-

Posts

3,462 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

I should have been clearer to specify that aside from the concerns over 2&3 cylinders, 5&6 are down considerably as well. If they did not climb after oil was put in the cylinder, I start thinking about valve seat seal-ability.

-

A most recent pic, and the story...Share your old Mopar!

keithb7 replied to keithb7's topic in P15-D24 Forum

I washed my Windsor today and drove it to town and back. The weather was stellar today. It was quite an enjoyable drive. -

While you are in there, check valve seat seal0ability. Lap the valves. No change in compression numbers when oil is used, leads me to valve seats.

-

I do get a lot of comments on the suicide knob. It seems nobody has seen one like it before. I've had more than few people ask me where I got it. I like that it is recessed and set lower down below the steering wheel ring. I don't hit it by accident. I do use it a lot and it is comfortable. I figure it must date back to the late 30's? Maybe the dealer installed it when the car was first sold? I'd love to have the original sales paperwork. I have a story ready for the Mounties. It's original and stock for the car. Who can prove me otherwise, right? The car has no seat belts or turn signals either. Some mounties aren't even sure if aa-oo--gah horns are legal. Pretty sure if I'm not driving like an idiot, and and pleasant, they'll smile and let me carry on my way.

-

Around here, a piece of halibut, frozen, 1 steak is a$22 USD per. Last time I looked at it and put it back down. So I figure there is a few thousand dollars worth there in your boat! Good job. Great eating. Battered and deep fried makes awesome fish & chips!

