-

Posts

8,230 -

Joined

-

Last visited

-

Days Won

93

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by ggdad1951

-

get that drill out!

-

I've seen so many and heard of so many people like that....looking for that last dollar and then when they are gone the kids don't care and just get scrappers....and then they are gone forever. Sounds a lot like a song we all know by Neil Young..... As for the value...yah it's tough...a good survivor is worth it if you can swing it....save the money on the paint/body work and think of it that way? Try to find a parts book maybe and you might see what what standard for what and such (ornament might not have been part of the build). I know next to nothing about the C series so that's my best advice. I don't know if Eric Bannerman's decoder tool works for C series trucks or not.

-

what's sad is he's a multi millionaire and looking to make a few grand vs. finding these vehicles a new home before he passes along. Likely if not sold they all will be crushed as it seems his kids don't care to do the work.

-

I'm bummed I won't get to see this work of art in person

-

51 B3B build thread - after all these years

ggdad1951 replied to bkahler's topic in Mopar Flathead Truck Forum

Yah if rabbiting the outside edge is a solution, we won't tell anyone and no one will know the difference except those you tell. -

51 B3B build thread - after all these years

ggdad1951 replied to bkahler's topic in Mopar Flathead Truck Forum

When I built FEF, I sent QR my back panel as a template for these. Before they were making them in 3 pieces and weren't correct. They aren't hard to install at all. Just gotta get the lip started and work it around. -

Now you are thinking like a Minnesotan!

-

Its just to remind ya all of what real cold is.

-

New B-3-B owner with some basic questions

ggdad1951 replied to ktb's topic in Mopar Flathead Truck Forum

good idea -

LOL BWHAHAHAHAHAAHA Yesterday when I got up the temp was -15°F with a windchill of -53°F.

-

I just grabbed the side that was on top....it was driver side.

- 712 replies

-

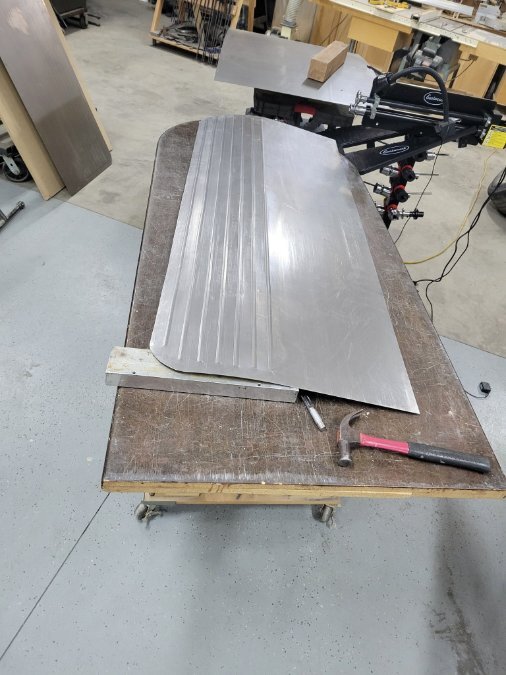

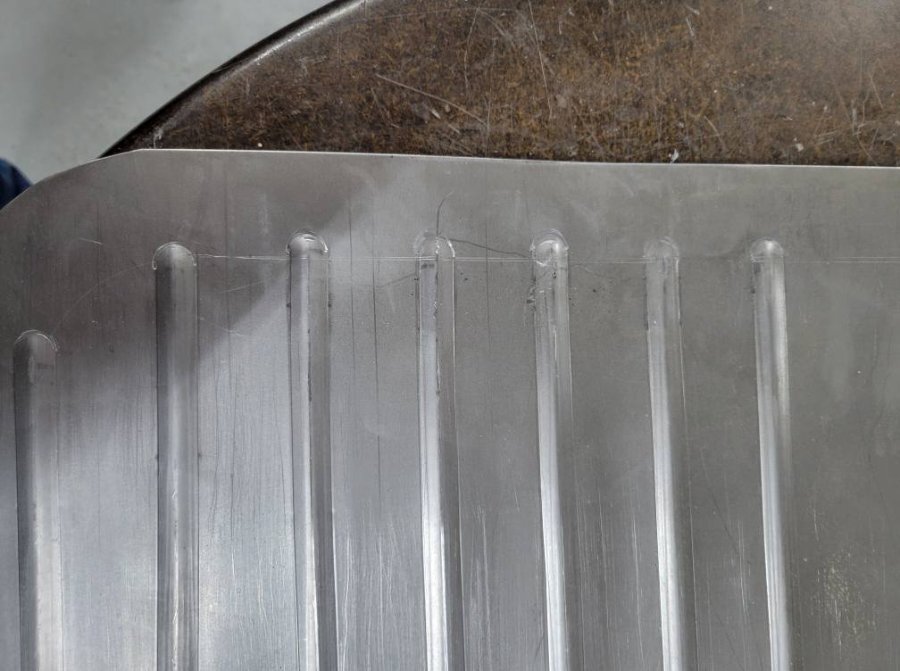

Passenger side done....as usual the second one looks better...I figured out a way to jig the beads so it would run straight. Way less stress on me and a better look.

- 712 replies

-

- 4

-

-

51 B3B build thread - after all these years

ggdad1951 replied to bkahler's topic in Mopar Flathead Truck Forum

Did you get them from DCM? I believe the parts I had made and sold to them had a hole for a cotter pin. JIC so it can't drop out...no reason you can't put another hole in or drop a spacer in. -

You can also stain wood with inks....

-

Base coat..

-

- 712 replies

-

- 3

-

-

My original bed wood is long gone in the fire pit, but I can tell you the countersink was factory and not a repeated tightening of a bolt. Wood in my bed was not by any means all rotten, was actually in decent enough shape, just not resto quality. From a factory setting, the rabbits and a counter sink are not that big of a process to do and litterally the right thing to do for someone that woudl be shoveling. I'd say countersunk factory.

-

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Have fun w/o your MN backup this year....at this point I am unable to commit. -

Actually a pretty simple hammer form I'd think?

-

Several things need to be cleaned up in the window slot, a different front channel and a different glass channel.

-

I went for it yesterday on the first running board top skin. Those long beads are tough to try and keep straight. Did I? Mostly.....at least its gonna be Rino Lined and not gloss back!

- 712 replies

-

- 4

-

-

51 B3B build thread - after all these years

ggdad1951 replied to bkahler's topic in Mopar Flathead Truck Forum

Sawhorses, 8x8 chunks and 2x4. My fuzzy memory says I used 3 sawhorses (2 sides 1 back) and used blocking to support the fron so I wasn't on the bed sides. Rear was just on the tail stock piece. You have a hoist tho and there are good ideas out there to lift the bed with that. Just be careful to not deform the bed side tubes with point loads.