bkahler

Members-

Posts

1,936 -

Joined

-

Last visited

-

Days Won

37

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

Diagnosis help needed - weird brake pedal issue

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I've believe the master cylinder has been ruled out due to the test results that I got. The pedal stayed firm once I clamped off the right front brake hose. -

Diagnosis help needed - weird brake pedal issue

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Everything is new and I've not yet driven the truck. However I'll pull the wheels and check to ensure nothing is sticking. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I'm currently leaning towards the rough side up but that means I'll be planing everything from one side to get it to the proper thickness. I'm not sure sure how well that will work. Decisions decisions..... -

Diagnosis help needed - weird brake pedal issue

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Yeah, another bleeding is going to be the next thing that happens to try and resolve the problem. -

Diagnosis help needed - weird brake pedal issue

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Thanks for the replies. Bleed nipples point straight up. I tend to agree that it has to be air in the caliper which baffles me because I bleed until no bubbles and I did both front calipers the same way. The drivers side seems to ok yet the passenger side doesn't. Just seems weird to me. I bought a pressure bleeder and once I get a rubber gasket made for the cap that goes on the MC I plan on trying it to see if that makes a difference. I know silicone is hard to get all of the bubbles out but I've done several other vehicles with silicone and didn't have an issue like this. As for hose clamps, there aren't any on the rubber hoses so that possibility shouldn't exist. Of course there is always the possibility that I THOUGHT I bled the right front caliper but didn't -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Brent, I thought you might find this interesting. I ran across this video on youtube today and noticed it had a 6000 GROSS label on both sides of the bed Apparently the truck is in England now but it supposedly came from the Oregon desert area. -

Diagnosis help needed - weird brake pedal issue

bkahler posted a topic in Mopar Flathead Truck Forum

Background: Rusty Hope front disc brake conversion. Rear wheel disc brakes with the Cherokee differential conversion. 97 Cherokee master cylinder. Silicone brake fluid. All new brake lines and rubber hoses. Problem: After truck has been sitting for a few minutes or more the brake pedal will go all the way to the floor but you can pump the pedal multiple times and it will build up pressure and it becomes reasonably firm. However, if you keep pressing on the pedal it very gradually goes to the floor. Once it does that you can pump the pedal back up and you can repeat the process again and again. Diagnostics so far: Verified all lines are tight. No sign of fluid anywhere and the MC reservoir is not losing any fluid. Initial research via google was the MC may not like the silicone fluid and it might be bleeding by the seals. However I don't think that's the case because of the results of the following test. One thing I found online was a suggestion to squeeze off the rubber brake lines and repeat the test each time to see if the problem can be pin pointed to an individual wheel. So I did this by putting a clamp on the rear hose to the differential and the results were still the same. So I then moved to the driver front wheel and again clamped the hose shut. No difference, pedal still went to the floor. Next I did the right front but the results were different. The pedal did NOT go to the floor and on the first pump there was reasonable pedal resistance. I pumped it a few times and the pedal stayed reasonably firm. I then waited about 15 minutes and tried the pedal again and it was still reasonably stiff on the first pump. So, I left things as they were for 24 hours and tried the pedal again and it was still reasonably firm. At this point I removed the clamp on the right front wheel and on the first pump the pedal immediately went to the floor and I had to pump it up to get a firm pedal. I then waited a few minutes and tried again, the pedal went to the floor. It would appear the problem has to do with the right front wheel caliper or hose or...? Nest step: At this point I'm not sure what to do next other than try replacing the caliper. Before I do that I thought I'd check with all Y'all to see if there were any other possible sources of the problem? What baffles me is what could be happening inside the caliper to cause these symptoms? Thanks! Brad -

