-

Posts

530 -

Joined

-

Last visited

-

Days Won

4

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by thebeebe5

-

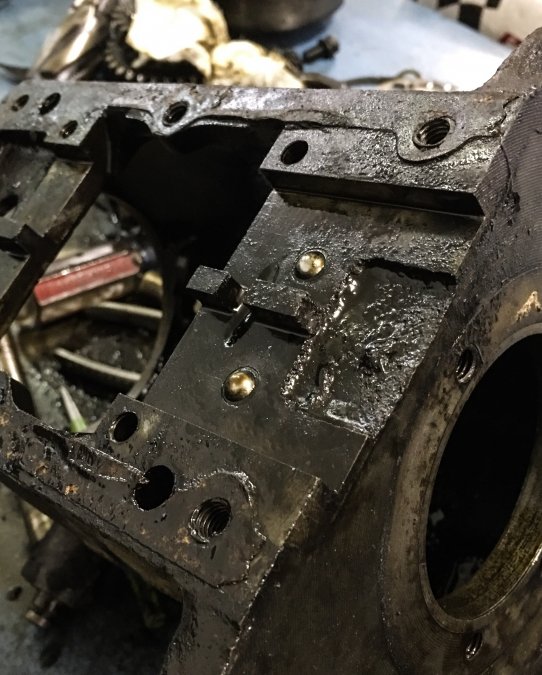

Got the '37s trans apart. Before sending the case to get hot tanked do these shifter check balls come out? Is it okay to leave them in for the caustic vat cleaning process? Disassembly wasn't too bad. Looks like some wear on reverse gear both front and back of the teeth. I know synchros were shot before I took it out so I'll be replacing those. Not sure there's much else to do but clean and reassemble.

-

My son has started our Scarebird conversation

thebeebe5 replied to medium_jon's topic in P15-D24 Forum

Look stock to me....- 99 replies

-

- 2

-

-

- conversion

- scarebird

- (and 4 more)

-

Ebay has been a good source, but know what you need. There are many different sizes out there. I picked up a couple of filters complete and a small handful of ceramic elements a while back to have as backups. Gaskets are HTF and I'm betting you could make your own in a pinch if you can find some material.

