-

Posts

4,726 -

Joined

-

Last visited

-

Days Won

37

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

Maybe I can help, I have a truck & not a car ..... The brake & clutch pedal rest on the underside of the toe boards. This means the toe boards are the definitive answer to the position of the pedal. So drilling the holes & mounting the switch on the underside of the toe board is the ideal spot for me. As @Sam Buchanan suggest, pick proper placement & no adjustment needed. You just want to mount it where the switch sits comfortably in a off position, then when you move the pedal it goes to on position. Because the previous link showed a chebby switch with a mounting bracket, just makes things easier. If you have under the floor pedals, you will need to mount the switch under the floor.

-

Beer .... If we hand out free beer it complicates everything

-

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

It sure does. Is my first time dealing with one. I'm not really looking forward to installing it. There is sheet metal heat shields or sound deadners? Under the body, had to go to a weird angle to clear them to get it out .... will be same way going back in. Not something I can get in a hurry & muscle my way in ..... just slow & easy, 1" at a time, stop & readjust angle, gain a 1" .... eventually roll it into home. It will be a all day job. Just wishful thinking on my part. Out of 15 suppliers, only 1 offers a 11" clutch .... more of a red flag warning that it may be in the wrong place .... I ordered the 12" I imagine a better high quality hydraulic master/slave cylinder would be a easier approach to a softer clutch pedal. ...... Same time the bigger clutch is good exercise. I Just find that being medically retired & having nerve issues in my legs ..... I probably should not have bought a truck with a stick ..... sure gives me a smile every time I drive it though I'm just being lazy today, time to rest up after pulling the transmission. Have some ribs marinating for the BBQ tomorrow. I have about everything needed to put it back together ordered .... I'm just not touching it til I get everything pressure washed & cleaned up .... good project for tomorrow while the ribs are cooking for 6 hours. -

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

I agree .... there were those days, they are gone for me. Last Transmission I changed was a C6 in my 1 ton van in a gravel driveway .... I kinda did the same thing but never bothered to strap it down. I changed the clutch in my 1962 Dodge 1 ton 4spd by hanging a chain over the top of the cab & through the window. .... I have changed some big transmissions. This one is the biggest by far. It is the baby NV3500, they have the NV4500 that includes a granny 1rst gear then the NV5500 for the larger 2 ton trucks. Just a big heavy transmission. -

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

Thanks @kencombs @Plymouthy Adams Luks sounds perfect to me is what I will order. I still need to remove the clutch tomorrow & verify it is the 12" .... I'm hoping my flywheel is double drilled & can accept a smaller 11" clutch .... I can tell by looking at it it is the big 12". The truck is a heavy duty 1/2 ton & built to pull a trailer. I personally would prefer a lighter 11" clutch if it is a option. I will order a Luks .... better then just blindly ordering from price. -

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

What a frigging beast ..... OK @Sniper lets see you bench press this one. I cant even get it out from under the truck unless I take it off the jack ..... I have no desire to do that. Glad I built the cradle, it was a battle to pull it ... will be a bigger battle to stab it. The good news is it is just a old worn out clutch. It just happened the throw out bearing gave up first. I thought something spectacular may have happened .... just s worn clutch. The inner race came apart from the bearing & sitting lopsided on the shaft. The Anyone know a good replacement brand name? Rockauto has like 15 different vendors for the 12" dump truck clutch kit for this truck. I've never heard of any of them. They sell from $70-$130 .... Then a GM kit is over $300 .... I would rather spend $150 then $300 .... anyone have a brand they have had good luck with? -

That is for every post, it is not required .... there is no pressure to use it ..... some post are just banter & there is no solution. Same time if you do find the solution & mark it, it helps future people when searching old post for a solution. That is when the solution button is at it's best.

-

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

There is so much truth to that .... what we used to do in a day now takes longer ..... But we now do it soo much better. I basically screwed the pooch today and built this. Pretty sure I will not be applying for a pipe fitters job anytime soon. I feel comfortable enough with it .... I may need some wood shims to get correct angle, I can strap some ratchet straps to the transmission & safely lower it 2 feet. When I was younger we never took the time to do it better ....We just got er did. Some day I may finish it & paint it, for now I can get the transmission lowered & start ordering parts .... because of the Holiday & 4th July Tuesday .... just no reason to get in a hurry for a parts order. -

Getting my 46 WD15 repaired and back on the road

Los_Control replied to lostviking's topic in Mopar Flathead Truck Forum

Thats a good tip on the workout mat from Amazon ..... sounds like something I might try. Something I have been wanting to do is visit my local truck tire shop. I have 2 of them within 1 mile from me I live near a freeway on/off ramp. I want to pick up a couple old junk truck tire inner tubes. .... Just saying a bit thicker then a car inner tube. The rubber they have to pay for disposal, I would be happy to pay a few bucks for them. They make some pretty decent spray on contact cement ..... My idea is to cut a adequate square of rubber, then attach it under the toe board .... A slit for the pedal to move through. Then with the toe board in place, make another one for the top side. I have the dust covers from DCM, I just feel I can do something a little better if I try & do not require 100 point restoration. -

