-

Posts

4,968 -

Joined

-

Last visited

-

Days Won

42

Everything posted by Los_Control

-

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

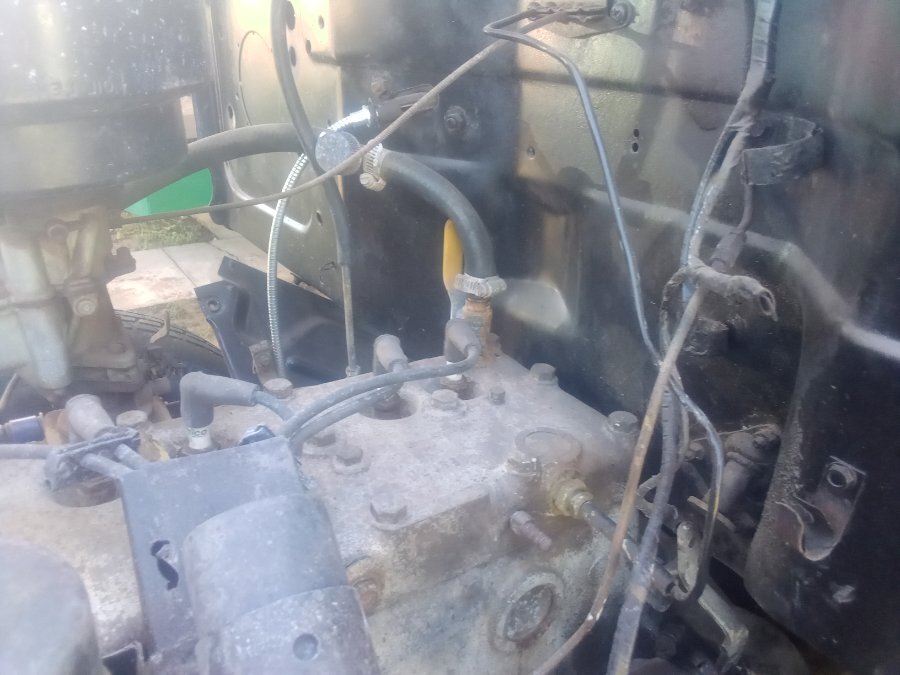

I'm thinking the coolant would drain by gravity from there .... if the coolant was low beyond that height .... top of engine, the pump would not pump it up and out. absolutely, usually there is a valve there. The purpose of the valve is to close off the water flow to the heater core in the summer when you do not want heat in the cab. If that valve is closed or clogged you would not get flow. Poor photo, you can see I replaced mine with a modern ball valve just to get things running, it works and will replace later with something more correct. -

As funny as it sounds, I was maybe 17 years old and working at a Union 76 gas station at night .... think we closed 10 or 11 pm .... I had full use of the garage during the evenings, I could bring my cars in and play with them while working ... while keeping the gasoline customers happy. I had a full garage with lift and tools at my hands .... The owner actually encouraged this activity, there were 2 bays and if customers needed help like a new fan belt or such he wanted people there that could handle the job .... I think he considered it on the job training. Just showing a photo because we all like pics. So I bought a car, not this one for $50. It was baby blue with a white vinyl top, hub caps and a 6 cylinder. Grandma's version. Everything was perfect on that car, interior, body ... car was 10 years old .... They ran Quakerstate oil in it, when I pulled the valve cover it looked almost like the photo above. Since I worked at a gas station, we had a barrel out front .... We would take the cardboard containers and insert the spout and pour oil in customers cars. When finished we would take the can and insert the spout in the barrel and let it finish dripping there .... We could use this oil anytime we wanted, it cost $$ to get rid of it. Just saying I mechanically removed all the sludge I could .... Then kept running fresh oil and ATF through it .... I would remove the valve cover and monitor it. Think it was 2 months and sold that $50 car for $500 .... It really ran well and cleaned up nice .... nobody complained.

