-

Posts

7,190 -

Joined

-

Last visited

-

Days Won

81

Everything posted by JBNeal

-

Look close & ya might see the COE ram hood medallion...but the D-O-D-G-E nose emblem & grill bars make me think 'Route Van'...I'm gonna guess that thar is a special order Cab & Chassis with a wicked steering, brake & throttle linkage setup

-

Emergency Brake Band Assembly Question

JBNeal replied to Dodgebawl's topic in Mopar Flathead Truck Forum

Here's a few pics to study, but they all say the same thing: the spring allows the brake band to float on it's mounting arm; the bolt is used to adjust the brake band; and the lock wire keeps the bolt from turning. On the '48 3 spd I added a zinc-plated flat washer, but it's not needed. The '49 spur gear 4 spd is similar to the '48. The '51 synchro 4 spd is similar to the '49 except that the mounting arm is in the 10 o'clock position instead of the 9 o'clock position. -

1948 B-1-B-108 BUILD THREAD Papa's Dodge

JBNeal replied to JBNeal's topic in Mopar Flathead Truck Forum

We're having wonderful weather so I've been cleaning out the garage. After finding an oilcan that I bought years ago and forgot about, I decided to take a break from the chores and have a li'l fun. Filled up that oilcan with MMO and started attacking old truck door strikers & hinges, hadn't done that in about a year and it showed as every door took a little effort to open, if at all. Was looking at the door checks in the '49, and both of'm were tore up...then noticed something I hadn't really paid any attention to before. So I looked at the doors in the '48, and they were in much better shape with a lot less crud on them. When the doors are opened fully to 90°, there they were: two oil ports each for top & bottom hinges. The shop manual mentions to oil these regularly, and with the old style oil can, the spout fits perfectly in these ports. The top hinges are a little harder to access than the lower hinges, I'm guessing the oil port is clocked so that it is fully covered to minimize moisture exposure. -

the carburetor will need adjustment with the addition of the PCV system as this is introducing a controlled vacuum leak into the intake charged air. There are two parts to the system: the PCV valve plumbed from the crankcase to the intake manifold, which draws vapor at low rpm; and the draw line plumbed from the oil filler pipe to the air cleaner base, which draws vapor at high rpm. The original PCV kit that was documented had among its parts listed a replacement idle orifice tube with no specifications listed. This has led to speculation that this tube allowed more fuel into the carb to compensate for the added air allowed into the charged air stream. grey beard installed his VPW PCV valve but had some trouble so he replaced it with a modern valve. He did some stewin' on the problem & was able to remedy the VPW PCV valve problem with some careful machining.

-

Bad news: your steering shaft tube + worm gear are only usable as a display item now as that tube is shot. The tube is supposed to have a smooth surface; I'm not sure how those grooves got there, but that will definitely weaken the steering tube. Also, I don't know where the floating ball bearings came from, as they are not needed in the gearbox. Good news: B-1 steering shaft tube + worm gear are also used in B-2, B-3 & B-4, so any donor gearbox assembly guts will fit in your gearbox. B-1 gearboxes castings are different than B-3 & B-4 and have a different part number than B-2 gearboxes. When I rebuilt the gearbox in my '49, I used the guts from a B-3 donor and everything fit perfect Verify that the gearbox casting has not been damaged. I've condemned various gearboxes because a roller bearing has shelled out, one of the rollers gets caught in the meshing teeth, and the casting will flex outward & crack. Bottom line: ya got lucky with that failure in your driveway rather than on the street at speed. I've messed with enough old stuff and had all kinds of odd failures at inopportune times & locations that I'm leery about putting my trust in an old machine that has sat for an extended period or has a lot of hours racked up without the assurance of a complete teardown & inspection. It's a lot easier to work on one in the driveway than on the side of the road...

-

the roadside semi engulfed in flames...A CLASSIC

-

How Many Pilot House Trucks Have Survived?

JBNeal replied to Bradley S.'s topic in Mopar Flathead Truck Forum

SURVIVOR: saw this article about a stray in the old country -

How Many Pilot House Trucks Have Survived?

