andyd

Members-

Posts

513 -

Joined

-

Last visited

-

Days Won

4

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by andyd

-

From the question I assume you are upgrading the engine?........what engine is going in?.........andyd

-

The Kingpin retaining Pin- Staked? Peened?

andyd replied to '41 Fat Bottom Girl's topic in P15-D24 Forum

I agree with Plymouthy, use a drift/centre punch that is close to the non staked end in size and a good sized heavy duty hammer, support the spindle/stub axle assembly and give the non staked side of the pin a good wack......check for movement......another wack.....check........wack......check..........etc........lol.........I must admit that I don't remember seeing a lock pin that didn't show part of the taper to make it easy to decided what side to wack from..........interesting..............andyd -

Robin........you are to be congratulated, thats a wonderful turnout........how many cars in total?...........that pic taken at the service station is a classic.........mnay thanks for your efforts......andyd.

-

These are the days of our lives....Aftermarket Parts Woes Water Distr. Tube

andyd replied to keithb7's topic in P15-D24 Forum

Al-P8........just a suggestion re your WDT........use a pair of pliers to flare the WDT ends out so that it fills the WDT hole in the block a little more, won't harm the WDT and will help to direct more water down the tube..........at least by my reckoning........andyd -

Hickory...I must admit I hadn't checked your thread till now but just did and am impressed and thankful that we get to see this as even tho' I'll never play with a babbitt bearing engine I have enjoyed your posts and more importantly have learnt things and for that I thank you........as for how much to grind the head, for me I'd be inclined to err on the side of caution as its hard to put back what you remove.......lol.........I have seen tables that show what compression increase removal of set amounts on later mopar engines results in......maybe try & find that and use it as a comparision to what you have...........either way as mentioned I've learnt things........those bolt on counterweights are a real eye opener...........regards & thanks from Oztralia.......andyd.

- 181 replies

-

- engine running

- engine rebuild

-

(and 1 more)

Tagged with:

-

I know its a PITA but the others will eventually join their friend in leaking.......I ALWAYS replace old plugs with brass ones, , 1 & 5/8th diameter from memory........as for flushing it out, yep, stick a hose in there and squirt away, it would be idea to replace the other plugs at the same time but I understand your reasoning........lol.........andyd

-

Wasyl, I like the idea of the IRS from a BMW, makes lots of sense being that its more available I suppose, if I was building my Dodge now rather than in the mid 70's I'd have at the very minimium a jag or similar IFS and IRS, probably a Mopar late model Hemi and various modern convienences.....so your approach is fine and just a different way of looking at it...........regards, andyd

-

In theory the spring being on the side shouldn't make any difference so long as the attachment points are strong enough although I'm not sure how the spring rate and action will be or won't be affected by the type of bushing at either end......coilovers as far as I know usually use 1/2" or better studs or bolts as their mounting points so that should provide a solid enough point that while the coil is now outside of where the stock spring lived it should still provide the necessary absorption of rebound..............you'll have to forgive my poor taste rat rod comment, its just that these things have given some people, especially in areas that are responsible for legistslating what can be done to old cars the wrong idea and a retrograde idea of what hotrodding is all about............lol.............andyd

-

Keith.........I appreciate the good words..........I use the dots as my poor index finger needs a rest after a few wacks on the keyboard.......lol..........but seriously tho' its generally to give me a chance to think what I next want to say...........or maybe not........lol.........re Gregs mention of artistic licence, I've attached a pic from an Oz Sales Brochure showing a D15 Deluxe same as mine.........its not artistic licence, lol........my cars just like that........will go sit in my corner now........regards from Oz...........andyd

