-

Posts

2,562 -

Joined

-

Last visited

-

Days Won

83

Everything posted by Sam Buchanan

-

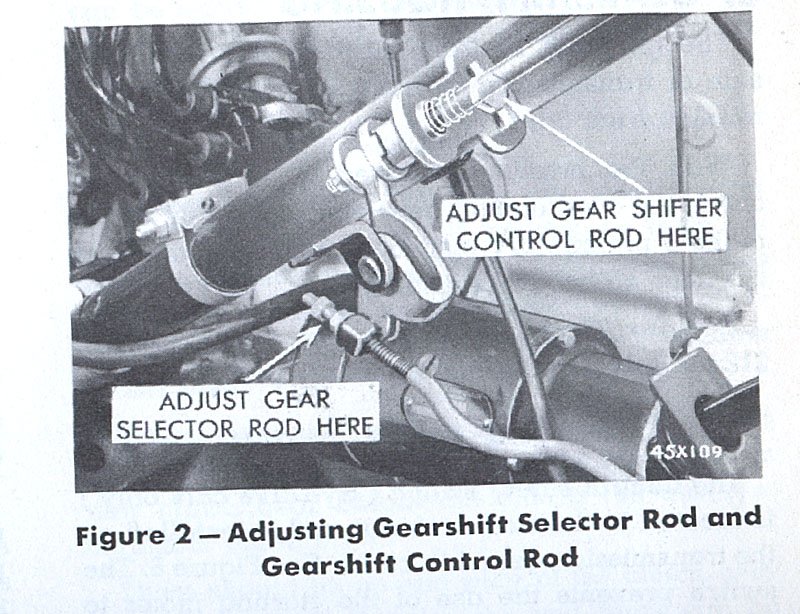

New mounts solved your reverse shift problem, but for future reference, it can be necessary to adjust the shift linkage after replacing mounts. This was the case with my P15, with new mounts it wouldn't go into reverse. The solution was to "shorten" the gear selector rod since the rear of the transmission was now closer to the shifter. The nut on the gear selector rod was tightened a few turns and reverse was then able to be engaged. Here is an illustration from the Service Manual:

-

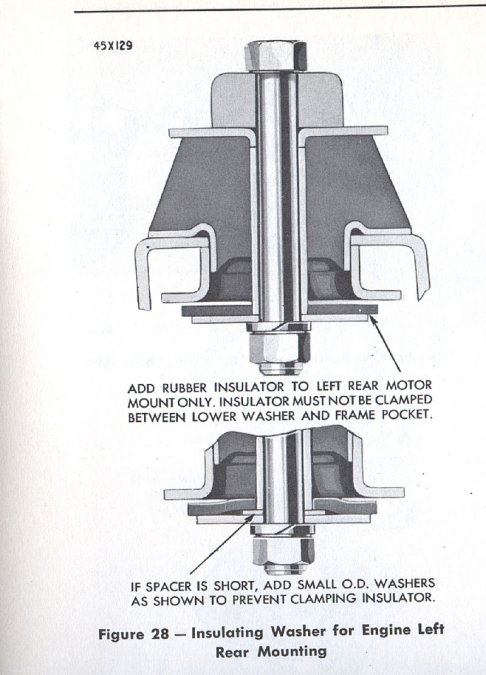

Yes, ordering mounts does indeed seem to be a crap shoot, the Marmon's I got were a rubber that leaves a black residue on your hands. But the best solution so far is to install only upper mounts. The Berbaum mounts I have are pretty hard but work fine without the lowers. Thank you for the feedback and glad you have a smooth ride back---hoping our cars won't need mounts for a very long time. My engineering degree was awarded under a shade tree but I suspect the vibration is primarily transmitted via the left lower mount as the engine rocks clockwise due to torque impulses. In this scenario the bolt would be pulling the lower washer "up" against the lower mount and creating a path for vibes to travel to the frame. Without a lower mount the washer just rides along without contacting anything. It seems the Chrysler engineers had this figured out nicely, we managed to mess it up due to lack of knowledge of how the mounts should be configured.....and clueless retailers who sell us lower mounts we shouldn't be using.....

-

Now is the time to add turn signal wires to the new harness...........