-

Thats a good point .... I noticed that on my first project I never could finish. There was only 1 cylinder that had compression and low. When I pulled the head, the valves were stuck open ... I was shocked at how easy it was to push the valves down by hand. Literally took zero effort, the springs just were weak and would not pull them down because of the gum on the valve stems going through the valve guides. While I could use my little finger and easily push them down. Since I was using a bar on the stomp starter to roll the engine over, I just used a small rubber hammer and roll the engine over then tap them down . I really felt like I was playing the kids game whack a mole .... Within 1/2 hour all valves were functioning correctly. A compression check on all cylinders would give a good idea on whats going on.

-

Agree with @soth122003 a engine flush is good .... I actually like to do a oil change and add 1 quart ATF then fill with normal oil .... ATF is a good cleaner and will clean sludge. You had your valve covers off and you would see there how much sludge your engine has. Here is a engine that has been properly sludged up .... I would expect issues if your engine looked 1/2 this bad .... I just installed a used engine had 135K miles on it in a modern OT car .... it had a little sludge in it .... basically evidence of it, tiny amount in the corner on top of a rocker arm. I just feel it is common to see some sludge inside a engine, the older the engine the more sludge you will see .... is just common. The engine above most likely used non detergent oil ..... even later oils like Quaker state and Pennzoil had a additive I believe was paraffin ... Had a buddy at work that had a new crate engine in his 67 Ranchero, ran nothing but Pennzoil in it ... pull a valve cover and looked like this. Long story short, if your seeing some serious sludge inside your valve covers, you should pull the pan also .... if not bad, never hurts to run a flush.

-

That Chevelle had a million miles on it already but did run ok. I ended up giving the car to my sister. It was her only car and she drove it to work for a couple years yet. It was very dependable and just needed normal maintenance to keep it going. .... Brakes, alternator .... the motor hung in there. Still ran but was getting pretty tired and sis was in a better position and bought her dream car 72 Nova. I'm sure you are correct it will hang in there the way it is. .... If only we had push rod extensions 🤔

-

Sad to hear, sounds legit though. Not really something we hear about on our flatheads. I remember it used to be a common thing on early SBC, especially the lobe that ran the fuel pump. I had a 68 chevelle with a worn out 327 .... cam was flat and could not pump enough gas at high speeds .... install a electric pump and it got enough gas at high speeds to tell you the rest of the cam was flat also. Just saying it happens, sad it happened here

-

Why? You are converting 100% to a totally different system .... why would you want to use any of the old charging wires that were put in place to work opposite of what you currently have. No expert here, but not my choice. You will be fine, you actually want to cut into the charging system after the amp gauge .... 78 amps going through your amp gauge could start a fire. Pretty sure your F& A wires cut in before the amp gauge ...... no idea but I think you better spend more time thinking about it. I'm replacing all my wiring and the power wire off the alt goes after the amp gauge .... then a volt meter is more functional and included in my wiring diagram. I'm just saying, the typical 48 cloth covered wiring needs to be replaced .... if your wiring has already been replaced that is fine ..... just creates issues if you are switching grounds and such from positive to negative ..... you sure do not want to run a positive wire into a ground wire.

-

how do you lubricate this 41 alternator?

Los_Control replied to GTfastbacker's topic in P15-D24 Forum

Really depends on your goals for the car in the future. If you want a daily driver I would replace it with a alternator. 12V neg ground If you want it totally stock, I would disassemble the generator to clean it, install new brushes if needed, deal with bushings or bearings .... then run it. Me I just tossed mine out and installed a Chevrolet 12V alternator I can purchase from any local auto parts store ..... I have to install new wiring anyways .... just makes sense to me to install something I want and not beat my head against a wall installing something I do not want. If you want original, the wall is all yours. -

I agree the reproduction knobs do not look like the original. Used choke cables are out there, few and far in between though .... seems they get used a lot and replaced over the years. I can only say what I'm going to do. I have not actively searched for the choke cable .... bigger things to worry about first. I did have a chance to pick one up for a 50's Chebby truck .... not correct but it is period correct and looks better then the cable from the 90's that is in it now. In my defense, summit was having a clearance sale and I went there mainly for a set of Flowtech chrome headers for a flathead Ford V8 Flowtech discontinued them, I image they sold for $250-$300 .... I got them for $40 Same time they had pages and pages of great deals. I picked up license plate/tail light brackets, brake hardware & springs, wiring pig tails .... all kinds of random crap .... I think the choke cable was $4. I got a huge package delivered with all kinds of goodies in it for about $75 including headers. So thats my post, use a get me buy until you find the one you want .... possibly make one that is unique.