-

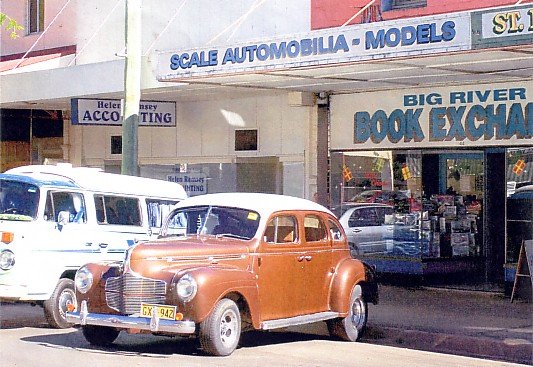

I think the main issue would be having sufficent clearance between the upper a arm and the coil over.........a relocated upper shock mount is doable as the new longer shock is essentially the same diameter as the standard shock however a coilover due to the extra width of the coil spring is wider and may foul on the upper A arm.............to be honest I'm only guessing here, I've made relocated upper mounts as shown in the attached pic and did think that a proper coilover might be an option but just went with the shocks I had.............it would be interesting to see how this idea would pan out........BTW I hope your build is more hotrod than crap rod, crap rods are at least to me a build trying to copy something that never existed in the first place.......tho' having had my 1940 Dodge since 1971 & it being a hotrod, built & painted by me since 1973 I am a little biased ....lol.......but everyone has their opinion I suppose.......main thing is to get it on the road......regards from Ozralia......Andyd

-

I don't know which way to hammer out the oil seal on the timing cover?

andyd replied to MarcDeSoto's topic in P15-D24 Forum

An old saying was.........."to flog a dead horse"........meaning that sometimes a person can do something over & over again without any success,ie, you can flog or whip a dead horse to get it to move but it still won't move.....its dead........lol........andyd -

Interesting story and I do like the pic of the mopar 6..........however if its the Oz Holden thats referred to they were originally body builders that were purchased by GM in the 1930's and from 1948 became the Australian manufacturer of GM's Oz cars until 2018/19 when GM ceased production here in Oz.........If the "Charger" referred to is the Australian Charger it was made by Chrysler Australia from 1971 till 1980 as the Valiant Charger, the "Hemi 6" was really just a marketing hemi in that the valve angle was longetudinal and was only a few degrees, the engine was not a crossflow as most normal hemi engines are......it was originally designed in the USA as a small truck engine but not used and was introduced into the Australian market in 1970 in the VG series Valiant as a 245 cube single,two barrel and a rare 4 barrel version.....from 1971 it was expanded to include a grocery getter 215 cube, the 245 and a 265 with a hipo 265 wearing triple DCOE Webers, headers and a few other tricks developing 302 hp in the Track Pack R/T Charger, the Webered versions were known as E37,E38, E48 & E49 versions and as sniper points out had nothing in common with a flathead mopar apart from the number of cylinders and maybe 1 or 2 bolts that may swap..........but I do like the pic of that flathead engine, seems like an Edmunds intake, finned head & headers, should go well..................andyd

-

Thinking of purchasing a front suspension rebuild kit

andyd replied to D35 Torpedo's topic in P15-D24 Forum

Torpedo..........err, yep.........thats what I'd call a bent spindle..........lol...........one good thing tho' is that there appears to be very little grease to be removed on it...............lol..........andyd -

The one that Stovebolt Engineering sell is a modified Chev S10 pickup distributor..........to be honest as S10's are not sold in Oz I couldn't say exactly what is modified but it was bought with the round coil that was sold with it, installed with new HEI plug leads and the plug gap set at 45thou and VAROOOM!!!!best thing ever.........I have also seen on this forum where an elebtronic Petronix conversion has been used on a mopar dissy and also where the Slant 6 disy has been modified to use........as slant 6's were last used here in Oz in 1969 finding one maybe a problem however I wonder whether the electronic dissy from the 215/245/265 Oz Hemi 6 might offer an option.........that price quoted for the Offy intake has certainly jumped from when I bought mine, think I paid less than half that with a better exchange rate also.......lol.........I have seen various comments on the forum that the Offy intake is not the best design wise and that an Edmunds and/or variations of other USA manifolds are better but as we/I am in Australia then we have to accept that paying to play from here comes with extra costs that the Yanks don't have to consider......lol...........regards, andyd

