-

Posts

4,986 -

Joined

-

Last visited

-

Days Won

43

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

Halibut is some good tasting fish ... I love fish. I cook fish every Friday, I could it it 2 or 3 times a week. But the adventure of going out and searching hunting then actually catching is the fun. The wife & I use to spend hours out bass fishing, during the week I would car pool with a co-worker, he would pick me up and we go to work and when we got back to my house, jump in my van and the boat was always connected, lived a 1/4 mile from a boat launch to the Columbia river. Crazy days indeed ... sometimes we just made it back off the river to make it to work the next morning. Today, all my fish comes from walmart ... sigh!

-

step bore to straight bore wheel cylinders.

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

I appreciate your info. As you say, so many BS artist on the youtube ... makes a guy wonder. Exactly, your opinion gives me peace of mind. Fact is I really did not know. was gnawing in the back of my mind. I am no spring chicken, but was hatched in 1962. was the 70's before I started working on cars ... Just because I drove a 51 ford in school does not mean I worked on it, just the cheapest beater I could afford. Only thing I have against step bores today is running a hone through them for rebuild ... otherwise I know nothing. -

step bore to straight bore wheel cylinders.

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

Since I did this swap ... plot gets deeper. Watching JonathanW on youtube build a old roadster, he is using a 30's mopar straight axle and he made a huge deal out of the fact he was using the step wheel cylinders and he took his brake shoes and cut the front shoe shorter then the rear shoe. Or opposite, but he acted like it mattered. Suggesting that the step cylinders were used to work different pressures on front and rear shoes on that axle. I guess that is where my question really lies ... Is there really a different set of shoes to go with the wheel cylinders? -

step bore to straight bore wheel cylinders.

Los_Control posted a topic in Mopar Flathead Truck Forum

I wondering if others have changed from one to the other. My truck had the step bore on the front and needed replaced. Me being the selfish person I am, wanted straight bore and saw they were a option and ordered those. They fit fine, I noticed it was difficult to get the drums back on. I did have to back off the adjustment on the shoes all the way, then basically leave them backed off and just a slight drag when turning the drums. .... exactly how I would have adjusted them in the first place. This is with the used thin brake shoes. Thinking if I had new shoes, may not have gotten the drums on at all. Now I am kinda second guessing my choice. ... My thought is when I get hydraulics working and get some pressure on them, they will get seated proper and then can or will need to adjust them up. While putting my rear brakes together ... my mind is wandering to the front brakes and wonder if I need to revisit them? Is it bad voo doo to go from step to straight bores? -

Or the 3rd thing ... long rope and extra transmission

-

Yes I have done it myself for one reason or another. I picture in my mind, previous owner takes it to mechanic to have the leaky wheel cylinders fixed .... Could just as easy be the previous owners work. I found it because am cleaning things up waiting on parts. If I had the truck on the rack and just swapping new parts in and connecting lines, would have been easy to miss. Would not be able to bleed the brakes and start tearing things apart chasing the problem.

-

First time I seen this, got a good laugh and thought would share. Someone added a copper blank into the brake line connection to the right rear wheel cylinder. I can only assume the wheel cylinders were leaking so they blocked it off instead of fixing. Seems like a professional fix, the fix I have seen in the past is to cut the line and fold it over. This time I feel is professional garbage mechanic, cause they took the line loose and inserted a plug and I assume probably needed to bleed them. But they did not really damage any line or wheel cylinder. Just different.

-

Rear Wheel Cylinders for 53 B4B

Los_Control replied to 53 Truck-O-Matic's topic in Mopar Flathead Truck Forum

The face of the cap, should be inside the tang on the yoke. This photo shows it sitting on top of the tang. This is wrong. That tang is there to hold the cap on the ujoint .... That cap needs to sit flush in the saddle of the yoke .... you are sitting on top of the tang and shows ujoint is to wide. Possible you may be able to change the caps for something narrower ... I have no clue. The ujoint fits the drive line, but does not fit the yoke. My daily driver 91 chevy has a 2004 or newer rearend installed while a stock 1991 drive line. I have to buy a ujoint for both years, take 2 caps from one and install on the other ... and it is fine ... but difference is diameter, height of the caps ... not the width of the ujoint. But what you show will not work as is. -

There is a how to thread on here where a guy did exactly that. 1 or 2 years ago. I really see no issue .... I thought about doing that to mine .... But I am lazy. Looks like my rear wheel cylinders will be here tomorrow, I have a bit more cleanup and paint to do, so I can re-assemble. Until I drive it, I am not sold on keeping this rear end. I may swap it out for a modern 3:73 in 6 months ... If I decide I want to keep it, then I may grind the 4 rivets off.

