-

Posts

478 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Tony WestOZ

-

Coles notes on 12 volt conversion please...

Tony WestOZ replied to laynrubber's topic in P15-D24 Forum

Depending on how it is set up you might not have to change the tubes. The one I am working on came as either 6 or 12 volts. The difference between the two seems to be the vibrator is change for a 12 volt unit and a choke is added to drop the volts from 12 to 6 volts for 6v heaters on the tubes. All the tubes are 6###. Also with this particular vibrator polarity does not matter. at least for a short time run time. I need to check more before I run it full time as a negative earth. -

I went down the same road many years ago. I might not have done it had this type of repair not been part of my work. One of those tools that makes you wonder why you put up with the others for so long.

-

Looks to be a 303 then. This link seems to be the new address of the poly site. They would have a lot more knowledge than I. They should be able to point you in the right direction if you require parts for the engine. 318Poly@groups.io

-

303 = 3.812" = 3 13/16" 313 = 3.875" = 3 7/8" Could you explain "top of the notes"?

-

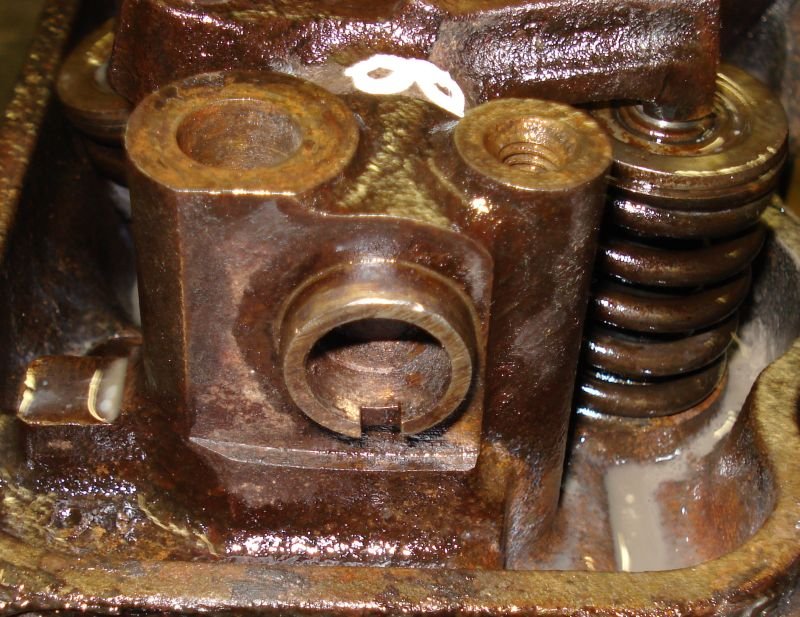

Because we imported our engines, engine date to vehicle date differences were common. Hard to know what happened in Canada but would not surprise me specially as this is a very limited run vehicle. The best way to measure would be to use the type of equipment left of centre in the pic. However that's an expensive way to go for a one off measurement. The internal spring caliper (top right) and a vernier set will give a close enough measurement. It depends on how far you want to go. I like to strip and measure everything before it goes to the machine shop (or scrap bin) then measure everything when it comes back from the shop before reassembly.

