-

Posts

1,912 -

Joined

-

Last visited

-

Days Won

14

Everything posted by Desotodav

-

Thanks mate. I'll make one up during the week while the seat is out. Desotodav

-

...but I think that if I had the funds I'd prefer a garage like this... http://bcove.me/vhumde9s Desotodav

-

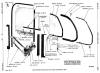

I can't help you with the grille bars sorry Ron. Your assumptions of the spare tyre mounted under the bed are correct. Hopefully the attached photos will help you. I have found both straight and curved carrier's (22-12-1) on the Oz trucks that I have played with. The end of the carrier closest to the rear of the truck is mounted (with a 2-staged bolt with butterfly nut) through a hole in the left chassis rail about 4 inches in from the end of the chassis rail. The front of the carrier is mounted with a long bolt through a hole into a small cross member (which runs across the chassis) about 2 feet in from the rear end of the chassis rail. I notice that different securing bolts are shown in the diagram from the USA manual that I have pictured. Maybe you did things different over there? Desotodav

-

Thanks Mark. How thick is the rubber? Desotodav

-

Engine fired up but First Gear very noisy

Desotodav replied to dontknowitall's topic in Mopar Flathead Truck Forum

Great job on getting it fired up Ryan. Not sure about the gearbox noise though. I'm sure that plenty of info will be forthcoming for you. Desotodav -

Mark, did you happen to find your fuel tank/cab floor seal (14-86-60). I'd still appreciate a drawing if you can manage it. I have my seat out at present as a result of fitting the 802 radio. Desotodav

-

I wasn't sure if the car mounts were the same as the truck ones so I didn't chip in earlier. I have attached a few photos of (truck) cab mounting items which I hope may prove helpful. The mounts were obtained from Oz trucks, so hopefully the ones in your part of the world are similar. I had my 'insulator' mounts cut down from a neoprene tube. The neoprene was easy enough to cut, but allowing for the locating lip on top of the 'insulator' was a little more difficult. I found that the metal front mounts had a longer 'bushing' tube pressed into the top washer, and the bolt was smaller in diameter but longer overall. The rear mounts had a very short 'bushing' tube pressed into the washer and the bolt was thicker. The washers were made so as to not slide over the tube (as per Hank's shop manual pictures). The 'bushing' tubes overall length was slightly lesser than the overall width of the 'insulators', possibly to allow for the compression factor? The trick in the end was to get the cab to sit level, and with many previous years of farm abuse of my 51 truck this made for interesting times. I was also handicapped with the fact that my truck is not a 'cab chassis', so the overall increased length of the vehicle made for a longer levelling point. Good luck with the mounts. I hope this information has proved helpful. Desotodav

-

Putting this truck on the road....

Desotodav replied to JoelOkie's topic in Mopar Flathead Truck Forum

... looks almost like a John Deere service truck! Maybe an earlier model of this one... http://www.ebay.com.au/itm/57-DODGE-STEPSIDE-PICKUP-TRUCK-John-Deere-Service-model-/200631197963?pt=AU_Toys_Hobbies_Diecast_Vehicles&hash=item2eb68d210b#ht_516wt_1139 Desotodav -

Here is a link to the website for Best Gaskets Andy http://bestgasket.com/ . Boxer, Did you try Les Sonter or Jim Robinson here in Oz? Email or PM me and I'll send you some phone numbers if you want. Desotodav

-

I remember worrying about having my engine bored 0.060 for the rebuild but the mechanic informed me there was nothing to worry about. He said that the 218's used much the same block as the 250's, so the walls were thick. I recall reading a previous thread that spoke of the motor heating up from the thinner walls. I'm hoping to get many years out of my motor before having to go down that track again. I hope it all works out well for you Kevin. I'd be interested to know if you can go to 0.080. Desotodav

-

I had the few holes in my tank welded and then applied a couple of coats of Red-Kote. The sealing procedure is a bit messy, but well worth the time and effort. I wouldn't weld the tank myself - too many bad stories of explosions! Desotodav

-

removing side window bottom channel & division bar

Desotodav replied to ggdad1951's topic in Mopar Flathead Truck Forum

The window regulator has a couple of guides that go through the channel and stay in place with washers and clips (hopefully you can see them in the attached photo). Even with the regulator seized - you should be able to remove those clips and washers, push the window up manually, and then slide the regulator out through the access panel. I found that it was easier to re-install the windows by installing the regulator (and then the window glass) and then attaching the side channel (23-09-50) once the other items were in the door in place. Desotodav -

Welcome to the forum from one of the Oz guys. I'm sure that you'll find plenty of information here to assist you with your build, I have. Be sure to include some photos of your new project so that we can see what you are working on. Desotodav

