-

Posts

4,979 -

Joined

-

Last visited

-

Days Won

42

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

Are those cheap, new, aluminum radiators any good?

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

Seems like the old style would be prone to leak under pressure .... seems when they start leaking it is time to grease them .... pressure would just wash the grease out faster. Sometimes I think higher temps would help the engines run better but more important burn the sludge off and be a cleaner running engine. I do have a original mopar heater/core in my truck .... I also have a new style water pump and a pressurized radiator. I do not know what the cap is rated for in psi .... is what came with it and has a custom aluminum cap epoxied on to it so cant read it. My heater core has not started leaking yet, but has only a few hours on it with pressurized system .... it is 75 years old and would not be surprised if it leaks regardless. I'm confident it would not be too difficult to find a new replacement core if it does leak. -

She aint pretty, but she is all mine Actually have the correct dizzy for the conversion. No chance to work on it yet, too busy with other projects .... I have to clean up and put things away just to get room to work on it. One thing I have not seen others talk about is wiring. ..... As far as I know, just need a ignition control module and wire it up to power off the ignition switch .... not expecting it to be difficult .... just wondering if anything else is suggested. Now that I have mine, A1A Auto parts Inc. located in Lakeland FL (863) 646-5785 Talk to Melisa, she is sweet They had 3, I bought 1 so 2 more available .... $35 + shipping.

-

Are those cheap, new, aluminum radiators any good?

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

IMHO, I think capacity is the key .... If it holds more liquid then the next, it will be capable of doing a bigger cooling job. Modern vehicles have gone with a smaller capacity radiator and raised the pressure so the engine runs at a higher temp without boiling over .... this works fine on modern vehicles. Our old heater cores were not designed for high pressurized systems ..... larger radiator with more liquid capacity and lower pressure/temps is not bad. Same time if you replace your heater core with modern, you can raise your pressure and temps and get a cleaner burning engine. I also think Amazon is fine if you pick a name brand such as Champion .... Amazon is just a middle man. I still think bigger is better .... also think our little engines do not care .... 3 row may block some wind for cooling, but is offset if it is holding 1/2 gallon more coolant then a 2 row. -

Are those cheap, new, aluminum radiators any good?

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

I admit to hearing conflicting opinions ..... size matters. They are still sold as 2 row and 3 row ..... If you have a truck you use for towing a trailer ..... is advised to select a 3 row. If you have a Hot Rod with a high performance engine and go to drag week and sit for long lengths of time in hot sun waiting to check in .... bigger the better. Granted our little 6 cylinders do not need a large heavy duty radiator ..... but if they are the same price ..... why not? My original honeycomb radiator is 2" thick ..... my aluminum radiator is 3.25" thick, taller but same width as original. -

Are those cheap, new, aluminum radiators any good?

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

Just for giggles I searched Champion 3 row radiators .... Here is one shaped like mine but not the same for a chevy truck. All the connections work on the flathead 6 engines. $245 ..... The mounting is different but may work ..... this took less then 1 minute to find .... search for something closer and look for different options. https://www.amazon.com/Champion-Cooling-Chevrolet-Aluminum-Radiator/dp/B00AOCUHV6 -

Naturally it was hardened, I tried drilling and got nowhere fast. So been working at it with a dremel tool and just hogging out the material inside with a carbide bit. Little further to go, letting the tool cool down .... there is minor damage. The threads are not damaged, I can start the nut and get 3 threads with my fingers and looks good and square. Shaft is slightly oblong and not round after all the beating it took. With all the material removed from inside, I can run the nut down and make it round again. .... Not a big deal. That is why I do not have the nut on the shaft right now protecting the threads. Working slowly with a dremel is pretty easy and I will try my best not to cause damage. Thinking that is the end of this issue .... what a mess .... something that could have been simple tuned into a 3 day ordeal. Now to move forward with other projects.

-

I think having it installed is more helpful to hold it ..... while I beat the crap out of the thrust washers and gears in the box The steering box is in remarkable condition for it's age ..... no play, no leaks. Whatever force I'm putting on top is getting transferred to the bottom. Seriously, cutting the tool I'm now convinced is the correct way to go .... All I need is a long bolt to replace what I destroy. I have a couple other pullers that use the same style bolt .... whats the chances of one of them fit in both tools and can share? My biggest fear is it will be a hardened bolt, I will not be able to drill it. ..... I doubt it is. No hole, no horn in the steering wheel. I will know in about 15 minutes.