-

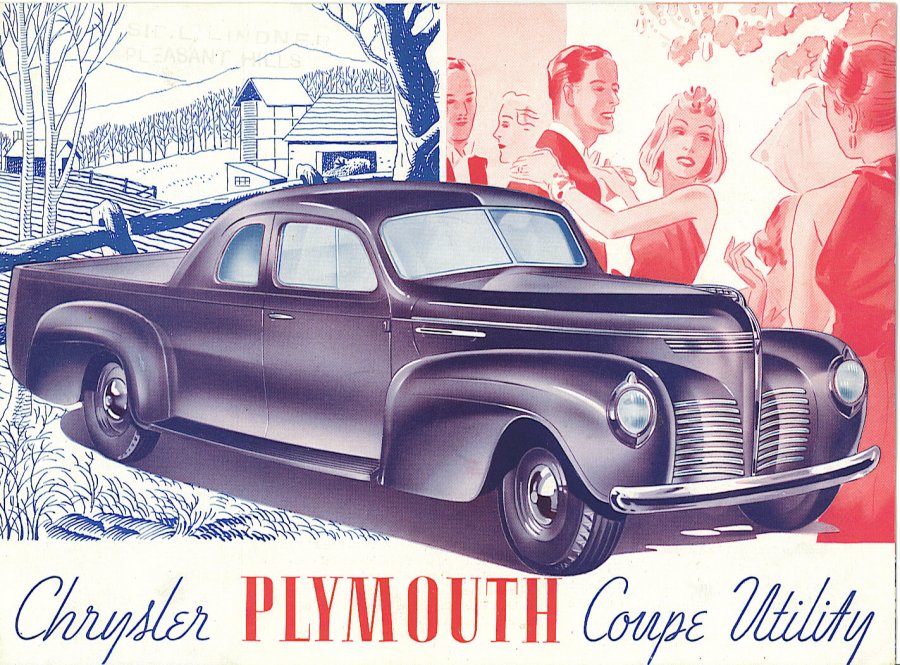

Car based closed cab utes were made from 33 to 1940. I have never seen a commercially available car model from 40 up to 53 as they had the truck based ute and then they stated on the cars again in 53. Not to say there was not a few custom made jobs done.

-

KV-182 62C From what little knowledge I have on Canadian numbers KV is 1957 V8 but it usually relates to the 303 that was in the Plymouths and Dodges cars . However the Custom Royal used the 313 so it should carry the KV prefix as well. The LV prefix is 1958 V8. C at the end is for Canada. The 182 62 I don`t know. Can you measure the bore? Being only one of 3 V8`s it would confirm 303 or 313. Tony

-

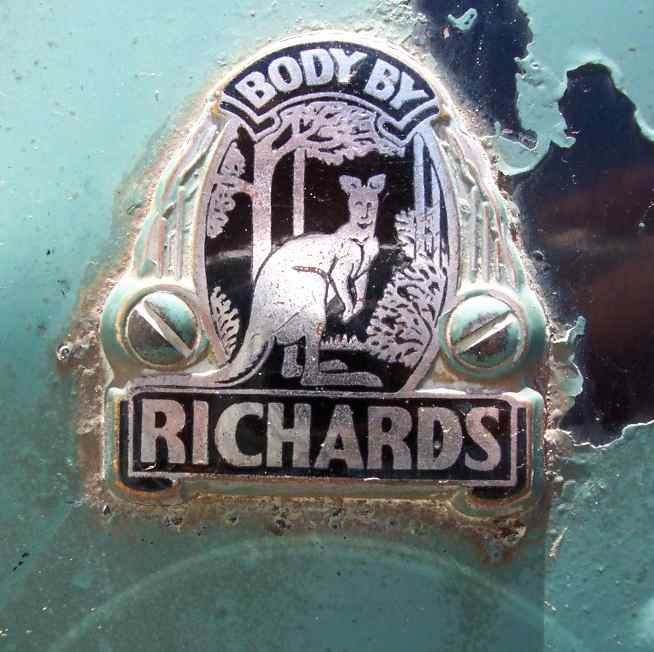

To add to what Andy has said, Firewall TJR stamping ID plate Richards badge Not sure about the Chrysler Plymouth though

-

1618721-1 appears on the two sets of spare heads I have. The numbers to the left are C90 and G148. I have no idea what year model engines these came off. The numbers for the 62 ( I think) engine are 2264095 and 1019 2. They could have came from cars or trucks and I assume they are Canadian as they were the suppler for V8`s to Australia. There use to be a Poly engine site on the net years ago, not sure if its still around but you might try them. Tony

-

Welcome I do love a van. What seat or seats does it have? Tony

-

Glad to help. I envy you. The swept lines never came here.

-

Standard heads for poly`s from 57-58 through to 64. Often called the A model or series. The earlier series sawtooth model I think have the towers that come off. I have never worked on one.

