-

Posts

939 -

Joined

-

Last visited

-

Days Won

5

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by chrysler1941

-

These are great. Chrysler Master Tech videos from 1940s - oiling

chrysler1941 replied to Bryan's topic in P15-D24 Forum

I was under impression you had some pre war film strips. Sorry -

-

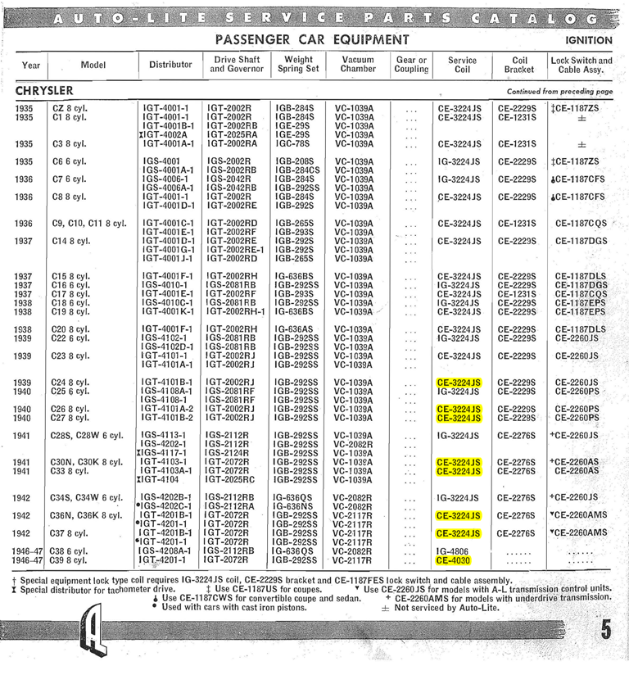

So, after some research I found some more documentation to support my statements. First of all, this thread is about 6-volt coil, so all info regarding ballast resistors is irrelevant. Attached page from 1947 Auto-Lite. Highlighted are coil for 8 cylinders. They differ from 6 cylinder. Why is not known. Could be size or shape or bracketry. Viewing a military ordinance document regarding current test procedure, clearly showing the exact same coil models. Both 6-volt coils, model IG and CE have different current draw. Why? Ohms law tells us it due to difference in coil winding. This is how they did it the 40s. Are 50’s 6 volt coils wound for a both 6 and 8? Any Documentation? Attached, just for fun, page from Pretronix coil data. These are produced today. And what do you know, there are different coils for 6 and 8 cylinders, for both 6 and 12 volts.

-

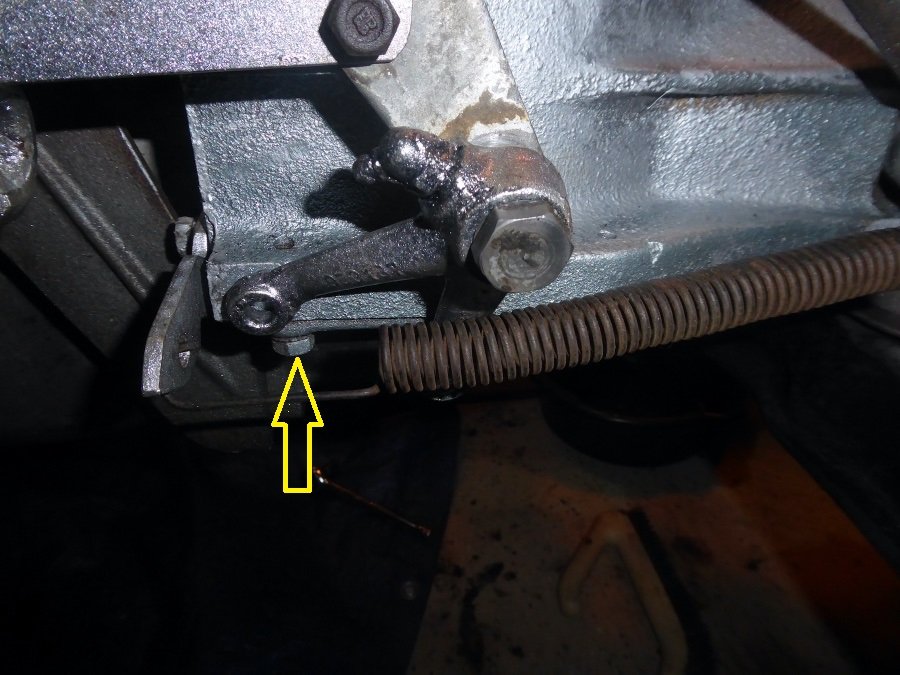

Oh I see now we are talking about clutch return spring and not over spring. 61spit is correct It should be flat pointing towards engine. See arrow, bracket goes here BTW love your original DPDC bolts

