Lingle

Members-

Posts

184 -

Joined

-

Last visited

Everything posted by Lingle

-

Got some good layout work done this weekend. Just need to quadruple check the engine placement, then build the engine mounts. Lots of good progress. Next weekend making a trip, hopefully, to a town west of Brainerd MN to get a transmission.

-

Also, to prep for the fitment of the engine, determined how much of the cab firewall had to be removed. As seen below, its not insignificant, but at least its not into the flat sections on either side of the stock bump out. The white tire marker is where I will be cutting. Luckily its below the cowl vent mounting as well as some vent tube openings. I will lose the foot starter, but dont worry, itll be coming back somehow, somewhere, too cool to lose.

-

Wow has time flew, and unfortunately little work done on the project. Life got in the way and it seems like summer wanted to just fly by. Got some work done removing 1/2 the radiator support(needed to lower front mount for engine), boxing that back in. Then removed the rear stock engine mounts and boxed the frame there. the new engine mounts will mount to these areas. My plan is to get the engine back in the frame and get the motor mounts built this weekend, so prepping for that. Also heading to a u-pull it yard, one of the only ones in Iowa to see if I can find some hydro-boost brake components(master cylinder, hydro-boost itself, PS pump) and some pedal assemblies. Need to match the steering box so itll be components from a 1999-2004 Ford Super Duty diesel. Clutch pedal will come from a Dodge.

-

looks good! When the time comes, I will be doing something similar but somewhat nervous at all the issues everyone seems to have

-

Ill be interested in this as well, I seem to recall them being called Acme thread but havent researched much lately given my truck project just started, its very interesting that on my 1951 B3F its a mix of super coarse bolts(like you show) and almost all my main structural fasteners are fine thread. I know that bolt you show is used in many places(floor pans, front sheetmetal) so finidng a source of parts with normal quantities will be good. Have you tried Fastenal or MSC Direct to see if they have anything?

-

wow been over a month since I posted, and unfortunately not much work done, life got in the way. I was able to put the engine/trans in the frame to see how much will need cut from the cab. Looking really good, not alot of firewall to remove(haha, like 1/2 of the firewall will be removed). Engine mounts coming this week, so should get a good start on the engine mounts. Will end up making a custom oil pan due to clearance issues. last photo was done after swapping oil pan in the first 3 photos, to clear the front steering arms, needed to convert to a rear sump, but even then its awfully close to the pumpkin.

-

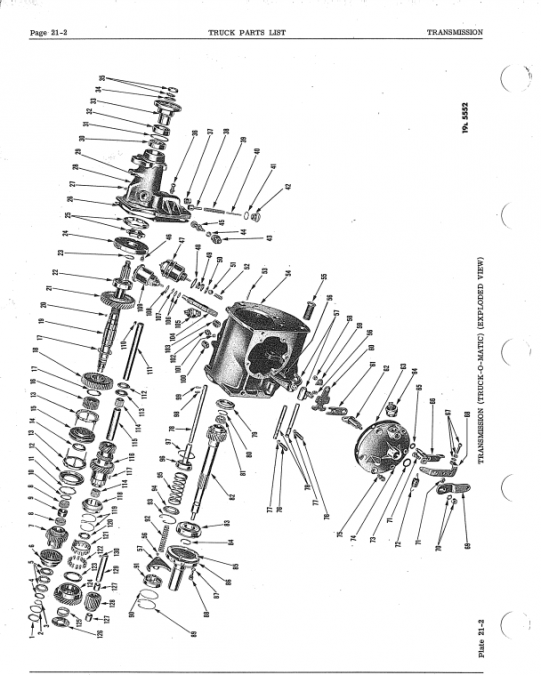

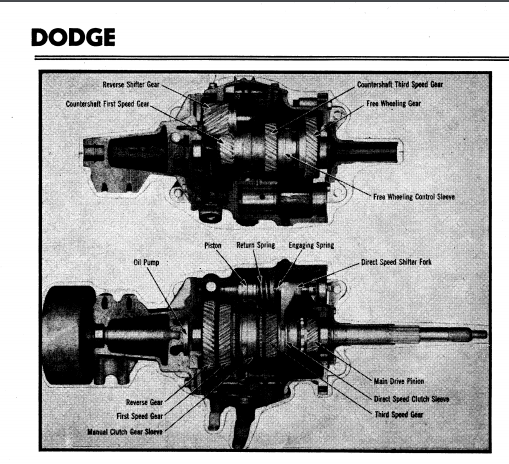

Cant be for sure, but from looking at the pilothouseclub website: http://dodgepilothouseclub.org/know/ph_parts/pilothouse.htm I think it looks close to the Truck-O-Matic, mostly because there doesnt appear to be a shift tower like on a manual transmission, but its also missing some solenoids/valves as seen below.. It may be worth going to their website and looking at both the repair manuals and parts manuals, Ive been able to identify some parts from their website before.

