-

Posts

218 -

Joined

-

Last visited

-

Days Won

1

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by rustyzman

-

GIve the folks at VIntage Power Wagons a call. Last time I talked to him about a year ago he said he had tons of engines, like 100's if I recall. He can arrange shipping too.

-

If you end up digging into the internals of the transmission, after you have exhausted all external adjustments of course, there is another item that you need to look for. A manual transmission jumping out of a gear can be quite likely too much gear end-play. The synchro itself can be worn and cause a rough engagement of a gear for sure. But a worn synchro ring itself should not cause a transmission to jump out of gear. Once the gear is engaged, the synchro ring is no longer really doing anything to hold a gear's engagement. It is just a friction clutch to help align all the engagement teeth of the various components so they slide together smoothly. A common older manual trans problem is that the thrust face of the gear wears down against the next component on the shaft and starts to create excessive endplay. This is prevalent in bevel gear transmissions, because the driving action of the gears naturally forces the gear up against whatever is next to it and those faces rub together if they are not rotating at the same RPM. Once you have enough endplay, the engagement teeth of the gear that are engaged with the sliding ring shift ring on the shift fork start to engage less and less. Eventually, they start to slip out and you pop out of gear. The gear face may even look like it has a nice machined counterbore on one side, but in fact, it is just worn that way. There are of course other sources of this problem too. The shift forks can also be worn and prevent you from getting full engagement of these same parts, as well as the engagement teeth on the gears or even the sliding shift ring. Once it is apart, some measurement with feeler gages and visual inspection should reveal your source/sources. A lot of cars were run with little maintenance or low on fluids for a long time in their lives. A lot of wear can happen that way. All of this again is suspect only after you have eliminated all issues with the linkages from top to bottom. And Redline MTL is wonderful stuff. It has revived many weak transmissions.

-

High Quality H4 Headlights for 12v Cars (Cheap!!)

rustyzman replied to Sam Buchanan's topic in P15-D24 Forum

I just bought 4 sets from my local Toyota dealer. $29.67 each set, no additional shipping, arrived next day for pickup. I had him search and he says there are 1700 sets left in the warehouse. He was actually quite confused by all this. He was sure that I bought four of the same side headlight. I explained it was a kit and we opened one up so he could see what they were, but the round headlights really threw him for a loop. He really was unsure what these could possibly fit. They fit my dodge RV perfectly. The '54 stake bed is next. I am only using the bulbs, the harnesses and relays will be saved for the future. Nice bag of zip ties too. -

Thank you!

-

Outstanding work. Old plastic failure is such an issue, this is very inspiring to see and know that with careful diligence small quantity reproduction is possible. A masterpiece.

-

Not going to be of great help, but I did a Thickstun intake on my '54 last year while I rebult the engine and trans. Fair warning, My carb setup is very unconventional, but I went with a custom cable system that I made and did not use the shaft bosses on the intake. All the components are custom, and it works very smoothly. The cable is a generic motorcycle cable (read bicycle brake cable), but all other parts I machined and fabricated. I made the the remainder of the upper intake and all the flanges, brackets, etc. too. The carb is a Mikuni 44phh that I modified heavily to work and breathe properly with the 230. It's working at about 85% of really-good right now, but needs more finesse time to really get it tuned right. I still have to make the high idle cable lever system for the carb. This carb does not have a conventional choke/choke plates, so the enrichment and higher idle are achieved through a fuel enrichment/bypass valve. The high idle system will only be if I need RPM for something, like a future PTO, or just to make it work like it should. Sorry that last picture is sideways... The Thickstun manifold is very nicely made. I did also make some custom exhaust to intake flange stepped washers to get a good seal because of some thickness differences. It has dual Fenton style cast iron headers and a handmade stainless exhaust too. The NiCopp tubing is just a routing carrier for the cable sheathing. Both ends of the cable sheathes terminate in drilled and counterbored ball bearings so they can pivot smoothly as the throttle bellcranks go from one end or rotation, over center and to the other end of rotation without bending the cable itself against the end of the sheath. Maybe helps a bit? This was the most practical setup I found. It is the second iteration of it as well. The first was on the manifold side and looked really great, but it had more bends and was binding the cable a bit, so it got scrapped.

