-

Posts

2,433 -

Joined

-

Last visited

-

Days Won

24

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by DonaldSmith

-

Auto choke connection on carburetor. 48 DeSoto

DonaldSmith replied to MarcDeSoto's topic in P15-D24 Forum

-

Auto choke connection on carburetor. 48 DeSoto

DonaldSmith replied to MarcDeSoto's topic in P15-D24 Forum

The rod in the photo is the "choker connector rod', which pulls the throttle linkage up when the choke is on, to increase the idle speed. (The rod from the Sisson choke (the auto choke rod? fits the other lever on the choke shaft, and its length is adjusted at the Sisson, with a pin gauge used to set the length.) The dimension of the choker connector rod is fixed. You could bend or straighten if it got out of whack, but the idle speed is adjusted at the idle screw. -

I just placed a want ad in the classified. I put in the part number that Sniper found in his parts catalog, 666348. The fifth number could be a 7 instead of a 4, but we'll see. The year range for the 25-inch engine should cinch it. Check your stash. See if you have an extra manifold lying around.

-

-

Actually, it's right-side up. as in position on the car. (The intake manifold outlet in the center of the photo has the hole for the infamous 13th bolt.)

-

The exhaust manifold on my 47 DeSoto has damage at the cast-in holes for the bolts that hold the exhaust manifold to the intake manifold, and at the exhaust pipe flange. Several years ago, I attempted to patch these areas with JB Weld. On driving to and from a car show last Fall, as I neared the end of the 40-mile trip each way, I sensed a strong phenolic smell from the engine compartment. I have the manifolds off now, and I see that the epoxy patches have been burnt. A welding shop advised against trying to repair the manifold. I am going to put in a want ad for a replacement exhaust manifold. I tried to read the part number. It could be 666376-4, or any one or more "6" could be replaced with an "8". Maybe someone verify the number, '47 DeSoto, 25-iinch block. Here's the main broken area, an angle I had put at the bolt heads, and what's left of the epoxy patch. (Upside down, I don't know why, maybe because I took the photo left-handed.)

-

I think the intent of the bumper guard/ over rider on your car was to keep the bumper of the car in front of you, which you just bumped into, from riding over your bumper and squashing your die-cast, chrome plated grille. Some of the parking maneuvers back then relied on sound and touch.

-

If I saw all those Chryslers and Plymouths coming at me, I might change lanes. Then there's the story of a country that changed the driving from one side of the road to the other. The first week was for cars, the second week for trucks. It didn't work out so well.

-

The diagram has parts of letters missing. I think the word is "battery", not RATTFRY, although that would be an interesting accessory.

-

There's no kickdown switch in MarcDeSoto's Dodge carb. I think the Dodges of that era had the fluid coupling with the 3-speed trans. The DeSoto had the semi-automatic trans that needed the kickdown switch. Is there a dashpot for a stick shift trans?

-

In 2015, I got my fluid drive carburetor exchanged at Carburetor Exchange, www.carb-x.com. It's been good. No more demons or gremlins. The only recent problem was that the link from the throttle shaft to the choke interfered with the downshift switch. I may have distorted the link somewhere along the way. A little judicious bending corrected the issue.

-

I have enjoyed this forum for years. It's been a great help and source of knowledge, and every once in a while I get to contribute my small sliver of knowledge. And then there's the banter and occasional smoke bomb. (Haven't had a knock-down, drag out fight for several years, thanks to the monitors.) We all have to consider that the printed word can be taken differently from the writer's intent, especially when the opinions get a little heated. And thanks to the administrator and monitors for keeping us on track.

-

Some guys put in a vacuum reservoir, to keep the vacuum wipers going during acceleration. I think the late, great Don Coatney did that. Some cars had a vacuum pump as part of the fuel pump.

-

Just as a test, try starting off in the "Drive" mode, and see if it slips out of gear shifting from 3rd to 4th. (Give yourself [plenty of time to get up the hill.)

-

Quote: When in first gear at speed, letting off the fuel allows an auto-shift into "first-overdrive". However, traveling up inclined road, transmission slips in-and-out of gear. Questions: Does this happen when you are in "Power" range? Starting off in first gear and having it upshift to second? How steep is this inclined road, that you would need first or second gear? Usually, we start off in "Drive" range (third gear) and let it upshift to fourth. The fluid coupling allows this stately acceleration. Some guys will start in first, but then shift to "power" range.

-

I nominate clarkde for the Master Cobbler's Award! Good Job!

