-

Posts

2,511 -

Joined

-

Last visited

-

Days Won

78

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Sam Buchanan

-

Might be the case.....that would be disappointing.... Mine came from Andy Bernbaum, any field history with those?

-

Resting height is maybe 1/2" higher at most, considering I was able to raise the engine at least 4" I don't think the engine is touching the body. I didn't replace the front mount so never got closer than a couple of feet to the balancer. I can see how firm mounts could transmit some vibration but the old engine has really been smooth thus far. I'll take a close look at the exhaust tomorrow.

-

Reverse is back, just needed to tighten the gear selector rod adjustment a few turns. Still have significant vibration at lower engine speeds but I suspect the exhaust pipe may have gotten tweaked enough in the course of jacking up the engine to replace the mounts that it is now touching the frame crossmember at certain rpm. It's a hard mechanical vibration....the engine runs smoothly and it isn't the driveshaft. Need to take a look.....

-

Haven't really looked at those yet....on my list.

-

The totally shot rear mounts on my '48 P15 have been replaced. I tightened the mounts down until they snugged up against the spacer and took the car for a drive. First thing I noticed was a significant amount of vibration being transmitted into the car at low speed, really not very pleasant. It was smooth at highway speed but not nearly as smooth at low speed as the old, smushed mounts. I also noticed a bit of notchiness going into second. However, it seems the previous clutch chatter has been minimized. Back in the shop I loosened the mounts 2-3 turns and the car is now much smoother. However, it won't shift into reverse. Is this because the gear selector rod is now too "long" since the transmission is sitting higher on the new mounts than it was on the sacked out mounts? Will backing off on the selector rod nuts allow reverse to be engaged? I've studied the manual and training film, just thought someone who has already been down this path might provide confirmation or suggestions. Thanks in advance!

-

-

These motor mounts should have a few more years in them.....but I decided to replace them anyway......pretty bad when you have to replace stuff every 72 years..... The reason there is no photo of the lower mounts is because they were.......GONE! As in "they done left the building....gone". I was dreading getting enough clearance to swap out the the mounts but there was more than enough to pull the old and insert the new. PlymouthyAdams, think this might help my clutch chatter?

-

I need to pull the manifolds to install a gasket between them at the heat riser. Three of the heat riser bolts are already twisted off and I'm dreading dealing with the manifold nuts. As a temporary fix I put a steel plate between the manifolds and that stopped most of the exhaust leak....but it needs to be fixed right. I'll be awaiting to see how your job goes and any tips you come up with.