-

My 46 one of those round tuit projects

rustyzman replied to Young Ed's topic in Mopar Flathead Truck Forum

Just an opinion, but I would leave the cowl lights as just regular lights. Given that you have done the nice work on the arrow lights, any additional turn lights in the front would only take away from the arrow effect of those. I think particularly at evening or night, the effect of the new arrows will be quite visually appealing alone. -

1/2 gallon per minute running is the basic standard for any stock gasoline engine. Assuming you can get it running of course. Carb or EFI is the same, just operating at different pressures. The old SUN fuel pump gauges had a spring clamp on a bypass hose to check it. Later EFI gauges also had a bypass button for it. This is the standard we used in the shops and whatever service data we could find from different manufacturers generally agreed.

-

251 Broken Crankshaft / Noise on Rebuild

rustyzman replied to Herding Goats's topic in Mopar Flathead Truck Forum

Have you pulled the head yet to check for carbon buildup or a foreign object? Worth a look. Carbon knocks can be quite loud and startling. Also, correct spark plug? Not too long and getting hit by a valve opening? It would be weird, but a wrist pin/connecting rod bearing or even a cracked piston could be an issue. The oil crossover pipe for sure could cause noise if installed backward, at least in the 218/230's. Crank will hit the tube. Pulled the belt and checked the water pump? I have had a few bad water pumps that you would swear was a rod knock. Distributor shaft bent, rotor hitting cap on one terminal? Just a few ideas. -

My 46 one of those round tuit projects

rustyzman replied to Young Ed's topic in Mopar Flathead Truck Forum

Thanks! I choose to go for these partially because it appeared the plastic was still intact. A lot of them have deteriorated over the years. Your Gel replacement looks very good. I was considering some colored acrylic sheet if it turned out that I needed to replace any. Mcmaster Carr has it for a very good price. The steep arrow pair in my first picture have some cracks, and I have not yet fully taken them apart. I think those might actually be glass fillers. They are certainly categorically older than the round ones and weigh about twice as much. -

