-

Posts

808 -

Joined

-

Last visited

-

Days Won

16

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Loren

-

An update: Somewhere along the line a previous owner lost the keys to this 49 Business Coupe. So they replaced the ignition lock (or perhaps the whole switch assembly) with a later Pentastar key switch. That happens. I bought the car to drive and enjoy, which means I need to park it unattended often. So I want the door locks and truck lock to work. Generally I like to hand off the specialist stuff to the specialists, but there are no locksmiths within an hours drive of my little town. So... I got 2 sets of NOS DPCD keys and proceeded to make them fit the existing locks. Heres how I did it. Unless someone has changed the ignition (as in this case) if you disassemble one lock for the combination, you can make a key. I started with the door key because I knew the ignition was changed. Once I got the key to work I had my hardware store duplicate it on my blank. The door key is the easiest to remove and disassemble. There is a strip of sheet metal across the top of the tumblers and springs. I filed the end of the lock case and pried the strip off. Then working from one end I took the springs out, then one by one the tumblers. The tumblers are two pieces. The piece that contacts the key is the variable one. The piece that contacts the spring is the same size as the others (and so is interchangeable with the others like it). The first thing I do is put them on a paper towel in the order I take them off and I measure the variable tumbler. On the door lock I could not take the cylinder out of the housing, so once I measured the tumblers I put the new key in and took a drill and touched the key through the tumbler holes. This marks the key so you know where to file. The start at one end and file the key one tumbler at a time. When it will turn in the lock you go to the next one. Once I finished filing I tried the key in the other door and it was PERFECT. So I reassembled the lock and re-staked the metal strip and put the lock back in the door. The photo is the trunk lock, which is ready to reassemble. This one you can take the cylinder out because in order to remove it from the handle housing you have to grind off the nub that holds it in the housing. That allows you to release the clip holding it together after you remove the tumblers. Other than that they are the same. The pin you ground off can be replaced with a small Allen Head set screw after you tap the hole it came out of.

-

Raymond Lowey is still with us! President Kennedy had him design the paint scheme for Air Force One and it is so timeless we've kept it for 60 years! Lowey was most associated with Studebaker and contributed mightily to the highest production numbers in company history. Bad management was able to overcome his best efforts and take down Packard as well...

-

Just my humble opinion, worth exactly what you've paid for it but... The T-handle Overdrive cable is for locking the Overdrive into direct drive mainly for parking so the car won't roll. The Sprag Clutch will allow movement in one direction (but not in the other) when the handle is in. A car stuck in gear will still move (with difficulty) by forcing the engine to revolve. Of course if the engine is stuck as well, it won't. Brake friction material will rust to drums (and rotors) causing the car not to move. On an early post war Mopar the parking brake set for decades could have rusted to the drum. I would take a look at that. If the engine starts and stalls when you put it in gear and let the clutch out, it's more likely the parking brake than the transmission. I can tell you a Mopar parking brake left on will stop a car dead in the water! (once it gets hot enough) Can you hurt the Overdrive while trying to roll the car? Not likely. I am concerned by any B-W Overdrive switched with a toggle however. They were not made to be used that way and they can be damaged. I would get it hooked up correctly pronto! If there is damage to it, then very likely it was done years before you got the car.

