bkahler

Members-

Posts

1,936 -

Joined

-

Last visited

-

Days Won

37

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I know what you mean. My other project is a Triumph TR6 and Triumphs are just like all of the older vehicle models, they leak.... I guess I was just hoping (i.e. wishing) that it would take at least a few months and maybe a road trip or two before the leaks started -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

No plans to change the cork gasket. It's new, shows no signs of leaking and I spent a lot of time making sure it was installed right. I'm fairly certain the leak is weeping through the threads on the bolt itself. I will say I'm amazed, and a little frustrated, at how many small coolant and oil leaks have been showing up since I added fluids and started the engine up. Sometimes I wonder if I'll ever stop the leaks -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Los, I'm not a fan of RTV sealants either. I typically use Permatex non-hardening #2 for bolts that penetrate oil or coolant cavities. I'll pull the bolt, clean things up and the coat the bolt with Permatex and torque to spec. Hopefully that will resolve the problem I still need to deal with the weeping valve covers. That's for another day.... Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I haven't looked through Bunn's book for a long time. I probably ought to pull it off the shelf and browse through it again. Thanks! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

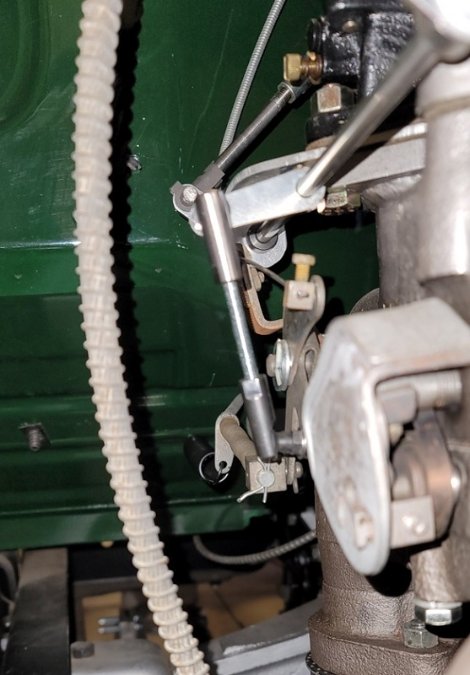

I wanted to check the head bolts one more time and see if I could get the generator to start charging so I pulled the truck out onto the driveway and let it warm up again. This also allowed me to see how well the new throttle linkage was going to work. There was zero movement on the head bolts when I torqued them. I used Merle's method of not backing them off before torqueing. Great success on the throttle linkage but zero luck on getting the generator to charge. I had an electronic conversion done to the regulator so I don't know if the problem is the regulator, my wiring or the freshly rebuilt generator. I did short the battery to field connection on the regulator and it didn't change anything. I have a spare NOS regulator that I will put on the truck to see if that makes any difference. After balancing the carburetors again (due to linkage change) the engine now idles at about 520 rpm and is fairly smooth. There is an ever so slight (+- 5 to 10 rpm) variation in the idle speed but it's hardly noticeable. Response seems to be immediate when I press on the gas pedal which makes me happy Of course, true to form, I found another coolant leak. This time it's on the stem of the heater shutoff valve. The valve is a NOS valve that I picked up from Mitchell Motors about 20 years ago. Hopefully I will be able to tighten the gland nut a little to solve the problem. Also drove it up and down the driveway again and up around the barn. It's definitely a responsive engine. I can't wait to get it out on the open road -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

