Lingle

Members-

Posts

184 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Lingle

-

Its been awhile since I had my rims, as I scrapped the front and rear axle on my 1.5 ton but 5x8.25 sounds correct. Coker tire makes some older looking, new stock tires that may be available. . there are several on the forum with larger trucks that should be able to confirm the bolt pattern and tire availability. I am unaware of any off the shelf wheel options, I believe most have had to have custom wheels made but could be wrong. sadly the pilothouse knowledge site is no longer available but looking at the body builders layout I have for the F, FA, H and HA, tire sizes were 6.00/20, 6.50/20, 7.00/20 and 7.50/20 all on a 20x5 or 20x6 rim. I know those are older tire sizes but appears Coker still offers some of them.

-

Guess I was unaware of a parts manual on this site. I checked the pilothouse knowledge site the other day and it appears to no longer be valid

-

is the 636 the gear ration of 6.36? just asking, I know that on my 1.5 ton before I scrapped the axle, the ratio was on the axle housing.

-

I agree with the radiator shop for any heater core fixes, I had a local shop rebraze part of my heater core and extend the inlet/outlet as someone damaged them prior to me getting the heater. As for the motor, if you can find them(as they seem to be disappearing quite quickly in today's society) a good alternator/generator/motor shop may be able to help. The one near me here in Iowa specializes in large motors but can do other work, however he is a one person operation, with no one to take over his work long term so that is unfortunate. They do make some quasi-drop in replacement motors. I bought a 12V replacement blower motor for my Mopar Model 65 header to replace the working 6V one as I dont like using a resistor to drop voltage. they are not inexpensive but you can find both 6 and 12V version. There should be some forum posts you can find via search for blower motor information if you go the replacement route.

-

I wonder if it wasnt a surplus truck at some point and "sold" into civilian population painted red? I know in the current day, you can buy retired military equipment, although in its original color, but I wonder if something different happened years ago for this particular case? Nice looking vehicle regardless

-

if you click on B1B Kevin name his website is on the left side of the screen.

-

Love following the thread, Ive struggled removing the latch mechanism for quite some time and havent actually been successful but this thread will be very helpful when I start assembly, keep up the good work!

-

How Many Pilot House Trucks Have Survived?

Lingle replied to Bradley S.'s topic in Mopar Flathead Truck Forum

co-worker was at the Gathering of the Green last week and saw this pilothouse with a Deere engine transplant there: https://www.drivingline.com/articles/it-s-part-dodge-part-deere-and-the-workmanship-is-off-the-charts/ I hadnt seen it before but sounds like its been around since around 2019 Plowboy Diesel on youtube has some videos as well. -

Tires, wheels, bearings, and brake maintenance....

Lingle replied to John-T-53's topic in Mopar Flathead Truck Forum

Ive seen NAPA charging outrageous prices lately unfortunately. WIX filters there are 50-200% more than I can get them from the web, but that only works if you have time to wait on a shipment coming in. I ran a AMC 258 6 cylinder with the front crankshaft surface wore worse than that and didn't leak so I suspect it would be ok. -

I know its a 1.5 ton but on my B3F it had helper/overload springs that looked like your 2nd picture(straight) and had riveted on stops(like picture 1).

-

I used a box from a 2002 F250 4wd but I'm running an all ford front end so no stock dodge parts to interface with. I had to fabricate the mounting pad by welding on a flat page with holes and stand offs into the frame to inset the box and then the lower bolt is below the frame and needed to build a mount for it too. I can find photos if you are interested.

-

Thanks! Unfortunately I fell into the old trap of using a "common" name for something with multiple variations(i call everything sand blast which is bad). Unfortunately here in Iowa its insanely difficult to find anyone that does media blasting near me, plenty of industrial sand blasters so my frame and axles went there, but finding someone to do a walnut shell or other media to blast my sheetmetal components or other softer metal is very difficult. I have a glass bead booth that works great for many things, but I will shy away from using any media blasting if I can. I am looking into some "aircraft remover" by Rust-Oleum and some other liquid/gel paint strippers as options if they are safe for use on this type of metal. Also looking into if anyone had used anything like that or the baking soda in water(or vinegar) method.