-

looks very nice! did the heater core check out ok or did you have to have it repaired?

-

Anyone know if its possible to bend the 2 styles together? I have vacuum wipers on my initial 51 cab but the replacement cab I purchased has electric wipers(but missing the passenger arm from the motor to the wiper arm mount, which is also frozen) but do not know if I can mix and match the different parts, and honestly haven't looked close yet but I think the arm lengths are different. In any regards the motor will either need a voltage reducer or rewound(if it works) since my project will be 12V. EDIT: both are factory wiper options, my backup is to use the DCM electric option but would still need replacement passenger arm)

-

What kind of heater is this? I happen to have one in my replacement cab that is missing the fan and blade. Id like to get down to 1 heater assembly, the replacement cab had 2 of them, a Mopar 70 and the one above). I may or may not keep my heater that looks like yours but am trying to identify the heater first.

-

I believe you are talking about the part that keeps the door from opening too far? if so I cut the pin holding the A pillar side, last I researched you had to remove the pin/rivet to remove that part. I plan to just bolt mine back together when I re-assemble the cab.

-

Block of wood works well or if you have a big socket that fits almost the exact outside diameter that works well. I purchased a seal driver/bearing race installer tool kit on Amazon for <$20 and it works for many different sizes but the general block of wood or socket works as well.

-

Awesome build! Good score on the Excursion, what are your plans for box/bed, if you have thought that far ahead?

-

Got some work done this weekend, primarily disassembling the replacement cab so it can be put on the frame to start the mocking up. It was interesting, this cab appears to be off a truck with a 2 speed rear diff(see my post on speedo identification) but it also had 2 heaters in it. One was a Mopar Model 70 and the other I do not know. It does not have a motor in it, but has a heater core. Anyone know what this is/was? Im contemplating if the Model 70 will be sufficient for both cab heat and defrost(it only has 1 output for non-defrost operation). I found some model 65 heaters on ebay but man they are steep! Also, how rare were electric wipers? It appears the replacement cab had electric wipers, however I only got the cab so I couldnt determine if this was a factory installed option or someone at a later date did this. Any way to identify the wiper vintage? The switch was located in the same location as my vacuum wiper switch was on my other cab so I tend to believe this was a dealer or factory install, but could be wrong.

-

that would make sense that somehow the rear diff/vacuum may feed into the speedometer sender since the transmission output would stay the same speed, but the rear axle would change speeds and need to compensate for the change, thanks! I still need to figure out how to adapt, when the time come, the NV4500 speedometer output to the factory speedo, but I have some time to do that. May need to see how ggdad1951 does his when he gets closer on his project.

-

I purchased a replacement cab and sheetmetal last fall and finally got around to disassembling the cab so I can start mocking up the new powertrain(see my build thread for more info) and when I removed the speedometer, it is very different from my 1951 speedo originally in the truck. I know the cab is a 51-53 given the gauge cluster layout but the part on the back of the speedo is different. It appears to have a oil(maybe air) line feeding a linkage on the back of the speedo. The original speedo I have the cable screws directly into the back, whereas on this one, the cable screws into the back of whatever has the steel line coming out off it. I looked in the parts catalog and didnt find anything special here, so maybe it was aftermarket? Sorry for the grainy photos, iPhone lens was cloudy due to excess humidity this morning here in Iowa. Thoughts?