-

Marc is right, "3 Passenger Coupes" were the cheapest of all Mopars. A Special Deluxe 2 door is vastly better equipped. This example has a heater but it is way down the price ladder than the one my Special Deluxe had way back in the 1970s. They are also the lightest of all Mopars which is one of the reasons Lee Petty raced them and won 19 races! He said they'd go 92 mph...but didn't use up tires or fuel and that's why he won. He wasn't the only driver to race Plymouths with the same stratagem. FYI the Plymouth only had to go a few hundred miles to win a race...unless you want your engine to last only 500 miles don't "go pedal to the metal". Besides NASCAR had him tear down the engine 15 times out of those 19 wins. I checked and it has the 3.73 to 1 rear end gears. I am thinking of changing the "Pumpkin" for a 1956 3.54 ratio I have. I don't think that's too big a change because the engine handles all the hills around here. However, it sure could use an Overdrive. Ordinarily I would agree that it should not be painted... There's big dent in the trunk lid, an old crappy repair on the driver's side and places where there's bare metal. I figure a decent paint job will do more to protect it for the next 72 years than it will diminish its originality. The paint of 1949 was not the shiniest by a long shot, so one has to be careful with modern materials. At any rate I know a very good paint supplier who can match colors amazingly well. I've decided to retain the 6 volt positive ground electrical system. to go to 12 volt I'd have to give up the "Bull's Eye" headlamps and I am not doing that. Besides if it works don't fix it. If you want electronic ignition I found a page on the web with a DIY project that duplicates a Delta Mark 10 in 6 volt positive ground. I used many of those on 3 cylinder 2 stroke SAABs and they were great! (but 12 volt) The idea then as now was to avoid changing points. The Delta Mark 10 used the points as a low voltage switch so the only thing that wore was the rubbing block. Now if I could figure out how to connect a Multi Spark Unit to it..... More fun!

-

I just scored a new car I’ve wanted for a very long time. This car has 37,400 miles on it! It’s about as original as it could be too. One thing I am amazed about is it doesn’t wander at all. There are a few things I’d like to perfect but I am not going to go overboard. A paint job and minor body repair to prevent rust is the biggest item on my list. I’ve been driving every day and it starts and runs like a near new 49 Plymouth.

- 34 replies

-

- 18

-

-

-

It never occurred to me until a museum curator told me. Museums don't restore cars if they don't have to. They buy a car they want then stay on the look out for a better one then sell the first one. A project car is a labor of love. A car you want to drive is transportation. I like my projects, like polishing a stone to make a diamond. Getting a car modified to your own specs will require a skillful trustworthy mechanic. If you know one go ahead, if not buy a car that meets your needs. Nothing worse than an unfinished project car, when you could have been driving.

-

A few years ago a friend of mine was in the dash customizing business. We took a tour of a factory in Grand Rapids that did Hydro Graphics for the auto industry. Everything was in a clean room and done by robots. After being dipped the parts were sprayed with clear urethane. They made very nice parts. Now days you can get a kit with the Hydro Graphic film for a DIY project. In all honesty if and when I need wood graining, I'd take my parts to someone who does the work daily. Sure you can get good results doing it yourself BUT like paint and body work I think spending a little money to get professional results will free your time to do the stuff you enjoy doing.

-

Over the last century of automobiles the fuel has been the big variable. What was sold as gasoline in the teens wasn't the same in the twenties and so on. When the government got involved with emissions there were 9 different blends of fuel mandated coast to coast and with ethanol I've lost count. One of the problems engineers found with emission controlled engines is that crud will build up on the intake valves. The strategy to keep this from happening was to chemically raise the temperature that this build up forms at. The crud just moves to the combustion chamber instead of collecting on the valves. That's what Chevron's Techron does (among other things). Since you can buy little bottles of the stuff, that could be added to your Ampco oil vapor injector Marvel Mystery Oil. Seems to me that might be a good thing.

-

Just a thought, one eBay there are lots of parts for South Wind Heaters, one of which are carburetor base plates for the vacuum supply. I don't know this for sure but it seems to me one of these could be used for the lubricator. Stewart Warner sold base plates to fit most popular cars such as the Plymouth.

-

Those oilers are especially valuable on Propane fueled engines. Propane is dry and there is zero lubrication to it. With unleaded ethanol fuels I should think they'd be helpful. Diesel fuel has more BTUs per gallon so adding a little can't hurt. Jet fuel even more but I wouldn't go that way. lol

-

The seal puller I've seen looks like a Bee Hive. (tapered thread) You withdraw the push screw then "screw the Bee Hive" shaped part into the seal. It gets a bite and you turn the push screw into it to withdraw the seal. One thing I know is that modern seals are much easier to deal with (going and coming). Your NAPA guy has charts/books that list seals by diameters so he can find you a substitute for far less money.