-

Thinking of purchasing a front suspension rebuild kit

andyd replied to D35 Torpedo's topic in P15-D24 Forum

I can't comment on the quality of the kits but generally speaking I've only had good dealings with Andy Bernbaums over the past 35yrs or so.........also I'm unsure whether buying a "kit" will give you a discount on the total cost as it maybe cheaper to buy the wearing parts individually via ebay, its unusual for the upper & lower A arms to have any wear, tho' the spindles or uprights have been known to exhibit a "bend" after I suppose a large pothole or similar .......also things like the kingpins, inner & outer upper & lower bushes and pins are the same up to 1954, tierod ends also are used for a number of years, tho' the sway bar links do change thru the years so you may have to get the specific year parts but once you know or get familiar with mopar front suspensions they do allow a certain amount of interchangeability between 1940 and 1954........andyd -

Dunno if you know but a common trick over the years was to fit Holden intake manifolds to mopar 6's...........the intake from the Holden Grey or sideplate engine was used on the Dodge/Plymouth 23" engine and the intake from the Holden Red engine was used on the DeSoto/Chrysler 25" engine.'''''''''as the holden intakes are on the Oz passenger side using them on the Oz drivers side on Mopar side valve engine meant that the carby mounting angle was wrong but I've seen angled adaptors used to compensate for this ............the Holden intakes also require some work/fiddling to get the mounting studs sorted out but it was doable, albeit it did require some work..........I bought my Offy intake from Speedway Motors in the USA, it might be worth checking with them, also I've heard that Offy is still going so that might be worth a try and there is a place in the US called Patricks who deal in vintage speed equipement..........andyd

-

Rex......and every nut & bolt is Imperial/SAE no metric crap ..as for the Holden Strombereg..there are 2 different sized lower Stromberg bases......the shorter between the bolt holes is I think from the Holden grey engine, or maybe into the early 60's but from my understanding the wider base is from the HD/HR onwards.........when I bought the 41 Plymouth Coupe I had it was supposedly an older restoration by someone in Victoria, an ex South African assembled Detroit built factory RHD car when I got it it had the Stromberg installed, as far as I remember it had the standard Holden jets.........went fine tho' I must admit that I installed a HEI distributor from Stovebolt Engineering in the USA....the best thing I did as the car was already 12 volt when I got it, before the HEI it took a few turns & pumping the gas pedal to get it started.........with the HEI, I could lean in thru the open window, turn the key & it started straight away(it had been rewired & had a late model ignition switch.......ran well, but only available as far as I know if the car is 12 volts......the attached pic shows the Holden carby, also after the HEI & Beehive oil filter install......I was going to install a 230 cube engine with an Edgy finned head, twin carb Offy intake & 2 Holden strombergs, split exhaust into a twin system, 1/2 race Waggott cam and a 5speed Chev S10 overdrive but due to financial things I had to sell it........dumbest think I ever did ...lol.......the HEI & Beehive would have swapped onto the 230 which with the finned head would have had around a 9.0:1 compression & would have given the flathead Ford guys a run.......lol..........the engine ended up over in Perth, the car in Victoria.......10yrs ago.......still miss it......lol........I strongly suggest getting an Oz Workshop manual, Scientific Publications did one covering 1946-1953 which turn up on ebay regularly.........depending on what you need, Les Sonter 0407290340 in Sydney is a good source, also Jim Robinson "Dodge Parts" in Victoria 03 53454094 is good and I'd always check Restored Cars magazine.........andyd