-

sorry for the lack of updates, been busy and with the COVID items, money has been somewhat tight. I was able to complete rebuilding the front axle(minus calipers) and have it fully installed in the frame. Since it will be a year or so before I finish, I will not buy the calipers until closer to finishing the project. Edit: just noticed that I do not have the steering link in the photos, it is attached, just not in these photos. I then moved on to putting the cab and hood on the frame to start seeing how to fit the new powerplant. As it sits on stands in the garage, it is about 10" lower than when finished, so it will for sure not fit in the garage, and how to finish the build is now a problem I will be looking to resolve. I think I will make some dolly's that bolt to the wheel hubs that have casters so I can move it around without putting the massive 37" tires on it. I am hoping to bring my replacement/spare cab back next weekend to start the true fitment of the engine, no sense modifying 2 cabs when I can just modify the cab I plan to use in the end. Hope everyone is doing well in these troubling times.

-

not necessarily the best overview but the Dodge Pilothouse Club has parts manuals on their website: http://dodgepilothouseclub.org/know/ph_parts/pilothouse.htm also has repair manual: http://dodgepilothouseclub.org/know/manual/manual.htm

-

Great holiday weekend, I hope everyone else also had a good time, despite the challenging times we are in. I made a ~280 mile trip one way to pick up another engine for the project, eastern NE is not the loveliest place but still nice drive. I maintained social distance requirements during the trip and it was worth getting an engine I was looking for. I spent Saturday and Sunday finishing up welding my frame extensions, so I can now say that the front suspension is ~90% complete. I will be adding shocks eventually, so its not completely done. Dana 60 will be partially re-assembled next, followed by putting the cab on the frame to start setting in the engine and seeing how much re-work the firewall needs, I am hoping for little rework, but in the back of my mind I suspect it'll be more than I expect. For only being a 4 cylinder, the Detroit 4-53 is ~40" long. Here are some photos of my trip to Nebraska and the mostly finished front suspension. It is hard to see but the engine came from Plainview, NE. A town of ~1400. Got a really good deal on the engine, plus steering box and some fuel tanks from a late 70's/early 80's Chevy C60/70 straight truck.

-

Roxanne - She don't have to put on the red light.

Lingle replied to FlashBuddy's topic in Mopar Flathead Truck Forum

wow those shipping costs are steep, I wonder if there is a Fastenal nearby that would be more economical? I sent an engine/transmission from my 51 from Waterloo, IA to Kansas somewhere and it was <$200 for shipping, and we all know the weight of the powertrain. Only downside is there is no tracking nor insurance and it takes ~10 days to ship, but that is anywhere in the US. -

I personally set jack stands under the axle with a little gap and support the frame so the leaf springs have only the weight of the axle on them, but either way should work. The leaf springs should be fairly stable because the bolt/pin that holds them together sits inside a recess in the axle, more or less fixing the location side-to-side and fore-aft.

-

Over the weekend I was able to re-make my frame extension, found out I needed to widen the frame a total of 6" and not the 6 1/2" I built the first time and the axle wouldnt fit. So 3" extensions for both sides were mocked up and half built so I could reinstall the Dana 60 to make sure it now fits...and it does! Will work on boxing the mounts and welding them to the frame. Plan to still bolt the leaf spring mounts on but the 3" extension will be welded to the frame for stiffness. Overall turned out very well.

-

Once again I was MIA but got some work done this weekend. 4wd Dana 60 is located, leaf springs re-bushed, painted and reassembled. Blasted cab mounts and first coast of POR-15 applied. Hopefully this week I'll finalize the frame extensions since the Dana 60 spring perches are 3 1/4" wider than stock axle. Am able to keep the stock suspension all around, which was the goal.

-

Welcome! Great forum and support here. Despite being MIA for a month, hopefully getting back to working on my project as well. Welcome aboard!

-

hey all, sorry for the lack of updates. Travelled internationally for work and got busy working on the truck and didn't do any updates! Got the front suspension removed from the truck, once again the shackle end bushings in both the leaf spring and the frame mount are shot. Luckily the spring bushings are a common size(13/16" ID x 1 1/16" OD) so those are easy to find but the shackle end frame mount bushings are completely gone, and not common size so back to machining(after I travel again?!?). On a good note, finally found a engine, unfortunately it is not the turbo version I am looking for but it does have the lower configuration I need to ensure it fits in between the frame rails. I can do all my major powertrain layout with this engine, still needing to source the transmission and bell housing adapter(when funds get refilled of course :). I hope everyone is having a good start to the year! Oh, and look at the way the engine squatted my 3/4 ton truck. Good thing I am keeping all 7 leaf springs in the front of the Dodge when I put in this engine!