HA! Kids now days....all they wanna do is have fun

-

David, thanks for the info. This would seem to indicate the metal bed pieces were assembled and then placed on the wood bed frame and everything bolted together and then lifted on to the truck. That's a good picture of the relationship between the shovel strips and the rear frame member. I think my truck had maybe two partial remnants of wood left when I got the truck. That's a really good picture with some good detail info. With the truck being a spring special we know that the sides of the bed were definitely NOT black. With the black paint on the metal cross members this tells me the wood bed with metal channel cross members was assembled and painted black as a sub assembly. I'm guessing next the metal bed was assembled as a separate sub assembly, painted whatever color it was to be painted and then the metal box assembly was set down onto the wood bed frame assembly. At this point they were bolted together and the whole package was lifted onto the truck chassis. From a factory production standpoint it makes sense, to me anyway I'm guessing the small 1" or so weld I had along the top of the angle strip was either done at the factory to hold it flat to the bed wall or a field fix by some previous owner. Based on the size and quality of the weld I'm betting it was welded at the factory. The weld wasn't really noticeable and it wasn't until I was drilling out the spot welds that I noticed it. It will be interesting to see if the other panel has a similar weld once I remove the angle strip from it. Yeah, basically you build two sub assemblies, the wood bed with metal channel crossmembers makes one sub assembly and the metal box makes the other sub assembly. Put them together and you're ready to place the assembled bed on the truck chassis. I think you are correct in that I should assemble the wood bed and cross members right on the truck chassis. I think building the metal box and lifting it onto the truck chassis would be easier, at least that's how I see it at this point. There are definitely a lot of different ways this job could be handled but I have to consider the logistics of what space and equipment I have available. My lack of readily available helpers limits me in some ways as well. Yes, the picture you posted showing the orientation of the grease zirk and the hole in the panel helps a lot.

-

My strips are the original style from Midwest Military. Interesting that you just happened to find bed strips by a dumpster. I've never been THAT lucky in my life ?

-

My strips are from Midwest Military. Sounds like making them 3/4" is the most logical thing to do. Were they originally unpainted? Getting 2 or 3 helpers to show up all at the same time is the reason I ended up buying a gantry crane! Besides, I'm getting old and hate lifting things

-

Wow. Kinda hard to believe the amount of wear on those links. I don't remember looking at that piece to close while rebuilding the carburetors. One more thing to add to the to do list.....

-

Looks to me like your shop supervisor was more interested in the comfort quality of the seat than the quality of the door construction

- 717 replies

-

- 2

-

-

-

So they were recessed to some extent. I guess I'll play around with overall depth until I find a setting I like. I don't recall Bunn's book talking about bed floor color when the buyer had the bed painted the same color as the cab. In other words if the buyer ordered the bed painted the same color as the cab did he get a black floor or a green/red/whatever color floor? So you had some spot welds AND welds along the top edge? I've only removed the angle strip on one side so far and overall I found about a 2" long section where it was welded along the top edge, the rest of it was all spot welds. I plan on removing the strip on the other panel this week so it will be interesting to see if there is any welding along the top edge on that panel. I had read your thread previously which is where I found reference to your wood thickness being .820". My boards are about 1-1/16" thick at the moment with one side already surfaced (or at least an attempt at surfacing). I don't mind planing them down, I just wasn't sure if there was a problem leaving them thicker. My truck didn't have any wood in it when I bought it so other than pictures, I've never seen a bed up close to see all of the details. I would like to assemble the bed (minus wood) on saw horses as you did so I can get an idea of just what all I will be dealing with when it comes time to install the wood. My preference would be to totally assemble the bed and then lift it on to the truck chassis. I have gantry crane so the lifting and setting should be relatively easy to do.

-

.....bed wood or the metal box? The next major task is the assembly of the bed. I've got all the information from Pilothouse.org on what size the wood planks need to be and I have read Dave Erb's excellent article on how to build and install the bed. Even with all that information I still have some questions. Did the rails originally sit on top of the wood or were they recessed? Dave's article wasn't to clear on that subject. If recessed then to what depth? I kind of like the idea of them sitting on top of the wood but at the same time I'm hesitant to do so, at least for now. I definitely want the strips proud of the wood surface but just how much is what I'm struggling with. Was the original bed a gloss, semi-gloss, satin or flat black? Right now I'm planning on painting the wood black but first I'm going to do some staining of a few scraps of the Cyprus lumber that I'm using to see if a stained and sealed finish might might look acceptable. In Dave's writeup he mentions that his angle strips were welded to the bed along the top edge. Mine were definitely spot welded in place and I plan to replicate that either using my spot welder or using a MIG welder. I'm curious how many other's had their strips welded along the top edge? I'm also looking for suggestions on how to assemble the bed, i.e. on the truck or on saw horses or some thing in between the two. And the last question for the day. Dave's article states the wood is 3/4" thick. Is there any reason to not make it any thicker than 3/4", say 13/16" or 7/8" ? I'm sure I'll have more questions about this subject and will add them as they come up. Thanks! Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Interesting idea and it actually makes a whole lot of sense. The humidity here has been atrocious and I know he had been trying to paint at the definite low end of the temperature range. I'll pass the info on to him, fortunately the weather is finally starting to warm up some. Thanks! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

