maddmaxx1949

Members-

Posts

250 -

Joined

-

Last visited

-

Days Won

2

maddmaxx1949 last won the day on July 25 2021

maddmaxx1949 had the most liked content!

Reputation

61 ExcellentProfile Information

-

Location

United States

-

My Project Cars

1949 Dodge Coronet and 1951 Dodge Coronet

Converted

-

Location

Ohio

-

Interests

old cars and acquiring things

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

maddmaxx1949 started following 6v Minimalist Ignition Wiring , What am I doing wrong? , Wiring and 5 others

-

Check the downloads section. There might be one there.

-

Guys it has been a while since I've been on here. I wanted to just give an update. I am alive so that's a plus but I am really struggling right now going through my late 20's crisis I guess. @Sniper I am still working on getting those distribution tubes made but It had to be put on the back burner. Apologies for not following up and getting things taken care of when I said I would. I'm hoping to get things turned around in the next couple months and get back on track and back getting this car restored. I haven't been able to get to this project as much as it deserves. On a side note, when I do get back to it full time I will need some paint advice....

-

Clutch Parts - where to get them

maddmaxx1949 replied to billrigsby's topic in Mopar Flathead Truck Forum

Yes I had fantastic results with these guys as well. -

miller tool c-853 49-51 Clutch overcenter spring gage

maddmaxx1949 replied to desoto1939's topic in P15-D24 Forum

Nice find Rich, any chance you could make a template and put it in the downloads with the other overcenter spring gage template? -

When you have that moment where you realize that stuff was supposed to be in there and you took it out because you thought it wasn't........ ooops. Thankful for this thread

-

Well just hit 1000 miles. and go for an oil change. Of course it never goes as planned, accidentally tipped the bike off the jack, dumped all the oil on the floor. Poured gas on myself swapping a suspect petcock, and to top it off the stupid idle jet was plugged for the umpteenth time and I stripped one of the heads of the float cover screws ggahhhh....I love this thing but sometimes I want to crush it.

-

I have a note in here on what I used with pictures as well. 2-2-349 and ran me about 50$ a piece.

-

Kind of why I bought it. Like to putter around town on it. Not really a go fast kind of person. I swapped the sprockets out to 17/40 and it's like a whole new bike. Only issue now is I think my petcock is leaking because I've run out of gas unexpectedly twice now after it sat for a few days. Got to check oil level in case it's running into the crankcase because that would be bad. Edit: Cheesy that's an awesome looking bike.

-

-

Making your own Emergency Brake Cable Assembly?

maddmaxx1949 replied to maddmaxx1949's topic in P15-D24 Forum

Probably wouldnt be difficult with the press. I do not have one or I'd be using it. But even a single ferrule smashed with a hammer on the end of a cable is remarkably strong. I've seen coyotes break snare cable before that ferrule comes off and they pull way hard than my baby man arms ever could. I wouldn't feel bad using a parking break with one I set like that. Especially if you double it up. I feel its harder to find the appropriate sleeve than actually building it. Could try a hand swager too however I wouldn't trust those as much. (but thats solely based on experience with the hammer smash trechnique.) -

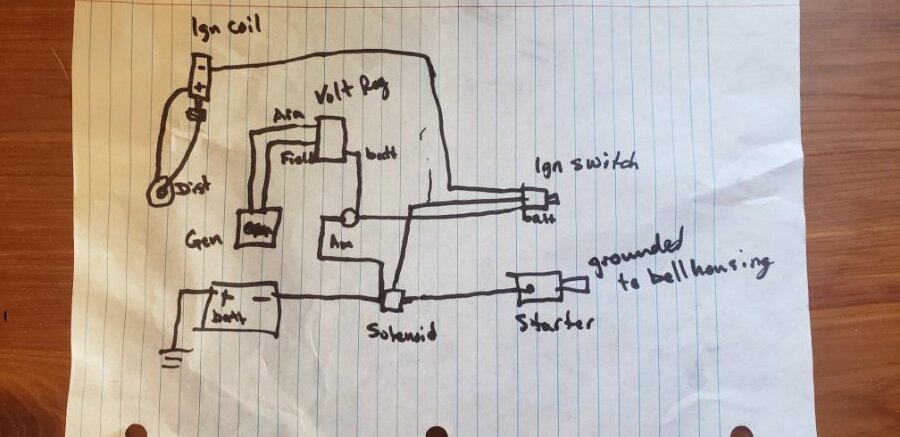

Do you mind if I add this diagram to my minimalist wiring post in the tech archives?

-

Hey all, here's a quick video I made to show the absolute minimum amount of wiring you would need to run your vehicle including the charging system (ammeter, voltage regulator, and generator. Fell free to comment or ask questions. https://www.youtube.com/watch?v=qoeqvsME_ZM Here is the diagram that corresponds to the wiring in the video. Am = ammeter because apparently I forgot to write the rest of the word halfway through...

-

Making your own Emergency Brake Cable Assembly?

maddmaxx1949 replied to maddmaxx1949's topic in P15-D24 Forum

It looks to be in fairly good shape though I do have a spot where it's wore flat from rubbing somewhere maybe on the crossmember or something.