-

Morning all, I have to remove some paint from the grill center section on my 52 B3F as someone painted over the piece at one time. Based on not having a magnet stick to it, I believe it would be cast aluminum. I could sand blast the part, but given its the only part I have, looking for options to remove the paint to clean it up. most likely Ill have it powder coated to look chrome again, but will search the site to see what others have done. anyone have suggestions on paint removal outside electrolysis or media blast?

-

when I took mine off the frame it was in a similar configuration and it took 4 people to move it, so I would guess in the weight range you list, however I've never measured it.

-

good point, I forgot about the need to move the seat fore-aft. I think in any regard some form of restraint would be beneficial and look forward to seeing what you have in store

-

only concern I would have is the long lever that the horizontal bar on the factory seat is and how it may deflect if you were to be in a collision or abrupt stop. One may be able to put in a fore-aft tube to reinforce the seat and also make 2 additional mounting points down to the cab where the seat bolts but this increases the mounting points but would keep the seat belts affixed to the seat frame. I also assume this would only be for lap belts or at least just the connection of the shoulder belt. The RV ones seem very close coupled to the vertical tube. Just some of my thoughts.

-

finished up my PS pump mounting bracket and layout of the AC compressor and power steering pump. Ran out of weld gas on Sunday so didnt finish welding the AC compressor bracket but will do so this week. Finished up the power steering cooler routing, itll be tight with the AC condenser line routing but should be good with some routing clamps. Waiting on some radiator hose material to come in then I can finish up hooking up the radiator. Next up will be getting the PT Cruiser fan mocked up and mounts built then finish up the battery box. One step closer to test firing!

-

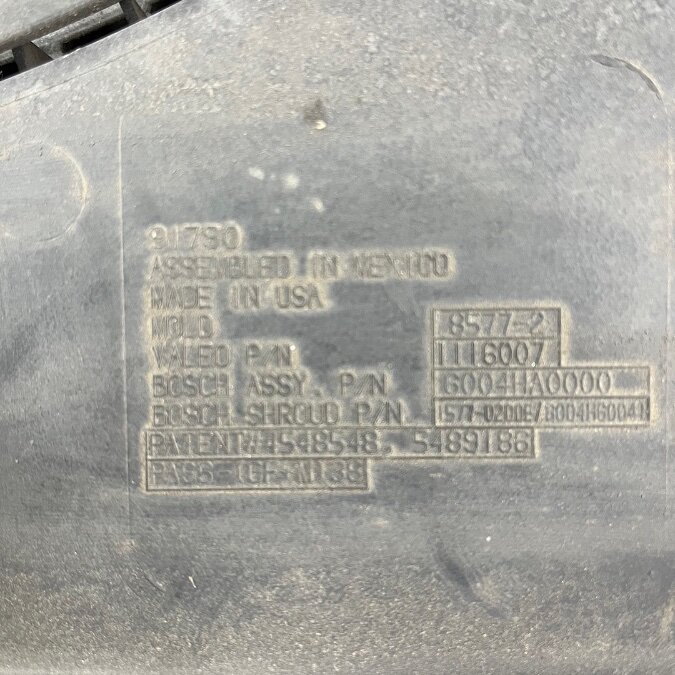

Got some work done while waiting on belts to finish the ps pump bracket. Mounted the Vintage Air condenser to the radiator support so I could remove the radiator independent of the radiator. Also mounted the ps cooler since I'm running hydroboost I need a cooler. Also found a perfect electric fan. If you have the DCM aluminum radiator and need a fan, a 2001 PT Cruiser fan fits this perfect if you remove one of the mounting tabs. I'll have to make some mounts on the radiator to bolt it on but shroud size is about perfect.