-

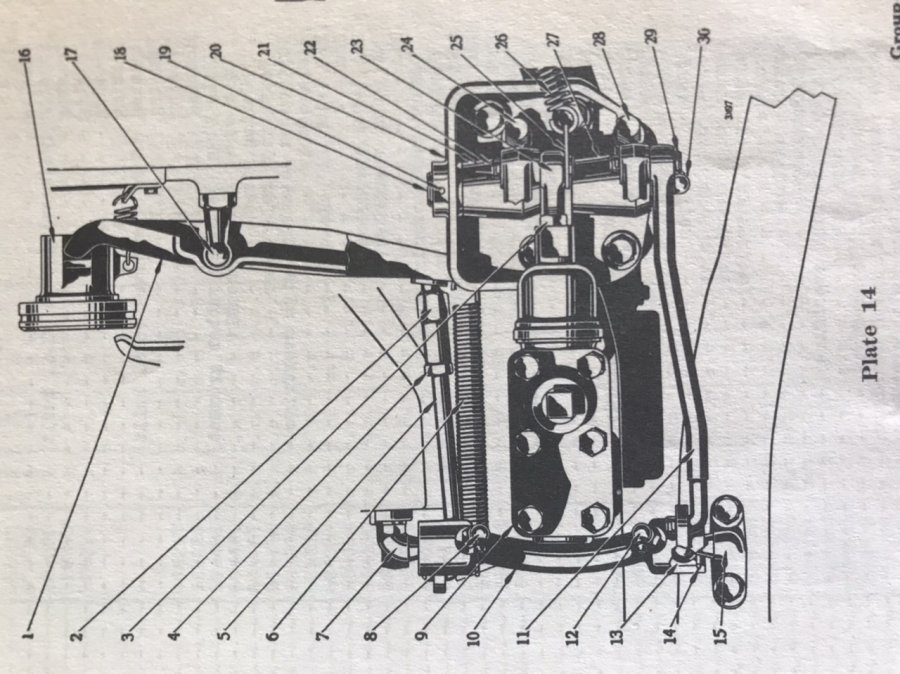

A good friend of mine has a spare 1949 251 engine. This is the 25" long engine. Original bores. He has offered it to me at a "best friend" fantastic price. I am interested in owning this engine as I "think" it may suit my long term needs. Both my 1953 265 and my 1954 228 engines that are in service today display the same symptoms. Rear crank seals leak, worn valve guides burning a little oil while greared down holding back on a hill. Both burn little oil driving up the hill home. Compression is about the same in both engines hovering in the 100 psi range. Neither require a rebuild immediately. My 1953 Chrysler has the 265 engine. Same block and bore as the 251 if I recall, just a little longer stroke (1/4" longer the 265). Meaning different crank throw length I believe. I assume possibly different con-rod length too. I am not sure, but I assume the 265 may have a larger flywheel. Not thinking I'd put the 251 in my Chrysler. But a spare 265 block is handy to have! My 1938 Plymouth has had the engine replaced with a 25" 228 ci. I kind of like the idea of putting this 251 in my '38. Torque galore from the 251 in that little car, I would think. I like the idea of building up the 251 on the side, while both of my cars are drivable. As time and money allow I can move along on the 251 rebuild. I am not interested in this 251 for higher top speeds or freeway travel. Nor driving 3.73 rear end. My 1938 has a 4.11 rear end. Some unknowns and thoughts that I have: I was hoping a few folks here with more experience than me, could fill me in. I have a few books here to reference, including a 1949 shop manual for Canadian cars that all had the 25" long engines. Comparing the specs from all the 1949 25" engines, they all share so many vital parts and vital dimensions. 1938 has the 25" engine now. Would the 251 engine mounts, bolt right in? My 1938 3-speed tranny, drive shaft and rear end, would they handle the extra torque of the 251 engine? I have no plans to drive it any harder than the 228 engine now. Other than pulling the hill home in 3rd, the 251 should lug down pretty good and pull harder than my 228. My 1938 Clutch diameter is 9 ¼". Optional 10" was available for taxis back in the day. I assume I'd should upgrade the clutch size. Due to increased engine HP and torque. Looking at a 1949 shop manual, I do see though that the C45 Windsor 251 had a 9 ¼" clutch too. 251 engine I suspect, should have a larger flywheel. The 251 engine bell housing was set up for use with an M6 tranny with fluid drive. I could swap over my 3 speed tranny bell housing, would it bolt up to the 251 block? Would my 3 speed tranny pinion fit the pilot bushing in the back of the crank of the 251? I suspect I would likely need to source a flywheel drilled for use with a 10" clutch if I go that route. The cooling system. Will my rad keep up with the increased HP (fuel burn and BTUs) from the 251? Not a big deal, but I could address that probably. Comparing specs: Original 1938 201 Engine in my Plymouth was 82 hp 3600 rpm, 1949 251 engine: 116 HP at 3600 rpm. 208 bs ft torque at 1600 rpm You thoughts are welcome. Wouldn't a little P6 be a fun driver with a 251! Any reservations? Thanks, Keith

-

1952 Dodge Cornet convertible, Six cyl flat - unable to start

keithb7 replied to anils50's topic in P15-D24 Forum

Thanks @Sniper...I see, something a little more modern...For my own curiosity I think I am going to install a fuel pressure dial gauge. Based on what I have experienced and the amount of inquires on here around fuel delivery problems, it seem like a good system to monitor. I located a 0-15 psi 1 ½" gylcerin filled guage. I have seen folks who have mounted them in the engine compartment. Would there be safety concerns if I ran a steel line up and into the cab, so the gauge can be monitored when driving? I'll only be running the mechanical gauge. I'd like to monitor fuel PSI under various driving conditions. -

1952 Dodge Cornet convertible, Six cyl flat - unable to start

keithb7 replied to anils50's topic in P15-D24 Forum

@Sniper what is this AF gauge you speak of? Air Fuel? Where does it get readings from? -

1952 Dodge Cornet convertible, Six cyl flat - unable to start

keithb7 replied to anils50's topic in P15-D24 Forum

I learned Something of interest lately. I had installed an electric fuel pump. Mainly used for priming. However I was also using it to supplement the mechanical fuel pump to climb the big hill home. I was running regular fuel. The car would buck a little as I climbed up to an 11% grade for a couple of miles. The electric pumped seemed to stop any bucking. A couple of times the engine stalled out, right after about an 1/8 mile of flat driving at the top of the hill as I coasted into my driveway. Hmm. That was interesting. I couldn’t quite peg down the reason for it. A short while later I switched to a premium plus fuel here, with no ethanol. I found I no longer needed to use the electric fuel pump at all. The engine and fuel got hot climbing the hill still. However no bucking. The mechanical pump worked just fine on its own. The engine has not stalled in the driveway after the hill climb either. I assume I was experiencing some vaporization? With the throttle wide open climbing the hill, the mechanical fuel pump could not keep up? The electric pump helped keep enough fuel moving to prevent any bucking. Yet when I levelled off for a bit I was over fuelling the engine. It stalled due to it being flooded? It all seems believable. All My poor performance symptoms have vanished since I switched over to no ethanol premium fuel. Hard and no-starts. Hesitation & bucking under certain conditions. Stalling. All gone. I’m a believer, ethanol is the devil for our old Mopars. -