-

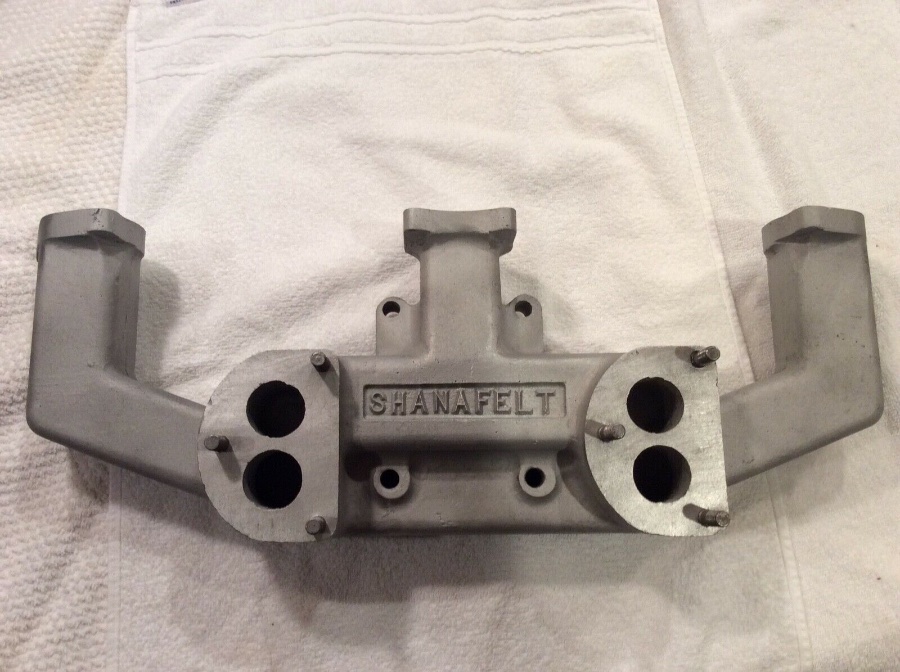

You have a treasure! I bid on one on eBay some time back. I bid twice what I knew was a high price for an Edmunds and LOST! After I started looking at other Shanafelt manifolds I figure three times might have been more betta. Does it look like this one?

-

My business was making and rebuilding large diesel Turbocharger turbine wheels, so we did a lot of cylindrical grinding. Hard chrome plating goes along with that kind of business. Southern California used to be an aircraft industry center in fact that was the largest employer in the area. Not so much anymore. The nice thing about chrome is that it is hard in the range 62 on the Rockwell C scale. Good chrome moly steel can be hardened to 52 c but it starts to get brittle. Normalized and tempered Chrome moly is very strong at 28 c but it can wear. Hard Chrome Plate it and you get the best of all combinations. Plus chrome plating makes an excellent bearing because it can be so smooth when ground. You couldn't get any better than a hard chrome plated and ground part. Trouble is chrome shops are getting rare and grinding shops even more so. If you think ornamental chrome is expensive, I would imagine Hard Chrome is worse.

-

Those are kind of pricey and really suitable for cars that are shown as originals. The canister filters with replaceable elements are available as reproductions now and the elements are still a little expensive but again good for car shows. Of course the old stand by Frantz filter will work well if you don't care about originality. There are also spin on by-pass filters as well. Two 1/8th inch pipe plugs can settle the problem too. eBay has reproduction Bee Hive Filters if you want style.

