-

Posts

530 -

Joined

-

Last visited

-

Days Won

4

Everything posted by thebeebe5

-

We use lots of Seymour paints, and this is the one I used on the distributor body: http://www.seymourpaint.com/product/hi-tech-enamels/ It holds up really well.

-

Have the cap!! It was just camera shy yesterday The whole process you all desribe makes sense. Learn something every day!! What color for the cap and cup? I was thinking a simple clear coat unless there's a specific color it should be...

-

Never saw it the frst time.... Several posts posted at once and I flat overlooked it. Great info, and thank you!

-

Ok, so this is a '38 unit? Also, can anyone tell me about this access? Mine was packed with grease when I disassembled, so I assumed it was for that purpose. Question is, do you just gob grease into it and hope it gets to the shaft? No real way to advance it into the center unless you just push it in with a finger.... Seems an odd attachement to me. Also, is there a source for a seal? This one's gone. I could find a neoprene o-ring with a little effort. Didn't see a solution when I shopped at Bernbaum this am....

-

-

Okay. Anyone have a photo? And can anyone tell by the number plate on mine if it is correct for a '37? The numbers mean nothing to me....

-

I I remove them on any engine block that is being completely disassembled for rebuild. All oil passages will get thorough cleaning, and the only way to do it is to remove those plugs. Otherwise they stay in place.

-

This hole above the horizontal generator bracket mount holes? Oil Galley plug holes. As @Plymouthy Adams mentioned the galleys had to be drilled somehow. The holes in the outside of the block (and on some engine types inside the block) are simply plugged up with a pipe threaded plug of various types. Some engine types have a pipe plug like a mini freeze plug installed. Some have an allen head screw plug installed. Some utilize the plug @Frank Elder shows us. Sounds like you have the same plugs I pulled out of my block a couple weeks ago; a simple NPT threaded screw.

-

I don't know what a red tag is, Young Ed... Young Ed-ucate me, please....

-

@Don Coatney is correct. We blast cast iron heads with whatever wore out media is in the cabinet at the time. When the gunk is gone we swap out for a fresh load of #8 glass beads and give the heads a once-over, and they almost come out looking polished.

-

The machinist I work with surmises that the issue started below the rings based on the wear or damage pattern of this piston. The lowest ring land was pushed up into the ring as the piston was pulled downward into the cylider bore. That could support the leaky fuel pump theory I suppose.... Definitely worth checking.

-

Distributor is all cleaned up inside and out and the body is repainted. I'll let it dry for the week and reassemble next weekend.

-

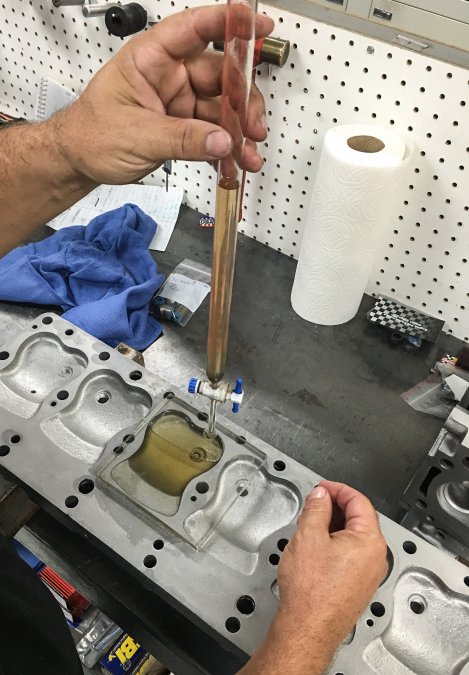

Also cc'd the head and found the chamber size to be 82.2cc. There was a recent thread pertaining to chamber size. I'll try to find it and add the information there as well.

