bkahler

Members-

Posts

1,936 -

Joined

-

Last visited

-

Days Won

37

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

......in this case I'm referring to the door latch mechanism or the window parts? I'm ready to start assembling the doors. Should I install the door latch mechanism first or install all of the door glass components first? Through searches I've found what sequence to install all of the glass components but I haven't found whether the door latch components should be put in before or after the glass components. Thanks!

-

Original Fuel Pump Filters / Strainers

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

My pump is rebuilt but it's the correct pump (i.e. Carter #). Do you have a part number for the filter? -

Original Fuel Pump Filters / Strainers

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I'm not a big fan of the stone type either. I have the same setup. ? -

Original Fuel Pump Filters / Strainers

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That's interesting. Are they the stone type or paper? In other words, please provide details of pump and filter! -

While I was looking at options to replace the filter I have mounted at the front carburetor I got to thinking about why it's there in the first place. So looking at the original fuel system it appears that the fuel pump just had a strainer (no filter) and the real filtering was done at the carburetor. In my freshly installed system I have, starting at the tank a glass bowl with paper filter, electric suction pump, mechanical pump with strainer and finally a glass bowl with paper filter at the carburetor. The filter at the carburetor is apparently a very porous piece of junk that I need to replace or eliminate. This got me to thinking as to whether or not I need the filter at the carburetor since I already have a filter at the inlet side of the electric suction pump. As a temporary measure I'm going to remove the filter at the carburetor and proceed with my engine start up. The question is with my current setup, do I really need the filter at the carburetor? Did any of the original mechanical pumps have filters or were they all just strainers?

-

JB, I'm beginning to think you have this secret desire to own a Route Van....

-

Bet I know why this eng didn’t run!

bkahler replied to kencombs's topic in Mopar Flathead Truck Forum

This subject brings back memories from my high school days long ago. My girl friend had just bought a car and I was of course trying to impress her with my mechanic's skills. I offered to do a tune up where I replaced the spark plugs, points and condenser. All went well until I tried to start the engine and it wouldn't start ? After much looking on my part I called a neighbor over who worked on cars as a hobby. After a few moments of inspection he found I had shorted the points to ground. A slight adjustment on his part and the car roared to life That was an embarrassing lesson I've never forgotten..... -

I'm guessing they slide in. I would assume the ones sold by Vintage Power Wagons fit into the slot at the right shown in the picture on the below?

-

The reason I wasn't sure is my doors look like they could accommodate the clips that have the clips that are 90 degrees to the track. You can see in the picture below why. Yesterday I stopped by the painters to pick up a rattle can filled with the green paint and he gave me the one clip he happened to find still attached to the door. Turns out it's the style sold by Vintage Power Wagons. So I can confirm Mark's guidance as to which clips are correct for the B3 doors. So I'll be ordering 8 clips from Vintage Power Wagons later today

-

I'm just about ready to bolt the grille bars to the front nose piece. I think the new weld nuts came out ok. The beads aren't that great but the will hold. I was really trying to keep from ruining the paint where it shows which fortunately I was successful at. I need to do a little grinding and then I'll rattle can the exposed metal. When I bought the paint I had them mix up enough to fill a couple of rattle cans for situations just like this My question is should there be some sort of rubber gasket between the nut plate and the nose piece where the bolts are? I don't really like the idea of metal to metal. Thanks! Brad

- 1 reply

-

- 2

-

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Good point about the dual carb setup. It will be interesting to see just how nice or how much of a pain the dual carb setup will end up being -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That would be a lot better than I was expecting I was thinking 9 to maybe 12. I do have the 3.73 diff so that's in my favor. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

A 1.5 gallon heel in the tank isn't to bad. I'm hoping my 1/2 ton gets a little more than your 1.5 ton truck -

So which one of these clips would be correct for a 51 B3B ?

-

Today I was digging through the various bits and pieces I still need to install and found this hole plug in one of the boxes! After all these years I don't remember having the plug but obviously my truck had at least one when I bought it Unfortunately I only have one but hey, that's a start!