-

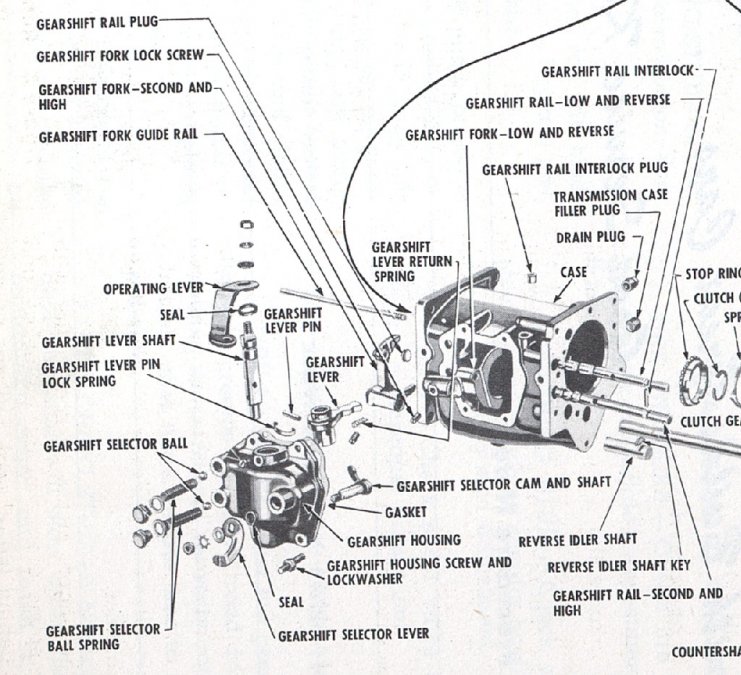

No need to go away, we're plowing good ground and maybe our shop floors will be cleaner because of our efforts. As it appears to me, the big gasket is for sealing the shift rails. The lower rail has a plug but the upper is open. The gasket within the retainer is responsible for keeping oil in the retainer. If oil gets out of the retainer, the big gasket won't prevent it from running down into the the slot in the gasket, also into the clutch housing, then onto the shop floor. This is what was happening with my car. I wonder if the upper rail isn't plugged because it resides above the oil level in the trans housing. But I'm not taking chances and will add a thin coat of sealant under and on the big gasket in the area of the upper shift rail to hopefully prevent oil from getting out of the rail bore. The slotted end of the gearshift fork guide rail will also get a dab of sealant. (see manual scan and the small slotted rod in my photo) If the rail bores are sealed by the plug and big gasket, the countershaft bore is sealed and the retainer is sealed, and the retainer is draining oil back into the trans housing as it should I can't see any other place for oil to escape the forward end of the transmission. There can be leakage at the shift housing and tailshaft, but those areas can be addressed with the transmission in the car.

-

Text deleted due to erroneous info.

-

No sealant was applied to the gasket, you are seeing the bellhousing through the slot in the gasket (well, maybe there is some Permatex on the bellhousing). I don't know the purpose of the slot, but I suspect it is there so you could install a new gasket without pulling the pinion shaft all the way out of the bellhousing. The gasket won't leak at the slot if the bearing retainer is sealed properly, the tranny will be oil-tight.

-

Don't recall but I didn't see any evidence of it leaking. There was a lot of oil getting past the retainer gasket, I suspect it may have been too thin to seal adequately considering the end play specs for the bearing. The large gasket in the photo is the one that was in place and it is dry around the plugged shift rail.

-

The lower rail has a plug and it appears to be dry, I had applied sealant to it the first time. The upper rail does not have a plug and one isn't shown in the manual. The sealant is non-hardening and can easily removed if needed, but I'm hoping I never see this scene again! Oddly the gasket has a hole where the upper rail is located. Guess this is a universal gasket that is also used for other applications? The gasket will get trimmed this time to remove the unneeded portion on the bottom.

-

Will definitely post an update, hope it is a good one. ? This is my second go at fixing the leak. First time the bellhousing and retainer gaskets were replaced but the leak was as bad as before. Upon teardown this time it was obvious the oil was coming through the retainer gasket and possibly out the forward end of the retainer. This car has had a significant leak for a long time based on the buildup of crud in the area. This time I'm added the sealant to the repair, really don't see how oil can escape this time. Both sides of the retainer gasket got a thin coat of sealant and there was squeeze out all the way around the retainer. The only other place I see where oil could leak is at the upper shift rail and the big gasket will get some sealant in that area when the tranny is reinstalled. The lower shift rail already had a plug and it and the countershaft got a dose of sealant. New motor mounts arrived today then we'll find out if the repair worked.