-

Well I'll be dipped .... I just bought last one from local brick & mortar store. I Assumed rock auto would be selling same switch ... Cant hope for no better then acdelco, I have the page up now and see it. I bet you are correct, give the part # to the dealer and would have a better chance of getting it. Rock auto works for me though. Thanks, now I feel lazy for not checking rock auto first .... I try to buy local when I can.

-

OK then, thats the way I connected it the very first time that the battery was still in the car ... The charger died ... I thought "well, we cant do that" And never tried again. I do not want to spread dis-information, that was just my experience the first time, never did it again. Positive ground still seems so backwards to me.

-

Last time I tried it, was a old school charger probably 20 years old think it was 10/6/2 with option for 12 or 6 volt. And it worked fine charging a 6 volt battery out of the car. The one time I connected it to the battery while still installed in the car (truck) It pegged the needle on the gauge and twisted it off. I assumed that was because of the positive ground still connected. And would myself assume would happen to solar charger also .... Maybe it was fine to connect it, and just was the end of the life of the charger?

-

Well maybe I am doing it wrong. I know that when I charge my battery using a standard 110 volt battery charger. I connect the red to positive and black to neg on the battery, just like any other modern battery ... except charger is set to 6 volt. When finished I then install battery using positive ground. All seems fine here. I know if I connect my charger this way and leave the positive cable connected, I will have a very sad battery charger .... I assume solar charger would be sad also.

-

I wonder how they work on a 6 volt car battery. I suspect these solar panels have modern day electronics in mind. A usb port typically is ~5 volts. Or at least the power supply in a computer tower, the wires that power a usb port is 5 volts. Same when you connect a 110 volt outlet with a usb port, The usb port should be about 5 volts. So I suspect these 6 volt solar panel are so popular to charge a cell phone in remote locations. Would also charge some tablets and note books, while a laptop and other larger electronics may require maybe 12 volts to charge. They vary. I know a guy who does maintenance on wireless internet towers. All the work is done with cordless power tools and batteries charged with solar. You need a better solar panel to charge the power tools and of course he needed his laptop to check the signal strength, he charged it also. Sure a little better solar panel charger, you get some adjustment on voltage to your electronics. Only point is, I am sure they did not have a 6 volt positive ground desoto in mind when they created the 6 volt chargers. I assume it will work, you will need to disconnect the positive cable from your car while in use ... I could be wrong.

-

difficult to take a photo up close with cheap phone. On the right I circled in black a young blossom. On the left in red I circled a stem where there was a blossom yesterday. Something is eating the nice fresh young flowers. .... I suspect a bird but not able to catch them yet. I may throw a net over it. A old trick is to pinch off the early blooms, let the plant concentrate on leaf and branch growth, then let flowers bloom to fruit later. I assumed by now, plant will put out enough blooms for all, but whatever it is ... is very greedy and eating all the blooms, tomorrow this bloom will be plucked clean.

-

While I wont call my fist attempt at this garden zone a total waste, I am not really pleased with fruit production vrs effort put in. I have picked a few peppers so far. The tomato plant is over 5' tall, not one tomato yet. Something is eating the blossoms off it. ...no blossoms no fruit. Cantaloupe is flowering like crazy and growing up both trellis, no fruit yet, Cucumbers have just been sitting, no fruit yet, all of a sudden they are getting a burst of growth. Same with peppers, some have done nothing and just now kicking in. sweet peas hate the heat, they are not dead but need planted at cooler temps. green beans were planted a few weeks ago, they are doing fine. still have 6 weeks of triple digit temps, then plant some cooler weather crops spice garden in front is going, will need refreshed when cooler and see what comes back All first year learning experience.

-

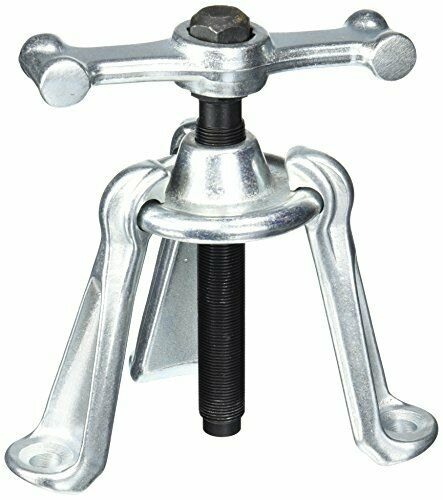

Be fun to watch the video, if you shared the url and not a pic. I joked about it a few weeks ago. I shared this photo awhile back. I suggested you stand to the side ... there is a lot of pressure on these drums and tapered axles ... you have to keep the axle nut on. They come loose with such a force, bodily injury can occur. I also suggested to stand to the side ... when this one came loose, it was enough force the dog bone handle hit the side of the house with a good bang. With the other side ... it was coming off a bit cockeyed. I have to leave the lug studs loose so the puller will fit. And may not had them even. Was obvious that when the drum was dragging on the brakes it was crooked ... 2 more taps and it popped free with no damage and handle just fell off and landed on the wheel. These old drums are built so thick and tough, I would suspect you would break one before you could bend one. Myself I could not imagine another way to pull them ... I hear the stories ... also stories out there of a driver doing circles in a vacant lot, and a mechanic riding on the fender adjusting the valves hot. Not saying it never happened, just you will never see me trying this.