-

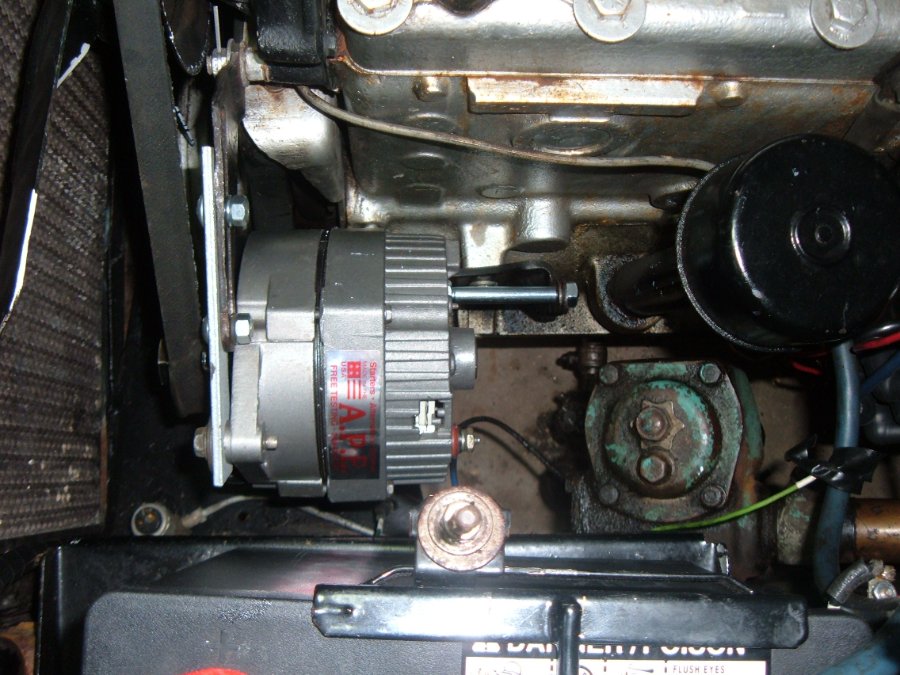

I cut the notch in my alternator with a hand-held hacksaw. The notch was wide enough that I could use washers for a final back-and-forth adjustment. I spliced something together to extend the adjusting arm.

-

When i got the alternator in 2011, I tried using the all-purpose, all-adjustable bracket, but everything seemed to be cobbled and too high. I compared the generator pulley with the new alternator pulley in regard to the existing generator bracket, and notched the alternator for the wing of the bracket. A series of washers, couplings, nuts and bolts completed the installation.

-

"Bolt has to be sealed..." I had to loosen the bolt every time I wanted to adjust the generator/alternator arm. I replaced the bolt with a stud, with lock washer and nut against the water pump housing, then a washer, the alternator arm, loose on the stud, another washer, and a nut to keep the arm from falling off, and a cotter pin drilled through the nut and the stud, to keep the nut from falling off. The arm is free to pivot when I tighten the belt.

-

Rebuilding My 218? 230? 1940 Desoto Flathead Suggestions

DonaldSmith replied to 40desoto's topic in P15-D24 Forum

The car looks like the DeSotos that were made in the Dodge plant and badged as DeSotos. (Firesweep?) Or was it built in Canada? In either case, it would not be a far stretch to provide it with a 6-cylinder engine instead of the V-8, especially for export, where government fees would be based on horsepower among other things. What Identification is on the cowl and doorpost? -

Maybe more than one way to design a clock (besides the modern electronic quartz wonders). Our mantle clock has a seven-day spring, with an escapement to control the mechanism that moves the hands. Most automotive clocks from my youth had the occasional thump to rewind the mechanism for a few minutes. Maybe the clock in question uses the escapement to control a constant thrust from a solenoid. Still a puzzle.

-

Loren is right on! My clock had the open connection that I had to re-solder. I never thought of the soldered connection as a safety link. There it is, off the winding and onto the points. All better, now, for the last several years.

-

From what I know about car clocks back in the day, a clock did not have a transformer, but a solenoid to rewind a mechanical clock mechanism every few minutes. As the works run down, the points close, to power the solenoid for the rewind. Typically, the clock would tick contentedly for a few minutes, and then would be firm clunk. The clock pictured above looks quite a lot different than my DeSoto clock. The solenoid creates a magnetic field at its ends which attracts the "ears" of the winding mechanism. A real piece of work.

-

I'm trying to imagine a pothole heading for ice cream. Heading for pizza, I could understand. (I'll go sit in the Andy D corner now.)

-

These battery hold-downs look like they are coated with plastic, which would electrically insulate them. I wouldn't want a fabricated metal hold-down to contact the live post or clamp. Or, the metal could contact the grounded post. If I disconnect the ground cable from the post, some current could still get through. Of course, one could put electrical tape or other insulator over the part of the hold-down near the live stuff.