-

O/k........apologies for delay in reply....have been playing hotrodder at the 25th Australian Street Rod nationals in Sydney........as for a carby..any single barrel Stromberg from a mid 60's Holden, ie 161/179/186/202 up to the early 70's HQ series Holden would be o/k, I would think one from a 202 HQ would be perfect.......now to find out what engine you have........measure the cylinder head.......if 23 inches long its a Plymouth/Dodge engine 201/217 or 230(unusual) BUT if 25 inches long then its a DeSoto/Chrysler based engine of 218/228 or 250( again not used in Oz till the mid 50's)..........to be absolutely certain...........remove the spark plugs, unscrew the small pipe bung on the top of the cylinder head above where cylinder # 6 lives and insert a 15" LONG piece of welding or brazing wire until it touches the top of the piston then SLOWLY turn the crank and measure the up & down movement of the piston..............the Oz 1946-53 Workshop manual has the 46-48 D25 with a stroke of 4 & 1/16th and 3 & 3/38th bore giving 218 cubes........the 1953 228 cube engine has the 4 & 1/4 stroke, note that if its 23" long then its definately the Dodge/Plymouth engine and if 25" long then the DeSoto/Chrysler engine...........if it has the letters "KEW" stamped into the start of the engine number on the Oz passenger side front edge of the block then it "should" also be the 25" engine ............ Also an easy way to tell the T J Richards 1939 to 1948 body shell in the exposed door hinge on front & back doors as well as the tapered shape of the boot or trunk lid.........another give away is that the inside door handles and winders SHOULD have the large, 5/8th diameter splined attachement which is same as the Oz FX-FJ Holdens and a few other Oz cars......these handles are unique to Oz cars....see pic of my 1940 Dodge with the same bootlid and exposed hinges.........note that the front door 1/4 window rubber seals are different onn the Oz cars to those used in the US cars............and YOU DO NOT have a plodge.........you have a DODGE.........end of story......albeit a different one to the common herd that the Yanks have........lol.........give me a call anytime if you want more info...have had my car since 1971.......52 yrs......I'm in NSW, South Grafton.......02 6642 5963..........Andy Douglas

-

What is Up?.........lol........well, my 1940 Oz Dodge has 1941-54 MOOG cast steel upper A arms, stock 1940 lower a arms, 1941-54 Spindles(actually from an Oz 1962 Chrysler Royal which was an Oz only car based on the 1954 Plymouth with the 313 Poly installed), 1956 Oz Ford Customline front springs with 1 coil removed, Oz Leyland PBR 11" vented discs & calipers that use Ford bolt pattern and a 1" thick custom made chromed sway bar with Nylothane bushes and adjustable Heim jointed links..........I had the sway bar made in the mid 70's by a Sydney suspension shop, I adapted the disc brakes in 1975 and made the upper shock mounts about 4-5yrs ago.......I also installed the 9" narrowed Austin 1800 Rack & Pinion, installed the 318 Poly & cast iron push button 3 speed torqueflite in 1973, made & installed the alloy steering column using the upper part of an Oz Valiant column on a custom made alloy tube, the Valiant centre console & shifter uses a custom made ratchet on a short torqueflite cable to operate the gears, the rear axle is an Oz 1990 Ford Falcon station wagon LSD diff with its unvented rear discs & calipers..........the front seats are 1975 Oz Leyland P76, Booster & Master cylinder is Leyland P76, body is stock apart from rear fenders widened 2"(see pic).....engine is a 313 Poly bored 80thou to 325, Wieand intake, 600 Holley, mild cam, remote oil filter with a. oil cooler in front of the radiator, also a 16 "electric fan in front of the radiator.........I originally painted the car last in 1978, although it had a vinyl top from 1975 till about 10 yrs ago when this was removed and a mates son painted the roof................I have owned the car since September 1971 & its been hotrodded since July 1973......regards, Andy Douglas

-

Nope, I just built the mounts for myself to suit a pair of short front shocks I had, tho' to be honest the Mopar and Ford pickup cast steel mounts seem to work quite well too and would probably offer a wider choice of suitable shock absorbers...............I actually couldn't find a listing of the Chev pickup shocks at local parts stores here in Oz so thats why I decided to see what I could fabricate.............I do appreciate your asking tho'..........thanks, andyd

