-

Posts

122 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by dcotant

-

"Can I unbolt the bell housing or should I try to remove the 4 bolts that attach the bell housing to the motor mounts?" I have done it both ways. If you unbolt the bell housing from the engine there is less to pull out, but if the dog house is off it doesn't matter much, just threading through the frame. Problem with unbolting the engine from the bell housing is that you are under the truck to pull the clutch and flywheel because engine won't pull away with them on. Transmission has to be off in both situations.

-

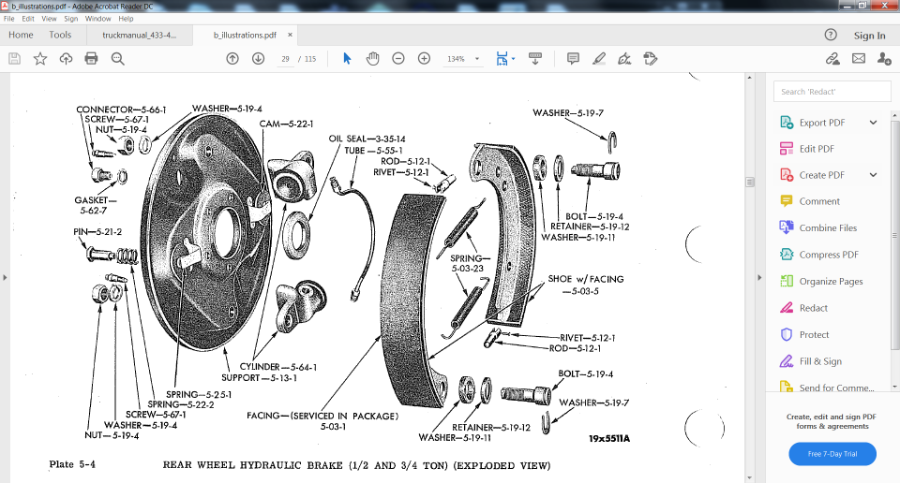

You can see the pin is smaller diameter in the part that goes through backing plate than the part that goes through shoes.

-

Yes the pin comes out the brake side. Loosen nut and drive from backing plate side out to the brake side.

-

I tried JB Weld on two machine screws that i ground flat to increase surface area. They were end studs, didn't last long. Was thinking maybe longer studs with something springy behind nut so flexing of the hood did not put so much pressure on them. Will be interested to hear what other members did.

-

Who has all B3-B shift diagrams?

dcotant replied to Fernando Mendes's topic in Mopar Flathead Truck Forum

Love the double clutch section, especially "advantages will be readily recognized" -

"Ran When Parked" 1954 Dodge C 3/4 Ton

dcotant replied to DrFate77's topic in Mopar Flathead Truck Forum

Something so right in working the come along to begin the journey, I agree that is a lot of ratcheting but it builds ownership! Looking forward to pictures of your rebuild. -

I think you have to remove the floor board(s). At least the toe kick ones.

-

I reinforced that section of the cab with square tube and angle underneath before I pulled the cab.

-

This is how i did the underside of my cab. I used POR15 on it and was very happy with results, though time will tell.

-

Where did you source transmission bearing parts and how did you find part #s?

-

I have found that instead of pulling straight back, if you apply angular pressure it works better, just kind of tip them out of their holes.

-

You are pressing from the back (nut end of bolt) right?

-

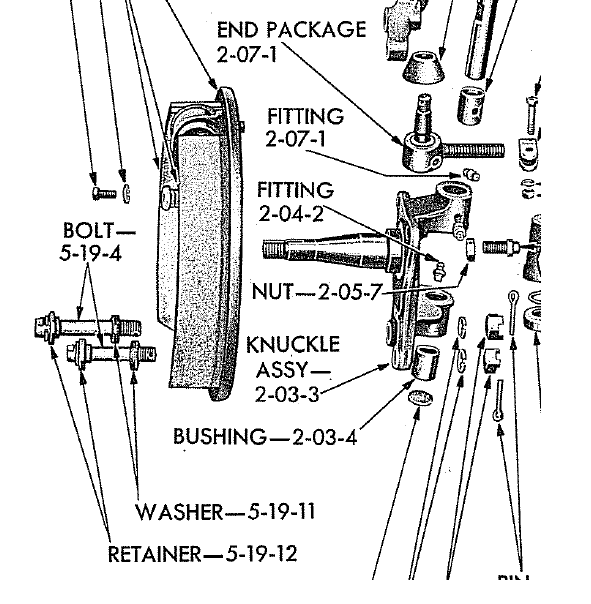

The bolts I was talking about are 5-19-4 in this picture. And what i call spindle is the Knuckle ASSY in this picture.