The thing with a broke exhaust bolt ....most of the time the threads are good & not damaged. The bolts are weakened & rusted so easy to break. Once the head is gone that does apply the pressure to tighten the bolt ..... now it is just the bolt no longer tight except for the rusty threads. Welding to the bolt will create the red hot heat that will usually break the bond of the rusty threads. Allowing the bolt to be removed. I think you are spot on with your worse case scenario. .... A lot depends also on how much access you have .... I assume the engine is installed & you have the inner fender removed to get to it? The other day I had to drill a bolt out of a nut ...... I had a floor pan I was preparing to weld into place. I ordered some U-clips that needed to be installed first & the provider never shipped them & was holding me up .... I decided to weld some nuts to the floor pan. This is fine, I drilled the holes in the pan then tightened the nut/bolt into place & welded them .... Perfect solution. I should have tacked the nuts in place then remove the bolts ...... I fully welded the nuts in place then removed the bolts. I got the nuts so hot I destroyed the threads on 2 of 4 bolts. 3 of 4 came out alright, 1 broke. .... Because of the damaged threads, I tried to weld a nut to it but it was not coming out that way .... I had to drill it. I got as close as I could with drill bits, then I used my dremel tool with a pointy carbide bit & removed the rest of the bolt .... you could see the shadow of the threads it was so thin. Then I used a small pick to get behind the thin metal that was left & pried it out of the threads, then used needle nose to grab & pull it out. I did run a tap down the nut when finished .... all is good. Only point here, I damaged the threads with heat, no way I could weld a nut on & turn it out. .... Was more work & I learned a lesson. Your threads are not damaged, they just have a bond on them from age & rust, they should turn out. There are still other ways to fix this .... my way I just used is not great, but it did work.

- 14 replies

-

I was looking for a particular video ... this guy was a diesel mechanic & he showed different ways he removed broken intake bolts. I found this one instead, guy had some good tips ... looks like he knows what they are doing. He is working on a aluminum head but is same for cast iron. .... He adds weld to the bolt to get it above the surface .... claims it wont stick to the cast iron. You do want to be careful & try not to weld directly on the cast iron of course. Might be worth a few minutes to watch, I got something from it.

- 14 replies

-

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

Well a change of plans today .... I was so disappointed I went to bed at 12:30 am last night still with no water or a shower ..... I had cleaned myself up the best I could with some of that gritty orange soap for mechanics ... I was miserable not sure would even work on the truck today to get more dirty. 3:00 am & still no water .... wife got up to use the bathroom at 4:15 am & flushed the toilet ..... I got a smile & a good 1 hour sleep. I was in the shower by 5:30 am & I felt like a brand new man ready to go face the world. I then spent a few hours in the garden doing some needed watering and fresh transplants needed to be put in the ground. My transmission would be easy today. I crawled under it late at about 9:00 just to figure out the cross over pipe had to be removed. I thought taking the complete exhaust system loose from the hangers I would have enough room to slide it out of the way ..... was not til 3pm I pulled that cross over pipe out from under the truck. It really kicked my arse ....going to require some welding but we got er did! .... I needed a beer after that escapade. Now literally I just need to lift it up & remove the bell housing bolts & drop it down. I have a bunch of this pipe, I think I will make a cradle that fits into my floor jack, so when I lift the transmission I can securely strap it down so it wont fall off the jack. Used replacement NV3500 are between $2k-$3k .... I do not want to drop a good one & break the case. So my 2 day job is now stretched into a 3 day job ..... Same time Friday afternoon, not really worried about ordering parts til Sunday night or Monday morning. -

Thats a good tip to use a washer ..... I have had mixed results getting good penetration welding nuts on. Sometimes I do not get good penetration & it sometimes is a one shot deal. Suggesting if it does not work the first time, you end up grinding off the weld & drilling it out. ..... perhaps a washer for a base welded in first would help. I just ran into the issue last week, I welded a nut on a stud with complete confidence .... I'm getting a lot better with my welding I had cleaned my surfaces, I held the nut with vice grips, I turned the welder on & welded the crap out of it. Thing is, the last time I used the welder was welding in 20 gauge sheet metal & had the heat turned way down ..... I never adjusted my heat settings to weld the nut on. I'm only suggesting, a good qualified professional welder would have no problems getting proper penetration on that weld the first time. For those of us who do not weld professionally .... the washer is a good buffer & possibly gives you 2nd chances ..... I will have to try it.