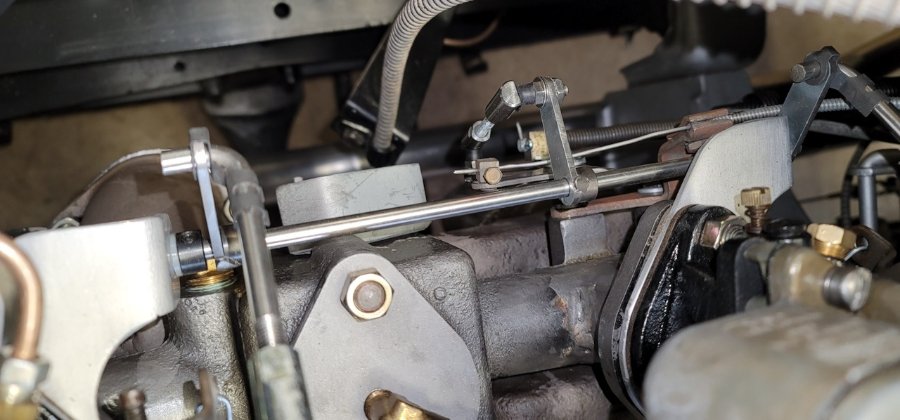

Here's a couple of pictures new linkage arm. One unexpected benefit of the new parts is they remove a lot of slop in the linkage when pushing the gas pedal. I just noticed I don't have a jam nut on the threaded rod, so I think this weekend I'll find a stainless nut and install it. This weekend after I've dealt with the leaky bolt, I think I'll take a test drive around the neighborhood -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

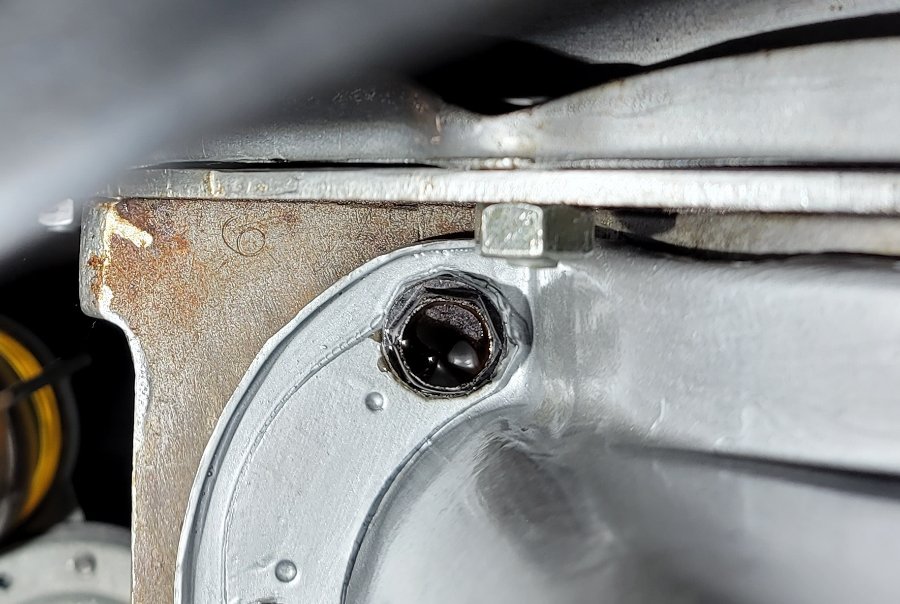

I forgot to look at the other bolts that might penetrate into the block and plan to do so this week. I do know it's the only one that left an oil spot on the floor. I spent a lot of time and effort installing the oil pan gasket so that it wouldn't leak and so far it's just that one bolt that seems to be a issue. This weekend I plan on removing the bolt and then evaluating what to do about it. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

