-

Posts

4,961 -

Joined

-

Last visited

-

Days Won

42

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

Need Advice on Choosing a Budget Laptop for College

Los_Control replied to metoodavid's topic in Off Topic (OT)

Think big ..... grow big -

Need Advice on Choosing a Budget Laptop for College

Los_Control replied to metoodavid's topic in Off Topic (OT)

I will toss in my 2 cents.. What you are asking is not a lot. https://www.walmart.com/browse/electronics/all-walmart-restored-computers/3944_9332706_7782955_2916436_4932219 I just think you can find something here that will do what you want, while not breaking the bank doing so. I have bought 2 desktop computers from this link in the past and still using them several years later. For your budget I think you can find something here that will do what you want. I'm just no good at laptops and could not point you to the correct one to buy ... can point you in the right direction. -

No bunny problem here .... just tall grass I have thought about having some critters like chickens in the back yard, just too frigging hot in the summer to try and take care of them. Be difficult and border on cruelty to animals in my opinion. ..... While I have seen a couple neighbors try it a few times, never for long.

-

Thats it! I have been trying to figure out my backyard ..... Thanks @Eneto-55 My backyard identifies as a bunny refuge

-

New guy here: 1949 Plymouth Super Deluxe

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

@DonaldSmith Just laughing because I think it is a good story .... I think we all have a story about doing it at least once. -

New guy here: 1949 Plymouth Super Deluxe

Los_Control replied to 1949plymouthdeluxe's topic in P15-D24 Forum

Remember when I was a kid just yesterday Drove a 51 Ford truck to school. The E-brake never worked good enough to actually use it ..... Since it was a floor shift truck and E-brake handle was next to the shifter, it would get kicked into the on position and could drive with it on no problem. Then after driving awhile it seems the brake would heat up and start grabbing, the truck would just chatter to a stop while your pulling to the side of the road. First time it happened was a real WTF moment. Then I figured it out and took the brake off and was fine again .... 3 months later same thing would happen, I was able to look over see the brake is in on position and take it off and keep going. Pretty sure anyone that have driven these old vehicles this has happened to at least once. ..... TBF, I was a 15 year old kid at the time and drove that truck for over 1 year. Now that I'm a little older, I might be better at checking to see it is off. Maybe age and timeline sounds off, I also quit school when I was 15 and went to work for a plumber contractor under the table and never got a drivers license til I was 18. -

I have been trying to time my chebby for 2 days now .... I'm just getting ready to wire wheel my timing mark and mask it off to paint it white so I can see it. I don't get much done in just 10 hours

-

-

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

Fair enough ... possibly stuck rings and one of them broke instead of releasing. Would do more harm to run it then to fix it. My issues was the distribution tube in the photo .... I live in West Texas and we have really hard water. So my tube had filled up with mineral deposits. It literally filled with mineral deposits and had to use a 4' bar with a 3 pound sledge hammer and physically clean the mineral deposits out of my way just to get water flow through it. My tube needs replaced, I would still have to use same procedure just to use proper tool to pull the tube out. ... Is best to pull tube when the engine is out. Is 25" long and behind the water pump ... You can imagine the radiator, core support, grille .... all the parts to remove to get to it. This is a unique issue to our engines .... sometimes the tubes just rust out and come apart in pieces. Next is casting sand. There is a lot of left over sand when the blocks were made, never properly cleaned out. All this sand and 75 years worth of other crap settle at the lowest point of the block, near the block drain valve, oil tube, welsh plugs .... If you pull the water pump and the welsh plugs, put a garden hose in the distribution tube and use wire to reach around and pull all the dirt and sand out ... you will be impressed how much it hold. These are the only 2 issues that are unique to our engines .... I think the casting sand is common on other engines though. Everything else is just basic stoofs .... radiator, T-stat, valves, water pump .... -