A possible internal short in the armature. Some voltage going to ground before doing its job and turning the engine over

-

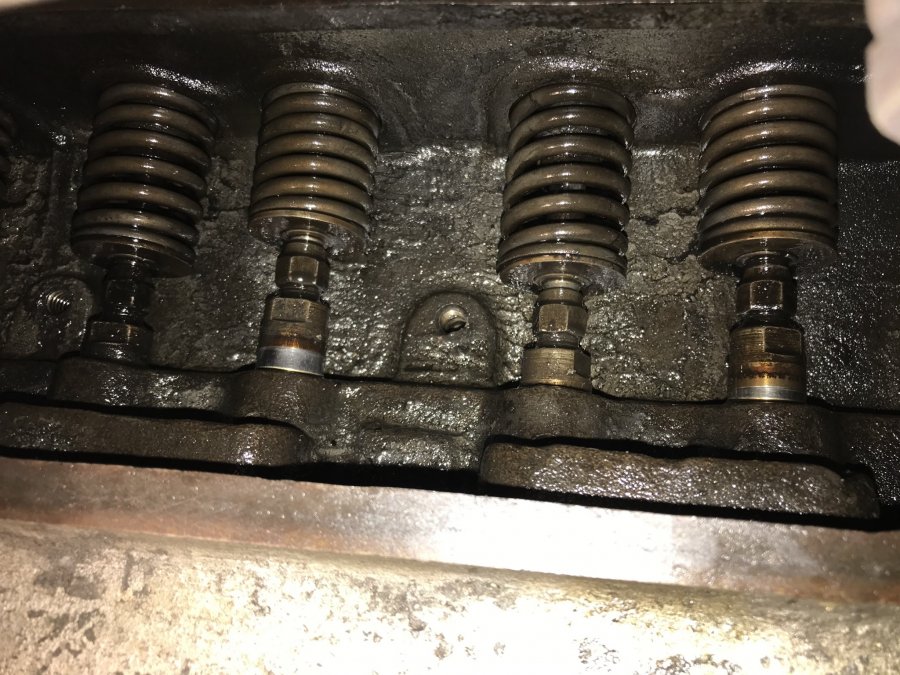

Today I got around the setting the valves on my '38. I stuck the wrenches in the hot running engine and set the valve clearance. It is do-able. However some tappets are difficult to access with the wrenches. For those who have done this several times, what custom wrenches are you using? I'd be interested to get myself set up. My '38 has a '54 engine. So the settings for my 54 engine are .008 intake and .010 exhaust. I set them until an 8 would go in the intake, but a 10 would not. A 10 in the exhaust but a 12 would not. Seems good. I can hear a small amount of valve ticking.I am ok with that. Better to hear a little then none at all they say. Any tips on tools is appreciated. Pic is after 500 miles with modern detergent oil. It was a fair bit cleaner than when I first when into the engine to clean out sludge back in March. It had been running on non-detergent SAE30 before. Dumping the oil and filter now to go with 10W40. Thanks, Keith