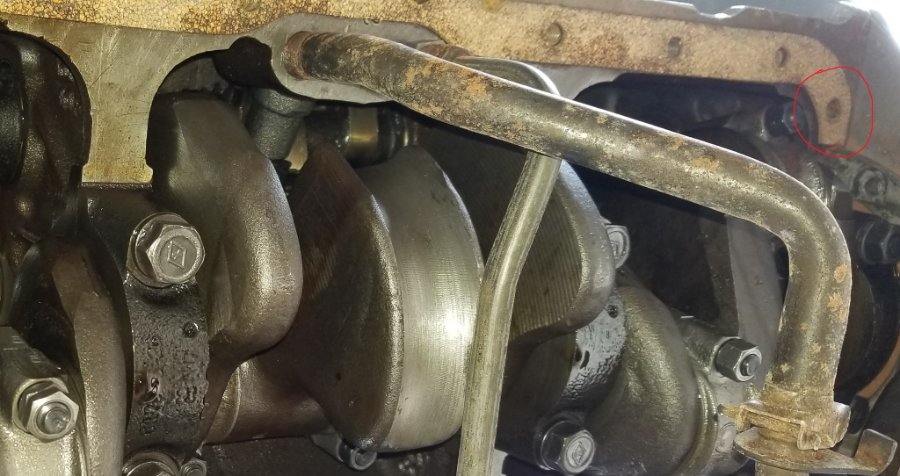

This weekend I corrected the throttle linkage binding issue by replacing the vertical link with two ball joints and a threaded rod. So far it seems to work just fine. I'll grab some pictures tonight and get them posted so you can see what I ended up doing. Recently I noticed an oil spot on the floor that had not been there previously. Crawling around underneath the engine I found the right front bolt on the oil pan was dripping oil. Oddly enough the oil only seems to be on the bolt head and around where it meets the pan. I can't find any indication that the oil flowed from some other point on the block. Here is a picture I took of the underside of the block while I was replacing the oil pan gasket. I've circled the offending bolt in red. Most of the oil pan bolts are through bolts on the outside of the block. This one appears that it might open up inside the block. Anyone else have problems with oil weeping through the threads on this bolt? -

Carter Ball & Ball throttle shaft source?

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

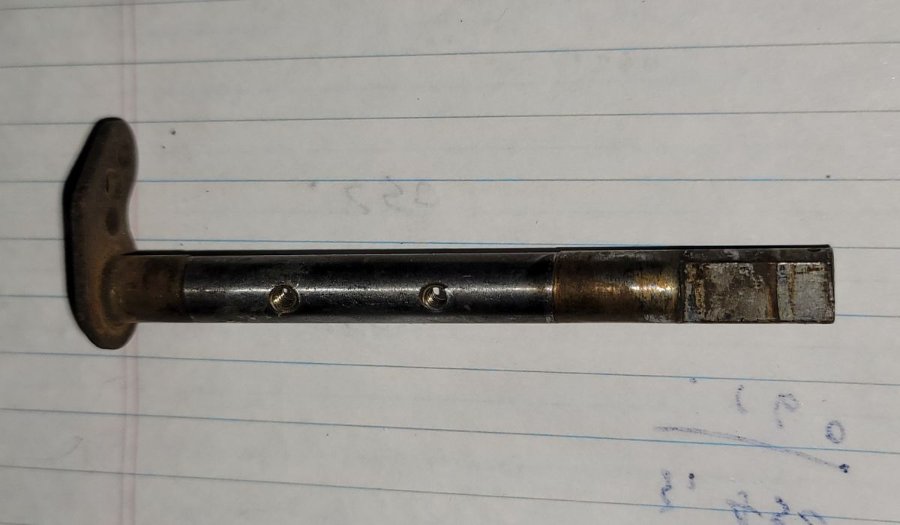

I might have had a stroke of good luck over the weekend. I dismantled three of my spare carburetors and found that two of the throttle shafts were brass instead of steel. The third one is currently rusted in place. What surprised me the most was the brass shafts seem to have little if any wear. Even the throttle shaft bores in the cast iron bases seemed to be in good shape. I've placed all of the pieces in Evaporust and will be pulling them out in the next day or two to see how things really look. More to come once I get the parts out of the Evaporust. -

Sweeper Clips and Weatherstrip

bkahler replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

My 51 B3B had the chrome beads up. -

Carter Ball & Ball throttle shaft source?

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

DTE1. Unfortunately shafts do not appear to be available aftermarket. -

Carter Ball & Ball throttle shaft source?