-

-

I bead blasted the head and checked it for straightness. It's all good and we'll just do a clean up cut on it prior to install. Before:

-

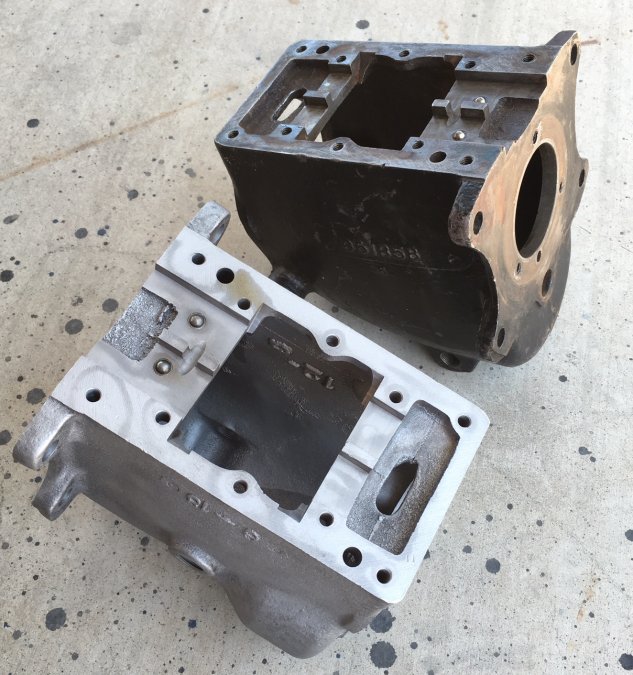

Today's efforts.... Radiator boxed up To send in to Brassworks. They "foamed up" a '37 they had at the shop and sent me the empty, fitted box. Definitely worth the cost IMO. Got a second transmission from a forum member here. It's disassembled and looks like it has a good, useable main shaft. My original was better overall, but there is some scoring at the forward bearing surface that fits into the input shaft. Better to use this second shaft I'm thinking.... My trans case is all cleaned and ready to begin assembly. Distributor shaft needed a little attention, so when Pat wasn't looking I chucked it up in the lathe and polished it with the crankshaft polisher. And there was a burr or something inside the upermost part that slides onto the top of the shaft and completes the weight assembly. Ran a valve guide hone throuhh it real quickly and it spins freely now. Ready for reassembly in the painted body.

-

It might, but as I have neither 230 crank or rods it'll go back in as original. It'll be fine compared to how bad it was initially.

-

Overheating could support the lean mixture theory. $5-7k doesn't sound too out of line for a proper and thorough rebuild. Start adding custom work and it can climb rapidly. My pal did a '28 Chrysler engine 6-ish years ago that approached $15k, but the custom work was extensive. It adds up fast, and quality mahine work is worth paying for.

-

Finally got the block back yesterday. Had it recleaned and de-rusted at Xpress Metal Cleaning in Phoenix (they did not do the first cleaning). This time its perfect. Water jacked is devoid of sediment and ALL the heavy rust scale in/on the block and is gone. Definitely a better place to start. Need to order bearings now so we can get the mains right. Parts are starting to roll in.

-

Bottom oil control ring land is damaged (at least). No real way to fix that. Better off replacing it. Sad to see, brother... Hope you can find what you need.

-

Thanks Niel. Gloss? Satin?

-

So, progress report. Last week not much done. Other things to do at the shop, and the block hasn't come back from the second dip yet. This week, resurfaced the valve adjusters. Some were dished as much as 0.050" where the valve stem made contact. Should help with valve adjustments... Also, tried to disassemble the drive shaft, but cannot get the trunnion cross pins pressed out of the joints even with the shop's 10 ton Sunnen press, so.... Not sure what next. Could try heat...? And knocked down the distributor. It had obviously gotten a Krylon rebuild at some point in the past. Blasted the black paint off and as it peeled away a rust layer appeared.... Not a bit surprised, but it's squeakey clean now. Internals look pretty good. Everyhing is nice and tight. I'll paint, lube and reassemble. By the way.... What color should the distributor body be from the factory...?

-

A 37 plymouth? Found this new in the package at a local goodwill. Looks fat enough... I just cant find the appropriate size on the web at the moment.... The one hanging here is 21/32" x 53"

-

Heads up. I just called these folks and the fellow says he carries none of the transmission parts any more. Everything is gone. Anyone have any other sources? I can probably find front and rear bearings locally if I had to. What i need most is a synchro drum and a rear seal.... Bernbaum lists the seal Don't see synchros listed with them Mainshaft is in great condition except... There's some pitting (moisture and sitting for years maybe?) at the front tip where the needle bearings support it. Low reverse sliding gear has some wear on both front and rear of teeth, but it's not terrible. Cluster gear is perfect as is reverse idler gear.