-

Posts

7,225 -

Joined

-

Last visited

-

Days Won

82

JBNeal last won the day on April 14

JBNeal had the most liked content!

Reputation

2,237 ExcellentProfile Information

-

Gender

Male

-

Location

76564

-

My Project Cars

>>>>

see signature

Contact Methods

-

Biography

[edited for content]

-

Occupation

Mechanical Engineer

Converted

-

Location

76564

-

Interests

[edited for content]

Recent Profile Visitors

24,602 profile views

-

VINTAGEPIC: saw this shiny Woody Power Town Wagon circled by gawkers on the internets

-

Tucker available...important stuff still there, low miles

-

Radial tires and new shock absorbers might help with ride and braking.

-

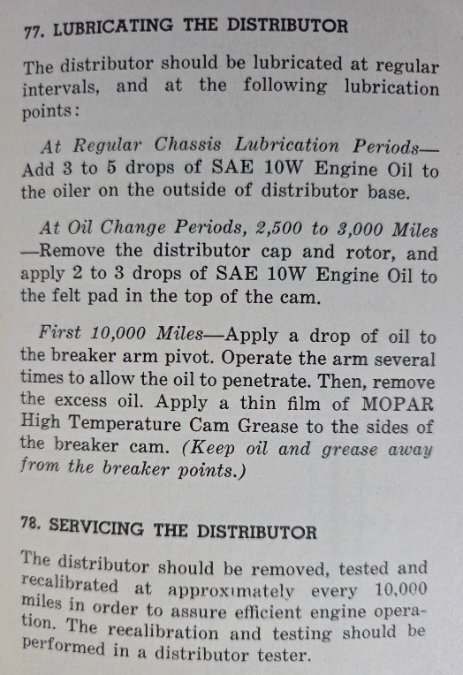

Here are the distributor lubrication requirements outlined in the C-1 shop manual: I have used hand-me-down tubes of cam lube, but if'n ya need to add to your inventory, look for something like Lubricam or similar. Application amount should not be any larger than the wiper block; I typically applied about heavy-half the wiper block size, and that lasted the year considering how few miles I racked up. Feel free to have jeweler's screwdrivers and Q-tips on standby for application + cleanup.

-

steam train crossing over a trolley car...how'bout that

-

VINTAGEPIC: saw this B-3or4 hanging "s" on the internets

-

-

VINTAGEPIC: saw some posers in front of this B-3 hamburger hauler on the FB

-

-

Tucker on the street, waiting to hit the bricks again

-

VINTAGEPIC: spotted this Route Van lurking in plain sight on the internets

-

Maybe that concealed cavity is where ya hide a suitcase key 🤔

-

As the shop manual might say, install a spare Ignition coil to verify if original coil is suspect. Them coils can break down internally and leak heat into the windings, increasing impedance which "cools" the spark.

-

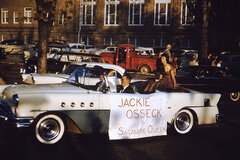

VINTAGEPIC: saw this B-3 heading to a tailgate party on the internets

-

Mondays, amiright 👀