My 46 one of those round tuit projects

Los_Control replied to Young Ed's topic in Mopar Flathead Truck Forum

My 2 cents, if running separate turn signal on the fender, I would not want cowl light to flash also. I also have a feeling about using cowl light for turn signal .... they just to far back to be effective ..... IMHO. several do use them though. Dating some of the women I have in the past, I want everything up front where it belongs .... I'm not certain they can decipher the meaning of a light set that far back in the time it takes to turn at a intersection. -

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

Are you sure it was not just steam burning condensation as the engine was warming up? I have seen this on other engines to start when heat gets into the block, then last for 30-40 minutes until all condensation is burned off. I'm no mechanic, I always thought blue smoke is oil, black smoke is fuel, white smoke is water or condensation. Are you certain it ever had compression on #1? .... These flatheads are notorious for having stuck valves. They sit with the valve open for years and sludge and gummy oil makes the valve stem sticky and the weak valve springs just wont pull them closed. Usually the engines will not start from low or no compression .... often if they do start and run them through a few heat cycles the warm oil will get things working again all on their own. When I first started my truck up I had enough compression to run, 115 60 75 85 75 90 all cylinders are now between 100-110 just by running it. I really can not describe all the ugliness that came out of the tail pipe the first few times running it. Another issue besides stuck valves is stuck rings. These old Dodges the rings like to stick to the pistons. Which means they will not expand to the cylinder wall or rotate as needed. It is 2 different metals fuzzing themselves together .... A few heat cycles and let the engine run and sometimes they free themselves up. Of course it is always good to open the head up and get a good look at what is really going on. Just suggesting I would let the engine run enough to prove to myself it will not clear up without tearing into it. -

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

I'm wondering if you have the engine running yet? I'm just guessing you are trying to do some preventive maintenance before starting it up? .... Not actually trying to fix a existing overheat problem. When I first started mine up, it sat in a field for 20+ years, it had major cooling issues and I'm certain today this is why it was finally parked out in the field. I had to go through every part of the cooling system including pull the water pump and rod out the waster tube behind it, replace radiator, T-stat, pull the core plugs and clean the casting sand out of the block .... the heater control valve on the head for the heater hose was frozen closed. All cheap and easy things to do at home. If you have a valve on the head I would pull it off. These are standard NPT threads and can get a nipple from Ace hardware and just bypass the valve. Same time, if it is clogged there, is not going to make the engine overheat .... your heater will not get coolant and not heat. It is normal to close the valve and run this way ... why the valve is there. IMHO, you may be getting caught up on small things that do not matter. ..... Maybe they could not close the valve to turn the heat off. Being cheap they pulled the valve and blocked it ... instead of spending $$ to replace it. Either way, if no air coming out the end of the hose you need to remove the hose and then whatever is there connecting the hose to the head, then check again. I'm guessing your issue is between the head and the hose. -

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

In my photo above, you can see in my heater hose going to the heater core I have a flush port installed. Means I can connect a garden hose there and remove the radiator cap. Then while running in the driveway flush the cooling system out. A serious clog would need to be removed by other means though .... Eitherway, flushing with water would be more effective then testing with air imho. -

All the way down in Texas here .... if you get lost and wander this far let me know ..... enjoy your trip.

-

Wax on ...... wax off .... All I got to say about that

-

More on additives, short story fuel additives good, oil additives bad

Los_Control replied to greg g's topic in P15-D24 Forum

In my daily drivers, I try when I remember ..... I use seafoam in the tank as a preventive cleaner .... I have seen others have good results with it. Also a firm believer that with moderate water in gas tank, 1 bottle of HEET will allow it to mix with fuel and burn through .... no instant gratification, next tank of clean fuel you notice it worked. Only thing I would add to the oil is ATF, do a oil change and add 1 quart ATF and top off with regular oil ..... ATF is a excellent cleaner, it will clean your engine over time .... it is too thin to be used regularly,but a good cleaner. Only thing that comes to mind, my 1951 F-2 ... 3/4 ton Ford that when approaching 55 the king pins would cause the death wobble and literally had to pull over to the side of road and start again ... It liked 50mph not 55. Other then that, I hated 55 in my other cars, never did get a speeding ticket though. -

