_shel_ny

Members-

Posts

6,257 -

Joined

-

Last visited

-

Days Won

4

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by _shel_ny

-

Not a "phantom", but an oddity would be the 1953-1955 Studillac. (Stude Starliner/Cad. V8) Sorry no pics. It was an apparent overpriced/underpowered failure.

-

Likely a 3 speed from a 1957, or thereabouts, Plymouth. Edit: and maybe not. This quote clipped from another site. "I doubt if the casting numbers will be of much help in identifying the transmissions, look for the part number and build date stamped in the case just above where the dipstick tube enters the pan."

-

Perhaps some truck forum person may have added insight beyond Gregs great answer. (truck guys may not all visit the car forum) http://p15-d24.com/forum/6-pilot-housecom-truck-forum/

-

Windshield & Cowl Vent Rubbers and Door Locks

_shel_ny replied to 1947coupe's topic in P15-D24 Forum

Some of the door lock set screws are a slotted head. There also may be a small cover over the hole, and it may be partially hidden under the door seal. -

It's always sunny in Philadelphia. Vinyl across the street. Bearings one street over. Edit: and you could go over to the Fishtown Beverage Center and get some Nirvana water bottled about 12 miles or so (as the crow flies) from me here in NY

-

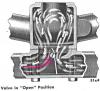

Original set up has the filter (bypass filter) return line connected above the pressure relief valve. Oil from the filter is allowed to return to the pan when sufficient pressure is available to move the relief valve plunger out. The relief valve and spring are behind a square headed plug, just out of view, at the center bottom In the 4th pic Edit: by original set up, I mean when it was installed. Not to be interpreted as all were original equipment, as it seems many were installed as an option.

-

I like the highway reports provided in Manitoba. Go right on the computer and get closure/condition reports. Looks like the Winnipeg area has found some shades of winter. Link may or may not work. http://roaddata.gov.mb.ca/map/gmap/map.aspx?lng=-100.04&lat=51.15&zoom=8

-

Horns weren't working...now they work continuously!

_shel_ny replied to Redmond49's topic in P15-D24 Forum

That's the way it should be connected. Still seems to me that the problem is under the horn button. You are providing a ground, and when you move the horn button the ground is being interrupted. Something out of position under there.- 35 replies

-

- 1

-

-

- horn

- horn relay

-

(and 1 more)

Tagged with:

-

Horns weren't working...now they work continuously!

_shel_ny replied to Redmond49's topic in P15-D24 Forum

If you look real close at the mounting tabs for the relay they are marked as to where they go. Bat, horn, ign, gnd Extra wires may be just a "common point" electrical connection. Edit: Seems like you have everything where it belongs. Horn stops when you press the horn button sounds like a little misalignment of bits and pieces under the horn button.- 35 replies

-

- horn

- horn relay

-

(and 1 more)

Tagged with:

-

-

windshields for 49 1/2 t dodge pickup

_shel_ny replied to Ken SMith's topic in Mopar Flathead Truck Forum

Ebay seller has an 800 # Offers 5 piece set, buy may sell just the windshields. -

The rubber on these dampers can look a bit cracked where it is exposed to the elements at the outer edge, and still be in good condition. This pic is of the markings on a Dodge damper. Edit: The damper and the pulley are 2 different parts. The damper is bolted in front of the pulley, and is held on by 5 bolts.

-

Make a copy. Open the copy with "paint". Resize. Save. Post smaller pic.

-

Gas Tank Removal & Fuel Gauge Sending Unit Service

_shel_ny replied to HanksB3B's topic in Mopar Flathead Truck Forum

-

- 1 reply

-

- 1

-

-

Gas Tank Removal & Fuel Gauge Sending Unit Service

_shel_ny replied to HanksB3B's topic in Mopar Flathead Truck Forum

I had one with a nice wire cone that was detached. Epoxy repair did not hold. Had another with the cone firmly attached, but the wire was toast. -

Gas Tank Removal & Fuel Gauge Sending Unit Service

_shel_ny replied to HanksB3B's topic in Mopar Flathead Truck Forum

If single terminal, 1 lead to the terminal, one lead attached to the body of the sender. Slowly move arm. EDIT: would expect 0-90 ohms same a car sender Edit : oops 10-90 ohms (tks Merle) -

D300 Pinion Seal Source Chrysler/Dodge/Mopar P/N1271 105

_shel_ny replied to Plym49's topic in Mopar Flathead Truck Forum

SKF #18924 Edit: NAPA ~ $20 Rock Auto ~ $7 Possibly: Double check OD ID National 6808N Rock Auto ~ $7 NAPA 18888 ~ $24 18891 ~$20 Auto Zone Timken 6808N ~$27 Collectorsautosupply 1271105 $70 -

There is a pin on either side of the bulb base. Some bulbs the pins are parallel to each other and allow the bulb to be put in 180 out. Others are 1 pin higher than the other and can only go in one way. Edit: spelling

-

The bell housing should not need to be removed.

-

4 1/2" angel grinder with a cutting wheel. Should take about 15 seconds if you go slow.

-

I believe that if you look real close that the terminals are numbered at both ends. They must be connected correctly for proper operation of the gauge. That may not be causing your problem. It will not hurt to swap those 2 wires. That being said, I am not responsible for the results You can eliminate the wiring as a cause of the problem by unhooking the existing wires at both ends, and running a couple of long wires from the gauge, out the door, and back to the tank for a temporary test.

-

For anyone reading this. Just a reminder when doing a compression check adding oil. As has been posted here in the past, the valves are under the spark plugs. A little tube of some sorts may be needed to get the oil over to the piston and rings for a good "oiled rings" check Edit: not saying your check was not good, or that you did not get oil to the rings

-

Have been some posts on that here. Seems most feel that it is not needed. Some have blocked off, or welded the flap in the "closed" position. Edit: or even wired the counterweight in the full clockwise position for lack of a spring. (not me)

-