My 46 one of those round tuit projects

rustyzman replied to Young Ed's topic in Mopar Flathead Truck Forum

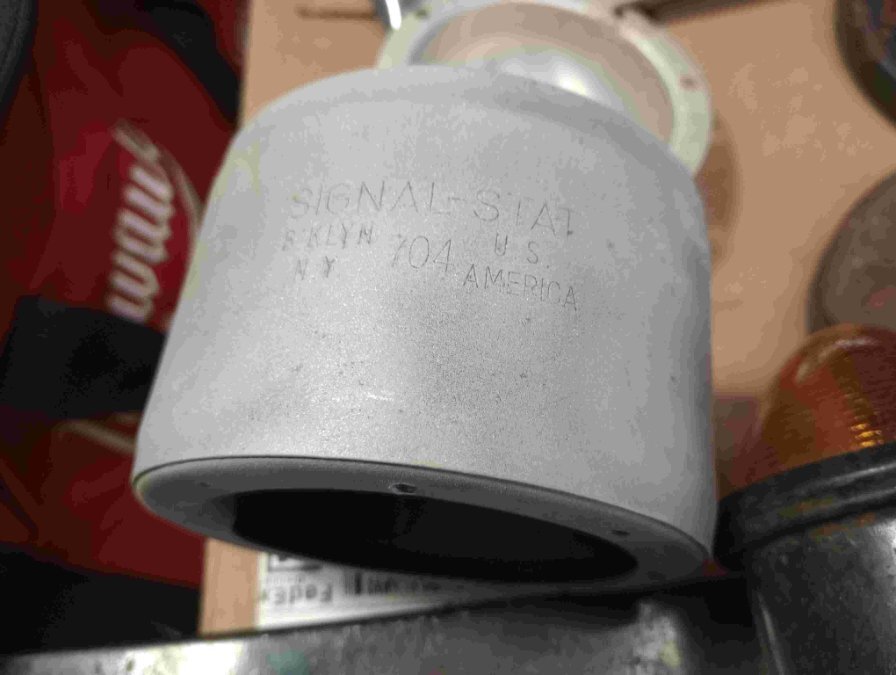

Funny timing on this thread. I have always wanted to get a set of arrow style turn signals for my '54, but never found the right deal. For my birthday my loving wife gave me ebay gift cards for whatever I wanted to get. I was able to score a great deal with a seller and ended up with four different sets. I just finished restoration on one of the two that will be on the front fenders. Signal-Stat, double face with front sided hooded. The group: Disassembly: Glass Beaded: Polishing the plastic inserts: Machining new pass thru bolts and a new base flange (original was mashed up badly): Cutting out new gaskets for the ends: Finished one vs. the next one: Once I get the second one done, I can get them mounted up on the fenders. Always loved this style! Your's look great on the '46. Very period perfect. -

Good info Dozerman! I did not realize that.

-

Really nice truck! Great Save! I have a 54 C-1-D and a lot of the basic axle and some of the brake stuff is pretty much the same. You should have normal Lockheed brake shoes on the rear which is better as they can be found in the world. I have the odd duck floating shoes that were only used for 1 or 2 years I think and then abandoned for standard Bendix brakes. I am thinking Bendix brakes showed up in 57 maybe? Probably still a trans parking brake though... For a parking brake alternative, a mechanical line lock might be an easy option. Like this one https://www.jegs.com/p/JEGS/JEGS-Hydraulic-Brake-Lock/1769685/10002/-1 As for an axle swap that retains those wheels, I know of none. The 6 x 7.25 bolt pattern is long obsolete. Several trucks (Studebaker, International and Ford I believe) and brands used them thru the 60's and some military trailers (military pull wheels I think?) used them only on certain models. Others have probably found them elsewhere as well, but a few were on motorhomes and they came in a 20" size as well as the 16". No modern or even not so modern 6 lug is the same or even reasonably close that I could find. I am sure a lot of other 1 ton axles could be made to fit with a bit of work. Newer brakes and wheels would come with that automatically, but then you have a mismatch front to back. Please note in case you want to try modern wheels on the old rear axle, a drop center tubeless rim will not clear the big drums on the 1 ton trucks. You have to use a two-piece wheel. Those wheels are very, very difficult to find in good condition. If yours are not rusted out or bulging with rust between the rivets on the center section, take good care of them and clean them up. If you choose to go a different route with axles and wheels, consider offering those up for sale to the group. Took me 5 years and 17 wheels to find 7 acceptable ones for my dually. (special thanks to a member here that really helped out on that one!) ME Miller tire is a great source for tires, tubes and flaps for them too. Great People that really know there stuff. What ratio do you have in the rear? 4.10 or 4.89? A T5 will help with speed. I can get mine to 50 but it is a task with the 230 and it is working hard. I have the 4.10. "

-

Spencer Harless, sent you a PM. Thanks!

-

Remove the drive gear carefully. It is easy to crack it or break teeth off. I started by trying to rebuild mine, but the gear lost a tooth in the process. Then the NOS assembly I bought seized after about 30 seconds of running (properly prepped ahead of time too) and knocked two teeth off that gear plus a minor bit of boogering on the cam gear. Third try was the ticket. All this because the cover leaked and I figured why not go for the rebuild. Also, the rebuild kit shaft is not drilled for the roll pin. You will have to do that after assembly. Just some thoughts.

-

Mine broke on me during a quick carb repair on the end of the driveway. I just cut a piece of thin brass sheet and made a replacement. It has been there since. Not to tough to do either, so if you don't find one, try making one. This was on a carter B&B, so your situation may vary depending on what carb you have.

-

Just FYI, I know Jim Linder of Bubba's and attended his Guru fuel injection school at his other company Linder Technical Services as well as other classes in auto/truck diagnostics. He is a very sharp, knowledgeable and nice guy. He is an old Allen Test Products guy and is very much into vintage as well. He really knows his stuff. I would not hesitate to contact him and see what he can do. In case it helps.

-

Lord help you if you crash in it. Between the dashboard, pitchfork seats and a steering wheel with NO give, it would be a bad day. I do respect and can appreciate the "use what you got around" way of doing things. I do a lot of that myself. It would be fun to see. He really should have a couple rolls of toilet paper by the rear seats though, just to complete the image.