-

My 46 one of those round tuit projects

Los_Control replied to Young Ed's topic in Mopar Flathead Truck Forum

I like that a lot. -

how do you lubricate this 41 alternator?

Los_Control replied to GTfastbacker's topic in P15-D24 Forum

I'm sure you realize this .... the brushes are there but the end of the shaft fits into the back of the case riding on a bushing .... thats what you are oiling. I'm not certain what I would do in this case, I would ask for advice .... my point is the open hole is allowing dirt & grit get into the bushing. I would feel better if I flushed it out some way .... my first thought is WD40, because it is a decent cleaner and cheap enough to use to flush it out. Then I wonder if brake clean would be better because it evaporates so quickly. ...... I would want others opinion on what to do. I'm leaning towards brake clean because would not want to get WD40 on the brushes. Brake clean evaporates. Either way, even if I had to whittle a plug out of a tree branch from the ground ... I would want to plug it til permanent fix is made. Probably been like that for years and who knows if any damage has occurred .... Knowing it was like that I would spend 5 minute on it and plug it. -

how do you lubricate this 41 alternator?

Los_Control replied to GTfastbacker's topic in P15-D24 Forum

-

It is just a Dodge Caravan SE model ..... basic low level trim and hood ornament is stock. Was bought new from a school teacher and used to haul around students to after school events. Nothing custom or modified about it .... just special because wife mother was the 2nd owner on it and father kept it up good .... now it is the daughters car.

-

Knuckleharley (Arthur Hines)

Los_Control replied to Plymouthy Adams's topic in Recognitions and Remembrances

Thanks for being a good neighbor and looking after him ..... I remember he was not in the best of health a couple years ago. He did take time out to appoint a guardian of his estate and a will ..... He was a good guy and looking ahead ..... I will miss him. -

Merle is correct as always. ..... like all brakes they need to be moving freely and with 75 year old cars this is more of a issue then with newer cars. My personal advice on these brakes, you need to be involved with them and willing to work on them yourself. There is nobody out there that will care for and have as much interest in these brakes as you the owner. It was the best braking system available in it's day ..... today they are obsolete. ..... There are only a few of us around that know these brakes and work on them. You are not going to find a 30 year old mechanic that gives 2 hoots about this old obsolete braking system .... I almost guarantee you will be his only customer .... not worth their time to learn it properly. A custom shop that only works on old vehicles, will be expensive and try to talk you into a modern disk brake conversion and is the most practical way to go. If you are willing to be the mechanic and work on the brakes yourself ..... then it is feasible to keep them ..... They are not self adjusting, the best working brakes need a routine maintenance check every year or as needed, if you drive it year around. .... Only you can do this. With the amount of love and care @keithb7puts into his brakes. The help and information is here and available. If you are not willing or capable, I recommend you save yourself headaches and update the brakes. Rustyhope sells a front disk brake conversion kit that you will need a mechanic to install .... sadly the rear end needs to be updated to get modern rear brakes. ..... A jeep cherokee or Ford Explores will fit and use same wheel bolt pattern. You can get modern brakes for not a lot of $$, easy to work on, easy to get parts .... any mechanic can work on them .... will work for years with no maintenance ..... Again the modern yoke on the rear end will not fit your obsolete u-joints ..... you need to change the yoke on transmission as well and get a drive line built for it. So there is a little investment up front, The car looks totally stock at car shows, you have modern u-joints, choice of rear end gearing, modern brakes .... The car runs and drives as original .... you just eliminated a bunch of future headaches. ..... trouble free miles without having to worry about brakes, u-joints, rear end leaks. Later update the distributor with the slant 6 electronic distributor conversion and add a alternator ..... You will have a trouble free car you can drive anywhere any time with no major headaches as we get older. It will run and drive just like it does now, it will show just like it does now .... it will simply be more dependable and trouble free ...... set goals. You either learn to work on it and we will help and you work on it yourself .... or you need to upgrade a few things ..... IMHO

-

I was thinking to toss a idea out there myself, if not in any hurry ... with the shoes on the work bench you could clean them .... a day or so later clean them again. Just keep it up for a week or so .... will it work? .... Is it worth it? ..... our shoes are easy enough to get, to me just not worth it. If they were some rare shoes hard to get .... soaking them in gasoline might be a viable option. Just my opinion, fire could cause more damage then good. Gasoline will evaporate .... so if the shoes were soaked for a day or so, long enough to thin down and remove the oil .... then let the shoes dry a few days .... it will just evaporate naturally.