-

There's a lot more where that came from....! LOL

-

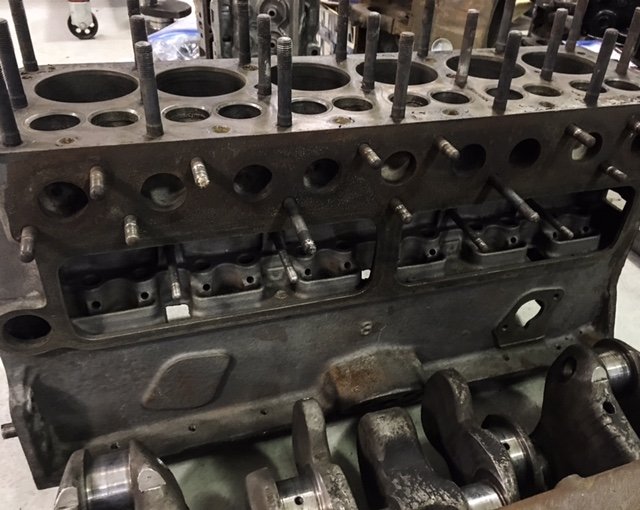

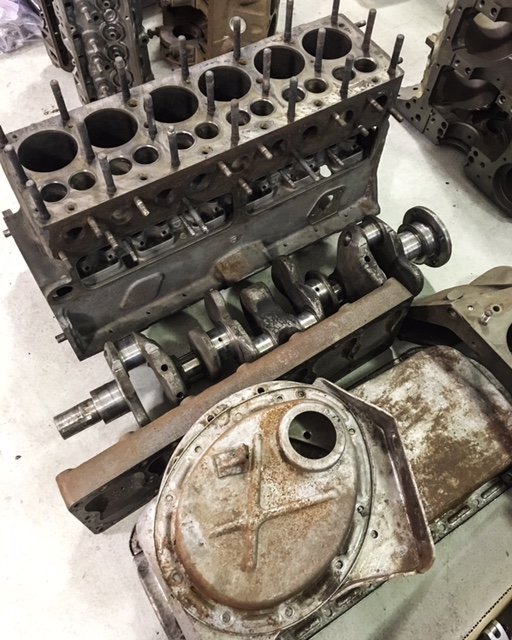

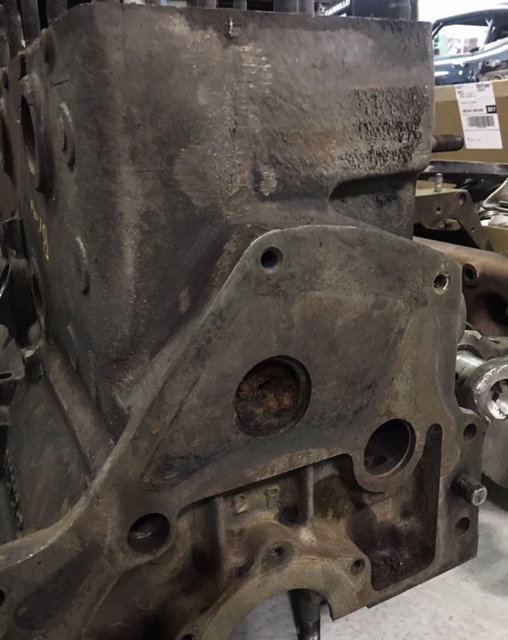

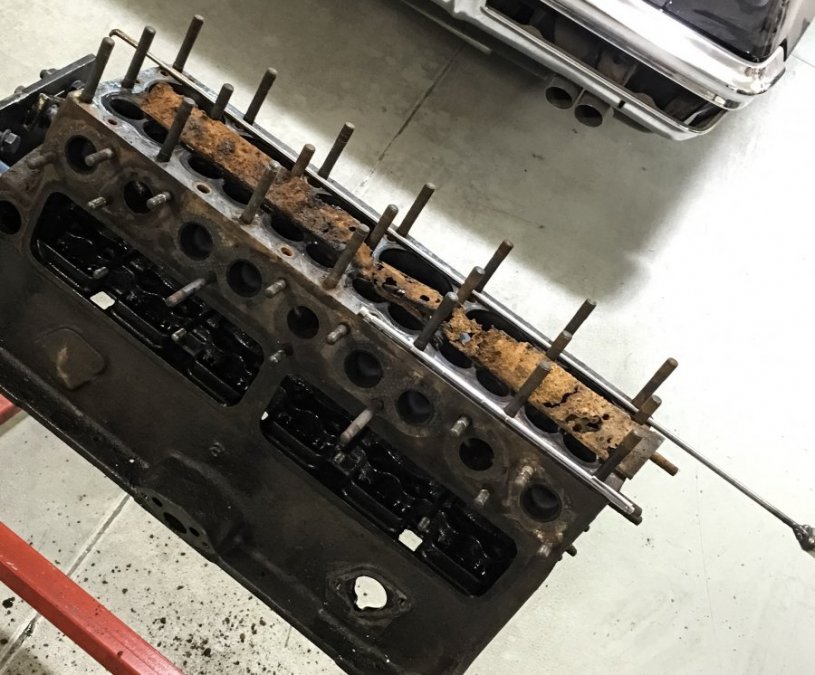

It had an overnight dip in a caustic hot tank, but the back half of the block is packed solid with soft sediment. Almost like a modeling clay.... Dug out what I could and will take it to a place that does a more aggressive dip. Got to get this goop out.

-

Block and various parts are back from vatting. There's still a good bit of sediment packed in the lower portion of the water jacket, especially at the rear of the motor. I'll have some work to do chipping that out tomorrow, and then will decide if it needs a chemical dip to dissolve some heavy rust deposits or additional leftover crud hiding in the interior nooks and crannies....