-

I remember reading that, was impressed with the actual fix ... a split die .... never knew such a animal existed ... what a life saver. Well I think I reached my limits on this .... I'm just not getting it out. I used a heavy chain with a weight and jerked it as hard as I could, I eventually got it to pull out about 1/4". I can move the tool around like a joy stick ... just cant pull it out. Then I put lots of heat on it and tried the weight and chain some more .... won't budge another millimeter. Now I have this hillbilly rig on it .... I have a lot of tension on the tool .... will not budge. If I try to put another pump on the jack the steering column flex's and afraid if I go any further I'm going to damage it So I give up. I'm going to sacrifice the tool and cut it off. Remove the wheel for clearance and keep the nut on to save the threads. Then cut it off flush with the shaft and drill it out. .... worry about the tool another day. Just sucks because it is a new tool and the first time I used it 🥵

-

No idea about best, I have been using this brand. I picked up a tube at the local parts store and was not pleased with it ..... It worked fine, once I opened the tube I should have finished it off ... All dried up and no 2nd use from it. I bought a 3 pack from Amazon of this stuff, seems to work fine. The tip saves it .... all that is inside gets dried up and have to cut the tip a little larger and dig it out, am able to finish off the tube though and not throw it away.

-

I would try soaking the cylinders with marvel mystery oil or 50/50 mix of atf/acetone. The cast iron rings tend to stick to the aluminum alloy pistons .... whatever they are made of .... rings are like a spring and need to contract -expand in the ring grooves to seal. If they are stuck due to corrosion, soaking them will help free them up. Same with the valve stems, the old oil gets gummy and the valves no longer slide easily. Soaking will help the valve guides also. You can remove the valve covers on the side to reach them .... Is suggested to adjust the valves with engine hot and running. Mine was better then yours when I started, I had one cylinder at 30psi, couple at 60-80 .... I just soaked them while working on other things. When I started it and ran it through some heat cycles, I soaked it some more .... one cylinder is at 95 the rest 100+

-

The bearing splitter worked fine to pull the wheel ... no damage to nut or threads. Now the tool is stuck in the center of the column .... the trick is to remove it without causing any damage. A slide hammer would be ideal, mine is too tall the roof gets in the way. I have another idea with a chain and a heavy weight to pop it loose .... Yesterday I tried knocking the tool loose moving it back and forth, put a impact on it and spun it around ... it moves but just wont pull out ..... I'll get it eventually. We ought to start a new off topic thread with "bonehead moves of the day" this one would qualify.

-

I'm coming out of left field here .... my issue is not very common. I noticed with my no spark to the plugs issue, I had power going to the points and could create a spark with a screwdriver. I ended up taking the distributor out and bench testing it I had a extra battery and rotating the shaft to operate the points .... the points caught on fire. The issue was the rubber insulator pad that insulates the points plate from the body of distributor ... when you connect coil wire to the distributor. The old rubber insulator was rock hard and failed. Connecting power to the points it was connecting power to the distributor body and a direct short. The only thing that makes sense to me, with the distributor installed the engine was a huge heat sink and absorbed the electricity .... so no fire or obvious reason for no spark to plugs. Once the distributor was removed and tested on the bench, the points literaly burst into flames 2" tall. It no longer had a huge heat sink to absorb the power. To correct this you need to remove the points plate and insulate the electricity from the body of the distributor. Not a huge deal, but there are a few different insulating points to look at. .... Lets not hope it is your issue .... these distributors are always easier to work on when on the bench .... same story as a bad ground wire that needs repaired inside distributor .... just a little more involved to repair. Again, just a posibility when you run out of ideas.

-

Wow, I did not expect this battle .... I got busy and it sat for a couple days, got back at it today and I got the steering wheel to pop loose. Sure I kept the nut on to save the threads .... The column has a center hole and the tool nipple is slightly larger ... While pulling the wheel loose, I forced the tool into the column and spent a few hours trying to remove it. The nut still threads on the shaft, the nut slides over the threads on the tool .... no damage yet and trying to avoid damage ... this thing is stuck good .... lot of coulda shoulda would have .... too late for that now. Think I finally found a fuse block to make me happy. I bought a aftermarket wire harness but hated the fuse block and refuse to use it. This fuse box is made for marine use, 12 circuits, all SS connections, water tight to a point. Very simple and easy to work With. ..... Just a nice box ..... Now where to put it?. I know they do not belong in the engine compartment. Honestly this is a really convenient place to work on one .... I picture a really clean wiring harness with it right here. Under the dash when I want to add a circuit or change a fuse .... what a pita to work on it. Think I'm convinced, I'm installing it here .... my truck, building it my way. Also working on the 12V electronic distributor conversion .... naturally the first distributor ordered was wrong. I have a 2nd one on the way .... Tuesday next week to be delivered. I hope it is correct. Tomorrow will be another day .... the wheel is coming off one way or the other .... then I can continue making progress. Always some sort of stumble stones in the path.

