9 foot box

Members-

Posts

639 -

Joined

-

Last visited

-

Days Won

15

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 9 foot box

-

I’m sorry for the bad references for a brake drum replacement. I think there is a brake drum replacement for less than $400. I haven’t found it yet. Call Then and Now Automotive, 781 335-8860.

-

The serial number on left front top edge of the block would start with T173 if it’s original 218. Search “t137 other engines”. It will tell you what engine you have and what the donor engine you intend to use is from. Or post the first letter and following three numbers, if you’re not sure. Rick D.

-

Several years ago a guy had a post “Found a brake drum solution”. You can still find it in a Google search, just add p15. If you go into RockAuto in 66 Fairlane with a V8, depending on your brake shoe size, there is a 10”x1 3/4” or a 10”x2” brake drum. 2623R and 2637R. Same bolt pattern. You would have to machine the center hole to make it hub centric. It might be a solution for a lot of us, when a new brake drum is needed. I was lucky enough to find a good drum, when a brake return spring broke and ruined my drum. This is an opinion, but for $30, I will probably buy a drum and see if it will work for my cars, unless you do it first. Rick D.

-

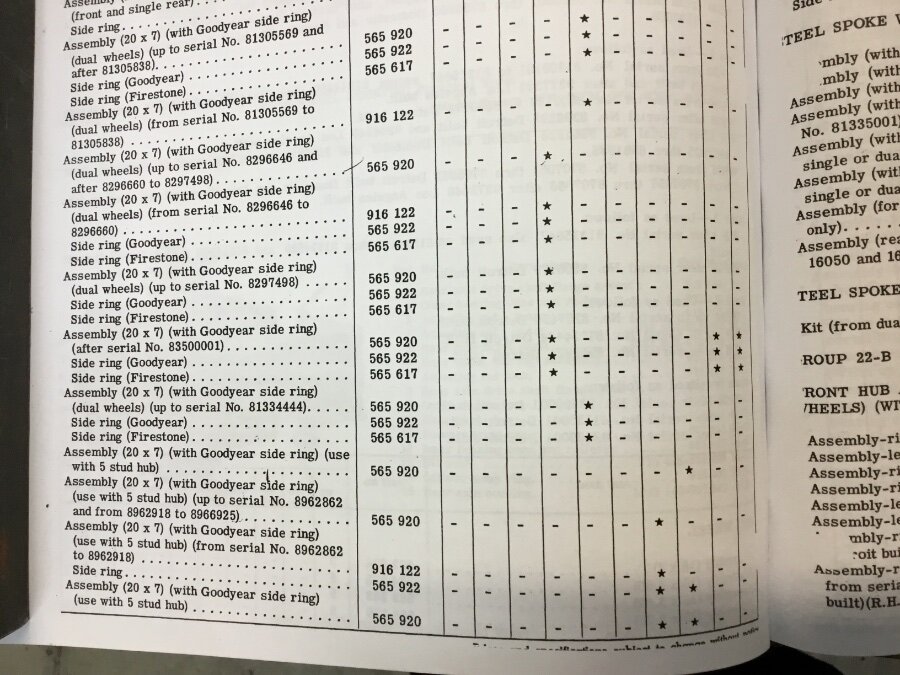

I have a couple 20” wheels. They are the narrow style. You wouldn’t have to feed the stem into a center hole. The assembled tire, tube and flap should drop straight in. My previous pictures are one ton 16” wheels. The flap covers the gap in the slot for the valve stem in a larger wheel. I’ve seen metal reinforced valve stems, maybe that’s what you need. I use this hammer to assist the lock ring to seat properly. A rawhide, dead blow or rubber mallet would probably work, just don’t use a metal hammer. When you dismount your old tires, you need to break the bottom and top bead, to be able to get the tire and lock ring off. That’s the hard part because the bead is rusted to the wheel. That’s why the rubber lube is important, not soap and water. It makes repairs a lot easier also. There is a slot on the lock ring to insert a flat bar to get it above the flange, I use another flat bar and tap it around the circumference to remove the ring. It prevents distortion of the ring. I’ve seen people pull the ring off after releasing it, but it stretches the ring. You can see that this wheel needs bead blasting or knotted wire wheel cleaning and my preferred aluminum paint. You got a long way to go, till new tires. Get though the front wheels okay, you got it figured out. Your wheels are probably cleaner than the flat tire I took off this wheel. Rick D.

-

I like aluminum paint, it dries without any buildup. Check the inside of the tires for any tags, that could eventually rub a pin hole in the tube. I wiped the inside of the tires and the tubes with corn starch with a cloth. It doesn’t need a lot. I paint the bead of tire with rubber lube, so the bead slides easily on the wheel as it sets, you can put the lube on the wheel seat to ensure a soft seating of the bead. The flap doesn’t need any lube. Set the opening of the lock ring opposite the valve stem. I have a special hammer/mallet with a duck bill on the other side. I use the rubber part to tap the lock ring into place as I fill the tire slowly by adjusting the pressure on my regulator. This assumes that your rings are clean and no cracks, they have been painted and the notch in the wheel where they lock is perfectly clean. I’ve trashed wheels and rings that had been beaten with metal hammers. The lock ring ends should be almost touching when done correctly. Any questions, ask, it is a risky job even if you’ve done it before. These are 16” wheels, but the same design as the 20” wheels that I have. Once the bead is set and the lock ring is secured properly, I let the air out and refill with the valve core installed to eliminate any tube wrinkles. After you get it to pressure, you can bend the valve stem for access when the wheels are on the truck. If there is anything you don’t understand, ask. Rick D.

-

Hello all, I’ll be adding a 47 WD21 to the forum

9 foot box replied to Eric WD21's topic in Mopar Flathead Truck Forum

This is a 3.9 differential that was handy. The upper flat is where a fill plug could be tapped, the lower flat is where the gear ratio is stamped. My guess is 4.3. Rick D. -

Maybe try searching for coil spring silencer. That’s what the parts book calls them. Roberts and A. Bernbaum have them. The book calls for a spacer on the top driver side spring. Silencer 691144 spacer 657770. I don’t know of a source for a spacer, or if they are metal or what they are made of. I put Aerostar springs on my 46, I believe that they are a progressive spring, that gets firmer as it compresses. I didn’t cut any coils.

-

Show a picture of your other clutch plate. It shouldn’t have the spring steel supports, like the one that broke. If you go to the web site, you can see the difference. I didn’t know that there was different clutch plates for Dodge until your post.

-

Andy B. has the best price. It looks like a clutch plate for fluid drive. Could be why most of the springs broke.

-

An updated picture, without shadow. Modello sent me an email with a $30 off my next purchase. That’s nice. I would have them add tire tread on the next one. I’m looking at a couple different Plymouth ship logo’s to do also. This was a whim purchase. It worked out OK, but I need carb and fuel pump rebuild kits. Rick D.

-

The eBay item number for the carburetor that I was referring to is 315193868798. It would be a direct fit. I don’t see the one you bought, working with a Gyromatic transmission. Like PA says, you have to pay to play if you don’t have the correct parts. I wouldn’t pay $700 for a E6U2 carburetor. But the D6M1 is affordable and should work in your application. Rick D.

-

In a Google search, type D6M1 2146357 carburetor. Other carburetor that may work E6U2. The eBay carb is missing a throttle piece, but you can use the one off of yours. Some of the price’s I’ve seen, $267 delivered is a deal. It has the electric dash pot and what looks like a kick down switch. Rick D

-

Will 1951 DeSoto car A arms bolt up to my 1940 Plymouth Coupe?

9 foot box replied to Noonan's topic in P15-D24 Forum

-

Will 1951 DeSoto car A arms bolt up to my 1940 Plymouth Coupe?

9 foot box replied to Noonan's topic in P15-D24 Forum

-

I saw an add for Modello Turbo that interested me. I sent a picture of my 46 P15 and they replied with a sample line drawing. I had them eliminate the spotlight and antenna, and this is what I went with. 27” wide, 16” tall, $118 delivered from Turkey, took 13 days from start to receiving today. I’ll probably white out the hanger bracket with touch up paint. I like it but the problem is I have an idea for a perspective of a 47 Dodge truck and it means more stuff, I have enough stuff. They are neat and affordable though. The shadow is from my lighting in the shop, it sets out 1/2” from the wall. A flash picture works better. But that’s on my PC with a digital camera. You get the idea. Rick D.

-

You can’t beat the price and the Texas sun has the paint striped off. It may have a 51 title, but the dash is a 52-53. I’m not knowledgeable in B-Series, just an opinion. The chrome center on the grill and vent windows may just indicate a Deluxe cab with electric wipers and two visors. That’s a nice project to bring back home. Your last project was a Chevy wagon, how did that turn out? It seems that if a person bides their time, a good deal will eventually turn up. It worked for me, in a recent 48 Ply Club Coupe for a 41 Dodge truck trade. The Coupe needed everything, I’m driving the truck daily, after changing a few cobbled changes that were done to the truck. Rick D.

-

There should be a notch in the bottom of the dash, under the key switch. It gives you access to a screw that holds the switch in place. Remove the screw and the switch can come out the back. That’s how mine are.

-

The exhaust manifold nuts and washers at the front and rear of the exhaust manifold are tapered and should go into concave bronze washers. The castle end of the nut shouldn’t be outward. A manifold stud kit has four castle nuts and washers. It allows the manifold expand and contract. Look in the spare parts that you may have gotten. Maybe you’ll find the correct parts. Rick D.

-

1953 B4B 1/2 Ton 218 engine and fluiddrive Tow Rating

9 foot box replied to Dan693's topic in Mopar Flathead Truck Forum

I fit and bolted a class 3 hitch to my frame. I can tow my 11’ single axle trailer to the dump, when pruning trees. I’m less than a mile to dump the branches. I don’t have lights. It has to have a lot of drop, to tow the trailer level. The top of the ball is 18” from the ground. It adds a lot more strength to the rear frame than channel iron and it bolts on with a 2” receiver. That would be below a stock bumper, I think. It should be bolted to the frame sides, the bottom web of the frame will rip out if you don’t. My setup is simple light tongue weight. Or I would have put fish plates on the sides, where the light bar is bolted. Rick D. -

I have two 6 hole 20” wheels that I removed the old tires. I set the ring on one, and it measured 5”. There is a number on the face of the wheel, that may help. I don’t know if you have 5 or 6 hole wheels. Rick D.

-

I agree with changing out brake fluid periodically. I thought I’d post on a tool that we all rely on. I’ve needed a good air compressor for years. I just couldn’t make the dive into spending a couple thousand for what I wanted. I have a school bus business next door. They had to replace their compressor. One day the secretary asked if I wanted the tank on a pallet outside. The motor was gone but the cage and grommets were there. I pulled the heads on the compressor and replaced the reed valves and head gaskets for $100, found a 5 hp. motor for $100, and changed the pulley to 9.250” on the motor. 21 cfm is what it seems to pump up to with a slower motor and larger pulley on the motor. I put it on wheels, so I can get it to various places in my home/shop. 80 gallon tank. So, for $300, I have a $2000.00 compressor. I was lucky that the heat didn’t hurt the rings on the pistons. My next favorite tool is my bead blaster cabinet, with a dust collector, instead of a shop vacuum. You can see my old Curtis compressor in the background. I only use glass beads, but the filter still needs periodic cleaning, for full suction/vacuuming of dust. You can tell by the suction on the gloves if the filter is clogging. Rick D.

-

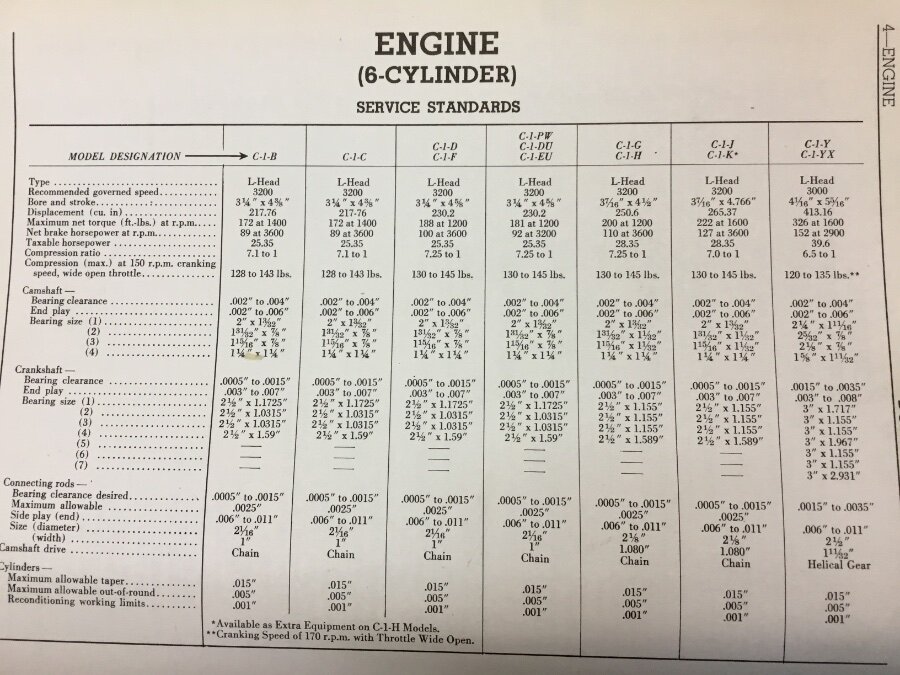

This shows the difference in bore and stroke of engine cubic inches. In order to use the pistons, you could buy Melling cylinder sleeves. I would like to see one of the pistons. I like the original style pistons with four rings. But you would need to find .060” over size after the cylinders are rebored. Sorry to hear of your problem. I’d give you another block. I’m trying to reason how a simple hone to clean up the cylinders, turned out like it did. Rick D.

-

Rebuilding the Mopar 3 speed: synchro choices Resolved!

9 foot box replied to FarmerJon's topic in P15-D24 Forum

It’s been 6-8 years ago, that I put an R10-G1 in my P15. It was missing some parts and needed a shorter input pinion shaft. I got what I needed from George Asche. He mentioned a fast second gear. So I found a 23T second gear, 853885 and 25T counter shaft, 692687. My spreader spring was bad, but a fellow member had mentioned one, so I contacted him for a replacement. I don’t know if it’s needed for non-fluid drive, I just wanted to replace it. My transmission was from a 53 Dodge, so it had a place for a detent switch for backup lights, that were on the car. Use the soft plug from the small parts kit on the left lower shaft, or a penny. There are old posts regarding slight leakage after install, even with the gasket. Thanks for sharing your progress. Rick D. -

I went back to your previous posts. Nov.2021. You stated that the exhaust smoke was light gray. That usually indicates a bad head gasket. Have you ever done a compression test? You have a tag of a rebuilt engine. If the head bolt torque wasn’t retorqued after the engine was ran up to operating temp and retorqued after cooling. It’s important that it’s done that way, to compress the gasket. That could be why you are having a problem. A new head gasket could be your solution.

-

1951 Dodge B-3-D

9 foot box replied to Pool boy's topic in DPETCA - Dodge Pilothouse Era Truck Club of America

Your wheels are a 6 on 7.250” pattern, with holes for 5/8” wheel studs. W series truck wheels had 9/16” studs. I’ve looked, and there isn’t an inexpensive way around the original wheels. There are 17.5” motor home wheels, but tires are pricey. Stockton Wheel can make new drop center wheels, probably $300 each now. If your wheels and lock rings haven’t been beat too bad, I would use those with new tires, tubes and liners. Bead blast and paint the wheels and rings. I do my own wheels and tires. I won’t pay what is charged now, to fix a lock ring wheel. And I know it’s done right. You might consider posting in the truck forum.