Leaderboard

Popular Content

Showing content with the highest reputation on 09/03/2017 in all areas

-

Drove on both right and left sides as that panel wandered like an old drunk at anything over 65!2 points

-

Went and looked at a 230 engine that's still in a 49 Wayfarer sedan, its stamped D30 on the engine pad which makes it the correct engine for a 49 Wayfarer. I'm also going to buy the transmission along with the motor, never know when I might have a need for it. Motor isn't seized up and I plan to rebuild it anyways. Seller said he would have the engine and tranny pulled in the next couple weeks.2 points

-

So, one day sitting around with nothing better to do and undecided to start checking Craigslist. Not locally but all over. Found a guy with a small stash of 23" motors. Since I'm new to this old Plymouth thing I figured I'd snatch me up a spare engine. So for a Benjamin I got a 1954 218. Bet this guy though I was off my meds when I called him in the Midwest about his Craigslist ad from Las Vegas. Needless to say I have friends all over the country, one swung by dropped off a hundy, loaded up my score, and delivered it to me this week. From what I have seen, the same thing I bought back east fetches at least 5 bills out here on the west beach. Now..i got a spare engine, gonna rebuild it. Feel more comfortable knowing I've had my hands inside an engine than leave it chance with someone else's work. Now I need to source an aluminum head. Either score an intake or make one..I was reading a thread on a 39 with a homemade job set up for 3..i just need 2. That tuning thing thing is a pain. And I'm going to make headers. Because 6 or 700 bucks a whack is nuts. 40 bucks in tube a mandrel bender and a little bit of welding is a better way to go i think. Plus I'll have the only set. Maybe mill up some valve covers. Got an old Bridgeport and a new lathe. Gotta start making stuff. P.S. if someone has a head for a 23" or knows of one..for a fee decent price PM me. And if you are looking for an engine and live in tornado alley I might be able to help.1 point

-

1 point

-

Some of the machines I work on have grease lines run to a distribution block with an automatic grease reservoir and a built in timer. This is what you need, just a matter of running 24 lines. Yea it might look like spaghetti under there but you wont have to crawl around under the ole Dodge anymore. lol1 point

-

My daughter, a high school teacher, sent us a picture of an object flying out of a planet. The caption was "Large mass expelled from Uranus".. Her comment was, "You kids in the last row, stop giggling." She's a good, no-nonsense woman, but growing up with two older brothers equipped her with enough coarseness to match anybody.1 point

-

I used a Mopar "E" Body 8-3/4" Rear that bolted to the stock springs without modification. I did stack the stock u-bolt /shock mount plate between the 8-3/4 u-bolt plate and the rear end or the shock mounting. Been running it since 1989.1 point

-

I have been busting my knuckles, stripping heads and breaking hardware for years. School of hard knocks I guess. No real training. I just kept learning from my mistakes. I have never used anything hotter than propane. It sucks in many situations but in some smaller-ish applications I've had luck. The reason I've tried nothing else is, I have no access to oxy/acetyne torches. I have never welded, and no access to one. The older I got I found that I had more patience. I learned a few tricks. I learned to take my time. Soaking parts in penetrating oil and leaving it overnight has worked sometimes. Tapping the tool end with a small hammer helps free things up sometimes too . Then lastly theres the reverse drill bits and easyouts. Hand-filing to re-shape bolt heads, was a good lesson to remind younger me to use the right tool for the job. If you've got nothing else, take some heat to it. Even propane might help. Worth a try. Some oil. Some tap, tap tapping. Add Time. Try fastnee and repeat as necessary. Fast it ain't. I've gotten things done one way or another.1 point

-

you probably have a leak in the system, which is why it is "shifting on its own" while driving. i had a hairline crack in the vacuum tubing, in a place where it touched the frame. the symptoms were as you are experiencing.1 point

-

I told my son not more than 5 minutes ago while digging out huge clumps of azalea that the best thing to so is work hard and run fast and that way old age can't catch you.....I'm afraid in the long run I will be wrong....1 point

-

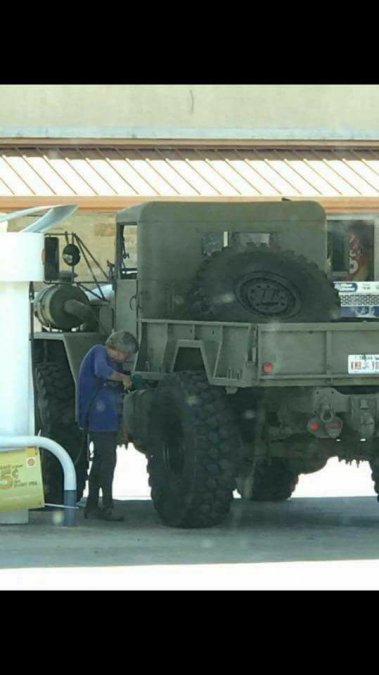

The truck is looking good. I really like the other one your looking at. As I have said before, I have always wanted a 2 ton pickup!1 point

-

Same here. Used to take the RV and tow my bike behind and stay a Elkmont campground for a week or so. Ride the Dragon, the Cherola Skyway, highway 411 to Clingman's Dome. Of course when you finish the ride, supper at The Old Mill reseraunt. Damn that is some good food. Joe1 point

-

1 point

-

1 point

-

Eastwood makes a Patina Preserver and a rust encapsulator that is in an aerosol can(rattle can). The patina preserver claims to preserve the finish for 12 months. The rust encapsulator penetrates the rust and tends to stop it for a time(not given). Being a California resident, rainy weather isn't a real issue and could mean that the preservation could last longer. Oxidation is an active chemical process meaning that as long as rust remains on the metal surface, the more oxidation that will occur. Another way that I have heard of preserving the finish was an application of linseed oil. This would tend to penetrate the rust down to the metal and maybe make your patina finish last longer without recoating. For sure, if you have deep flaking rust, I would advocate in removing it, possible replacing panels. I personally see no beauty in rusted out holes in the bodywork. Your feeling may be different so to each their own. Whatever panels get replaced, they can be chemically treated to promote rusting to catch up and blend with the other body panels. Everything I have read on the subject only speaks of preservation and indicates that it is not a permanent finish like paint would be. I have heard of other who clear coat it with urethane, but rust being an active process, the clear coat peels after a short time. There may be other methods people use with better results. On the subject of rust I do have a way that can remove AND promote rust. It's an old trick called a molasses bath. 10 parts water to 1 part molasses. Leave it in 2 weeks and it strips rust to bare metal, Just take it out and pressure wash it. If you want rust, take bare metal, put it in for a week and take it out, let it dry. All the rust you could ever want.1 point

-

If the windshield frame in the second truck is good then you have a small gold mine.... As to the driveshaft; have you called Big M or Wildcat?0 points