-

Posts

1,548 -

Joined

-

Last visited

-

Days Won

19

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by mrwrstory

-

I think I've been on that road. Nuthin like the back roads and the view from an old car.

-

I'd suggest "gusseting" the shock mount where you show it tacked to the side of the frame. The frame material is .080-.090" at best and the shock bracket material is probably .375". You can rip a chunk right outta the frame with a good impact. Gussets or some sorta plate under the .375" material will spread the load.

-

Tx guys. Great looking car. Tony, try reducing the size of the pic or cropping it to a smaller size or,...emailing to yourself and then coping that image..

-

Without a pic,....they didn't exist.

-

Welcome Tony. How about a picture or two. A 39 Plymouth 3 window is a new one to me. I can imagine what one would look like but never have seen one.

-

Ooooh! A Hemi in your Windsor would be so cool! Significant job but I think no more difficult than most swaps of a V8 where a 6 wuz. What I think of is the transmission. Probably a 2 speed automatic right? Just boring hardly worth the effort in my opinion. I'd suggest a manual or a later model automatic. Probably are some Mopars that bolt right up. The steering column will be an issue as well whether Hemi or other V8. Mopar just slide the engine off center to the drivers side which seems like an ugly fix but once done no one even notices. And hopefully you'll hear from "Wayfarer" who is near Bend. He's a hands on guy, has lotsa Hemi experience and is generous with his information.

-

I think you got your answer! If so inclined, shoot me a PM and perhaps we could have a breakfast or beer in So Cal. with a few other car nuts.

-

-

I have a coupla car buds and we have breakfast together quit often. Steve asked me to drive his 41 pickup because he was particularly pleased with the transmission that was recently rebuilt. Before the cruising was over, the three of us had all swapped to the others cars. What a hoot and what a great idea it was. If you feel good enough about your car and have friends you trust, it's a new dimension to enjoy. Maybe the best part is seeing your car on the road, as others see it. However too, it's a great opportunity to enjoy the seat of the pants experience of anothers' ride. I am going to propose this to others in the future.

-

If you just look at the A--arm it's pretty obvious. One of those "damn, that's too easy".

-

Good friend Jim Dugue' introduced me to this forum after buying a '40 woody pile of kindling about 100 years ago. He's still working on it. I sent him this link for inspiration. His will be spectacular too,......some day.

-

-

Great project! New springs will be waaay tall. They will settle some. Understand that cutting a coil or so while lowering some will also stiffen the ride. And your 318/904 probably weighs a little less and the center of that weight will be further to the rear. I'd suggest start with the stock springs and cut from there. Also respect the location of the stock core support and look at mounting the radiator on the front side for more engine clearance. And, and,....don't be afraid to mount the engine off center if need be for steering/manifold clearance. Mopar did that for years and nobody notices. Keep the pics comin. We love pics!

-

Not to take exception to the Drs comments, I agree to the frailties of the MII frontend kits. Re my project and my complete satisfaction and trust, the Kugel crossmember is a complete assembled package with the MII geometry established. A more robust unit. Not a bucha parts to piece together with the "long bolt" that can become the weak link.

-

Greg, Tx for the tip. Nothing there. Probably a time when I did not choose that option over PhotoBucket which I no longer use.

-

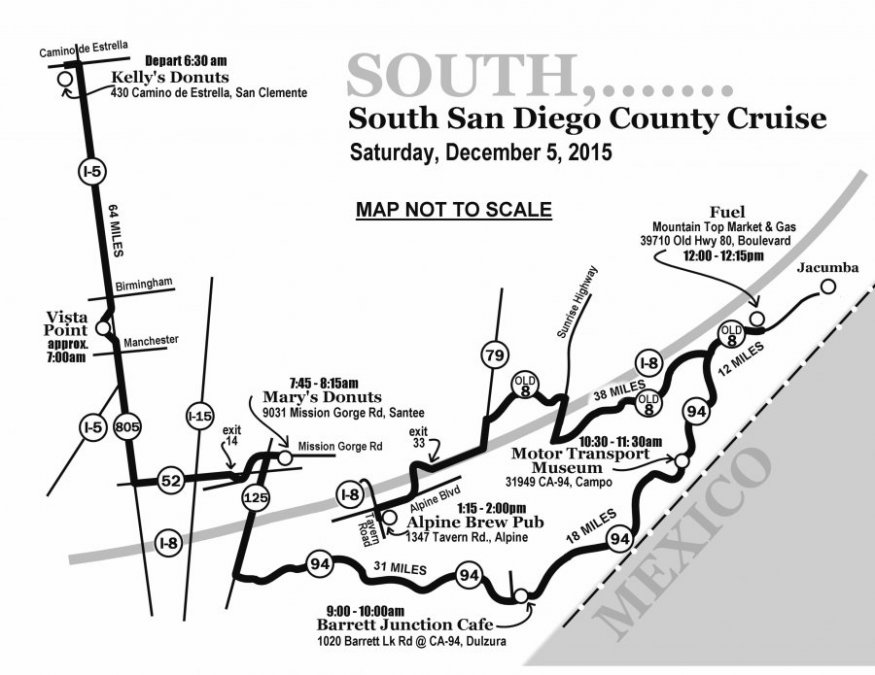

and doing Paint Shop Images for flyers to events where I participate. always try to learn something on the computer

-

-

I decided to get on top of this subject 'cause I had no idea where to find the old pics. Succeeded in the hunt. Check the attached. Gime a shout if you have questions.

-

Oops!!!! Egg on my face, eh! Missed that even after viewing your extensive video record. I still like your car and the impressive project you have taken on. And I still like Safaris best!?

-

How cool!!!!!!!!!! Great looking car. Even better than a Gomad. They're all winners. That said, if you have that big piece of stainless side trim, it's a rare piece and it would be nice to show it off.

-

My understanding is that in Calif. plates cannot be repainted/restored. However it's kinda like a "don't ask, don't tell", deal. That said, it's done all the time and the reg. would not discourage me from doing the resto I have put off for years. I saw a really nice and believeable restoration of plates a while back where the owner used two panels of MDF or plywood connected by a door hinge. The plate, with background color previously applied, was attached (face up) to one side of the panel/hinge assembly. The opposing panel was liberally coated with the second color and while still wet the panel mounted plate was rotated "closed", pressing the letters into the wet paint. A little practice and a little tuning gets the surfaces parallel before committing to paint. The result I saw was very convincing as original even to the degree that the color on the letters very slightly wrapped the edges and was very slightly wavey.

-

Another, you can see the weld seam along the center of the stock P15 frame rail

-

Here's an image I picked from my earlier thread where most of the pics are gone. I now have about 35K miles on the modification and couldn't be happier. Please feel free to shoot me questions

-

Yes, great looking car! I did a similar IFS swap on my P15, documented on this forum with photos some years back. I think it's all evaporated by now. I'll do some digging and see if I can come up with some pics. Briefly, I used an aftermarket clip from Kugel Komponents that is designed for early Ford applications. They will make them to accomodate any frame/track width. There are other manufactures who produce a similar concept. The concept assumes a vertical surface i.e. a "channel" frame section at the point of installation. I split my frame from the firewall to the spring pockets in a straight line and at a width similar to an early Ford. I then welded in a 1/4" plate from firewall to spring pocket which yielded two parallel surfaces similar to the outside surfaces of an early Ford frame. The IFS cross member kit slipped over and were welded to the vertical surfaces. The frame haves that were previously removed, were welded back on yielding an almost stock look to the frame.

.thumb.jpg.53bd2a14643d2b1deeaafe61d343adbe.jpg)