-

Posts

787 -

Joined

-

Last visited

-

Days Won

7

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by lostviking

-

You need to get the numbers stamped into the side of the block, drivers side up near the head in the front.

-

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

If you've been following this, you have noticed nothing getting done. I'm married Repairs on the house have taken priority and since I only work (mostly) on the weekends, it has taken some time. I am finishing up the last of the paint and plaster work this weekend, I hope, and will get back to plumbing the brakes next weekend. -

Take the plug out of #1. Take the cover of the lifters. Put your finger over the #1 plug hole and rotate until it's pushing air out...and the lifters are both on the base circle of the cam. Unless you want to take the head off, that's probably the best you can do to getting it to TDC. Figure out if that mark is anywhere close. Personally, I'd take the head off and indicate TDC, then mark it again so I know it's in the right location. You can't assume that someone else put a mark in the right place. Obviously, something is not marked correctly...I doubt the engine would run at all if it was 30 deg's off. I'm married, so I've been wrong before.

-

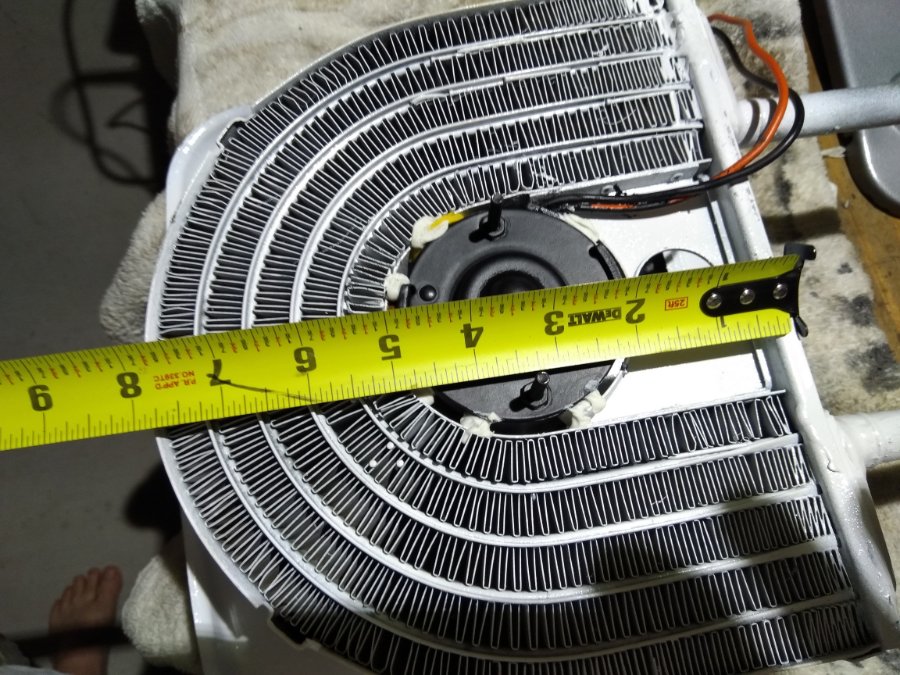

Mopar 36 heater core fabrication

lostviking replied to Greg W 41 Dodge WC's topic in Mopar Flathead Truck Forum

I took a scan through the cores in that link, however I didn't see any that would be a replacement. At least not for the heater I have. It's a U shaped core. -

Mopar 36 heater core fabrication

lostviking replied to Greg W 41 Dodge WC's topic in Mopar Flathead Truck Forum

I got lucky and mine was fine in a pressure test. I did think about how to fabricate one in the event I had to. My plan was to have sheets of copper cut to form the fins, and use a couple tubes. I was going to push the "fins" over the tubes one at a time, solder them and push the next one on. For me, my time is free. Tim -

I hope my previous post wasn't taken as an insult. It certainly wasn't intended that way. I was just curious why you chose that particular rear. Tim

-

Why would you go with such a small rear? The Ranger 8.8 is a great rear and easy to find and the Jeep 8.25 is almost the exact same width and also easy to find. I personally just finished installing the Jeep in my 46. I'm really curious why you would use such a weak rear end?

-

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

I pulled the axle out from under the truck today and welded the spring perches on. I was set at about 120A on the welder and ran about 1 inch at a time, moving from side to side as I went. My welding skills are crap, but I did see the weld pool wet out onto the metal, so I think it's a decent weld...for a beginner. I painted over the weld area's with some self etching primer, then satin finish black. After I put it back in, I noticed I missed a bunch under the axle. Of course. Got it back in, with the U bolts tightened up. Due to the thickness of the spring pack, they just go past the top of the nuts. They are at least 1 inch tall nuts though, and I'm going to remove a few leaves later on. Put the U joint saddles back on to connect the driveshaft and called it a good day. Almost forgot, I still need to fab lower shock mounts to replace the ones that were integral to lower U-bolt (not really U) plates. I do have a plan, hope it's a good one -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

In between working on the bedroom's ceiling repair, then painting it...I found enough time to crawl under the truck today. I measured the trans output angle at 1.6 degrees and my eyeing the rear end seemed pretty dead on at also 1.6 degrees. I put a couple tack welds on the rear inside edges of both spring perches. Next I pull the rear again so I can fully weld the mounts. I've got new spring center bolts so I can remove a few leaves, but I'm going to get the truck mobile again first. If the rear end moves up a 1/2 inch or so, that doesn't change the angles so I figure I can do that later. First get the rear fully installed and get the brakes plumbed again, bled and working. -

What make it beyond repair? Block? A 218 block is essentially the same thing as a 230. Crank and flywheel are different.