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I was kind of surprised to find after reading the manual page that Merle provided that there is no adjustment on the fuel gauge. I had 5 gallons of gas in the tank and the gauge needle hadn't moved so I assumed that either the gauge was bad or the new sender was bad. First thing I did was disconnect the wire between the gauge and the sending unit. Next was to test the sending unit. I believe the sending unit is a 90 to 10 with 90 being empty and 10 being full. The reading with 5 gallons was 70 to 71 ohms. I poured about 1/2 gallon more into the tank and the reading changed to 69 ohms. That told me the sending unit was working (it's new so it should be good!). Next I grounded the sending unit wire to the gauge and the needle pegged at full! Ok, the gauge is good, or at least functioning. I then hooked a 0 to 100 ohm wire wound potentiometer between the gauge and ground and slowly started turning the pot until the needle moved on the gauge. At 63 ohms the needle was just starting to come off Empty. I plan on pouring more gas into the tank In order to determine just how much gas will be in the tank once the needle drops to Empty. The only thing I won't know is how much gas is in the tank before you can no longer suck anymore out. -

Merle, thanks for posting the page out of the manual. It would appear there is no adjustment of the gauge. So things either work or they don't Thanks again. Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

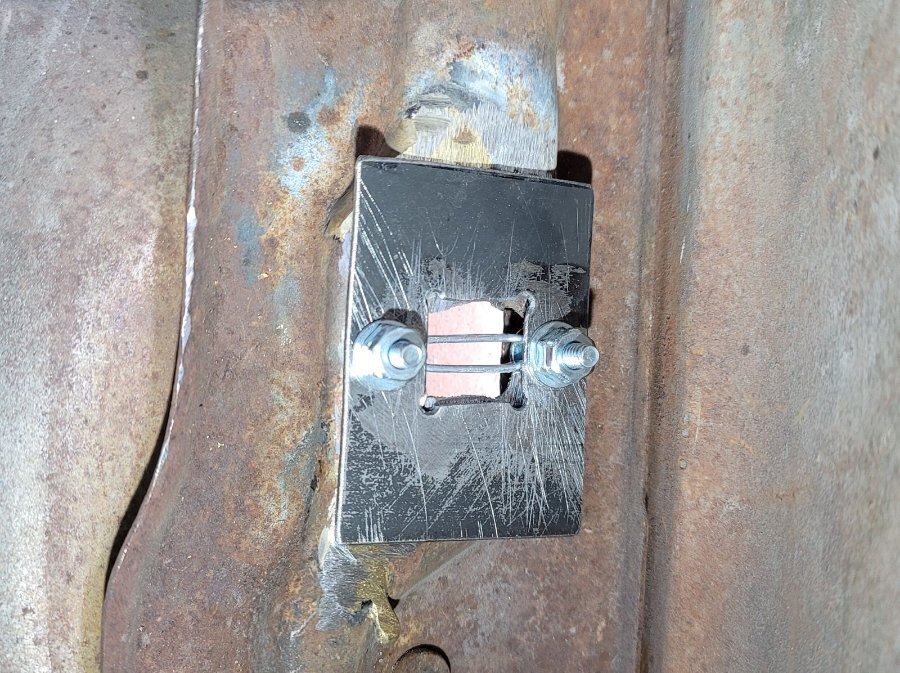

Well for what it's worth the door catch repair is done. From the inside it's not very pretty but I think it's serviceable. I debated for a few minutes as to whether or not to weld the plate in place but in the end I decided it would be stronger and make it easier to replace the catch if it ever breaks again. For the most part I think it's a good repair and should work just fine. The outside opening needs to be smoothed out some and I'll have the painter take care of that little problem. The door is heading to the painter this afternoon. Big thanks to JB for finding a source for the door catch parts, it's kind of hard to repair something if you don't have parts I now have all the parts and supplies on hand to repair the radiator and the water pump gasket. I hope to have that work completed by the end of the Memorial day weekend. -

Merle, I realize this is somewhat of an old post but it sort of hits home for a problem I'm having. My B3 Series service manual published in 51 does not have any info on the fuel gauge. It covers the horn, lights, ignition, etc. but does not cover the fuel gauge. Does your service manual have any details on how to adjust the fuel gauge for proper readings? Thanks, Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That's definitely an idea worth trying however I have a hunch that I won't be able to get a big enough washer through the rectangular opening on the outside. I'm pretty sure the opening is only 7/8" wide. However after thinking about it for a few minutes a rectangular flat plate might substitute for a washer and I believe a long narrow (7/8" wide) strip with a hole drilled in it just might work I'll report back this week. Thanks! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