-

The timing issue has been discussed many times over the years, While 7:00 O'clock is the ideal position when everything is correct ... it is not always true ... my No1 plug is at 6:00 O'clock position. Depends on who installed the oil pump and if they followed instructions .... the oil pump is geared and is easy to get off 1 or 2 teeth when installing. These engines do not care, just make sure thee plug wires are installed to match distributor. So find TDC compression stroke for No1, where the rotor is facing is where No1 plug wire goes ... start your firing order from there, You stated the previous owner had the wires wrong, might be possible he was right.

-

You scaring me Sam ..... and we are getting lost in the weeds. ..... One thing to consider also is positive or negative ground? Maybe on positive ground it does not matter so much. I'm in the process of going 12V negative ground ..... maybe I have a new issue not even considered yet ..... although others never complained when switching. As far as the OP original question, the screws are too small my tap/die set does not go that small .... only way I could find it is taking it to the hardware store and match it up .... I have spares so I can not answer that question.

-

I was going to add, if the gasket failed behind the gauge .... it is still insulated by my gasket going to the housing. If this is true, the whole back plate would be hot, not just the post for wiring ..... Is this a bad thing? .... you decide. Now if the gasket between the case fails ..... Bake lite or not, I think we will see some smoke ..... We have a couple of safety features installed, up to us to keep them functional.

-

Ok here is what I see. With the gauge removed you can see I used cork because that is probably the closest I had to match the thickness of what I removed. If you look closely, the bakelite on the back of the gauge is recessed so the back of the gauge is flush ..... this is 2 ways the gauge is insulated from metal. Now if you look at the back of the gauge, the bakelite is actually proud of the back plate. .... Then there is a gasket that covers this area .... this is a 3rd way the gauge is insulated from metal. ..... you can see my insulator gasket just crumbled into pieces when removed. All ya All make up your own mind if it needs insulated. I'm going to do this while I have the gauge out and am running new wire. .... As far as gasket material I'm using Fel-Pro 3060 Just a random assortment of material that is nice to have around the shop ... I will be using the blue one for the back of the gauge .... closest to original.

-

It will need to be insulated I believe the correct wiring is from the starter to the input side of gauge, Direct voltage, and if the insulation fails you will have a weenie roast going on. This just happened to me in a different situation. I was having strange run issues and losing spark to the points. I could not figure it out, so I removed the distributor and bench tested it. When hooked up properly I instantly had the points catch on fire and had flames over 2" tall. Where the power wire from the coil connects, it is insulated from the case and also the point plate is insulated where it is attached to the distributor. I'm guessing with the distributor installed, the engine grounded to the frame grounded to the body acted like a big heat sink and absorbed the electricity. So there was a dead short, but no fire and no spark to points ..... The rubber insulation to the case was hard as rock and just fell apart when I removed it. Distributor on the bench the points got full brunt of the dead short and burst into flames. So I'm just paranoid right now. The amp gauge is same principle as the points ... need power to the points that needs insulated from all the metal around it. 2 weeks ago I would never have thought about this .... first the distributor fails, then I pull the gauge and see my insulation is failing .... This is my issue and you might be better off to ignore me. Same time it is, once you see it, you can not unsee it .... I'm looking at my insulation areas because I'm getting ready to build a wire harness and wire the complete truck.

-

You getting awfully wide in the rear buddy .... not so sure if a diet is in order