-

Bob, we used a block and tackle to remove my cab. It was probably a little more difficult to perform a balanced lift than a 'cab chassis' truck due to the 'ute' style truck that mine is. We had to mount chains front and back to balance or centre the lift. I made a solid trolley for the body (with fair sized wheels) and bolted the body down onto the trolley. This made life a little easier for moving the body around after it was off the chassis. The body was still attached to the trolley when we lifted it onto the stands for sandblasting (pictured). I used a 2 post hoist with the 4 swinging arms to mount the body again after it was painted. I didn't want to use the block and tackle method again as it might scratch my new paint. I was so impressed with the ease of using the hoist that I'm now thinking of installing one at my shed. I had a mate use an 'A' frame and block and tackle to remove his 'cab chassis' truck body. He mounted eye bolts through a 3x2 length of hardwood which he slid through the truck and lifted against the underside of the roof. Good luck! Desotodav

-

removing side window bottom channel & division bar

Desotodav replied to ggdad1951's topic in Mopar Flathead Truck Forum

I wasn't sure that you had the manual Mrtomatohead, so I attached the page for you. I did both of my windows the same way as Merle and had no problems. Although, the windows were a little tight to get back in. You guys were fortunate over there that you had a lower access panel. I haven't seen a door over here yet with a lower access panel in it. Desotodav -

Gareth, I'll check with a mate of mine that has a heap of NOS FJ/FX stuff in his possession. I wasn't aware that the handles were for the old Holden's - good job Andy. Desotodav

-

Good job on the motor mate. It looks like you got the colours all right. The project appears to be progressing very nicely! Desotodav

-

Have a look at the attached video for tools guys. This company is able to PRINT 3D working tools. I found it a little hard to believe... until I watched the video. I would imagine that the process would not be cheap, but it would be a great way to replicate those old tools that you seek. Enjoy... http://www.youtube.com/watch?v=ZboxMsSz5Aw Desotodav

-

Happy, Happy, Joy, Joy....1941 Santa arrived Early

Desotodav replied to Andydodge's topic in P15-D24 Forum

Well done Andy. It seemed to arrive fairly quickly. Have fun installing it. Desotodav -

Cowl Vent Gaskets Revisited . . . Again

Desotodav replied to grey beard's topic in Mopar Flathead Truck Forum

Thanks Carl, I might contact him down the track for the weatherstrip/s for the next projects. Desotodav -

Cowl Vent Gaskets Revisited . . . Again

Desotodav replied to grey beard's topic in Mopar Flathead Truck Forum

Another job to take of the list of things to do. Thanks for the heads up guys. I chopped the two weatherstrips that I had and made one to fit the channel. I'll give it a couple of days to dry and then install the lid. I wonder if those who supply the part (23-61-110 'weatherstrip') have any intention to supply them in the correct length? One can only wish! Desotodav -

removing side window bottom channel & division bar

Desotodav replied to ggdad1951's topic in Mopar Flathead Truck Forum

Mine were loose enough to work them off without much effort. I couldn't imagine that heating them up slightly would cause any harm. They should slide of easily enough once the seal is softened. Desotodav -

From memory Dan, I think my longer shocks went to the front. Desotodav

-

new member with an old truck

Desotodav replied to mrtomatohead's topic in Mopar Flathead Truck Forum

Andrew, welcome to the forum from one of the Oz member's. You'll find plenty of info on your truck here. I'm pretty sure that you'll even find that a couple of other member's have modified their rides with Dakota chassis/parts too. Use the search button from the tool bar to find a quick link to subjects. Enjoy the wealth of knowledge that the forum has to offer. Post some pics as soon as you get a chance. Regards Desotodav -

Cowl Vent Gaskets Revisited . . . Again

Desotodav replied to grey beard's topic in Mopar Flathead Truck Forum

You're a bad boy Andy D!!!.. LOL... You are right Ryan, things are similar here in 'banana bending' Queensland. I just have to get the tick of approval from a Certified Inspector because I haven't modified the truck. We have a family friend that is an Engineer and Certified Inspector. I'd like to think that I won't have any problems due to the time and effort that I've put in to the rebuild. This might have been a different story had I have strayed away from 'original' in any way, shape or form! I had a mate that had to close in his rear corner windows and weld up his cowl vent to please the Inspector enough to register his (modified) 54 Dodge truck. I'm glad that we don't run along the same system as your people over there Hank. I can register my truck here on 'club' registration (limited use) for about $190 per year, or on full registration (unlimited use) for around $800 per year - with no back charges applicable. Desotodav