JB found them at LMC Trucks. The hole spacing is slightly further apart, 1-3/8" vs 1-3/16" but as mucked up as mine was that turned out to not be a problem. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I have ordered gaskets and hose clamps from DCM Classics and I should have them early next week. After doing some research I've decided to try and solder the radiator seam myself. From what I found, using a micro torch with solder will allow me to target the small spot that is leaking. Solder and acid flux is on order as well and I'm hoping to work on the radiator next weekend. This morning I tackled the damaged driver door catch. Whoever made the "repair" was more of a butcher than a repairman. They brazed a small bracket on the inside of the door that the door catch arm passed through. It definitely worked as a door stop but it was crude at beset. From the looks of it he used a large round punch from inside the door and beat the opening until it was bulging towards the outside edge of the door. After removing the brazed in bracket I did what I could to beat things inward and used a small rotary grinder to cut out the old broken pieces. if you look close enough you can see where I've sort of reversed the direction of the bent opening. This will allow me to get the new catch piece inside the opening in the right orientation to work with the door catch arm. What I need to do now is figure out a way to flatten the opening. This will likely require some heat, a bucking bar and some help. The goal is to use the pieces in the picture below to repair the opening. The metal plate will be on the inside of the door and the catch piece will be between the outer skin and inner support frame where it belongs. I plan on using a couple #10 screws to hold the two pieces together, sandwiching the inner door brace and once everything position I'll weld the plate in place from inside the door. Stay tuned...... -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

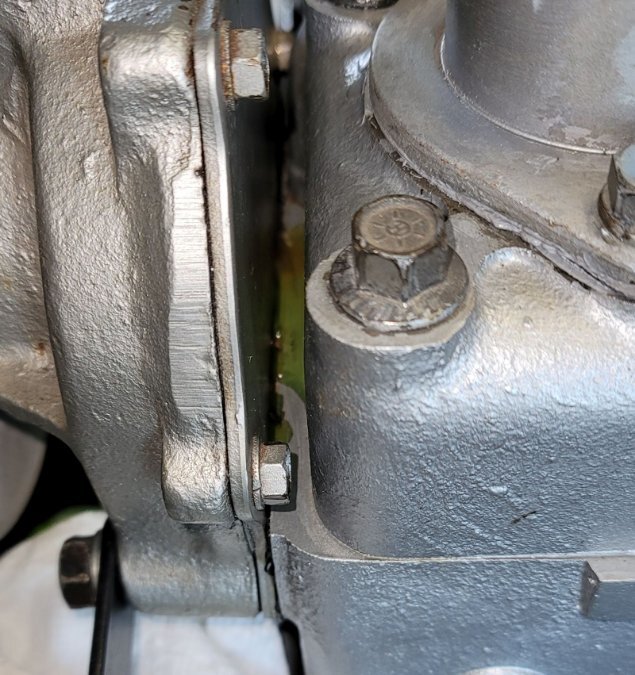

Well, I think it's pretty conclusive that the gasket between the water pump and the block is weeping. So it's time to drain the coolant system again and then pull the radiator and the water pump. So far the closest radiator shop I've found is about 2 hours away -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Well the news just keeps getting better and better..... The radiator shop that has done all of my radiator work for years is out of business Aside from this one small leak they always did great work. So now I have to try and find a shop somewhere in the region that can fix it. While checking for leaks yesterday I found one between the head and the water pump just on top of the block. I wiped it clean thinking it might have been from when I replaced the thermostat housing. Fresh coolant showed up overnight so that tells me either the head gasket is leaking or the the back side of the water pump is leaking. I'm going to have to keep wiping it down until I find find out from which direction it's coming from. I've built and installed a lot of engines and have never had this many issues with small leaks before. Starting to get frustrating! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

It would appear I'm going nowhere fast While poking around looking for more leaks I noticed this one on the top front of the radiator. It appears to be leaking right at the seam. I guess the next step would be to pull the radiator and take it back to the shop to be fixed. I'm not sure yet but I think I might have missed putting sealant on the threads of the bolt holding the generator pivot bracket to the water pump. I'm not 100% convinced it's not residue from previous leaks from above so I'm going to watch it for a little while to see if it progresses. As far as the fuel system leaks I'm beginning to think there is nothing wrong with the front carburetor gasket. I pulled the top housing off of the carburetor and the bowl wasn't filled entirely which tells me fuel hadn't reached the level where it would be forced through the gasket. The other reason I think that might be the case is because the top surface of the carburetor housing was damp and it wouldn't have gotten that way from fuel seeping past the gasket. I think what happened is a mist or very faint stream of fuel is/was coming off the top of the fuel filter housing. You can see in the picture below that the top of the filter housing is wet but there is no fuel around the fittings or around the edges of the filter. It's coming through the top! I'm not going to pull the radiator until I'm sure I've spotted and fixed all of the other coolant system leaks. Once I'm convinced there aren't any more leaks then the radiator can be fixed. What fun