-

My truck is crapping on it self.......ideas?

lostviking replied to Jeff Balazs's topic in Mopar Flathead Truck Forum

Or old? How long did it sit? -

I haven't painted any of my frame. The previous owner may have, I don't know for sure. There were some mildly surface rusted area's. I applied a product called CoroSeal, which is a rust converter. The places I used it will never rust again. It turns violet at first, but then becomes a dark black color. Pretty sloppy job, but I put some on a rusty bellhousing.

-

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

still working on the house, which is the priority...but today I had a few minutes to go out and install the longer wheel stud I purchased. Yes, one. I bought one at first to try the fit and make sure it was going to work. $6.50+ each makes me want to test fit. Anyway, popped one out and installed the new one. I now have a few threads left over when the wheel spacer is installed. Life is again good. I ordered another 9 today. As soon as I can get back to it, I'll get under the truck and pull the drive shaft so I can measure the angle of the tranny flange...then set the pinion the same. Tack the perches in and pull the rear out to fully weld, and so I can get the passengers side axle out. Since I have access, I'll use a press to remove and install the studs. After that I need to do something about shock mounts to the axle. I have a basic idea, and left over metal that should work. I'll take pictures. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

So you might have noticed, there has been no progress in a while. The master bedroom's popcorn ceiling was damaged and of course, it tested positive for asbestos. We had to have it removed, and then I have to fix the damage that caused. I've done most of the mud work to get any damaged area's smooth again. Now I still need to paint it next weekend. After than the truck project resumes. I hope If you are married, you understand that last comment. -

Stock bore for a 218 is actually 3.25.

-

experience in engine/tranny swap possibilities needed

lostviking replied to Dodgefran's topic in Mopar Flathead Truck Forum

My bad. I'm following too many threads...I didn't see the year when I made that comment. -

experience in engine/tranny swap possibilities needed

lostviking replied to Dodgefran's topic in Mopar Flathead Truck Forum

That picture of a Hemi is not a very good example. The Hemi is wide and the heads are huge. There are LOTS of pictures of V8 swapped 1941-1947 Dodge trucks online, and not one of them has any trouble keeping the V8 under the hood. I see a few with Gen III Hemi's also, still have the hoods closed and uncut. There are several on this site, frame swapped or not. It fits under the hood, but the firewall may need to be cut. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Thanks. I'll give it a try. The 3/4 ton trucks have lots of leaves. It they weren't so expensive, I'd just buy an 8 leave 1/2 ton set...but that's over $700. Can't see that right now. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Any advice on leaves I should NOT remove, and ones (counting from the bottom, shortest) that you have removed without causing problems. Since my truck is a 3/4 it has a total of 10 leaves on both sides. Only the top two are clamped, the rest are progressively shorter and only have the center bolt and the U-bolts holding them in place. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Should have just looked in the parts manual. They are 5/16-24 it appears. p/n 120 368. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Would you happen to know if that's a 3/8 center tie bolt? I want to remove two to three leafs on each side to begin, but I want to do it before I weld the spring perches. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

A note for anyone who like myself, started with the larger bolt pattern and wanted to use adapters to keep their stock wheel. Maybe if you have thick mags also. The stock lugs on my Cherokee axle are not long enough to fully engage the nut. They maybe get 1/2 way through. Not something I wanted to drive on. I found this Dorman part number (610-449) on a Jeep message board. They are a for a Jeep that comes with aluminum wheels from the factory. The knurled section is .005 larger than the original ones, but that doesn't seem to keep them from being used. I was able to find them on Amazon for less than $7 for a 10 pack. Looks like I'll be pulling the axles and replacing the studs. -

I'm still figuring out how I'm going to do mine. I want to use the stock handle that comes up through the floor next to the shifter. I seem to remember someone doing it that way along with a T5 swap I think. I'll need to search for that thread.

-

Get one from a 97 or later Jeep. Those have 29 spline rather than 27 spline axles. Same width or course.

-

Scarebird disk brake conversion

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

AAAAAAAAAAAAAAAA! The flexible lines up front need to go through a hole in the frame. The problem is the frame is just barely too thick (not a bad thing for a frame) for the retaining clip to go on. YA! I had to buy some tabs to mount to the frame so I can secure the lines. Another delay while I get the parts I need. Bummer.