-

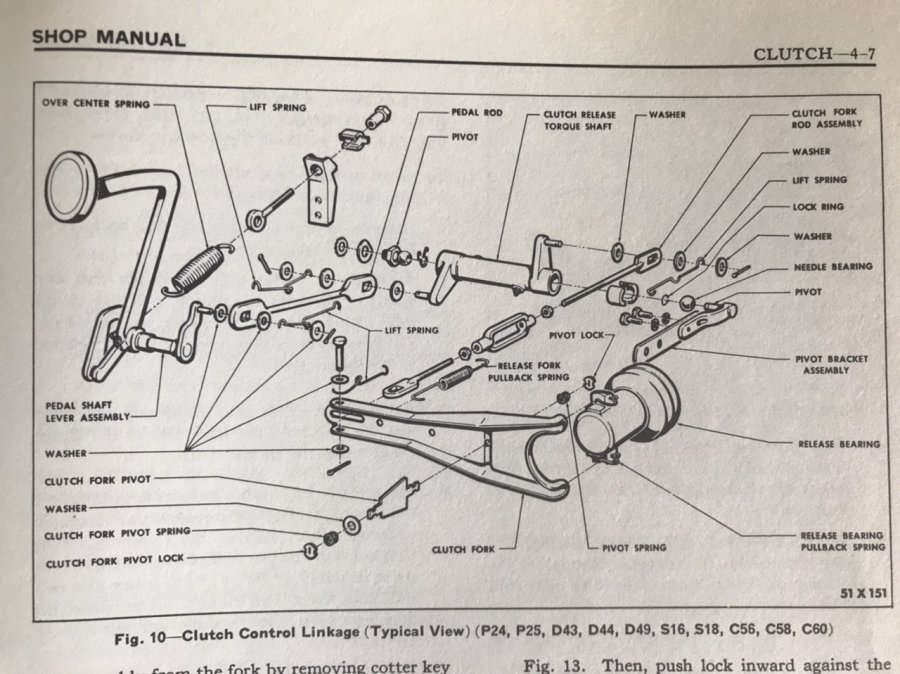

I’m not 100% clear on where you are in the job process. Is your tranny removed? Throwout bearing became dislodged and you trying to line things up? Or is the tranny fully assembled and installed, and the springs shown in the pic above were moved out of their locking place, allowing end the shift fork be dislodged from it’s resting place?

-

-

You have a couple of options. You can back off the clutch adjustment threaded fastener (nut) that will shorter the clutch rod. This will give you some room to work. Or you could release the spring that maintains pressure on the clutch shift rod linkage. This will allow you some room to move the rod, to set it back in place, in the recessed ball socket of the shift fork. Once all reassembled you can re-adjust the clutch free-play to your liking by adjusting the threaded nut on the rod again. Tightening things back up. Just be sure to leave some free play to ensure the throwout bearing is fully disengaging from the pressure plate.

-

The reason I asked was, on some years, the entire floor boards are removable. They unbolt offering very good unhindered access to the transmission and rear of the engine. This was extremely beneficial when I working on my 1938 clutch and tranny earlier this year. I was able to get a good view and understanding of how it all went back together. Basically you have 2 looped wires on the throwout bearing housing. You also have 2 flat spot n the housing. These machined flat spots line up with the 2 fingers of the fork. The looped wires are springs and flip down around the fork. They assist in holding everything together firmly. Seen here, this bearing housing is assembled incorrectly. The housing needs to rotate 90 degrees counter clockwise so the fork ends aligns with the flat areas seen on the housing. Then the springs slide up and into the back side of the fork, recessed areas maintaining pressure.

-

1952 Dodge Cornet convertible, Six cyl flat - unable to start

keithb7 replied to anils50's topic in P15-D24 Forum

Listening to your symptoms, there are clues. It would appear that after things get good and hot, the problems occur. When you say it won’t start, if you could give us a little more info it might help us, help you. Do you get home, safe in the driveway then shut off the engine, and immediately it won’t re-start? Or do you leave it sit for 15 minutes, then it won’t restart? Pulling the air filter and looking down the carb when it won’t restart is excellent advice. You are lookIng for fuel from the accelerator pump. Or at the least a fog-mist of fuel down deep In the carb venturi. A screw driver and a flash light are beneficial to see down there. The problems with fuel delivery are so common among us, it would seem that a fuel pressure gauge mounted in the cab would be a huge benefit to so many. Taking fuel pressure measurements just before delivery to the carb bowl inlet could immediately let us know whats going on with pressure. Due to either vapor lock, mechanical fuel pump pressures, electric fuel pump pressures, tank pickup screen blockages, pin holes in fuel lines, plugged fuel filters, etc... -

What year/model car are you working on?

-

Chirping back in to say this tool was far superior than the older clamp-style. I have used both. This tool here was a breeze. Factory looking flares every time. I'm glad I bought this tool. I was getting pretty frustrated with the older tool that I was using. https://www.ebay.com/itm/Cal-Van-Master-In-Line-Double-Bubble-Flaring-Tool-Set-w-Tube-Cutter-USA-Made/141938469377?epid=1238088211&hash=item210c312a01:g:w~wAAOSwwpdW8yYk

-

@Pete it came from E-bay. Likely Asia as Plymouthy alluded to. Most of these USB plugs have some kind of a trick light that is lit up when it's active. Therefore pulling power all the time. This was why I wired it up to switched power at the ignition. I wondered if the digital voltage gauge might show a drop if the 6V battery was losing power? Thinking, it might serve a dual purpose, offering a clue to system voltage health? I am not sure how the 6V-12V converter functions. It's some type of solid state sealed device. It may continue to put out 12V even as the car's 6V system voltage drops. I saw a sticker on the back stating that it'll accept down to 5V. Likely meaning it will deliver and record consistent 12V even with a 5V input. The funny part is cell phone chargers put out 5V. However try finding one that will run directly off a 6V system. I have not seen any. The usb plug steps down to 5V from 12V. So in reality what I have done here is take a 6V system, step it up to 12V, to run a usb charger. Then the usb charger steps the 12V down to 5V to charge a phone.