-

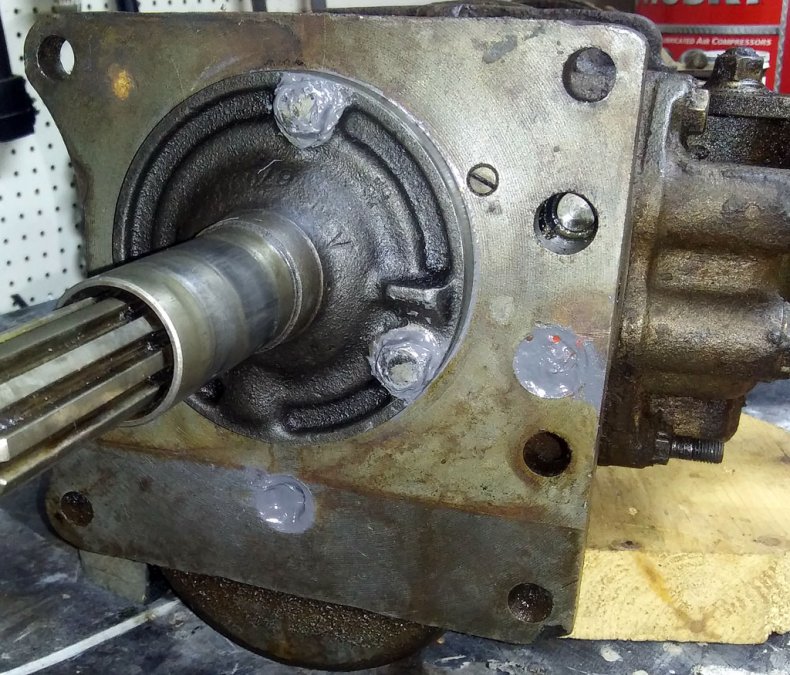

I'm using all the gaskets per the service manual. The bearing retainer was also checked for proper end play per the manual. The countershaft doesn't have a metal to metal contact. You can see the faint coloration in the photo where it resides just below the junction of transmission to bellhousing.

-

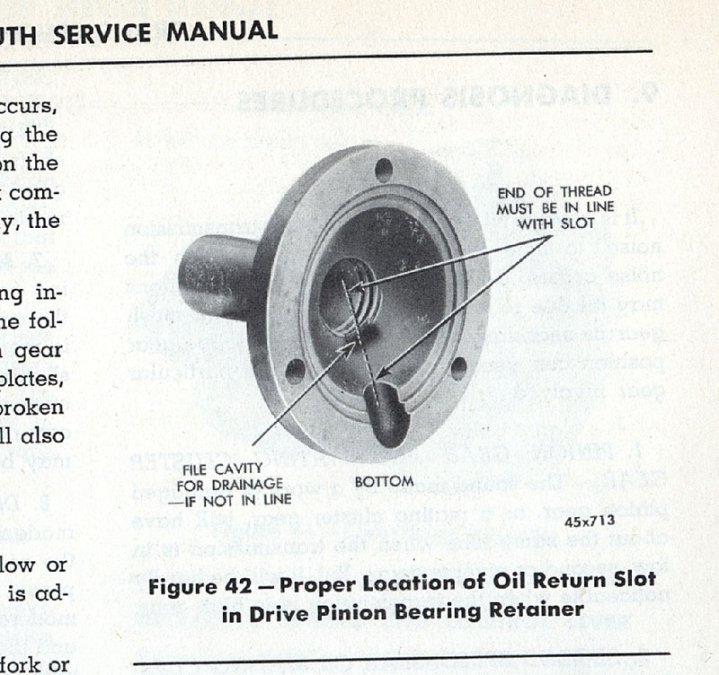

Decided to modify the bearing retainer per the service manual: The threads ended at about 8 o'clock instead of in line with the drainage slot. I applied sealant to all surfaces including the bolt grommets, basically bonding the retainer to the transmission. Hope this stops the leak. The end of the countershaft also received a coat of sealant. FYI, the sealant is a fantastic product, also is a great non-hardening adhesive. It was developed as a fuel tank sealant for the B1 bomber and has sealed over 20,000 RV aircraft tanks. My 20-year-old tanks are still fuel-tight. If anyone is interested in having this in their shop here is a source: https://shop.vansaircraft.com/cgi-bin/shop.cgi?ident=1565367378-16-348&browse=misc&product=proseal If stored in a refrig it will keep for years.

-

Criminal, eh? It's not torn...just a little dirty.......the oil keeps it soft and pliable.....

-

Joe, the rear 2/3 of my transmission is dry, oil is definitely running down the front end of the tranny and dripping off the protrusion on the bottom. The "end of the threads not in line with the slot" is what I'm failing to understand. I don't see where the threads end and don't see a path for oil to drain out of the threads. Guess I might as well take care of the rear mounts while I'm in here.....think these have timed out?

