47 dodge 1.5 ton

Members-

Posts

406 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 47 dodge 1.5 ton

-

Tank removal W series

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

I had minimal access on the ones closest to the drive shaft. The outer ones close to the frame, I used a bore scope along with a 6” tube extension to spray Kroil on those and was “lucky” that I didn’t ring them off the tank. Not sure there would have been enough access for a wrench as the tank frame was pretty tight. I wanted to clarify that those (4) bolts were the first that I removed and not an issue. I am restricted sliding out due to the filler neck sticking up through the cab by 3”. I was able to lift the cab corners about an 1 1/2”, still not enough to clear cab. -

Tank removal W series

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

Must have been a good change somewhere along the timeline. I know the new tank purchased is designed the same as mine. Nuts are floating in a welded cage on top of the tank (original was welded direct to the tank). I can’t access the top rail to weld nuts with the cab and bed on but that would be an improvement even just one side. -

Tank removal W series

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

The hole would be plenty large but the tank can only be lifted out (cab removed) or slid out as there are (2) heavy rails that it sits on. There is about 1/2-3/4” inch movement upward from the cab floor/tank top. Was hoping I could jack cab up enough to twist tank. That didn’t work because there is not enough free movement between the tank rails affixed to the frame. -

Tank removal W series

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

Guess the pickups tank might sit lower? I have a good 3” to make if I slide it toward the driveshaft. I started jacking with the back (2) cab bolts off and could hear a bunch of unwanted noises so I quit for the day. Can’t drop out, only slide across towards the passenger side. I dropped the middle shaft and carrier bearing. That will still be plenty tight to clear the trans brake assy. -

Tank removal W series

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

Think I am going to try jacking drivers corner behind mount. Not sure if it can take the weight. Just unbolted both rears so I’ll see how this works. -

And body cut the neck off, filling the tank with water? There was a post awhile back and not sure how he had made out. Option 1. Unbolt cab and front and lift a few inches. No good way of lifting really that I can come up with by myself. option 2. cut the cab for clearance. Not into that idea option 3. cut bolts holding rails and drop tank. Almost impossible to reinstall correctly. option 4. Cut neck off with cutoff wheel. note for others; always buy a new tank if in question when cab is off, do not have lined I’m asking because my brother blew one years ago, guessing it wasn’t quite full of water due to a leak.

-

Looks like a simple installation, do you think it makes much difference?

-

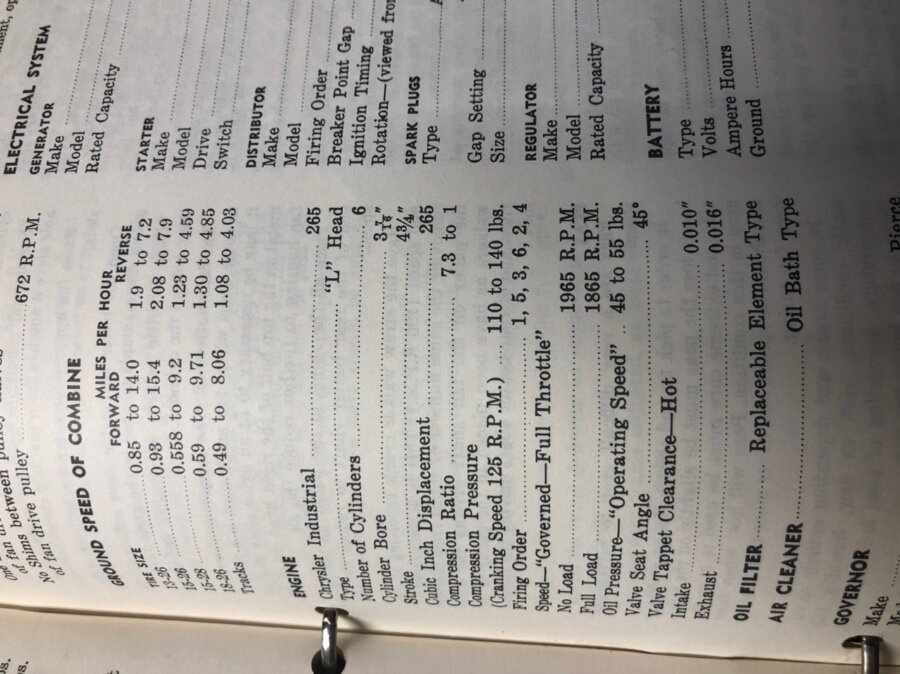

I’m thinking the first letter’s in the Chrysler nameplate “32” are an indication. I hate to make a run for a 251 but have a gut feeling it could be a 265.

-

Fellow sent me a note about a flathead to be had. Serial number on aluminum plate E031161 Chrysler model 32/1565/1. He also gave me some numbers B219 22 1400229 03086. Claiming it’s a 265 “smith air compressor”. Meaning head would be of no use. Don’t need it but would be saving from salvage. It’s a pretty good run from me as well.