-

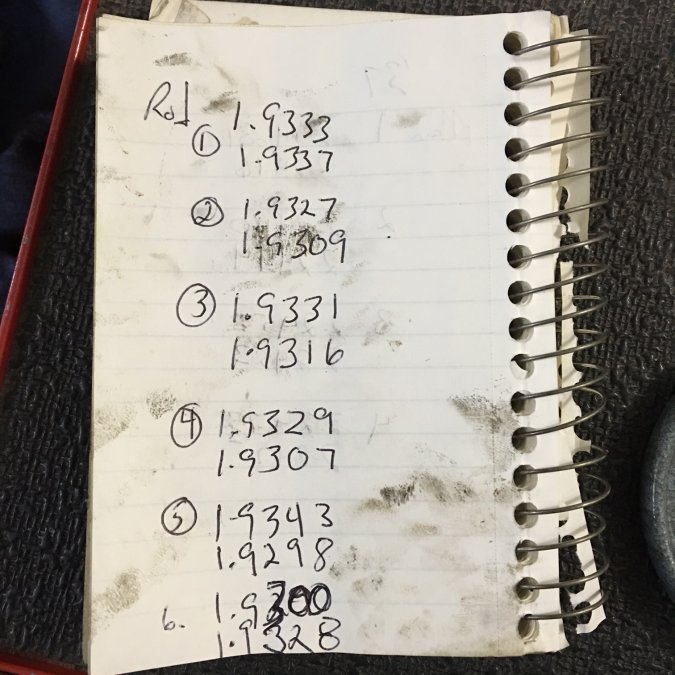

Well, judging by my journal measurements compared to published specs for what we think might be the same as my 201 I'd still say nothing has been done to the bottom end on this one. Right now I'd be confident ordering +0.010" bearings for both the mains and rods and, once line hone is done, assemble to determine where I want the relief to land. We usually shoot for 0.0020-0.0025" for racers running a 20w50 VR1 oil which works out nice. Great oil pressure bearing life at that spec. On this motor I'm leaning toward the factory spec of 0.0015-0.0020" and will likely run a thin synthetic. I like having cases of just one weight of oil at the house for all the cars and might go with the Amsoil Signature 0w30 I run in all our modern stuff. The only deviation would be the hot 390 I built for my 67f250 where I run the Amzoil ZRod oil for the zinc content. That truck has a high lift cam with some reasonably high spring pressures for a non-roller sold lifter motor. Likely a non-issue with thr Plymouth's well worn in cam at pressures between 45 closed and 100 open psi. Heck, I can almost squeeze that much in my hand. Nothing compared to the high lift cams and high spring pressures for something more modern. The numbers you folks have provided have been a big help

-

Thanks DJ. Yep. Have that service manual. Frustrating that little bit of information isn't in it, but it's not an all encompassing publication. Will figure this puzzle out piece by piece.

-

Valve Work - 1953 L6 264.5 CI C60 Windsor Deluxe

thebeebe5 replied to keithb7's topic in P15-D24 Forum

+1 when I grind valves I shoot for about 0.070" -

Man, that's a super sweet looking ride. Love the color! Already mentioned, but going through that motor to fix a "knock" would be the easiest thing to manage in my book. Keep is posted with info and MORE PICTURES!

-

Thanks fellows. Jerry, I'm guessing the T25 would be the specs for my motor.... Here are the measurements I posted earlier today in my "overhaul" thread. Andy, can you confirm this with your information? We doubted this motor had been apart ever in its life, but it's obvious that at least a valve job had been done as a couple of exhaust valves had been changed.

-

Thanks @Andydodge. Found the nominal sizes for the (i guess 217.8?) in the bearing books, but that would mean that my crank had been turned .250" already because I am measuring mains at 2.2450 (roughly). Certainly excessive, and the bearing shells were thin, not super thick as if the crank had been turned to death... Still scratching my head ATM....