- 734 replies

-

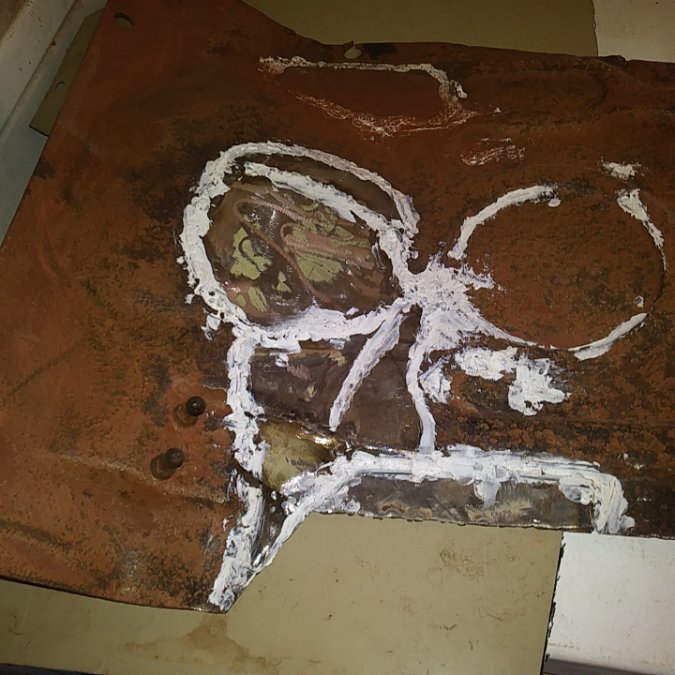

Here is a photo I'm not proud of, but because it also supports the gas pedal it had to be repaired ... while I searched for replacements ... they were not much better and $100+ to purchase. I spent a afternoon and think it was 12-14 small individual pieces I welded in and made it a strong usable piece again. Over a year later the truck is still not on the road, but the transmission cover is fine and solid. Will last longer then I'm alive. Same with your trunk gutter. Your bigger issue is the rear valance panel ....While you may be able to reuse the one from your parts car, it needs some patches made. That will be a bit more tricky because of the curves in it. .... A very special but simple tool is a homemade roller. I made this one out of scrap metal, there is a piece of angle iron bolted to it now. if you pull the metal to you, get a sharp bend. If you push the metal away from you, get a curved bend from a 3" pipe .... I have 1.5" pipe and 4" pipe to replace the angle iron to dictate what bend I get. Just something simple you can make at home .... If I was to repair or recreate the rear valance on your car, I would be using this tool.

-

Well first of all, lets not get carried away and expect to get a 100 point concourse car when finished .... But the repairs can be done fairly easy. And this is how I would approach it. First of all, do not cut past the red line .... Some welders like to cut exactly on the red line because it is easy to get to and weld grind without being seen. any rust on the other side is a separate repair. .... just cut out the left vertical side along with the rest of the gutter to keep it intact for a pattern My paint program is killing me on size .... Just use whatever scrap metal you have and cut out the left vertical side and try to be precise to match original. You can see in your photo the gutter turns in down at the curve ..... you can form that by hand. Tack weld it to the body. Then cut the floor of the gutter wider then it needs to be ... the floor will go straight at the bottom where the side curves in. tack weld it in place. then cut the right vertical piece to match original ..... What I see is a rounded edge on top ... A piece of metal line will fix that. Just some scrap brake line I have, they sell smaller sizes .... figure out what you need and dimensions, make it work. Tack weld it in place. Then when satisfied, grind the tack welds off to the car and finish welding it on the work bench .... turn it upside down, weld and grind from the bottom where nobody see's ... some seam sealer on top in the corners ... finish weld the piece onto the car and is work but simple work.

-

But your reply is superb .... Honest, knowledgeable and straight forward ... also you prefer to keep the car exactly like it was when it rolled off the show room floor. If anyone could write a book on caring for a old car, you could ..... I mean that as a compliment .... I meant writing the book as a joke. Nobody expected these cars to be around as long as they have been, no books were written for it. I'm also a firm believer, sometimes things happen for a reason. ..... If a minor screw is missing, maybe it is time to investigate and find out why the screw is missing. For example, if the gasket dried up and shrank or fell apart, the screw would become loose and eventually fall out. While simply slapping another screw in to replace it is easiest .... maybe a closer look to see why is a better idea ....

-

100% not the answer to your question .... just a suggestion. I recently pulled the gauges on my truck which I assume are similar but different .... I'm prepping to paint the interior. What I'm baffled by, you can see I replaced the insulator gasket between the gauges and the housing .... Why the heck did I put it back together with the damaged insulator gasket between the amp gauge and plate? .... If I hooked up power to that amp gauge, it is extremely close to burning the wiring to the ground. The fuel gauge gasket is in very poor condition also. Dried up, curling, cracked ..... it needs replaced also. So thats my suggestion, when was the last time you inspected the insulating gaskets on your amp gauge? Think I might pick @desoto1939to write the official long term maintenance schedule .... At 75 year check up, replace insulator gaskets on amp gauge If there was any help I can give you on screw size I would, mine are different though. .... Maybe it is time to remove the gauge for inspection and replace screw in the process.

-

Are those cheap, new, aluminum radiators any good?

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

They just do not make the good products anymore. I have in the past used Bar's Leaks product. It was a brown syrup with pellets in it that looked like rabbit ********. I had a 1961 D100 truck with 6-8 holes in the radiator where the fan hit it .... I drove the truck a few years and then lost a fan belt and it overheated. I fixed the fan belt and the radiator started leaking, I put the bars leak back in and drove it a long time with no issues. 25 years ago they changed the formula and no longer had the pellets in it .... it never worked as good since then .... now all available is sealants for aluminum radiators and a whole different animal. -

Are those cheap, new, aluminum radiators any good?

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

I bought a used one, just the way I am What the Hey, I needed one to run the engine, was local, it was a wide 3 core, all hoses were in correct location and it was easy to adapt to install. Best of all it was $50. It is not a name brand, is some custom made by a shop in Louisiana .... originally in a 57 chebby .... was replaced because of age and appearance. It is old, it looks bad and it works perfectly. .... My engine will not warm up to operating temp without a T-stat installed to control flow. A little black paint and it looks right at home in a old truck. Only point is, the radiator is old and been in service for 15+ years by someone, and still works fine.