-

My Dad had a friend who loved motorcycles and when he was offered a great deal on a then new 1948 Velocette, he bought two. He rode one and the second one remained in the crate...in his living room! I have a brand new 26-27 Model T block still in the crate that I've tried to sell a few times. I am thinking of making a plexiglass case for it and turning it into a bit of furniture. Think of how nice your rebuilt engine would look under glass!! On the storage of engines: I've seen devices screwed into the spark plug holes that are filled with a desiccant that turns a different color when saturated. These are used for aircraft engines. I'd think they are probably available for sale from say Aircraft Spruce. My Project: Since my car is buried in warehouse #2 of 3 and my engine is going to #3 and we are moving, things are somewhat stalled at the moment.

-

I didn't discover it until I was about 2/3 rds into the assembly. Also I don't believe I will be going back to that shop. They seemed to forget my instructions for their own convenience.

-

The supplier I went to deserves the bad review as they didn't inform me that they twice cancelled the order. MSC-Direct. Their price for a tap was $125 and 152.00 delivered. The Chinese Tap & Die pair were $44.76 delivered. Yes it takes 3 weeks from China but it came. The order from MSC-Direct took 6 months and it didn't come! At the very least eBay would have refunded my money if it took over a month to get here, so there wasn't much risk. Then when it worked it makes you think why use an American supplier with lousy customer service for more money? Besides how often am I going to need a 1 1/8 x 14 tap & die? Just finding it the next time I need one will be a challenge! lol

-

When I took my crankshaft to the machine shop they said it was too worn to economically repair. But they just happened to have one they could regrind and sell me. When I got the replacement home and started my re-assembly I found that the "NOS" bolt that holds the pulley on wouldn't thread into the crank. So I decided to see if I could get a tap to straighten out the crank's internal threads. After ordering a tap from an online supplier and waiting and waiting and waiting, I found out they had cancelled the order. So I re-ordered it......same result. Finally I ordered one on eBay, from China. For one third the price of the one from the U.S. supplier I got a tap and a die.....and it came today. Good thing too. The NOS bolt needed its threads dressed as well. Carefully I cleaned up the threads in the crankshaft. When the two parts came together they threaded perfectly. Can't get an American tap but you can get a Chinese one that works perfectly....no wonder they have the bomb. Clearly this is not a high production item. The size was hand written on the tap and the die with an electric pencil. The size of the threads are 1 1/8 x 14 which are not real common. If anyone should need to know.

-

They have a special shape. I don't believe you can get new ones but www.vintagepowerwagons.com has recycled ones. Expect to pay dollars for something that should cost cents.

-

After I had a local shop do the front seat of an old Travelall I wanted to sell, I swore off trying to DIY upholstery. They got it done so much faster and better than I could ever hope to do. I didn't think it was cheap but the results were great and the seat was comfortable again. In my humble opinion paint & body work are not my strong suits and now I've added upholstery to that list. Better to do what I am good at and let the guys who make a living at the things I am not good at earn a paycheck. Gives me more time to enjoy my self.

-

For Entertainment only. From Model T days there was a tool maker who discovered how badly Henry Ford's cams were off. Now the "adjustment" for Ford tappets was done when you did a valve job. When you ground the seats you also ground the stem of the valve to get the right clearance. The theory was that the seats wore with the valves and the tappets equally. KR Wilson realized that Ford valve action really wasn't timed right and that changing the tappet clearance could make a big difference in the performance of a Model T. So they made a simple tool which "timed" the valve based on the piston position. You turned the crank until you felt the tool move then you ground the valve stem til the valve was just seated regardless of the clearance. The tool corrected the inaccuracy of the cam/gear set/timing by changing the clearance. Making sure the valve didn't open too soon and loose cylinder pressure. They say it worked. Model Ts had so many things that made noise I suppose loud tappets were never a worry.

-

There are many ways to skin a cat. I bought a Vacuum Bleeder from Harbor Freight $35. It has the refill bottle which "rests" in the opening of the master cylinder and refills it as the fluid is drawn out. Its operation reminds me of the old battery fillers. The procedure works like this set up the refill bottle then go to the furthest brake cylinder. Attach the vacuum line to the bleed nipple and suck the air out with the tool, then repeat till you get to the last one. I wouldn't think it would work as good as a Pressure Bleeder except that I have used a Robinair Vacuum cooling system filler on a very complicated Vanagon cooling system. Those things are almost impossible to get the air out of. You can find leaks and fix them without wasting coolant and then it fills the system completely full with no air pockets! In my humble opinion $35 bucks is Joe Cheap for such an efficient way to do the job.