- 14 replies

-

That is a excellent idea, they even have the proper shape. Thank you very much for sharing. Once you mention it it seems like such a obvious solution .... I never thought of it.

-

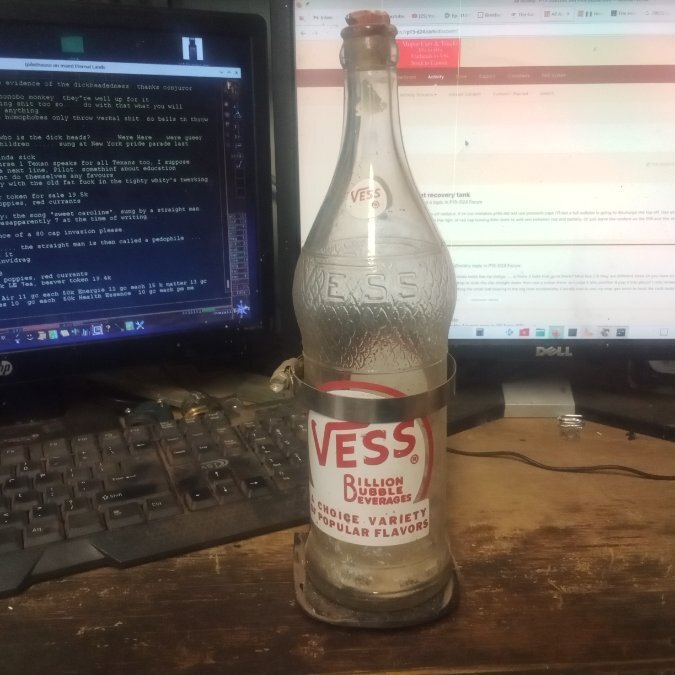

I think it would be easy enough to add one. Every now & then I get some ideas that ....... well lets just say they probably should stay that way .... ideas, & not carried out. I saw this bottle at a thrift store, the top is drilled for a pour spout. Would be easy to drop a metal brake line in it to connect to radiator. The bracket I made & is covered with 1/4" felt for the bottle to rest on. ...... The hose clamp idea stinks, need something better then that. I do not worry about the glass because of hot coolant, I do lots of water bath canning & put glass jars in boiling water all the time. I figure on a daily driver one year, 2 years, 3 years? ..... sooner or later that glass will break .... if driving down the road would probably drive over it & get a flat tire .... But look around you should be able to find something. ...... I'm thinking about a old Boy Scouts water canteen. They had one made of aluminum that snapped on your belt. Would be easy to polish it or paint it to hide it. I have a modern aluminum radiator now with a pressurized cap & expecting it to exchange water back & forth like a modern car. I assume @Doug&Deb has a original size radiator, where they were made bigger then actually needed. The cooling system is in good condition & working as it should. I personally feel like I want a overflow tank, fill the radiator to the top & add a bit in the overflow tank, let it find it's own level and hopefully will be no spills on the ground.

-

I have not been following along, kinda looks like my dodge ..... is there 2 balls that go in there? Mine has 2 & they are different sizes so you have to get them on the right hole. Looks like you have 2 holes also? Can you just drop or slide the clip straight down then use a screw driver to nudge it into position & pop it into place? I only remember watching Mike's video to assemble mine. Only problem I had was putting the small ball bearing in the big hole accidentally. Literally had to use my map gas torch to heat the carb body up to release the little ball bearing. Maybe a Desoto carb is different & only has 1 ball bearing? I dunno. There are 2 short videos, this is the 1rst & will bring you to the 2nd.

-

Actually gives me a idea. I acquired a DR stethoscope ..... from a yard sale or somewhere .... no idea. They are very sensitive, if you tap on the listening piece with your finger it almost blows your ear drums out ...... works really good. But, they are missing one of the rubber ear bud pieces, very uncomfortable possibly dangerous sticking the metal tube in ear ..... I always hold it with one hand away from the ear. I looked online for new ear pieces for this model, they were between $45-$60 .... I wonder if I could not rig something up with surgical tubing. I imagine I could go to amazon & find a automotive stethoscope for $20 ...... hard to justify $50 for 2 ear buds.