-

I know the price is quite high, but this is hands down the finest flaring tool I have ever seen or used. http://www.mastercool.com/pages/flaring_tools.html If you plan to do multiple vehicles, this is the stuff. Single or double lap. It will also do GM FI fuel lines, Metric Bubble flares, GM and Ford push lock fuel lines and if you are clever, hose barbs. I have done so many brake line jobs over the years at work and home and this ranks as one of my top 5 automotive tools of all time in any category. Plus, because it sets up inline instead of perpendicular to the line, it fits in tight spots for splice jobs. I get a perfect flare every time. For bending I turned a Delrin tool with rounded grooves that allow the brake line to bend into them, but not kink. It is a great help when making the really tight 90's in 3/16" line. +1 on the springs not working worth a darn. Even if you do get a tight radius with no kink, you will likely not get the spring back off. Plus, NiCopp line from AGS is extremely nice to work with. Lasts a lifetime, just not good for fuel due to the alcohol content.

-

Just an update on this truck. I was there this morning and bought some parts off it. Basically two nearly stripped cabs left. Rear axle housing and third member. Front axle, knuckles and springs. Two front fenders, two doors. Nasty steering wheel still on gearbox in the truck. Most of the engine, but it appears frozen, and a four speed trans. Manifolds are still there, full of water. There is a gas tank, but the bottom is crushed and looks like it got dragged. No radiator or heaters left. One broken speedo left. Two sets of gauges remaining. Misc switches and such as well. I would suspect that this truck will disappear from there soon given how much is already gone. The frame looks very solid, cabs had some rust. Pretty much everything came apart with little effort, at least for around here. I got the brake drums and remaining wheels. If anyone needs what is left, better get there soon. Just so you know, they don't haggle on prices at all, but everything has a warranty! Wonder how they would honor that one on this stuff? (refund of course)

-

New member, old truck, lots of questions

rustyzman replied to tonkaman's topic in Mopar Flathead Truck Forum

Welcome. Looks a bit like mine did when I got it. Close to the same color, grill guard, etc. I know what you mean about the special moment. Some things are just meant to be. You can get to the valves through the valve covers under the manifolds. Pop them off and start PB Blaster-ing the valves through the stems and springs. You may also try shooting them through the spark plug holes with a long nozzle pointed at the open valves. It will likely take some love taps to get them to move, if they will do it at all. tap carefully, don't want to unseat the spring and have the keepers fall out. Be patient, it may take some time. If they are corroded in place, the valve faces may not seal even if you get them free, but give it a shot. My engine was frozen when I got is and it took a bit of time and effort to get it going. Burns some oil now and smokes. Rebuild is in the future plans. -

In case this helps anyone in the future, here is a master chart of Dorman wheel studs with all the dimensions and part numbers. This is what I used when I replaced my 1 ton studs. Sorry I did not see this post sooner or I would have posted this. I am posting it as an attachment because it would be a mess if I pasted it in the post. This is a zipped Excel file, so you will need a viewer or Excel to see it. Wheel Studs.zip

-

Found the elusive Napa shock Part #'s

rustyzman replied to nj viking's topic in Mopar Flathead Truck Forum

Does anyone know for sure if the 31000 fits the front of a 54 1ton? Rockauto has them for $15.72 each. Love to pick that up if they will fit. -

Nice job. That is a great looking truck. The left rear brake on my one ton was locking the wheel when I picked mine up too. Rust popped the lining off the shoes. Luckily I had a flatbed to drag it up and it was on grass, so no big trouble there. Still have the marks on my driveway where the 6' pinch bar had to be used to roll it back to the garage though. Very cool truck.

-

Not sure which engine you have, or if this would even be helpful but Dorman makes new steel pans for that vehicle. http://www.dormanproducts.com/applicationguideresults.aspx?y=1998&mk=DODGE&md=STRATUS&e=L4+-+2.4L+%28148+CID%29%3a+GAS%3a+FI%3a+N%3a+X&c=337&cn=OIL+PAN I have used many of their stampings and they are actually nice. Just a thought.