-

Engine Mounts P15; Harshness Problem Solved

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

Don't know if you can install new uppers with the tranny in place, I had the transmission out when installing new mounts, but it would certainly be worth trying. The bolts won't be a problem, you just need enough of a gap to pull the old mounts out and insert the new ones. There was plenty of gap with the transmission slid back free of the bellhousing. I had to use a pry bar to nudge the bellhousing a bit to get the bolts to drop back in place. -

Engine Mounts P15; Harshness Problem Solved

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

The last configuration of the lower mount installation I tried prior to removing the lower donuts was to loosen the bolt to the point that the mounts were not compressed at all by bolt tension, the washers just barely touched the lower mounts. This still resulted in vibration being transmitted to the frame. My engineering degree was awarded under a shade tree but I suspect the vibration was primarily transmitted via the left lower mount as the engine rocked clockwise due to torque impulses. In this scenario the bolt would be pulling the lower washer "up" against the lower mount. Without a lower mount the washer just rides along without contacting anything. It seems the Chrysler engineers had this figured out nicely, we managed to mess it up due to lack of knowledge of how the mounts should be configured. A more detailed discussion of this can be found in this thread. The real problem is retailers not having a clue as to which mounts should be used in which applications. They blindly sell the lowers for a wide range of cars which should not be using them....and those of us with a limited knowledge base don't know any better than to attempt to make them work. -

Yes, things are much clearer now than a couple weeks ago, the education continues. I just assumed the people selling parts knew what they were doing when they listed lower mounts for our cars.....silly me. ? I hope this thread is useful for those considering replacing mounts.

-

Engine Mounts P15; Harshness Problem Solved

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

The lowers did fit into the pocket of the frame member but I didn't mic everything so don't know if they were in contact with the upper mounts. Something about removing the lower mounts increased the elasticity of the system and prevents vibes from being transmitted to the car. I suspect the bolts are now more free to vibrate and allow the upper mount to absorb vibrations. But at this point I'm just speculating about why vibration level is now much lower.......but I'm now enjoying a smooth-running drive train. -

There was no packaging....except the clear plastic bag they came in.........I suspect the vendor has a large box full of rubber donuts......

-

Yes. They are the same lower mounts seen in all the vendor ads for many early 40's through mid-50's Mopars. Here is the listing on their site, note 1 (L-346) is upper, note 2 (L-347) is lower: And here is a listing on Roberts Motors site: https://www.robertsmotorparts.com/lower-motor-mount-6-cyl-dodge-truck-plymouth-truck-fargo-truck-chrysler-dodge-desoto-plymouth-1939-1954-1 And another one: https://www.ebay.com/itm/1939-1956-Plymouth-Dodge-Engine-Motor-Mount-Set-for-Straight-Six-FRESH-STOCK/173244888404?hash=item2856333554:g:f10AAOSw9vlaYRxs For some reason a lower mount is being marketed by multiple vendors that doesn't match what we see in the Service Manual, I've not seen any mounts that look like the original lowers. My knowledge base is way too thin to know the reasons for this.....

-

Engine Mounts P15; Harshness Problem Solved

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

I assume they are. -

I agree. But the problem is the lower mounts now on the market are not "original design parts" for the P15 application. They are too long and cause the mounts to be compressed before the washer can snug up against the t-tube. I have not seen any lower mounts advertised that appear to be the same shape as the lower mounts in the Service Manual illustration. Here is what you get now when you purchase lower mounts, they are about 1/2" too long:

-

Advance Auto has a regulator in their warehouse, but the one I got was DOA.

-

Engine Mounts P15; Harshness Problem Solved

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

The mounts shown are the new lowers I removed, the ones sourced from Bernbaum. The Bernbaum uppers are still installed. -

Great news, Scott, glad you were able to work through this. I may just continue to tolerate the small exhaust leak between manifolds....you would think I would have learned my lesson by now about fixing things that ain't broke...... Yes, drive your car for awhile to get the good vibes flowing again before tackling another major repair.

-

This is an update to the thread about installation of too-firm transmission mounts on my P15. It seems the issues I experienced were due to the lower mounts I installed. After removing the lower mounts to return to an configuration more like the one shown in the Service Manual illustration the car now runs smoothly as it did prior to installing the new mounts. Here are the new lower mounts that I removed that are currently sold by vendors: These mounts require longer bolts than the originals due to their thickness. Compare this to the Service Manual: It seems the transmission of vibration to the car was due to the mount bolt being captured by the lower mounts. When I removed the lower mounts smoothness returned. It appears the closest arrangement to the original design is to not use the lower mounts that are currently available. The lower mounts may indeed be correct for some applications but my '48 P15 is much happier without lower mounts.

-

UPDATE; Smoothness has returned! I removed the lower mounts and snugged the large bottom washers up against the bushing. The washer does not contact the frame member. The car now runs smoothly as it did prior to replacing the mounts. It appears the lower mounts were the primary contributor to the harshness that has been present since new upper and lower mounts were installed. Apparently it is best to just have the transmission "resting" on the mounts vs "secured" to the frame member via lower mounts. I wonder if this is why Steele only offers new vulcanized upper mounts. At this point I don't know if the new mounts are indeed too firm and elimination of the lower mounts is a work-around or if the new mounts are made from a satisfactory material. Whichever is the case, we seem to have a solution. It has been an interesting saga....hopefully this will help others who are replacing mounts......install just upper mounts!

-

Thanks, Marc. I'm still unclear on how the original mounts were designed. When I removed the old mounts there was no lower mount, just the upper. I assumed the lowers had deteriorated enough to fall out. But the illustrations in the manual show a small lower mount, much smaller than the lowers that are shipped with mounts nowadays. I've never seen lower mounts from any vendor that look like the lowers in the illustrations. Matter of fact, the original bolts aren't long enough to go through the lowers that are sold now. I had to get 4" bolts to install the lower mounts. So should we install just the upper mounts now? Are the large lower mounts correctly used in some applications? The manual seems to show the large lower washer riding just below the frame cross member. I think I'll do as has been suggested and remove the lower mounts and snug the large lower washer up against the bushing and see how that works.

-

That might work, Joe, I'll give this some thought. Might delete the lower mounts, too.

-

Oh its been out....about five times.....

-

Well...lookee what I found.....was poking around on the Rock Auto site for a couple of items and found some transmission mounts listed under the 1954 Plymouth section (my car is a '48 and no mounts listed for that year). Matter of fact they had two sources for upper mounts from which to choose. And.....one of the mounts was only $2.45 instead of the $12 I paid "the other place". Hey, why not order a pair and see what they look like? Here they are: And they do a passable job of passing the thumbnail test! These were made in India and appear to be rubber instead of the hard stuff my other new mounts are made of. Now...if someone wants to volunteer to pull the transmission out of my car we'll pop these puppies in and see if Smoothness returns. (I've had ponderings about whether or not the bellhousing could be wedged up enough with the tranny in place to swap out the mounts....it would be very tight but might work.....)

-

The Resources section of this forum is a friendly place. Here is the link found in that section about how to polarize your genny: http://p15-d24.com/files/file/16-flashingpolarizing-generator-guide/

-

If your car has been truly changed to negative ground the coil and ammeter wires have been reversed. If that is the case (ammeter shows discharge when you turn on the lights without the engine running) turn the battery around so you have the negative post grounded. Probably need to install the regulator from the donor as well since it is set up for charging the 6v battery. If your donor items turn out to be sketchy you can go the alternator route.

-

The dewpoints here are in the 70's......almost need gills........and three showers a day.......

-

I forgot to add....there was a question about my alternator order and the vendor took it on himself to call me and make sure I had received what I wanted. I talked to him a couple of times and came away impressed with his integrity and eagerness to follow up with a customer. Great price, excellent personal service.....I like. One other item; the alternator pulley nut protrudes more than the generator nut. The old nut is flush with the forward face of the generator pulley, the alternator nut protrudes forward of the pulley face a bit. In my case I used a slightly longer belt (mine is 5/8" wide) so there would not be interference with the fan blades. The vendor told me he had heard of other instances where the belt length needed to be tweaked. He also stated that the nut had enough meat for minor machining if the installation is particularly tight. Mine worked fine.