-

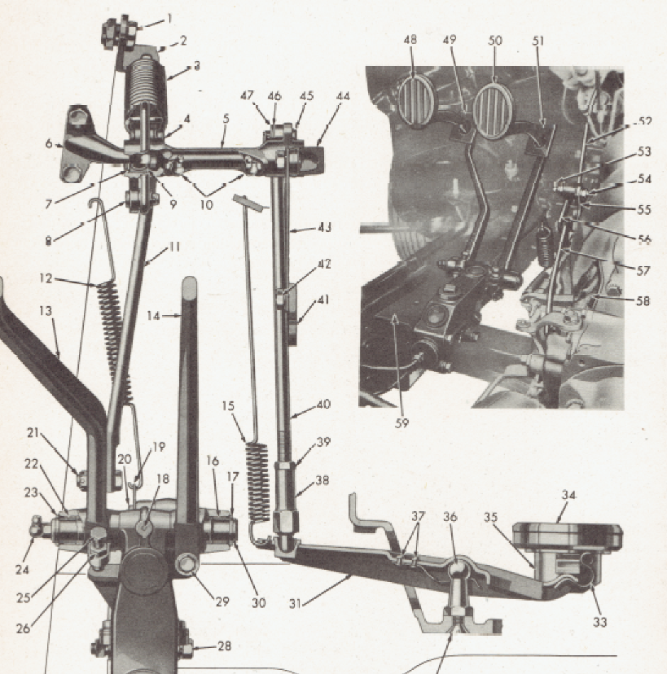

Looks you opened 2 threads regarding your linkage endeavor In the other thread you asked: "Is it OK to remove the top bracket first to remove the spring, or should I first remove the bottom bracket first, or does it matter? " https://p15-d24.com/topic/56599-how-do-i-connect-linkage-on-48-desoto/?tab=comments#comment-608528 I was wondering about top bracket question. Over spring has only a lower bracket. Upper part is hooked around a stud.

-

Brake lever return spring.

-

When I removed and reinstalled mine, I had to use bottom bracket first. Spring top hook is too stiff. Watch out you don't strip or cross threads in frame.

-

Could you point out number of what you mean with bottom bracket on previous photo?

-

You're welcome Maybe you missed it earlier but here is what I did. install top part of hook. Insert a philips screwdriver into one of the two holes in bracket and aim for same hole on frame. Then pry downwards until bracket meets frame and screw in bolt for other hole.

-

OP is about 6 volt coil so I don't understand why you write about 12v DC ballast resistors. Impedance is AC resistance. It's a completely different matter. 6 and 8 cylinder coils have different impedance due to transformer coil saturation time. 8 lobes gives less time than 6.

-

Typical 6 cylinder coils are around 3-3.5 Ohms Typical 8 cylinder around 1.5 ohms This why 6 and 8 cylinder Chrysler have two different part numbers.

-

I think you posted a wrong link. Impedance has absolutely nothing to do with 12 v coils with ballast resistors

-

These are great. Chrysler Master Tech videos from 1940s - oiling

chrysler1941 replied to Bryan's topic in P15-D24 Forum

So when will you post your pre war film strips ? -

If it's 6 cyl, impedance should be ok. It's different for an 8.

-

This is guy is a guru when comes to modern transmissions. Even has a 4 hour video about the first automatic transmission, Hydra-Matic. Upper hole is fill, lower is drain. You want to drain it completely. M4 where vacuum operated unlike the M5/M6 hydraulic operated. Functions exactly the same. M4 even had a cable to detach vacuum shifter for non-start towing.

