-

Posts

789 -

Joined

-

Last visited

-

Days Won

7

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by lostviking

-

Did you manually move the float to simulate a full tank? If not, maybe it's getting stuck mechanically and only moves to half way. What tests have you performed? Have you measured the voltage that is going to the gauge?

-

Oh darn. It only gets Canadian stations.

-

If you headlight switch is "frozen" spray it with WD40 and let it sit. Don't worry about getting some inside. Spray heavy. It will free the shaft up with a bit of wiggling and time. I did that with my trucks original switch, which the PO had replaced with a universal POS. Inside it was like brand new! I put a bit of dielectric grease on the internal surfaces and closed it back up. Good as new.

-

I think that guy is messing with you. That IS a radio. There are zero fuses, and that big thing is all the plates is a capacitor used to turn the radio. DON'T THROUGH IT AWAY! That is something that can never be replaced. If you don't want it, I'll pay the shipping if you send it to me. I've been in electronics since my first stint in the USN, 1978. I'll get it running and use it. Do you have the control head? Tim

-

I didn't read the line about you having bought the manual already.

-

I'd have to look through my old gmail folders. Just do a web search for 6V heater blower motor. Then check the dimensions. I paid about $37 for mine if I recall correctly.

-

It is most likely rusted in place, but there is a set screw that holds the fan on the shaft. The two screws/bolts hold the motor to the housing. I rebuilt my Model 31 in this thread : It might have some information that is helpful.

-

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Go figure. I remember when it was routine for the USPS to deliver Sundays. If they want to stay in existence they better keep up with the competition. -

Thermostat Advice 180 instead of 160 degree?

lostviking replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

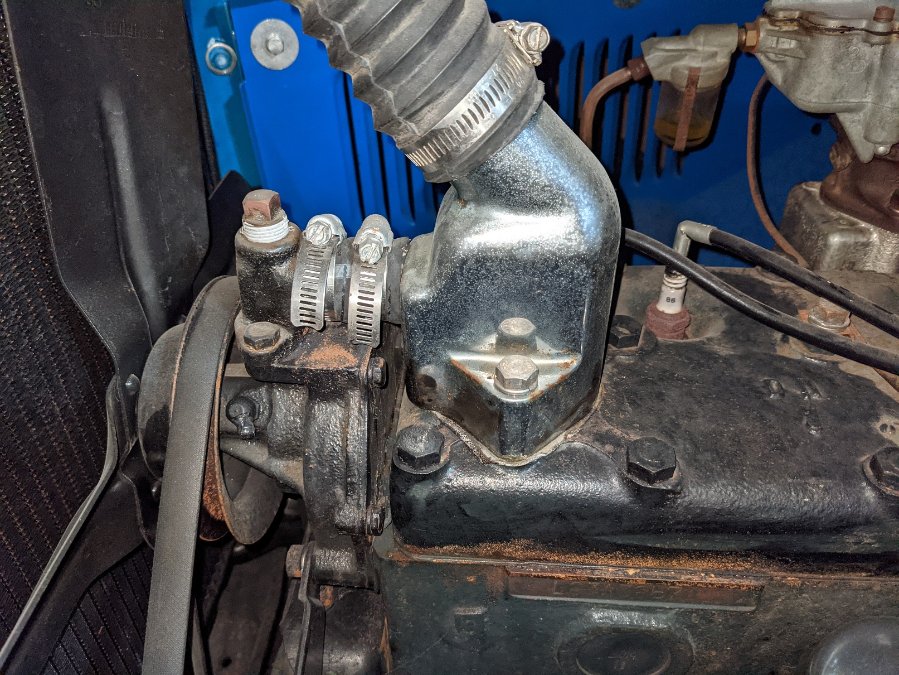

None taken. I'm still learning about this 70+ year old stuff. The oldest I've worked on before was late 60's muscle cars. Now that I've done a bit more reading, I guess I know that I have a external bypass thermostat (?). That hose at the front being the bypass line. I should flush my cooling system anyway so I'll take a look at what is in there now and change to a 180 if necessary. -

Thermostat Advice 180 instead of 160 degree?

lostviking replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Is that directed at me? If so I did use the what it fits section on the website...all it said was no it doesn't fit a 46. -

I'm hoping to reuse the stock lever, even if I have to modify the bottom end to give it more throw. I've heard they don't have the travel needed, but I can't be sure until I try. What I'm interested in, is how people have connected the two emergency brake cables to the lever. I've got the Jeep plate that the two rear attach to, but the boxed section that rides in, and the front cable mounts to are part of the Jeep. I need to duplicate that function. Anyone done it and can share? TIA.