JBNeal replied to Bradley S.'s topic in Mopar Flathead Truck Forum

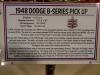

SURVIVOR: was out & about a few days ago and stopped by Dick's Classic Garage to see their '48...there was a nice red car there too -

bed parts can still be found, there's Mar-K in OKC but be prepared for some sticker shock...them fender bolts are also known as elevator bolts but the originals had the Phillips head...McMaster-Carr and Grainger have non-original elevator bolts that can be had but probably would be cheaper to throw them in with an order with some other parts to save on shipping & whutnot. I reckon one alternative is to get the non-original elevator bolts since they cost pennies, cut a slot in the head to use a large slotted screwdriver for assembly & paint over them later

-

something I learned about heat exchange is that different materials conduct heat energy at different rates, and that the mass that is storing heat energy acts as a capacitor as it transfers that heat to another mass in the presence of a temperature gradient. Grandma's Diplomat's 318 was notorious for pegging out the temperature gauge after the engine was shut off, as heat from the lower areas of the engine radiated upward towards the temp.sensor, but once the engine was running again, the temperature would stabilize to normal operating temps. On my '48 & '49, I can drive around at operating temperature for a good while, then shut off the engine and watch the mechanical temperature gauge rise to boiling temps. When I first saw this phenomenon, I thought I was doing damage to the engine, so I would start the engine and rev the motor to get the water pump to moving coolant, which would bring the temps back down to operating temp. Shutting off the engine would see that the temps rise again, so I stewed about it and let it shed heat on its own. If it's overheating during operation, then ya have a problem, as the temp sensor is measuring a constant high heat radiating from the engine internals, and that's not always a good thing. Heat generation is from the combustion process, but also friction from rotating & sliding parts, so if one of those heat sources is too high, then ya might have a charged air mixture problem or an internal mechanical problem. Or in some cases, a blocked coolant passage will cause area of the engine to not shed heat at the same rate at other areas of the engine, causing hot spots that can do damage to the engine. And if ya think about it, if ya boil water on a conductive stove top, then turn off the stove (heat), does the stove, water pot or water cool off right away? As for the ticking noise ya hear when a modern engine is shut off, I'm purty sure what you're hearing is the various heat shields on the manifolds and exhaust pipes that are moving around from the heat. They are thin sheet metal and expand quickly compared to cast iron. If ya hear a ticking noise from a flathead, RUN FOR DA HILLS

-

How Many Pilot House Trucks Have Survived?

JBNeal replied to Bradley S.'s topic in Mopar Flathead Truck Forum

SURVIVOR: a friend of mine saw this'n near San Diego while she was on vacation last year: -

From the B-3 service manual: flywheel nuts [7/16-20]: 55-60 ft-lbs transmission to clutch housing nut/screw [7/16-20 or -14]: 45-50 ft-lbs clutch to flywheel bolt [5/16-18]: 15-20 ft-lbs

-

I've never had an offer over 3-digits, and several of those offers were insistent that I was rolling around in a hunk o'junk and that they were doing me a favor by taking them rust buckets off my hands. One ethnic fella got particularly upset and that I was insulting him by not taking him up on his paltry offer. My country boy politeness at turning them 'offers' down was met with more than one disappointed harrumph. And then there are the parts trucks next to the house...several fellas have rolled up and volunteered to haul them off for no charge, one kid and his rather husky girlfriend wanted to take the Spring Special, paint it bright yellow and put it on a chevy 4x4 that he had

-

Flat Head Books That You Have Used For Your Engine Rebuild

JBNeal replied to rkldesign's topic in Mopar Flathead Truck Forum

the flathead engines are simple by design, hence their inherit reliability vs. overhead cam engines. The shop manual does give specifications & procedures on rebuilds / repair of the powertrain, electrical, body, etc. But sometimes there is information in between the lines or left out altogether. Examples are the window riser adjustments, steering gearbox dust seal lubrication access hole, B-3 B-4 turn signal conversion & installation, horn rebuild dos & don'ts...that's when a build thread on this forum comes in handy, folks will chime in with all kinds of help (some of it more useful than others)- 19 replies

-

- Flat head

- engine book

-

(and 1 more)

Tagged with:

-

-

truck picture B-1-D-116: I found this '48 B-1-D-116 on CL for a C-note four counties to the south, picked it up back in February under the cover of darkness. It has a rebuilt '49 motor from a Plymouth, judging from the block dipstick tube and carburetor linkage shaft on the head (although I do not recognize the fuel pump). The block number boss appears to have been ground down and a new # stamped that is almost illegible. When this big red wagon was new, it had the comfort-ride seat (upholstery & seat bottom missing), a heater/defroster (missing, factory holes punched out at firewall), dual sun visors (RH broken off & missing), dual extendable mirrors (RH partially missing), electric wipers (linkages + arms missing), radio (missing, but station call letters scratched into dash), stainless grille bars (in need of massaging), and no oil filter. The motor has been open for a good while, the manifolds are cracked from some sort of impact, the cab has holes in the roof where marker lights were installed (but a good floor & doors), the steering column is partially missing (never seen this kind of modification), and the spare tire & original carrier were lost years ago, according to the previous owner, who had started to fix the truck in the 90s then lost interest after partial disassembly, then got his son to dispose of it. I have no solid plans for this truck as I've got a few other projects ahead of it, so for now it's a wildlife refuge

-

Ask Don Coatney about that T5 adapter on eBay, it might be an interesting story...Langdon's also sells T5 adapters I reckon

-

I reckon they made changes in the rear main seal and internal bypass coolant passage in '51 or thereabouts, changed some of the head machining to boost CR through the 50s, but the block itself didn't change much...Dodge, Plymouth, DT or Industrial 23" blocks were mostly the same...good luck finding one that'll be usable

-

During some office cleanup, I found the '04 receipt for the new-style pump I put in the '48 (65 bucks!). I picked it up from Terrill Machine in DeLeon (same place I got my fuel pump repair & carb kits), though I don't know for sure if it's sourced from NAPA or the actual rebuild service

-

here's a little more info about Clem's... there was an ad on the TV the other day about this car museum... there was a re-run on The Day Tripper the other day that showed a decent eatin' joint down the road from the museum

-

did I mention that I had left the windows down too? they enjoyed decorating the dash, floorboards, door panels, steering wheel, bench seat & back

-

-

I took some photos the other day of the linkage setup on the '48 with the Ball&Ball on the 218; the '49 1-ton with the Stromberg on the 230 was an almost identical setup (currently partially disassembled for short test runs), as well as the '51 1-ton with the Stromberg on the 230...the return spring is attached to the floorboard with a cotter pin as shown. The return spring has tension on it while at zero throttle. Also shown is how close the throttle linkage on the back of the bell housing gets to the bottom of the cab when the cab mounts are worn and the motor mounts are new. The only other engine setup that I have that is complete is on the '53 Spring Special, and it's a bit of a head scratcher. The engine appears to have been replaced at some point, so I'm not totally sold that the B4B setup is original. The return spring, which is smaller than the ones used on the B-1s & B-3s, is attached at the throttle linkage rod at the pivot linkage as there is no clip present like the ones shown in the manual. This spring is then hooked to the lip on the floor board, not to a cotter pin through the floor board. I could not locate a hole in the floor board for the cotter pin to fit, so I'm kinda wondering if this might have been a running change near the end of B-series production...

-

Good barbecue takes skill not only in meat preparation but in smoking wood choice. Mesquite for smoking requires that it needs to be well seasoned, upwards of 2 yrs is best. Mesquite trees can produce creosote when burned while too green. This can produce a bitter taste in the meat that is being smoked; green oak or pecan can do the same thing but not as severe. When I helped out in barbecue competitions, the best tasting meats were smoked with mesquite, oak or pecan, and most of barbecue joints in the area will smoke with a combination of these woods as they become available. There was a local outfit that sold brisket sandwiches, and his side business was construction & land clearing. So he would have mesquite or pecan coals for smoking, but on occasion he would toss building lumber in the fire box (sometimes with the lead paint still on it while stacked up next to that home-made contraption)...he made a mean brisket, but sometimes ya'd wonder how he made it..... For a little more research information for trip planning, there are two television shows that have some interesting stories that can be followed: Texas Country Reporter and The Day Tripper. They not only give ya places to see but places to eat