-

Yep. First time I pulled one apart I thought they would be like the LA`s were everything comes off together. If these are the same type of heads the OP has the tower between rocker number six and 7 will have a pin or a grub screw which locks the shaft in place.(its been too long). The shaft will then slide out sideways. Remember to keep all the rockers in order as you slide the shaft out. Tony

-

-

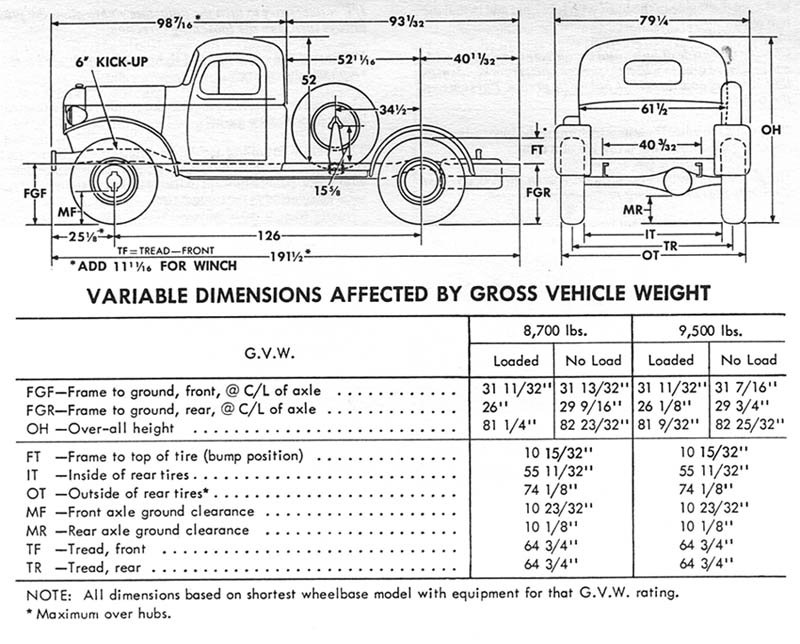

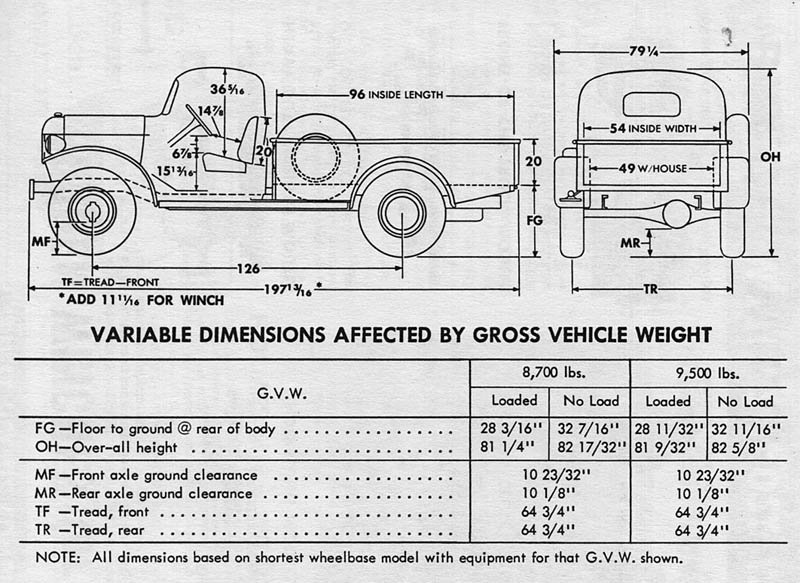

Power Wagon vs. B2B Bed Dimensions

Tony WestOZ replied to David A.'s topic in Mopar Flathead Truck Forum

21 15/16" radius -

Power Wagon vs. B2B Bed Dimensions

Tony WestOZ replied to David A.'s topic in Mopar Flathead Truck Forum

-

What model truck? I am not up on NZ trucks, some seem to have come straight from Canada others from Oz.