-

Carter B&B: The worst carburetor ever made?! Discuss...

Loren replied to wagoneer's topic in P15-D24 Forum

That is silly over pricing! I've bought brand new ones for around $75. $125 is more like it. To get two exactly the same I've had to buy three brand new ones. I don't mind because I've used so many and have a good collection of parts. I bought one brand new one that had the Overdrive switch bracket and the throttle lever to engage the switch. -

FYI There is a Mopar pumpkin on eBay right now that has the four spider differential that is billed as a 3.54 ratio. I am thinking it had to come out of the bigger Chrysler because of the 4 spider diff. The seller has the housing casting number in the listing. This might be what someone is looking for.

-

Three speed low gear is meant to get you across an intersection 2nd gear is meant for in town driving and third gear was meant for the highways of the time. My Dad told the story of Mrs. Heddington who's first car was a 1919 Center Door Model T. She drove this car for 20 years and finally had to give it up for a new 39 Ford. Not being familiar with gear shifting and a clutch that didn't work at all like her Model T she found driving a little confusing. My Dad who was born the same year as her Model T took great pains to teach her how to drive a stick shift. In the Model T the left pedal controlled low, neutral and high. Put the hand brake in the middle and it depressed the left pedal enough for neutral, step on the left pedal and the car moves forward in low. Put the hand brake all the way forward and take your foot off the left pedal and your in high. He said she got the clutch figured out pretty fast but gear lever position was a mystery. You would see her driving along with the engine racing (low gear) or lugging horribly (high gear). He patiently explained the "H" pattern numerous times and finally got her to start in low gear and shift to second. She never drove fast enough to select high gear. Her comment was "Why did they have to change it?" How many times have we said that when getting a new phone or some other device we refuse to read the manual for? The dealer wouldn't take the Model T in on trade so Mrs Heddington offered it to my Dad for helping her. At this part in the story I asked the burning question, "Why didn't you take it?" I got the answer "Oh I would have had to fix it and there were more free Model Ts around than takers." It seemed obvious to me but I had to bring it up anyway, "If you had fixed the Model T, she might have traded you the 39 for it." He didn't have an answer for that. One of the most appealing things about post-war Plymouths is that they simple basic cars. How much can possibly go wrong with them? When you start changing things like transmissions its a cascade of re-engineering. Change the transmission and you lose the eBrake so you have to change the rear end to get an eBrake back. Change the rear end and its brakes then you need to change the front brakes so the service brakes work right. Ugh! In racing I found out proof positive I am a much better mechanic than I am an engineer. I don't like to change the design of anything unless there is no alternative. If something performs less than desired, try the next bigger version of the same design family. In Mopar brakes, 10 inch Plymouth to 11 inch DeSoto to 12 inch Chrysler. In rear ends if the ratio doesn't work for you, change the pumpkin. They made a lot of ratios and if you get it wrong it's easy to change back or find another ratio. I've never heard of anyone breaking the 8 1/4 rear end but if it happens then you could get a 8 3/4 with even more ratios and limited slip differentials. If a 218 Plymouth engine is not fast enough maybe a 230 Dodge might be and if your speed crazy a 251 or 265 Chrysler might be more your style. The Plymouth Overdrive transmission does nothing but add to the charm of the car. It is not a "Speed shift" racer gear box but neither is the rest of the car. It was good reliable transportation not a racer (apologies to Lee Petty). If you want a racer get something later because Plymouth certainly made them. The 1940 gear set is just an alternative. A fun thing you could add or try if you want to. Just my humble opinion your mileage may vary.