-

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Unlike the USPS, Amazon does deliver on Sunday's. Once more under the front of the truck to connect the rear line to rear fitting on the PV2. One more double flare on a line under the truck. There was plenty of room, but it is always nicer to work at a bench. I reinstalled the Jeep rear cross over lines...but one more gotcha to defeat. I reused the junction block from the Dodge rear so that the flex line was able to be reused. Unfortunately this time saver wasn't, the Jeep uses 3/8 flare nuts, the Dodge 7/16. Mocked them up to make sure they were going to work, then pulled them and went to the work bench. I cut the flares off the very ends and dressed them up with my countersink tool. Then another couple double flares and it was back under the truck. Now I have a dry, but complete brake system. I'm done for this weekend, so I won't try to fill/bleed them until next. I sure hope there are no leaks ?. -

Getting my 230 to run after starting

lostviking replied to Salty51's topic in Mopar Flathead Truck Forum

Cool beans. I'm glad you got her running. That's what it sounded like when you were able to start it. People do forget that there are both a start and a run position on ignition switches. The coil needs to get powered from both. Have some fun now. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Continuing on from yesterday a few more pictures. Across the front plumbing. I'm going to remove that metal clamp in the center and use one of the rubber coated ones there. The drivers side has the T-fitting for the front brakes. And the master/proportioning valve back in place. Just need the last fitting, which I should get soon and the brakes are plumbed. I do still need to put the two lines back onto the rear end, but those are the Jeep factory lines I saved. I have plenty of line left in case I don't like the way they go in. -

Thermostat Advice 180 instead of 160 degree?

lostviking replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

-

Thermostat Advice 180 instead of 160 degree?

lostviking replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Isn't there a conversion to a modern thermostat? I thought I saw a thread on here doing just that. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Back at it today. I have the two front brakes plumbed to a t-fitting along the drivers side frame, same place they were run before. It was fun doing that on a fully assembled trunk on my back, but it's done. I have a couple insulated clamps where it travels under the radiator along the cross member. Sure looks better than the four or five sections the PO patched together for that same span. I have no idea what he was thinking. I pulled the master and proportioning valve back out so I could plumb them together on my (very messy) work bench. I really need to put my tools away and stop trying to work on so many things all at once I have the bleed fitting in the proportioning valve right now. It's that blue thing on the top. It keeps the valve from locking in front or rear only when you try to bleed it. I need a fitting for the 1/4 inch line that runs to the rear. I was going to replace it, but since it's tucked behind the gas tank, I'm just using it. It was new line when the PO did his work, and other than a bunch of S bends I can see along the frame, I guess it's not too bad of a job. I cut it past the end of the proportioning valves so I can cut the final length when I put the flare on it...after the nut goes on. Ya, had that happen twice today Too big of a hurry I guess. Here's the candy so far... Not too wide, should fit back in there nicely. Now I just wait for tomorrow when I get the missing fitting. Then one more line to the front brakes T-fitting. I have a pressure bleeder that I'll use to force fluid in once it's all back together. Just hope I didn't create any leaks, but we will see. Started to pull the plates in the floor to give me some more room, but it just seemed like more work than it was worth by the time I saw how many things I had to remove. Have a great Saturday everyone. -

1946 WD15 rear end swap...and full replumb of brakes

lostviking replied to lostviking's topic in Mopar Flathead Truck Forum

Been a while, but the bedroom repairs are finally done. The wife is off hanging pictures, so I have a small window of opportunity... I bought a mounting plate for the PV2 proportioning valve, and today I was able to get under the truck and get it mocked up. I used the bottom bolt for the master cylinder. I like it's location and I just need to bend up some brake lines. I decided to keep the 1/4 line that goes to the rear, since it is almost new anyway. I just need to get a 1/4 fitting now for the 9/16-18 port. I cut and bent the existing line and I'll have to flair it under the truck. I should have enough room, since I was able to get the tubing bender in there. While I was at it I got the drivers side hose from the caliper mounted. I did enlarge the hole where it passes through the frame, but it's in the "stock" position. The passengers side is harder to get at since the truck is tucked into the garage. The garage door took a crap last week, and one of torsion springs is broken. I'll be putting a new one in next Wednesday, then the new opener...but that will be installed for me. -

Very nice looking truck. Great condition.

-

Nice job Jim. I wasn't able to reuse the stock mounts going with the Jeep axle, which is 3 inch. The stock axle in my 3/4 ton has smaller tubes. I like the idea of being able to use the stock components. I still have to fabricate my shock mounts.

-

Getting my 230 to run after starting

lostviking replied to Salty51's topic in Mopar Flathead Truck Forum

I don't know anything about the specific parts you have tossed together, but some times there is a separate wire for power during run as opposed to the start. It will start, but as soon as you go to the run circuit, you lose power. -

I don't know anything about the DMC kit. The other one that many people have use is the Rusty Hopes kit. I didn't just because it required machine work to the spindle, thereby it was no longer backward compatible. I may never, or probably will never, go back, but why not be able to? Here is my scarebird conversion thread: Here is the dual circuit master cylinder thread I found and used :

-

Very nice. Welcome.

-

There are plenty of build threads with pictures. You can do a search and find ones that are probably better done than mine, but I just did the Scarebird install on the front, copied another members Toyota dual circuit master install and swapped the rear end for a Jeep one. I have modern brakes all around (as soon as the wife lets me finish plumbing the brakes and bleeding them), and I have a 3.55 rear end ratio so I won't be topping out at 40MPH. Look around the site. There are people who have used other parts and had great success. I used the Scarebird because it does not require any modifications to the stock parts. I could return to stock at any time, but why? Just giving myself all the options I guess.