-

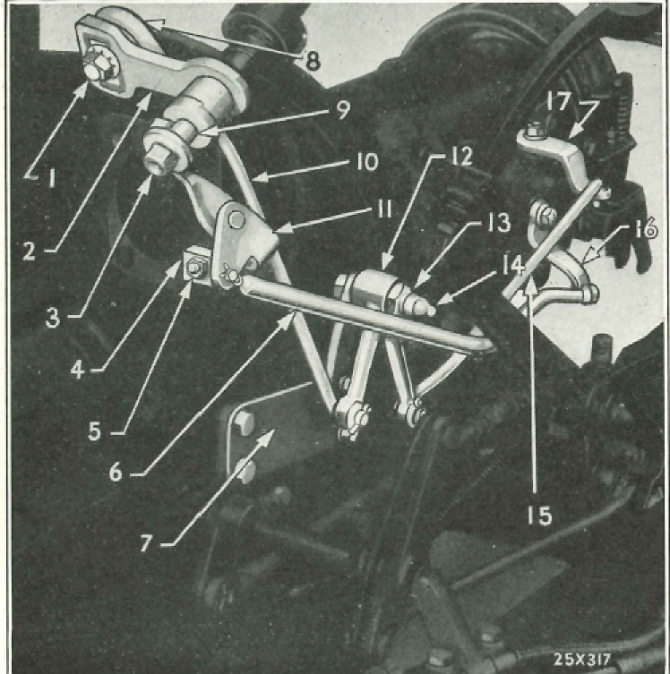

I smiled when I saw your photo with split bearing and clutch spring bracket. I had lengthy discussion with everybody on this site some years ago asking about where my clutch return spring is attached. I even showed them photos of my clutch housing has no room for it but no cigar. Everybody insisted this is the correct bracket 6-26-6. Some time after, I got the shop manual and it clearly shows the pre-war M4/Fluid Drive uses a long clutch spring also inserts into frame. Here's a photo, maybe you can use it.

-

1941 Chrysler Shop Manual. Pictured is a M4 but linkages are same. And do you need a special tool to remove that heavy spring? Nope install top part of hook. Insert a philips screwdriver into one of the two holes in bracket and aim for same hole on frame. Then pry downwards until bracket meets frame and screw in bolt for other hole. In my opinion this spring is useless useless one has chicken legs Then there is a long spring behind it. what does that spring go to? , into a hole on frame. #12

-

No Mr. Sniper, I didn't say they where bad, only it's not the correct lubrications viscosity during startup. All my statements are regarding flatheads and when engine is cold. As yourself have stated, all oils are thin when hot. You wrote about quick oil flow and using 5-30 as an argument. Thread starter mentions 15-40. I tried to explain this oil is not recommended and nor is 5-30 as they are too thin during cold engine as these have been made with tolerances for 30W. Even the page you posted says 30W SHOULD be used and gives you an alternative 10-30 as satisfactory. In my world satisfactory is not good enough when for a few bucks more I can get the correct oil. I also grew up thinking multi grade oil was sublime This is what we were told. No one would ever consider using "tractor oil" But all this changed after invention of the internet. Today we have access to all the sorts of documents and findings and many of the old urban myths turned out to be wrong or misunderstandings. Anyway this will be my last post in this thread. it takes me 20 min to type all this and struggle with translations. You use your oil, I'll use mine

-

This is also what I stated. ca mid fifties when higher HP OHV took over, multi grade was needed. Notice they say "30W engine oil should be used" (meaning flatheads) and later gives you and alternative 10-30 would be satisfactory as single grade oil disappeared from normal consumer market. So a multi grade oil is ok, but a 30W is correct. Nowadays 30W is available everywhere and no need for a lesser substitute. My car is a hobby, I spent a lot of time and money. Therefore it will get the best oil. 30W This means his 15-40 and your 5-30 are not recommended.

-

I read through the thread twice and still confused what you need. Let me know if it's not it. M5/6 and manual transmission have different bell crank bracket. Maybe this photo will help.

-

It's all very logical when you think about it. Flathead engines where fabricated with a certain tolerance and all (GM, Ford, Chrysler) manufacturers back then specified 30W. Not until ca mid fifties when higher HP engines were in demand, tight specification demanded thinner oil. Engines today are computer designed and assembled with super finish tolerance with short lifespan, they require 0 or 5W. If your theory is that fast lubrication and thin oil is ok for flatheads, it's your choice. The big three disagree

-

Oh you thought ethylene glycol is modern technology? Here is a snip of text from Shop Manual from 1940

-

When these cars where made, temperatures where the same back then. Engineers at Chrysler designed them for 4 PSI and it worked. Same goes for other makes.

-

I disagree. 5-15W when cold will give you quick flow, but not lubricate engine parts enough as they are made for tolerances for a 30W. 40W is too thick for warm engine. When hot, any weight will do.