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Sorry about the delay in responding. Got side tracked cleaning up downed tree limbs from the last storm. The Carter number is 3-449S and it doesn't show up in any searches which doesn't really surprise me. I've got 7 of these carburetors on hand and all of them have at a minimum bad shafts. The one base casting that I have dismantled might be useable and I'll know more once I get a piece of 5/16" drill rod in my hands. I should in theory have one tomorrow but more likely it will be Monday. Since I have so many base castings I will likely install bushings in a pair of them using Thermoplastic bushings from MSC. That leaves fabricating some shafts. This particular shaft has over .007" of wear in parts of the shaft. The only difficulty in fabricating replacement shafts is the arm that is peened onto the end of the shaft. I'm going to make a slight design change in this end of the shaft to facility easy installation of the arm. On my Triumph TR4 the SU Carburetor shaft has a very similar arm but instead of being peened in place the shaft is threaded on the end and a nut holds the arm in place. I'm wondering if it would be more beneficial to have the new shafts made from brass rather than steel? The machinist I talked to suggested tool steel. Ball park price for each shaft was in the neighborhood of $40 each which I don't consider bad at all. What would be ideal would be to find a CNC shop that could make a run of these shafts. Thoughts? -

The title says it all. Anyone know of a source for new replacement throttle shafts for the B&B carburetors?

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Last night I lengthened the threads on the two throttle arms and the fit now looks to be good. While making the adjustment on the front arm I realized why I wasn't getting full throttle opening. When I was fabricating the linkage for the dual carbs I reversed things a little and I ended up causing a jamming point between the vertical rod and the throttle pull cable pivot arm. It's not a big problem but I did order a couple of right-angle swivel joints and will fabricate a new arm that will allow full movement of the throttle. I did find another problem while installing the throttle arms. Both throttle shafts fit within the throttle bodies are really loose, i.e., sloppy As I was fiddling with the linkage, every time I pushed on the pedal the accelerator would squirt gas down the bore and some of it started dribbling out of the throttle shaft openings. That kind of leak will certainly affect idle adjustments among other things so it's time to fix the issue. Back in 2008 when I rebuilt the carbs I knew they were loose in the bores but didn't have the equipment/tools on hand at the time to do anything about it so I ended up kicking the can down the road. Fast forward to the present. What I plan on doing is boring out the throttle shaft openings and installing bronze bushings. It's a common fix for this problem and shouldn't be too difficult to resolve. Just another case of 2 steps forward, one step back. I seem to be experiencing a lot of those with this truck Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Once I get my truck front sheet metal and doors installed, I'll definitely be taking some test drives By the way, Nice looking truck. I love the color ? -

I plan on following Mere's suggestion doing at least a third re-torque. Also as Merle suggested, this time around I won't back bolt off 1/4 turn, I'll just try torquing to the required value. It will be interesting to see how that works out. Stay tuned.....

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Yep, it's a beautiful property. Almost all of the trees along the right side are gone. Between the power line risk and pine needles 1" thick on the driveway I just got sick of them. Sounds like a nice place to grow up -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