-

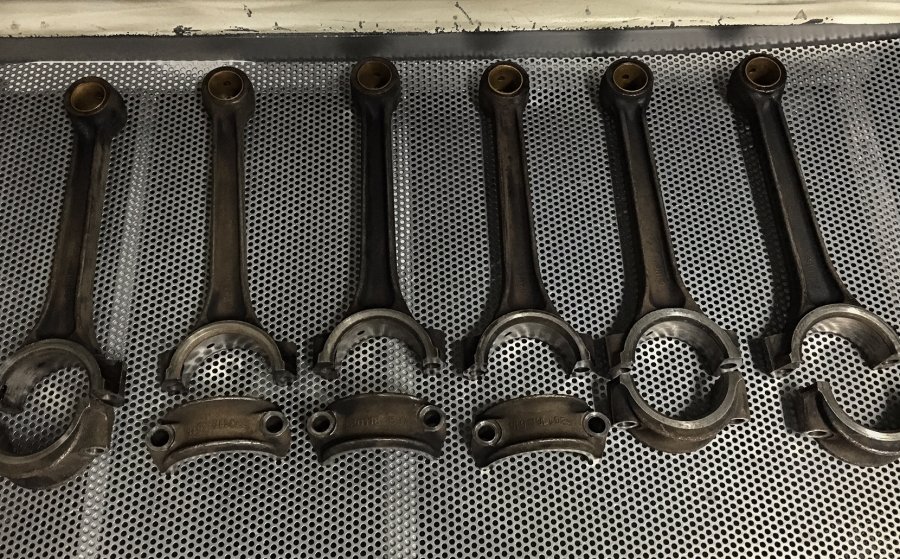

Pistons off and rods bead blasted. I'll check the wrist pin bushings for size before leaving the shop today. 'Bout time for a cold beer...

-

Checked valve installed height to be 1.635". That puts the existing springs at 45lb seat pressure and about 97lbs open at a 0.321" lift as measured on the cam lobe (Exhaust and Intake have the same measured lift). Doesn't seem like much, but there's less than 10% variance in measuring every spring. I'll poke around a bit and see if that's good enough for a stock rebuilt 201.

-

@Plymouthy Adams Would be happy to have your numbers as a reference because I have nothing else. If you wouldn't mind reposting. Or PM me?

-

I work at the machine shop, Don. This isn't an engine we routinely deal with. Looking up bearings in Clevite, Fed Mogul and King books and we can get back as far as a 218cid. No 201cid. Would like a link to a published spec for both crank and rod journals.

-

Can anyone direct me to a source for some crankshaft journal specs for a '37 201cid motor? Trying to get a rough idea of where this crank is in its current state and get some bearings on the way so we can spec the grind on the crank. Thanks!

-

-

Got it. Used 1/4" tooling stock with a hook fashioned at one end and a 1/2" 20 thread nut of slide hammer use. Picked a lot out with a magnet as well. I'll weld it up for re-use.

-

Got that already PA.... It's safely out of the block. I can see some leftovers of the water tube. Trying to pick them out now....

-

-

5 litres or 5 quarts? Hoping you have oil registering to the "full" mark on the dipstick.....

-

Valve Work - 1953 L6 264.5 CI C60 Windsor Deluxe

thebeebe5 replied to keithb7's topic in P15-D24 Forum

Unless that motor has had guides done already at some point they're likely cast as part of the block. Cast iron works fine as a guide and the casting would have been drilled to precisiy fit the valve stem at the factory. For worn "guides" in a cast block a machinist would drill the cast section out and drive in a (usually) silicone bronze replacement guide which is an upgrade from the old iron guide. Not something to be done in an assembled engine. You'll end up with a metallic mess.... New valves might tighten things up a tad as valve stems do wear, but that metal is harder than the casting it rides in, so it's likely not worn much. I expect (hope) to be reusing most of the 80 year old valves in my engine and I'll be updating all my steps in my "time for an overhaul" thread. At some point two exhaust valves got replaced, so I don't have all the original valves available. Some of my guides are fine, but some exhibit wear enough to certainly be out of spec (although I have not measured any at this point, just noted there was too much "wiggle" upon disassembly). I'll be drilling all guides and replacing with the silicone bronze inserts. -

I'll be CCing my '37 201cid when it comes back from its vatting. Will add the value i find here.