-

It is a 93, I just installed a 94 engine in it a few weeks ago. .... not perfect but is a good work horse and we enjoy driving it.

-

Just my opinion. If they are dirty with grease or fluids from your hands while working on them, then you can just clean them up. If they are saturated with brake fluid from a leaky wheel cylinder for any length of time, the shoes will absorb the oil. Now you clean the surface and they look clean, then the oil inside the shoe will seep back out to the surface again. Some say you can never make them right again.

-

I'm only suggesting the post @GrumpyJim made, suggest non stock wiring. Absolutely nothing wrong with that ..... just depends who replaced the wiring in what decade. ...... Possible they were running shine and have a few extra electrical oddities to it. We know nothing with the information provided.

-

Tough call and from the information you have given, I doubt anyone here can tell you what it is. I do not think that a flashing e-brake light is stock ..... the electric fuel pump is not stock ..... I'm thinking your car has been rewired. Thats perfectly fine. ..... Is it still 6 volt or 12 volt? ..... there are so many things a person can do when they re-wire a car. I bet @Sniper has more crap wired on his car then any 1950's car thought of having. Then there are those that were taught in the 40's and did more crap then should be allowed. Nobody knows what you have by your description. ..... When multiple items goes out at one time .... I suspect possibly a fuse or a junction box ..... something that powers multiple items. It might be easiest to start with the fuel pump and trace the wiring back to where it gets power. Then figure out why it has no power. Just saying, your issue is not a stock factory wiring problem. You will need a test light and trace the problem back to the origin. ..... starting at the end of the line, the fuel pump and working forwards might be the easiest way.

-

If you are young and dumb you can correct that. I was 15 years old and had a 1963 Rambler .... it was a big job for me to replace the clutch in it. I had no $$ left to fix the brakes .... So I just pinched off the brake line going to the left front wheel ... so it obviously pulled to the right. The old hippie I sold the car to for $100 just laughed, at least it pulls you into the ditch and not oncoming traffic. Just saying, we can adjust such things. In your case, I probably would want to completely disassemble the brakes and use a wire wheel to clean the backing plates, I would clean every moving part and probably paint .... not needed though .... then properly grease all pivot points. If everything else is correct they should work fine .... @soth122003 had a great point, any brake fluid on the shoes they need replaced .... grease and such from your hands you can clean off. .... not brake fluid though.

-

I'll never forget my time at a wrecking yard I called in to pick up a part .... I drove 1 hour & got there and they were just going to lunch .... I had to come back after lunch. Then it took another hour for them to go pull the part and deliver it ..... After 3 hours of this waiting game I was frustrated ..... I was laying into the poor lady clerk ..... Gawd Dang it, I'm retired!!! ..... I dont have time to sit around here all day to get a part! She busted out laughing and that made me laugh and I felt better

-

The only weather I got from it was cooler temps in the 70's-80's and fair amount of rain .... my tools suffered because I left them on the work table overnight and they got rained on Garden has been watered good for last few days Now the grass needs to be mowed again I pray for the others, yesterday a friend on another forum lost power for 3 hours ..... Me there was nothing of significance.

-

I want to sign a petition complaining about my new Gates water pump. Sure it works fine .... Just because my bypass hose leaks .... my new pump looks like it is 20 years old. Them dirty devils should have put some forethought into it ...... Now I'm going to have to remove it just to add paint to it. Probably fix the bypass hose leak while there .... My Gates pump works fine .... I wish I did paint it before installation ... I did not .... I will replace the worn spring clamps on the bypass hose with worm drive. Just sucks I have to do the job twice .... just a heads up for others.