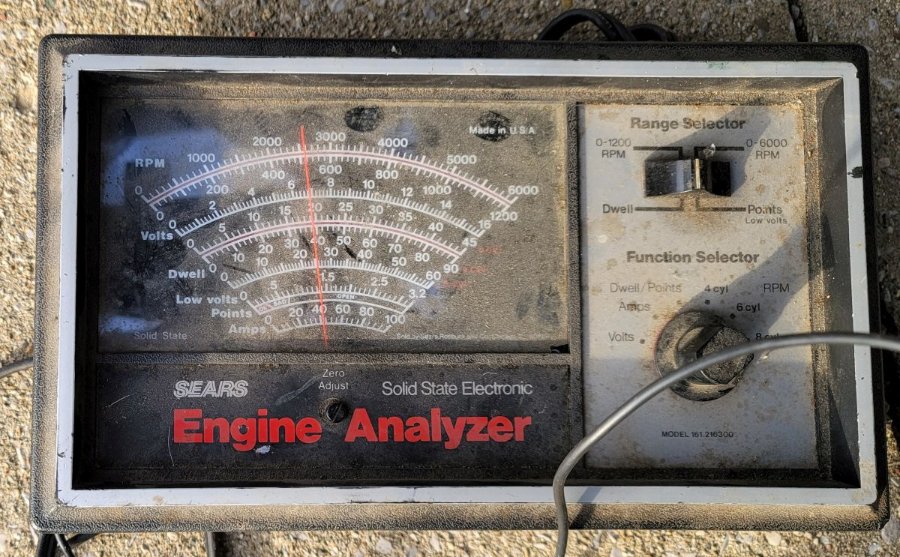

Weekend update. Didn't have a chance to do much until Sunday afternoon. I finally rolled the truck out of the garage and started it up with the goal of tinkering with the idle speed and getting it hot enough so I could re-torque the head bolts. After a couple of revolutions, it fired right up and started idling at about 1200, same was the break-in period. After it warmed up a bit, I checked the carburetor balancing with a Uni-Syn and found that the front carburetor was pulling a lot more air than the rear. So much so that when I placed the Uni-Syn on the front carb the idle really dropped and the engine almost stalled. I then disconnected the throttle linkage from the two carburetors and immediately the idle dropped down to about 800 without me touching anything. The main reason for the idle problem ended up being the linkage arm on the front carburetor was forcing the throttle open a lot more than I anticipated when I original fabricated everything. The front arm needs to be shortened by possibly as much as 1/4" to provide a good adjustment range. I'm not sure why but the rear arm is almost 3/16" longer than the front but fits just fine. I need to spend some time and revisit all of the throttle linkage to make sure I haven't missed something somewhere. At this point the carburetors were now independent from each other, so I was able to better dial in the idle settings for each carburetor. At one point I had it idling down around 450 or so although the idle was pretty lumpy at that setting. For the time being 600 to 650 seems to be the best idle point. I'll know more once I can check the plugs to see how they look. Due to the issue with the front linkage, once I reconnected everything the best idle I could get was about 800 or so. I'll spend time this week reworking the front linkage. I successfully re-torqued the head bolts and then drove the truck up my driveway, turned around and drove back down. I have a gravel driveway that's about 1200 feet long and there is a long slow uphill rise in one area and the back end really bounced around as I was heading up that stretch The truck has a stiff suspension to begin with and with no weight on the back end you can imagine what it felt like Other than the carburetor linkage the only other item of concern is the generator only seems to be putting out 12.8 volts. My regulator has been converted to solid state and if I remember right, I was told I shouldn't have to polarize it. I'm going to revisit that issue to see if maybe that isn't the problem. It's a freshly rebuilt generator along with the converted regulator. Brad -

I've known other people doing the same thing with no issues reported. Do you do this more than one time (heat cycle) or do you repeat until the bolts stop moving? I ran the engine for about 20 minutes yesterday and right after shutdown I re-torqued the bolts. I was surprised that I was able to get another quarter turn or more on each bolt. I'm not used to that much change.

-

That is a heck of a find.

-

The cat nonchalantly coming out from behind the tire is hilarious!

- 717 replies

-

- 1

-

-

THAT is a scary unloading operation Just doesn't look stabile enough for me.

-

That's the spirit

- 717 replies

-

Merle, thanks for the info! I didn't have easy access to my shop manual last night, just my computer tablet. Next time I have the engine running I would like to try and check the valve lash and also re-torque the head bolts. Which reminds me, in the past when I've re-torqued my Triumph engines, I always loosened a bolt 1/4 turn and then torqued it back to spec, doing so in the normal torquing sequence. Does this same process apply to these flatheads?

-

Back in 1998 I purchased all of the engine rebuild parts. The only cam I could find was a 230 cam bought from Andy Bernbaum. My engine builder didn't think it would be an issue especially since the engine was being bored .060" oversize which puts the displacement at 226 ci. The valves were adjusted by the builder at the time of the build, but I don't know what numbers he used for setting the valve lash. Last night I started looking for specs on the 230 cam and found what appears to be early and late grinds. However, I was not able to find anything about valve lash settings. It was getting late, and I finally gave up. I figured asking the gurus here will likely give me better more detailed answers anyway So, the question is, what do I set the valve lash at? I'd like numbers for both hot and cold if they are available. Thanks, Brad