-

'47 era Dodge D24 Front Hood Support positioning?

andyd replied to hbpaints's topic in P15-D24 Forum

If you look at the pic I posted showing the top of the radiator support frame there are a pair of 1/4 UNC captive nuts that hold the bolts for the front hood hinge and in front of them there are two small 3/32 slotted head machine screws that hold the rear of the curved "nose" divider piece.........."busycoupes" pic shows both bolt on pieces in a side view........yes I agree that attaching parts backwards is "possible"....... BUT in this case it would be painfully obvious and as the attachment holes on the top of the radiator support are a pair of 1/4" UNC threaded captive nuts and a pair of 3/32nd holes it would not be possible to swap these ............yeh I have only worked on OZ 1940 Dodge(Plymouth based) cars since 1969............BUT I recognise the same basic attachment setup so feel confident enough to base my comments on this................andyd -

Dodgeb4ya..........WOW........many thanks for that pic of the straight 8 radiator..........they are a different animal to the 6 cylinder version....lol...........andyd

-

I would definately make a few inquiries regarding what should be there as I know from experience that 1940/41 Dodge & Plymouths use just a pair of 1/8th-3/16th thick 2" square steel flat washers or shims........ NO rubber of any sort .........and I would expect that the later mopars used the same type of mounting.........anything thicker will affect the way the side pieces of sheetmetal line up together with the hood alignment........and as the side panels and inside engine bay panels ALL BOLT TOGETHER I have trouble seeing what good a flexible mounting on the bottom of the radiator will be when everything else is solidly mounted to that radiator support...........my Oz 2 cents worth............andyd

-

'47 era Dodge D24 Front Hood Support positioning?

andyd replied to hbpaints's topic in P15-D24 Forum

Sniper.........the radiator support can't be installed backwards as it has a taper on each side that allows the side sheetmetal to attach......see "busycoupes" 1st pic with the single bolt holding the sheetmetal to the radiator surround...........I am curious as to whether the whole front sheetmetal "doghouse" is in fact slightly "droopy" as there maybe sufficent play in the various attachment points to allow the doghouse to droop.........the 1st pic from hbpaints may support this theory and/or does the radiator support frame have some sort or spacer underneath it where its 2 studs go thru the front crossmember........all mopars from this time period I've seen have some sort of spacer or spacer plates that whilst it maybe only 1/4" in height all go towards helping to keep the doghouse level and at 90 degrees to the firewall......more or less............lol.......andyd -

'47 era Dodge D24 Front Hood Support positioning?

andyd replied to hbpaints's topic in P15-D24 Forum

Whilst I can't offer help that directly relates to your D24 I have an Oz 1940 Dodge which uses US sourced 1940 Plymouth parts and has the same type of hood support bracket that bolts onto to sheet metal at the front and onto the radiator support frame at the brackets rear with a pair of small bolts/screws then the hood centre hinge front bracket bolts onto the radiator support frame............. .............on looking at the 1st pic you have posted the radiator support frame appears to have a "bow or bend" in its side profile.........now that maybe just the angle of the photo but if it IS bent then that may cause a gap at the rear of the hood ........ .................I've attached an old pic I have of the engine bay of my car, yep its a hotrod, 318 poly has been there since 1973 but this pic does show the top of the radiator support frame and clearly shows that hood support bracket attached to the radiator frame......although my car has the full length 1940 Plymouth hood as shown(see pic) the bracketry would I think be similar......... ............dunno if this helps or just confuses the issue.........lol.........regards from Oztralia......Andy Douglas

.jpg.4bf40281411cce8f02d6d6ec5a96f7a2.jpg)

.jpg.8c960427650d66bbb645ad253d4fa097.jpg)

.jpg.9623de38b40ed0084397b006551afbc8.jpg)

.jpg.22940143b3eb1f229225b062f8edab93.jpg)