-

Great photo. I like the idea of heading out for a drive and not needing to check the weather forecast. You can see the bad weather coming from 2-3 hours away. I don't have that luxury. I have about a 15 minute lead time that I can see. The mountains are all in the way. I love that Big Sky Country in the summer months! That car...What a unique look. A small coupe cab yet a huge boot! From that angle it appears that the hood is actually stubby and shorter than the trunk. Is that correct?

-

Lol. Good eye. Yes. The car does have a built in cup holder. Only usable when parked. It was pre-war time, so certainly appropriate. The engineers needed a little more time to perfect it.

-

Hidden inside the glovebox of my ‘38 Ply, a modern USB charger. This particular USB charger required 12 volts to work. My electrical system is still the stock 6V system. I wanted to try installing a 6v DC to 12v DC 10A converter anyway, so I went with it. This USB charger has a built in digital volt meter. I wanted the modern convenience, but didn’t want it visible in the car. The cell phone should be out of sight in the glove box anyway. So it seemed appropriate. There was plenty of room behind the RH wall of the glovebox for the depth needed to mount the USB charger. I also installed the converter up in there. This charger puts out 2.1A to charge a phone. I tapped into the power wire to the fuel gauge as it is key-switched off the ignition. There are only 2 items off the ignition switch. The coil and the fuel gauge. Everything else is hot to the battery via the ammeter. I have heard of instances where too many electrical devices hooked up to the key’d ignition switch can cause problems with feeding the coil. Then leading to ignition system problems. My car seems to run fine as it is now. Does anyone have examples of too many amps pulled off the ignition system where it caused a problem? Perhaps a stereo would overdue it? Likely. I’m pondering an alternative wiring scheme, for those inclined to hook up yet more devices. Devices that are active only when the key is turned on: Possibly a 6V relay system. Ignition switch turned on activates the relay. Then power could be pulled thru the ammeter, thru the relay, to a small fuse block, distributed to each device. ??? One tip, any metal in the car is grounded back to the 6V battery. Do not allow the exposed end of the USB charger cord, when plugged in, to touch any metal part of the car. You will likely see a quick flash followed by a Poof! I saw a friend do this by accident. No-workee any more.

-

I can't speak about where to source pre-made brake lines for these old cars. I can tell you that it is likely that if you were to pay someone to replace these lines I would wager, they would build the lines themselves there in their shop. This is what I did, at home in my garage. I bought the steel lines and and decent double flaring tool and made my own. Not sure if you have the desire, space, or tools to do this. Just passing along that this is how some of us do this. A few flubbed up ends, yes. A few skills to be learned yes. But it's good cheap, rewarding fun.

-

A most recent pic, and the story...Share your old Mopar!

keithb7 replied to keithb7's topic in P15-D24 Forum

Tonight I headed out to a local cruize-in car meet. All types of cars. Hot-rods, muscle, tuners, vintage, classics. Everyone is welcome. It's a weekly unorganized gathering in a local parking lot. I took my '38 Plymouth out. It was the my first sort of semi-formal gathering with my '38 among other car enthusiasts. It was a fun gathering. Lots of folks approached to talk about, learn about and see my '38. It was great to hear people's stories and I was also able share some history of my old car. I thought about taking a photo but got I distracted with questions from people. Stayed longer than I thought I would as I was having a good time chatting with friendly folks. Even got to use the headlights on the way home. Was a great night. I will attend again next week and report back with a few photos. Pretty sure I was the only pre muscle-car Mopar there. I asked everyone who showed interest if they knew of any other 37-38 Mopars here in town. Nobody was able to confirm, as they could not recall seeing any. -

Might as well add that my budget level 6V battery is in it’s 4th year. I’ve always maintained it with my Genius 750 charger. Battery always installed in the car. Starts my 265 without hesitation. It will be interesting to see how long the battery lasts.