-

Back to the max rpm— I have seen these engines make 5k if allowed to breath. My biggest concern is cylinder ridges on later life engines. If the engine spent any amount of time at lower rpm’s, cylinder bores most likely are worn there, stretching rpm’s may allow a few extra thousands above the ridge, potential cause for ring failure. If ran in at high rpm’s from the start, think they are capable. Question is— where you feel comfortable.

-

bringing in the ice harvest

47 dodge 1.5 ton replied to wallytoo's topic in Mopar Flathead Truck Forum

That’s really cool on several levels. Can you explain the process of storage, how long it last into the year and how warm the summers get up there? Would even like to know how it’s used. Out of school part time (a few years ago), I hauled ice from a few local ice houses. It took 24 hours to make a 300# cube and the largest ice house I hauled from only made 24 blocks a day. I have always been on the look out around here for old ice houses and have never seen one that wasn’t refrigerated/insulated. I’m just guessing from the mid 40’s and newer. Would love to learn of how that was processed. -

Another option maybe worth a thought. A shot of weld to the portion sticking above might be enough heat for removal. Do that a lot on bearing races at work with success(never tried on valve guides). Same with induction heater.

-

Although you may want to wait for some of the experienced people to make a determination before moving forward on this motor. Your idea of tapping the hole very well may work. I have removed many guides on some of my old tractors by tapping and using a slide puller with a threaded rod. I want to add— if you move forward with this path, make sure no chips end up in uncontrolled places. I guess my first thought, if the guides are that rusted, guessing you are doing a full rebuild?

-

The head I posted is a virgin head. I agree that it needs to be cc’d. Another method for true accuracy would be a 3d scan. When I get that far in my motor, I plan to check a few of the heads I have here and hopefully a spitfire head(not acquired yet). We have used scanners now for pattern work (past 6-7 years or so) at my day job and this definitely would be justified valuable. Just wanted to mention this as some may know of folks that work in foundries or have access to a scanner.

-

I measured a 1959 265 head this morning. Head thickness measures 1.915” , valve pocket depth .490-.510”(has carbon).

-

Going back to the original question, were they just ship lapped, TG’d, or spaced with a hold down strip?

-

Wood here from the planing mill can be purchased order specific, same from a saw mill. Few years ago, I built this bar which sounds like an option you are planning. I had a walnut tree and saved the wood for a gun stock. Afterwards, I made this bar top, doweled, glued, relieved and used a 3/8” steel plate hidden on the underside. Very expensive approach, but if you needed to keep it flat over time and hide the fasteners, may be a good option.

-

Not sure how much shipping you would have from the east. 1 x 8’s in oak here are called fence boards. You would need to make sure kiln dried to 15% and ask for white oak. A local mill to me probably has them in stock and supplies to a shipyard in Baltimore Md. Just a thought if you wanted white oak.

-

I agree on the white oak. When I did that bed last winter, price for the white oak boards 2 1/4” thick x 12’ long with all the mill work was under 900$. That was about 200$ over the original estimate. I would like to know more about sikkens product. Does this soak in and allow touch up down the road?

-

Don’t think I would use plywood. If for a pickup, there are guys that you can buy pre-finished. I had to hand cut each board to match the pre-existing holes and transfer from the bottom. That made a lot of work but the alternative was Swiss cheese my bed frame. I basically took a measurement for every board per the drilling prior to the mill work. Most boards were around 9 1/4” width. I did end up using 3 rows of spaces though the picture only shows (2).

-

Fuel Tank replacement

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

I bought one manufactured by Tanks, looks great. I have not installed yet though. All measurements and holes appear to match the original, just with quality paint on the outside. I just need to remove the center driveshaft again for installation. -

Well decided to look at the master cylinder tonight. Cant see anything causing an issue but was surprised to see the fluid somewhat dirty. Note for future; Wished I had spend more time cleaning the entire system at once instead of just flushing while adding parts. Hoping I didn’t gouge the expensive wheel cylinders that I had sleeved in bronze last year. Given more thought as I am pretty disgusted tonight thinking of how important FME is inside of equipment (I teach/preach classes on this!), seems I may have found a path to investigate further.

-

Current Build Card Request Status

47 dodge 1.5 ton replied to billrigsby's topic in Mopar Flathead Truck Forum

That’s neat. Maybe a tow lift? Searching for any providence is always the best part of a hobby. I purchased a vintage LC Smith double shotgun some years ago. Turned out to be once owned, shot in several major documented matches, the owner being a “TK Lee” that invented the Lee Dot scope. Not long after the purchase, remaining family sent me several letters that had been written about the gun, him, and pictures of his accomplishments. It was really cool to have those documents dating to the original purchase on 12/24/1924. -

Good point, I only tried backing off the shoes a little. I’ll see what’s there for adjustment. Going down the road when I let off the brakes, I’m picking up a drag that takes several seconds to feel full release. Acts like the springs are not strong enough or could use more. Out of curiosity, does anyone know when the hoses dropped to 1/8” or the supplier that had 3/16” ID last? I know by theory this “should” work as is but have not talked to anyone that actually used the 1/8” hose for the rear duals.