-

Posts

32 -

Joined

-

Last visited

Reputation

13 GoodAbout Jared Duramax

- Birthday 08/24/1990

Profile Information

-

Gender

Male

-

Location

North Carolina

-

Interests

old trucks and farm equipment

-

My Project Cars

1950 Dodge B2B-108

Contact Methods

-

Biography

I like working on old trucks and tractors

-

Occupation

mechanic

Converted

-

Location

North Carolina

-

Interests

Trucks

Recent Profile Visitors

736 profile views

-

The cab mounts are done the fender to cab brackets are made all the interior bracing has been cut out and the cab brace blocks are done now it is time to start working on the hood. I am going to make it a 1 piece hood and remove the upper brow and turn it into part of the grill.

-

Look at Truck-Lite they make really good DOT approved lights. https://www.truck-lite.com/lights.html

-

I’ll have to keep that in mind.

-

I am starting to look for a new bench seat does anyone have any recommendations? I don’t plan on using the original I would like to put something nicer instead.

-

Looks great how much fighting did you have to do to get the doors to line up correctly after all the cutting?

- 640 replies

-

I got the cab squared to the frame, the front clip apart, and hammered out majority of the dents. I rust converted the inside of the fenders then re assembled the clip. It took a long time to get the fender to door gaps correct. Radiator crossmember, front clip gussets, and fender to cab brackets are next on the list. This cab and clip has been a pain to get everything set right. What is everyone’s opinion on rust converting products?

-

Thanks this is my first car build so I am kind of flying blind learning as I go. I am just outside of Charlotte in Monroe.

-

No the floor and firewall is 1/8” plate and it will have a 3”x3”x3/16” tube sub frame with cross members for the seats

-

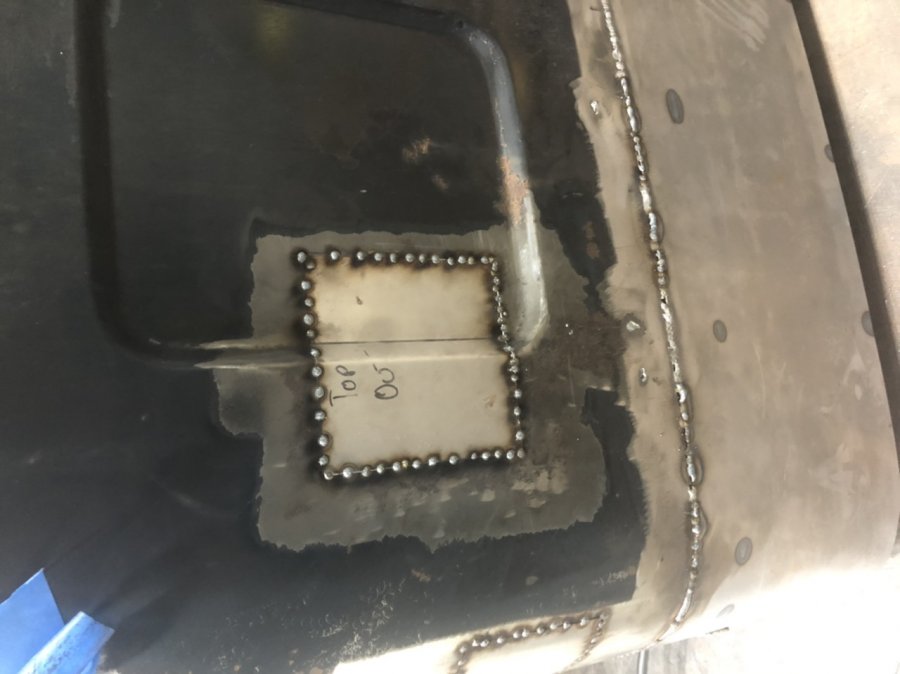

Front cab corners done, gas door filled, patch panels done, lower cab radius done, floor needs final welding then back onto the truck for the cab mounts.

-

It will have a 10’ flat bed

-

Back onto the frame for fire wall and floor mock up.The fire wall and floor is made with 1/8” plate. Then onto the table to square the cab and welding in the floor and fire wall . Everything is drawn up on the computer then CNC plasma cut then bent on the press brake.

-

-

I have the motor trans and cab mocked up for alignment along with the motor mounts and transmission mounts fabricated

-

I got the cab off the excursion and the motor and trans pulled. Ready to start the install of the 5.3 LS and 4l60e trans.

-

I got this truck about 5 years ago and it was supposed to be a restoration but after tearing it down I found this was not going to be a good candidate. So it sat in my garage in parts until I figured out a good plan. During that time I have been collecting lots of parts and ideas. I came across a 2000 Ford Excursion that was 4wd for $500 and I knew this would be my best start. The original frame was not square and was beyond repair.