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

IMHO, I believe there is a direction it should flow through the core .... basically hot water going into the top and exiting out the bottom ..... just easier then putting water in the bottom and exiting from the top. Realistically probably makes no difference ...... I have never seen instructions on which hose goes where on a heater core. I would remove both hoses from heater core and test it individually ..... pushing water through it would be best to actually clean and flush it. I would do same thing with the radiator .... disconnect hoses and run water through it to flush it. Then do your first start with a known working temp gauge and monitor it while the engine is running. When you get this far and have issues .... there are more things to do .... not for first start though. -

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

Ok now I'm confused .... what are you checking ..... engine block or heater core? All the water pump is ..... like a childs pinwheel it directs air .... it does not actually pump water, it directs it in the proper direction .... Because it is powered by the fan belt it may be able to achieve some pressure like 1 or 2 psi .... it just directs the flow of the water and keeps it moving. A pressurized system comes from the heat and the radiator cap .... heat builds pressure. The whole system should be clear for air to travel through though. -

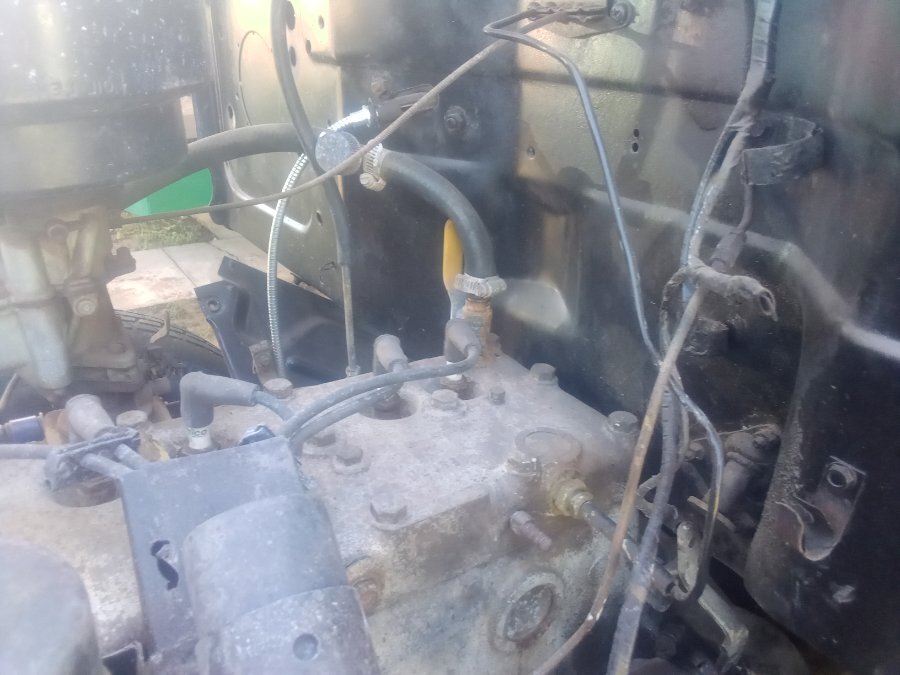

Coolant flow to heater core

Los_Control replied to General23cmp's topic in Mopar Flathead Truck Forum

I'm thinking the coolant would drain by gravity from there .... if the coolant was low beyond that height .... top of engine, the pump would not pump it up and out. absolutely, usually there is a valve there. The purpose of the valve is to close off the water flow to the heater core in the summer when you do not want heat in the cab. If that valve is closed or clogged you would not get flow. Poor photo, you can see I replaced mine with a modern ball valve just to get things running, it works and will replace later with something more correct. -