-

Power Wagon vs. B2B Bed Dimensions

Tony WestOZ replied to David A.'s topic in Mopar Flathead Truck Forum

-

Power Wagon vs. B2B Bed Dimensions

Tony WestOZ replied to David A.'s topic in Mopar Flathead Truck Forum

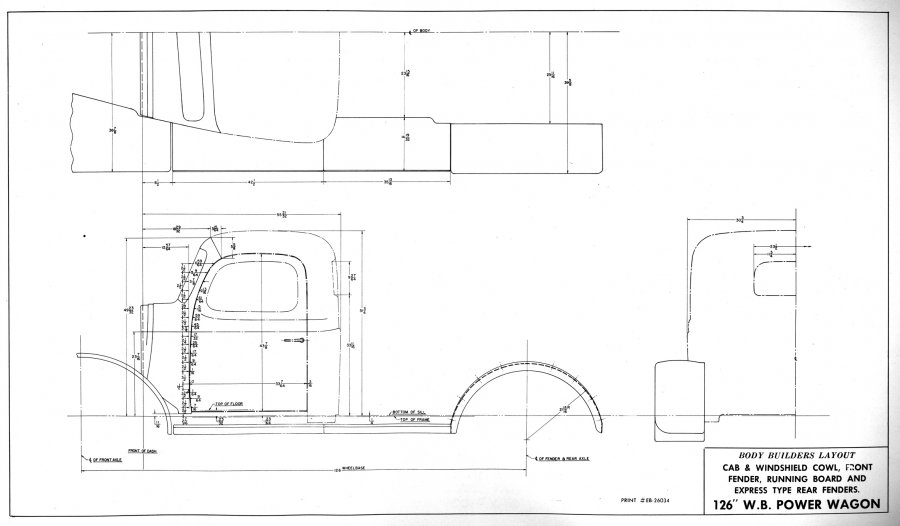

Not sure if this will help. Does not have full tray but it shows wheel arches. PW-128%20WB.pdf Tony -

Those are the usual type that we had out here, Plain steel cover. I have wandered if its an Army thing as that's where the motor was suppose to have come from.

-

This type of manifold was used in trucks and cars here so it needed to be sculptured differently to suit RHD.

-

Were the US or Canadian engines usually fitted with asbestos covered heat shields. This is the only one I have ever seen in this part of the world. Tony

-

No snow here, expecting 40c tomorrow. I have a no number block. Was told it came from an army surplus sale. I do have a question, why the Detroit 4-53T 2 stroke? They were a good engine but extremely noisy and heavy on the fuel. Tony

-

1953 Dodge - What have I got into

Tony WestOZ replied to peteandvanessa's topic in Mopar Flathead Truck Forum

Wooo Hoooo IT WORKS and I have to say a big thankyou for the inspiration to have a go at this radio. I went through and changed out the old paper capacitors for new film type (some not the correct values as I cannot get them locally) removed the cover from the vibrator cleaned and reassembled it. You can hardly hear it now with no volume. There is still a lot to be done. Hopefully a better aerial than the screwdriver I have stuck in there now will clean up some of the static. A lot of wires still to be replaced. I replaced a few badly rotted ones on the way but I did not want to get to carried away if it did not work. I have had 3 or 4 hours listening to it while cleaning the head and cables with a bit of lube being applied where required. It all turns a lot smoother now. I am getting about 6 or 7 channels at the moment from reasonably clear to some real fuzzy ones but its about 2 am here so we will see how we go during the daylight hours. Its going to be a while before I can go Bluetooth, wifi or what ever it is, but I am going to try to cut in the wires and switch to get it ready. Will test it by taking feed from the computer if I can. Thanks again all Tony -

Sorry no only have the one full flow engine they are rare in this part of the world. I have a quire regarding oil flow. Restricting oil to the cam bearing to me is not going to send more to other parts of the engine. These engines are running at 40-45 psi and this is governed by the pressure relief valve. Restricting oil to one place is only going to send more oil through the pressure relieve back to sump. Granted over sizing holes and galleries to the crank potentially will increase flow, but without larger bearing to crank clearances oil flow is not going to increase. Increasing pressure to me is the way to send more oil to various parts. This is of course relative to engine RPM but these engines are known for there long life in day to day operation even if you like to push them slightly over their red line limit. If you want to push these long stroke babies to extreme RPM ok things will require more flow. Back on the original forum there were stories of the guys pushing these engines racing in the day. 5500 RPM was not to much of a problem, 6000 and you went around and picked up the bits you left on the track, went home and started on your next engine rebuild. Lack of oil did not seem to be the problem the strength of the parts spinning at high rpm was their down fall. Tony