-

So by "long bolt" do you mean the brake anchor bolt ( goes through holes in bottom of spindle ). That should have flattened sides on the brake side of things that you can put a wrench on it and possibly turn it. If not that one then perhaps a picture indicating the problem bolt. If it is that one, there is nothing holding it but rust and the wisdom of years.

-

-

51 B3B build thread - after all these years

dcotant replied to bkahler's topic in Mopar Flathead Truck Forum

I agree! Ok, maybe they are 5/16, now I have to go look. -

51 B3B build thread - after all these years

dcotant replied to bkahler's topic in Mopar Flathead Truck Forum

Ha, I run the exact same part on the tie rod of my MTD Ranch King. I guess Dorman gets the prize for imaginative re-purposing. -

51 B3B build thread - after all these years

dcotant replied to bkahler's topic in Mopar Flathead Truck Forum

Nice use of garden tractor tie rod ends for your link ends. Never ceases to amaze me how people on this forum re-purpose parts. -

Yes I have trucks with both wheelbases. Shorty doesn't have bracket, long wheelbase does.

-

I used the molasses method on some parts, pretty amazing but weeks instead of overnight.... Love the golden hammer.

-

Ready to Start the Engine Build (what am I missing)?

dcotant replied to billrigsby's topic in Mopar Flathead Truck Forum

I would add, mark your timing mark on the crank pulley, i wire brushed mine off while cleaning up the pulley and it is a bugger to read way down there afterwards (at least for my old eyes ). Actually does anyone have a picture of the marks on the pulley, i think there is a major mark at 10 BTDC, TDC, and 10 ATDC but like I said my eyes are not allowing me to see the actual writing on the pulley. This is for a 52 B3B, I will try to look at my 49 pulley and maybe it is the same. Never mind I found the pulley for my 49 and it does appear to be the same 10, 10, and TDC between them. -

So I tore down my 49 some 10 years ago, bought a 52 parts truck about 5 years ago and started driving it about a week after I bought it until about 6 months ago when I started transferring parts from the 52 to the 49. Always decisions to be made on which part to use and of course I wanted to use the best parts with a tie breaker being original 49 parts getting preference. When it came to the radiator, the 49 was in much better shape and slightly different ( bigger top tank with baffles, larger opening and cap ). As I mentioned it had been in "storage" in my barn for about 10 years but seemed good, flushed clean, so I painted and installed it. First few trips on the road, no problem. First actual drive was on father's day this year, no drivers door, no windshield, no box, no floor boards, no front clip or fenders but at least I had a milk crate for a seat. About a month ago I had it "street legal enuff" and started longer runs to test everything out. Then finally a run to town to get lumber for a project. I am one of those guys that works their truck. Well that run to town is when the trouble started and the engine overheated. As most of you know how disappointing it can be to think you had that work already done, and of course after having this truck for 45 years I am well aware that you are never really done, there is always something that needs fixing, but it was a bit devastating. Well digging into the problem I found a bit of something in the top tank of the radiator that looked like mouse nest. Near as I can tell a mouse family moved into the top tank and the nest they built didn't cause any problems in the beginning ( must have been bunched up at one end ) but when it began to disintegrate it plugged all the tubes enough that the coolant could not get to the bottom tank to feed the water pump. End of story I am running the 52 radiator and happily back on the road. Hauled a load of elm yesterday that would have brought my 1/2 ton 52 to its knees but the 3/4 ton 49 didn't even notice. Moral of story is to plug those orifices on the parts you store. I am not unfamiliar with mud wasps filling every hole they can fill and mice doing what mice do, but I just wasn't thinking they would move into that upper tank. To add insult to injury I am pretty sure they used the cotton from my seat to build that nest.

-

FINALLY - My 1948 B-1-D Build Thread, 33 Years Later

dcotant replied to billrigsby's topic in Mopar Flathead Truck Forum

Proud of you! My 49 (Clementine) has been waiting since 1996 to get back on the road and finally is. I have had it since 1975 and was pretty much a daily driver until 1985 or so. Then in 96 there were too many things that needed fixing for me to drive anymore. Life for me changed in 85 ( kids ). But now she is rolling on the road again and I took care to handle rust and pulled what i needed from 52 parts truck ( rest in peace JR ). Hope to drive this baby until the kids take my license away. Oh and by the way, all my repairs were done with oxy-acetylene welder. Oh and also by the way, seeing those parts hanging from chains in your shop, pretty much what my barn has looked like for the last 6 months. -

This was discussed earlier in this forum, hope this helps: