9 foot box

Members-

Posts

639 -

Joined

-

Last visited

-

Days Won

15

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 9 foot box

-

I have that taller manifold for an engine going into a 47 WD21 that I’m working on. I like it for the higher flow and the disc at the bottom to atomize the gas better. I have one from another W series truck, without the disc. A S15 Desoto 251 that I have has the tall intake, as does the 49 Chrysler Spitfire in my 47 flatbed. I haven’t taken the carburetors off to see if there is a diffuser disc. The manifold is 47 and earlier in my opinion, and used on the one ton 230. The 251 engines had the taller intake port at least till 1952. The B series truck engines that I have, are short intake, like my cars. Your manifold appears to have the disc. I can only presume that atomizing the gas at the single port at the center of the block would be an improvement in performance or fuel efficiency and keeping the gas suspended in the intake manifold for the other cylinders to intake.

-

LED running lights and halogen headlights for my '47 Super De Luxe

9 foot box replied to 46Chris's topic in P15-D24 Forum

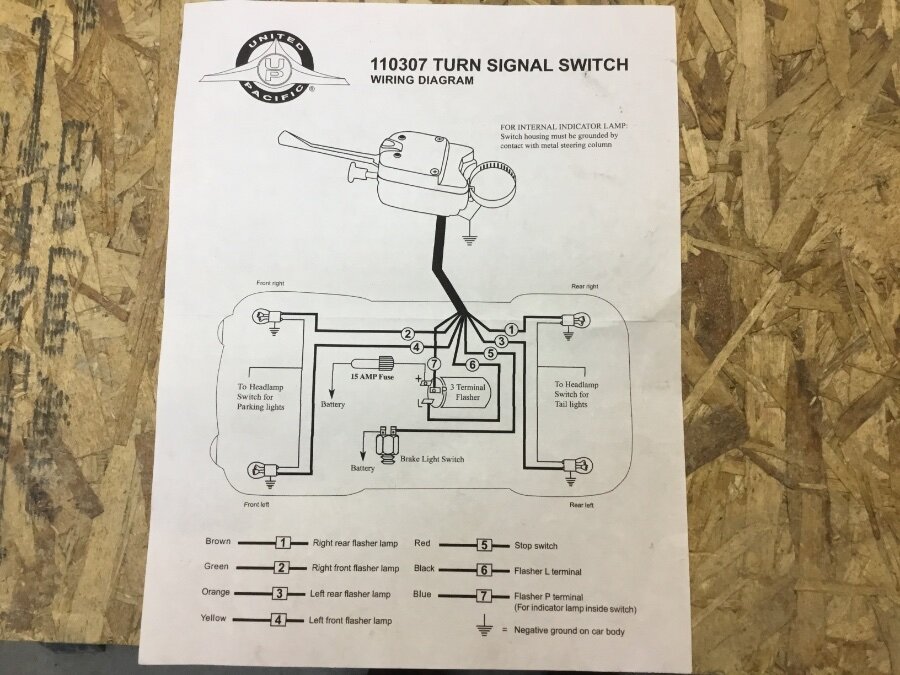

This is diagram of the signal switch on my milk truck. With the 5 wire connected to the brake switch, it will show braking, turn signals and four way on front and rear lamps. The center trunk brake light on your car should be a single contact bayonet socket. Run a single wire from the proper socket to the brake switch and terminate the 5 wire, so only the trunk light shows braking and doesn’t go through the turn signal. At present, I use an 1129 bulb single contact bulb on my center light, and 1154 double contact bulbs, front and rear. -

I had to weld the bearing surfaces on the worm, turned down and new 68-3571-A bearings, gaskets and seal from Dennis Carpenter. It wore in and I took out some gaskets and readjusted. This was on a 41 that had been changed to R&P, I replaced with parts that I had. To do it correct and guaranteed, I would have Power Brake X-Change Inc. rebuild it. My truck needs more attention than a $500 steering column. Rick D.

-

There is an Autolite Service Parts Catalog online, for referencing. The coil for your car is a IG-3224-JS. Another reference source is “ply33.com”. What stage of getting your car running are you? Can you post a picture or two? Others with similar models may message you regarding your project. Now that you are participating, maybe you/we can get the car roadworthy. You will need a Service Manual. Rick D.

-

LED running lights and halogen headlights for my '47 Super De Luxe

9 foot box replied to 46Chris's topic in P15-D24 Forum

The flasher pictured is 68934 neg. ground. They sell a 84787 flasher for pos. ground. -

LED running lights and halogen headlights for my '47 Super De Luxe

9 foot box replied to 46Chris's topic in P15-D24 Forum

I looked at the taillight bulbs on my 46, with turn signals. The bulb is a 1154 that is Index style socket, not 1158 Bayonet. The front are probably the same, because I don’t have any 1158’s in stock. I would need 97465 for the taillight on my car. I have used the brightest 1129 bulb for my center brake light. I mention this for others that might want the LED bulbs, check the socket for pin orientation before buying. This is an old bulb download that I found. I’ve posted it before. -

how do you lubricate this 41 alternator?

9 foot box replied to GTfastbacker's topic in P15-D24 Forum

This generator doesn’t have a plug above the wick, it should have one. Your picture shows a plug. As previously mentioned, it would be easier to install a dry wick from the top. Here is a picture of where oil is added. Swivel the tab to expose the hole. You haven’t watched the video on You Tube or you would have seen how the bushing has a notch milled into it, so the wick draws oil to the shaft and bushing. A lamp wick has a different absorption rolled into 1/4” hole than a felt wick. It’s the wrong fabric, in my opinion. Your rear bushing is already compromised by seeing the bronze particles in the end cap. The service manuals don’t tell us how to change a rear bushing, but I think that video on You Tube explains a lot. You can’t over fill a rear bushing, the oil will run out the vent. Over oiling the front bearing can pollute the generator with oil. -

New guy here: 1949 Plymouth Super Deluxe

9 foot box replied to 1949plymouthdeluxe's topic in P15-D24 Forum

Buy a Service Manual, the proper way to tighten the steering is to remove gasket material at the end cap first, for major adjustment to the worm gear. Then tighten the cross shaft for free movement for minor adjustment. The best manuals are used and have a grain type cover. -

That style coil was a hot wiring theft deterrent on Dodge trucks till 1947. The coil mounted on the firewall and the hot negative wire was shielded to the back/bottom of the coil from the dash mounted key switch. The pos. terminal wire went to the distributor with the coil wire and went through this style of wire loom that was bolted to an accessory type head bolt, not to the side of the head, like later model plug wire looms with coil mount studs.

-

how do you lubricate this 41 alternator?

9 foot box replied to GTfastbacker's topic in P15-D24 Forum

There is a You Tube series by Steve Blancard. “Autolite GDZ4817A Generator Repair”. His 8th video shows the end plate and how capillary action of the oil in the small reservoir lubricates the bushing and shaft. If you find a material that will suffice as a wick, pull the top plug and insert it dry through to the reservoir, soak it with oil and put the plug back in. I was mistaken as to what generators that I have. Here’s two that show the wick. McMaster Carr sells wick material, but you have to buy 5 feet of it @ $3 and change a foot, depending on size. You only need about 2”. An oiling cap like the one on the front won’t work with that style end plate. An other option is to replace the bushing with an oilite style bushing that has been soaked in oil. The bushing probably needs replaced anyway, because it’s been run dry. That’s your copper residue. It will eventually ground the armature to to the field coils and you will need a new generator or change to an alternator. I like to Keep It Simple Sometimes and do preventive maintenance before it fails. -

how do you lubricate this 41 alternator?

9 foot box replied to GTfastbacker's topic in P15-D24 Forum

-

how do you lubricate this 41 alternator?

9 foot box replied to GTfastbacker's topic in P15-D24 Forum

Your generator is different from what I have. I don’t have the screw on end cap. I looked for a service manual for you and found one for $38.60 on eBay. It was the only one that showed a few pictures. Most reprints have bad picture quality. Shipping to Germany is another $35. A Service Manual is essential to the maintenance of your car. It will have the information needed for repairs, adjustments, maintenance and troubleshooting. I can’t guarantee if the pictures are a bait and switch, but that’s the service manual I would buy, if you find the same post. It does say almost gone. Rick D. -

Some cars used a simple rectangular weather strip adhered to the trunk lid. It uses the body channel as a gutter and is easily wiped clean, when needed. That’s my preference.

- 5 replies

-

- rubber

- weatherstrip

-

(and 3 more)

Tagged with:

-

Maybe this is the “front disk brake conversion” post that Hookieroot was looking for.

-

Check the vented gas cap. The button can stick from humidity in the filler neck. It’s been awhile since anyone has mentioned it, but it happens.

-

When I built my home/shop 26 years ago, I had mice. I bought a couple Pest Raider III ultrasonic units and put one on each end of the shop. They are powered by an AC adapter to 12 volts to the units. I have no indication of mice in the building or my cars. I had a unit fail and had a hole in a dog food bag. I replaced the unit and the problem went away. Maybe something like that, solar powered, would keep the mice away from your sedan.

-

The stock forward generator bearing is 602454. A 6203 has the same dimensions, 17x40x12mm. I believe that a 6203-2RS is the sealed bearing that you would use.

-

Your original wiring had two wires, tail lights from the headlight switch and brake light coming from the brake light switch. You need three wires to the rear of the truck. One for tail lights, one for left and one for right. You need to change the wiring so the brake light switch is wired through the turn signal switch. I like to keep mine from the cab, color coded to brown-tail lights, green-right turn and yellow- left turn. The color of the wires are different on aftermarket turn signal switches. But I would wire the rear lights like I would a trailer. Maybe that helps.

-

Dodge and Plymouth cars used a 146 tooth flywheel up to and including 1956. You could use an MCH-6001 6 volt starter till 1955. In 56 they changed to 12 volt and used a one year only MDG-6001 or MDK-6002 starter. In 57 they changed the flywheel to 172 tooth count and used an MDL-6004 starter. All the starters are 9 tooth bendix drive. Rick D.

-

Vintage Power Wagon.

- 16 replies

-

- head bolts

- 230

-

(and 1 more)

Tagged with:

-

That is what I was wondering, from the picture. You can’t have PCV and a draft tube.

-

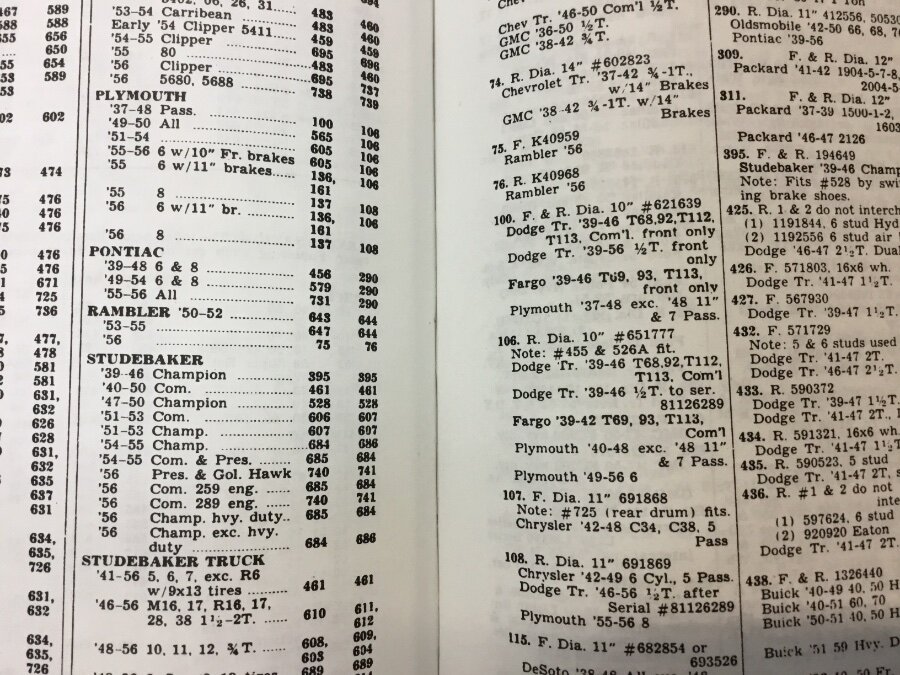

If you’re not familiar with a Tod Fitch web site, you should be, it’s “ply33”. In group 22, it shows brake drums from 1936-48 used the same front and rear brake drums. Evidently the same drums with 10” brakes were used until 1956.

-

There is a vendor, Old Parts Source, that sells on eBay as old.parts. They sell a BD1976 brake drum for $95, but almost $60 delivery. The ad has a Kanter banner on it. The eBay item #312278878867. I don't understand how the Rockauto drum didn't fit, if you didn't use the hub from the broken drum.

-

hbrepair.com, Dale Manufacturing. He might be retired. He is in Salem, OR. The other one that I found is Damper Doctor in Redding, CA. I chose Dale at the time, because he was an independent, hands on business. The other is probably good, but I went with Dale. Rick D.

-

I had to try it for myself. I used a 2003 D Honest Abe penny. I just show one picture, but I have another through the driver side window showing oil pressure. This is on my 49 first edition Coupe, I did have the harmonic damper rebuilt on both Coupes. I think the quietest engine I’ve been around was my wife’s 36 Hudson Terraplane 4 door sedan. It would easily pass the smooth engine coin test. Cute garage trick though. If that doesn’t work, use a nickel. Rick D.