn't lose my camshaft. No update since 30 May after it left Charlotte NC going to WA.

-

If the diaphragm is leaking is the fuel going into the oil? Not good if it is.

-

Spark Plug Wires - Loose Terminals

Bryan replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

As long as they don't pull up easily off the plug, and just twist around a little should be okay. If they loosely jiggle back and forth horizontally with a gap I'd say that's too loose. You'd have to get the touching edges of the terminal part on the plug to overlap to make the diameter smaller, or maybe curl them in somewhat.- 4 replies

-

- spark plug wires

- loose wires

-

(and 1 more)

Tagged with:

-

Well, that was a no. But already bought Hastings pistons. Hello Bryan, Thank you for your request for quotation. However, we are unable to quote this item this is not within Grover Piston manufacturing capabilities currently. Kind Regards, Diane Was wondering if you could make custom rings for a 1953 Dodge flathead 230 CI motor? 3/32 top compression, 3/32 - second compression. Depth about 0.18". Bore is cast iron with aluminum pistons. Not needing anything like nitride coated rings, just for regular driving. Something like ductile iron or steel with a moly coating. Just wanting something like modern ring materials that fit existing pistons. Hastings and Sealed power only make cast iron or chrome top rings for these engines. Bryan

-

My Ex's Aunt's husband in Germany worked refinishing furniture most of his life. He started getting symptoms like MS, eventually died from it. They finally figured it was the solvents and not a disease.