-

My P15 transmission has a large oil leak that has so far remained unresolved....but I'm going to get it this time. I would appreciate input from those who have been down this path already. Here is a scan from the service manual showing a mod that may be needed on the drive pinion bearing retainer: And here is my retainer: Am I correct is thinking the lack of a drainage relief at the slinger threads per the manual is preventing oil from being evacuated from the retainer? Should I file/machine a relief as shown in the manual? Also, should the end of the countershaft be sealed to prevent oil migration? I have some high performance sealer (Flamemaster fuel tank sealant) that I have used many times previously to stop persistent leaks. I'm thinking the end of the shaft needs a sealant "plug" and also a thin coat on both sides of the retainer gasket. Does this sound like a good path to follow?

-

Lots of suggestions about how to swap out brakes, rear ends, etc, but the owner stated up front he is not disposed to work on this car himself. This has created an awkward situation. If the car had been close to driveable as advertised, this may have been a good ride for him.....until the next mechanical issue popped up. But to have a shop replace brakes, rear end and the fabrication involved is going to double the cost of the car (I saw the sales ad). He will then have a driver but be upside-down financially. Being upside down is one thing if you enjoy working on the car (cheap therapy!!), but quite a different animal if writing big checks to someone else....... Tough spot to be in and I feel for him. My suggestion would be to fix the stock brakes, get it as safe as it would have been in 1950, then drive the car and decide if it is going to be a long-time endeavor. If the car endears itself to him then future upgrade/repair expenses will be easier to justify. Best wishes, friend!

-

I feel your pain. ? My P15 had extensive brake work done five years before I purchased it but it needed a complete brake rebuild. After also replacing the complete fuel system and much of the electrics I have come to the conclusion that an old car shouldn't be purchased unless prepared to repair/replace nearly all the systems.....regardless of claims by the seller. I'm also convinced complete system overhaul is better than piecemeal repairs on old components. There are no shortcuts when it comes to brakes. I suggest you replace ALL the brake lines when you redo the brakes. If you keep the single chamber master cylinder you are only one small leak away from being a passenger in a brakeless missile...... Hang in there...after the financial pain you will have a car that is fun to drive and own!

-

Frank, I selected an exquisite JB Weld product from the auto restoration department of Lowes. This stuff starts firing off in about 5-6 minutes so I only mixed up a one-inch long bead each time. My steering wheel was in pretty good shape, the only large cracks were on the back side. A Dremel was used to open up the cracks so the epoxy could be forced into the cracks. To facilitate that process masking tape was firmly applied over the epoxy repairs to help it flow into the wounds. After an hour the tape was removed. Even though the epoxy was a little tacky it sanded very easily with 120 sandpaper. After some quality time priming and sanding the repairs and entire wheel, it received several luscious coats of Rustoleum Gloss Black and the paint is curing in the warm shop as we speak. Reassembly is complete and the ol' girl should be back on the road and no longer insulting her driver by gifting smudged hands.

-

New to the forum and 48 fuel pump issues...

Sam Buchanan replied to whippersnapper48's topic in P15-D24 Forum

I've seen this movie before. Six months ago I started awakening my '48 P16 from a five-year hibernation. I ran into fuel delivery issues just as you described and tried many of the diagnostics others have suggested. The solution; new fuel tank, new fuel sender, new fuel lines, new carb float, and new electric fuel pump. The ol' girl runs great now, just needed to get rid of a bunch of 71-year-old fuel problems. I tried piecemeal repairs for three weeks, would have been far better off just replacing the entire fuel system first thing. Remember the old TV commercial? "You can pay me now or you can pay me later"..... Get it fixed and enjoy your new ride! -

Glad to see that, my new set of cables should be here in a few days, thanks for the referral! Sure is nice to see a vendor charge a very reasonable fee ($3.97!) for shipping instead of using "shipping" as a backdoor way to jack up profit margins. One of our best known vendors charges $14 even if you are just ordering some paper gaskets.........Com'on Man..........

-

Yes, paint would be a good option. What I was wondering....is it worth the effort to use a catylized automotive finish ($$$) or is a single-stage finish over primer durable enough on the material the old wheel is made of? I've used the high-dollar two-part stuff on other wheels but would like to avoid the considerable expense if a simple enamel gives good results.