-

I just used battery cables USA but using weld cable vs battery cable. More flexible and higher current capable. $1.81/ foot for 1/0 and really cheap shipping. I'd recommend them. What I've heard is up size 1 to 2 for 6V so I'd recommend like a 00awg or 2/0 cable.

-

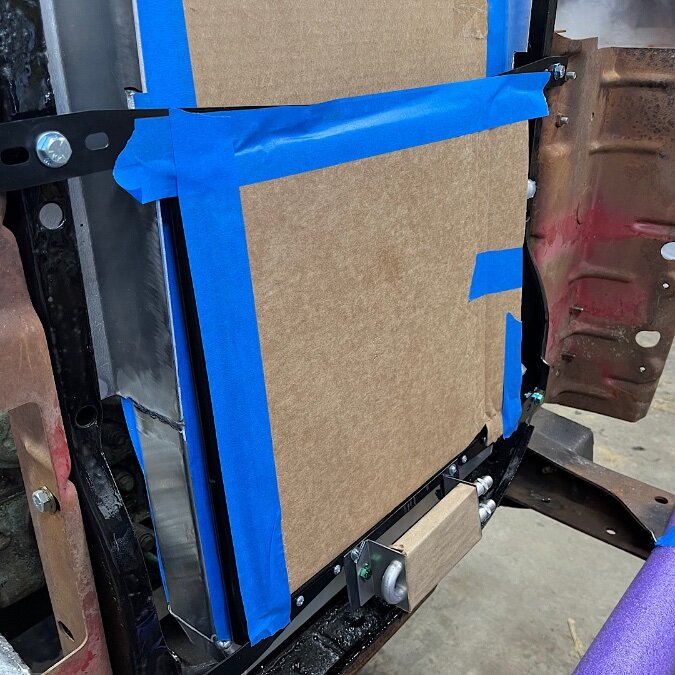

Got the battery box installed. Using a under belly box and will build a custom dual battery tray to hold the 2 group 31 batteries. Remote jump start terminals and battery disconnect on the outside of the box. Finish the ps pump then move onto the battery cable and charging wiring.

-

Got some photos taken. Almost done with the ac compressor mount. Had to make a new power steering bracket due to the double v pulley offset. Had a oops and dropped the ps pump and bent the pulley so new one is coming tomorrow. Lower plate is the start of the ps pump bracket

-

there is a FB forum for these trucks where there is a guy who deciphers engine models and details, if you cannot find the information here or the other site it may be worth reaching out there as well.

-

awesome project! there are some people on the forum that have larger trucks but do not know they are that size. there is another website that is tied to this one and they do have some good info, including the service manual for the B4: https://dodgepilothouseclub.org/know/B4_manual/manual.htm there is also a sticky with several vendors that may be handy as well. Good luck and welcome to the forum!

-

ggdad1951, I will be interested in what you find out as I am looking at integrated belts. I have a set of Ford seats but off the cuff I think they are too large to fit in the stock cab and leave room for driving. I've heard about Sebring convertible seats having integrated belts and sometimes 3rd row seats from a SUV may have integrated seatbelts as well. Been too cold here in Iowa to visit the u-pull it place, and sadly there are very few here that I know of in the NE part of Iowa(closest is ~1.5hrs away near the MN border).

-

wanted to send a quick update, I haven't been working much on the project, had COVID back in October and spent a few weeks in the hospital then at home on oxygen until thanksgiving so work has halted. Really started up again the week of Christmas and been trying to catch up when the wife allows me to. no photos at this time but Ill try to upload some yet this week. I got the rear axle fully welded up(spring perches, shock mounts) and reinstalled. Front axle was out for a panhard bar install only to find out I need new material and a pipe bender to make the panhard bar work. purchased a underbody box(like used on trailer) to make into a battery box so it mirrors the fuel tank roughly in size to look similar to saddle tanks. Vintage air system is partially here so my focus is now on building a bracket to mount the AC compressor to my engine followed when I get the inside unit placement of that. Here is to a new year and continued awesomeness that this site is.