As funny as it sounds, I was maybe 17 years old and working at a Union 76 gas station at night .... think we closed 10 or 11 pm .... I had full use of the garage during the evenings, I could bring my cars in and play with them while working ... while keeping the gasoline customers happy. I had a full garage with lift and tools at my hands .... The owner actually encouraged this activity, there were 2 bays and if customers needed help like a new fan belt or such he wanted people there that could handle the job .... I think he considered it on the job training. Just showing a photo because we all like pics. So I bought a car, not this one for $50. It was baby blue with a white vinyl top, hub caps and a 6 cylinder. Grandma's version. Everything was perfect on that car, interior, body ... car was 10 years old .... They ran Quakerstate oil in it, when I pulled the valve cover it looked almost like the photo above. Since I worked at a gas station, we had a barrel out front .... We would take the cardboard containers and insert the spout and pour oil in customers cars. When finished we would take the can and insert the spout in the barrel and let it finish dripping there .... We could use this oil anytime we wanted, it cost $$ to get rid of it. Just saying I mechanically removed all the sludge I could .... Then kept running fresh oil and ATF through it .... I would remove the valve cover and monitor it. Think it was 2 months and sold that $50 car for $500 .... It really ran well and cleaned up nice .... nobody complained.

-

Thats a good point .... I noticed that on my first project I never could finish. There was only 1 cylinder that had compression and low. When I pulled the head, the valves were stuck open ... I was shocked at how easy it was to push the valves down by hand. Literally took zero effort, the springs just were weak and would not pull them down because of the gum on the valve stems going through the valve guides. While I could use my little finger and easily push them down. Since I was using a bar on the stomp starter to roll the engine over, I just used a small rubber hammer and roll the engine over then tap them down . I really felt like I was playing the kids game whack a mole .... Within 1/2 hour all valves were functioning correctly. A compression check on all cylinders would give a good idea on whats going on.

-

Agree with @soth122003 a engine flush is good .... I actually like to do a oil change and add 1 quart ATF then fill with normal oil .... ATF is a good cleaner and will clean sludge. You had your valve covers off and you would see there how much sludge your engine has. Here is a engine that has been properly sludged up .... I would expect issues if your engine looked 1/2 this bad .... I just installed a used engine had 135K miles on it in a modern OT car .... it had a little sludge in it .... basically evidence of it, tiny amount in the corner on top of a rocker arm. I just feel it is common to see some sludge inside a engine, the older the engine the more sludge you will see .... is just common. The engine above most likely used non detergent oil ..... even later oils like Quaker state and Pennzoil had a additive I believe was paraffin ... Had a buddy at work that had a new crate engine in his 67 Ranchero, ran nothing but Pennzoil in it ... pull a valve cover and looked like this. Long story short, if your seeing some serious sludge inside your valve covers, you should pull the pan also .... if not bad, never hurts to run a flush.

-

That Chevelle had a million miles on it already but did run ok. I ended up giving the car to my sister. It was her only car and she drove it to work for a couple years yet. It was very dependable and just needed normal maintenance to keep it going. .... Brakes, alternator .... the motor hung in there. Still ran but was getting pretty tired and sis was in a better position and bought her dream car 72 Nova. I'm sure you are correct it will hang in there the way it is. .... If only we had push rod extensions 🤔

-

Sad to hear, sounds legit though. Not really something we hear about on our flatheads. I remember it used to be a common thing on early SBC, especially the lobe that ran the fuel pump. I had a 68 chevelle with a worn out 327 .... cam was flat and could not pump enough gas at high speeds .... install a electric pump and it got enough gas at high speeds to tell you the rest of the cam was flat also. Just saying it happens, sad it happened here

-

Why? You are converting 100% to a totally different system .... why would you want to use any of the old charging wires that were put in place to work opposite of what you currently have. No expert here, but not my choice. You will be fine, you actually want to cut into the charging system after the amp gauge .... 78 amps going through your amp gauge could start a fire. Pretty sure your F& A wires cut in before the amp gauge ...... no idea but I think you better spend more time thinking about it. I'm replacing all my wiring and the power wire off the alt goes after the amp gauge .... then a volt meter is more functional and included in my wiring diagram. I'm just saying, the typical 48 cloth covered wiring needs to be replaced .... if your wiring has already been replaced that is fine ..... just creates issues if you are switching grounds and such from positive to negative ..... you sure do not want to run a positive wire into a ground wire.