-

I have to agree. Locally owned parts plus store, you just described the owners son to a T, And this clown will someday be the owner. The kid at the dealer I get the feeling my truck was older then he was. I said was a shot in the dark and explained why calling and hoping for better quality .... Same switch was used in many chevy for many years. It was a fail. I know several people who have these old chevy trucks ... bad ignition switches were never really a problem. My truck had a after market security system installed in the 90's, that included a aftermarket switch. And it was wore out, you could start the truck without a key. I needed a grinder with a cut off wheel to remove the aftermarket crap, return it to stock. I do not have keys for the doors .... I am thinking to go to carpart.com, see if I cant find a ignition, door locks, keys and have them delivered .... see how long the used oem switch last.

-

What you describe is for poor mechanic, that does not have the proper puller to do the job. Back in the day that was common and people were creative ... did it anyways without the tool. I just bought mine from ebay with shipping it was about $110. I see this one listed for $68 ... Some I bid on name brands were going for almost $200 + shipping. But with the right tool, it was very easy to pull the drums.

-

I really want to avoid that on this old chevy. Would like to see this one be a survivor, maybe a grand kid or nephew will enjoy it when I no longer need it. That frugal engineering can be a slippery slope ... Think I will run a temp button inside the cab, run 1 wire to the battery and leave disconnected ... then if this happens again, I can connect it and verify it is the switch. Kid at the Chevrolet dealer snickered when asked for parts for a 1991, said would need to order and may not be able to get. Wondering now if maybe a used original switch would be better quality then a new china switch??? Will need to research and see whats next.

-

Thats where I am at ... We can buy parts for our old Mopars from different suppliers ... DCM, Hagen, Roberts etc... chances our they are all getting the same part from the same source. While a ignition switch from a Chevrolet dealer ... may come from the same place Autozone buys them? Being a proper grumpy old man, I have no friends to help me if the switch fails again .... Thinking I may just run a push button under the dash somewhere out of the way, Then if it fails again, I can sit in the drivers seat and use the clutch and a remote starter switch. I remember my Uncle he always put a push button on his cars with a bad ignition switch ... young kid like me I laugh and think to myself, why not replace .... I see why now, replace it with junk and 6 months down the road you need to replace it again. While a button works just fine. If I thought I could get a good one, I would pay more and be done with it ... I just have doubts on quality. My John deere riding mower I needed to add a button to it, but ignition switch is soldered to a circuit board and doubles as the fuse box ... a button works just fine thank you.

-

We can teach you, first you will need a multi meter both black & red colored electrical tape depending on hold down style, you may need to flatbed it to a shop and have removed .... union electricians are not allowed to do mechanics When you get the hold down removed, let us know

- 43 replies

-

- 1

-

-

- positive ground

- electrical

-

(and 4 more)

Tagged with:

-

While I do not want to say my 91 chevy truck will be my last vehicle, not sure if sad or proud it will be my newest vehicle. This chevy has enough miles left in it to last me my lifetime, if taken care of. I fully expect to die of old age and it will be my newest truck I own. I expect to park it and drive my pilothouse in the future. My wife does have a 1993 dodge caravan, it has a rebuilt trans in it ... 180k miles on it, runs perfect ... when the trans dies again, will get her a newer vehicle and the seats are going in the pilothouse. But yeah, old school was good. I drove a zillion miles over 12 years with a 1987 ford work van 351/C6 ... just got to take care of them.

-

sounds awesome, your old car is doing just what it should

-

Thanks, that is a good suggestion and will carry a remote switch with me in my emergency tool kit. Because I did change it in last year, it is suspect to be junk. Kinda seems to me also it is most likely culprit. quality Replacement parts today are so hard to come by. More I think about it, the more I think you are correct. ... I would bet 10 cents that a remote starter button with the key on and it would start. I wonder if dealer would have a oem switch for a 1991 and if it would be better quality? I might check. This truck has 417k on the clock ... way beyond original motor/trans/rear end But would drive it anywhere today. They really are good trucks.