-

Nice recycle of old junk .... will be very useful

-

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

Think I nailed it for 2 days to drop it. Went really well today and got as far as I had hoped. Exhaust was a pita, I made a bit of a mess did not have the drain pan in correct position ....need to clean it up.... not too bad though. drive line ... check. Only thing left for today is to clean up the work area for the next stage tomorrow morning is to block up the engine ..... set a jack under the trans then loosen the trans & lower it. ...... Then prepare for the wallet flush. So life just keeps happening, our town got some storm damage to the water well fields that supply our town. They have been fighting issues for a few weeks, then they had to shut things down & make needed repairs about 4 days ago. They put us under a voluntary water conservation order while they refill the water holding tanks and rebuild pressure. 110F weather, people just use it up as fast as they can replace it & never let the system get built up to proper pressure. So last night they put the town under a emergency water condition ..... Just shut off the water. They have all the pumps working, they are filling up the water storage tanks to get things where they need to be. So I have not had a shower in over 4 days, my doo rag I wear on my head to keep my long sticky hair out of the way is soaked in sweat, my body is disgustingly sticky from sweat, now I'm covered in grease & oil from preparing to drop the trans. ..... Life would be great if I could just get a shower. -

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

I have no choice, I think this is what we call life .... I have no control over the situation. You sure rack up the miles ..... There is no access cover to see anything, I'm certain it is the throw out bearing or the arm/linkage that holds the bearing. Transmission has to come out. There is a clutch pivot ball inside the bell housing, right now I'm thinking it could be the problem. .... If the stud broke & the arm has come out of position on the ball it would cause the symptoms. Even in neutral not touching the clutch pedal it squeals like a stuck pig. Worse when you try to use the clutch. Hoping the pivot arm is not damaged, would have to order it from a wrecking yard & have it shipped A clutch kit from RA is only $150 going to replace it if pulling the transmission. I had it up on jack stands last night, decided I needed to turn it around pull it straight in instead of backing in. Now I know the trans is coming out. I'm just taking it easy .... back on jack stands today, this evening when it cools down I might start pulling it apart ....Going to bed early tonight. I want to be out there at 6:am with air tools ripping it apart before it gets too hot. .... Probably take me 2 days to get it on the ground ..... I will use my 3 ton floor jack to raise & lower it. I was a little freaked out yesterday but got it under control today -

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

What really pisses me off, I sold a radio to @Kilgore47 & we were talking about how to ship it .... Then my clutch gave out & I no longer have time to mess with it. I sure hope they forgive me for a few days while I work this out. ..... I never planned to be stuck with no transportation. -

Errr, shure would like some help on this clutch problem

Los_Control replied to Los_Control's topic in Off Topic (OT)

@Sniper you are welcome anytime .... bang on the door at 3:00 AM we will find a spot for you ...... to come up to help me work on my truck, that makes me feel old. I would much rather sit you down & cook A fine meal & a cool drink. It is obvious I do not have the hydraulic pressure needed to activate the clutch ..... But I have some pressure & the master cylinder is full of fluid ... so no leaks. Not sure if it is possible for a slave cylinder to go out & provide no pressure without leaking. I'm thinking possibly a throw out bearing came off the fork & no longer doing its job ..... This truck is so fun to drive & never gives any problems. You hit a freeway on ramp, start rowing through the gears you hit 80mph by the end ..... You get the look from the wife. But never ever gave any indications of a bad clutch. Something gave away while backing into the driveway .... I just suspect I will be dropping the transmission .... 8:15 pm & already down from 112F to 106F -

Errr, shure would like some help on this clutch problem

Los_Control posted a topic in Off Topic (OT)

This is a off topic 1991 chebby with a 350/NV3500 5spd. My problem is when I drove it to town today over 1 hour both directions it ran perfect in 110F heat. When I arrive home I swing wide & back into my driveway ..... was this point the clutch started to squeal. I backed into the driveway & shut it off. ..... I restarted it in neutral, the clutch was not working well enough to change gears. I can put it in gear then start it then move it ..... but the clutch is not working, it is squealing & wants to inch forward with the clutch in. I'm just asking for others opinions on it, Hydraulics do not work as should but full of fluid. Pedal just went away .... & it squeals ..... I think I'm pulling the transmission ..... Any other ideas? -

Ever clean a dimmer switch?

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

Thanks @greg g good advice .....To be honest I only check my headlights to see they work once a year for the annual safety inspection. I'm usually in bed by the time it gets dark ..... no headlights for me. A toggle switch may be a better choice. The one switch from rockauto just looks like crap ready to fail. ... The switch from DCM looks better ......but if you yank on the wires, it falls apart & need zip ties to hold it together .... not exactly what I want either. I just need lights to pass inspection ..... for now. ..... The only time I use headlights is when it is a dark & dreary day & turn them on for visibility .... not because it is after dark. -

Ever clean a dimmer switch?

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

Thanks for the reply @Rodney_Hamon ..... I probably will just order a new one. Going to give it another shot at putting it back together this afternoon. When it gets too hot for welding. I can sit in front of the fan with a cool drink & play with it. I would prefer the original, while it is dirty inside it can be cleaned & greased. It does have tabs on it so it will snap back together & stay. But, if I am still missing a piece it will never work & have to buy a new one.