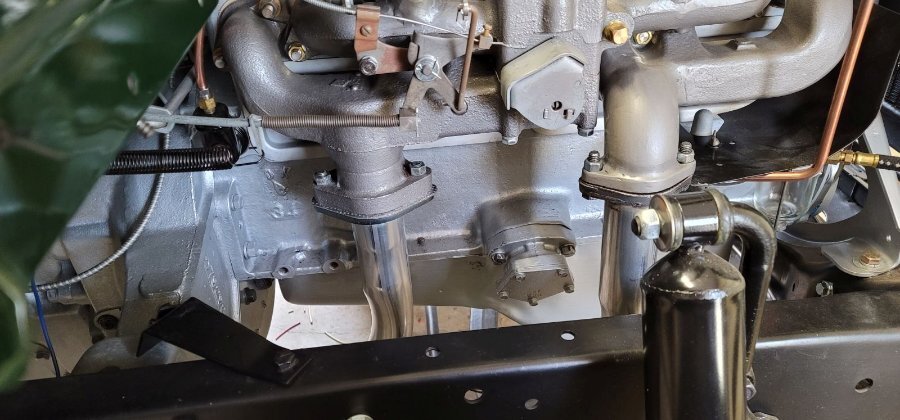

Exhaust system is done. All gaskets are in place along with all clamps and hangers. The weather is finally turning nice enough that I will soon be able to push the truck outside for it's first start -

You want me to take a chain to the nicest thing on the truck?!! Brian spent a lot of time and effort on these decals with great attention to detail. It's little details like this that help bring these trucks back to life. Thanks Brian!

-

I can't help you with any info but I do like your truck

-

I've installed one of Brian's decals on my 51 filter housing. The engine is almost ready to fire for the first time. I still need to finish the oil line from the gauge to the block. I had the line installed but in the wrong location which blocked the starter from fitting correctly. The decal came out really nice. I'll have to post a better picture one of these days. The decal is a lot nicer than the rest of the restoration I did on the filter housing

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I mentioned that to him and he said he changed the oil very recently, possibly he heard the same thing you did about old oil being a problem. I think he mentioned something about looking into what type of filters he has and whether or not they need changing. Thanks! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Actually I don't think the sawn surface is quite that rough! I'll be posting more about the wood in the near future. I have lots of questions on bed building and assembly -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The seller is probably having supply chain issues like everyone else -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

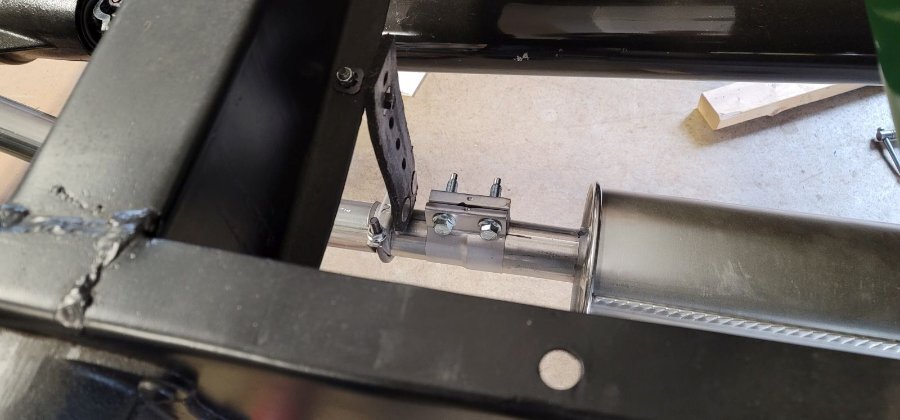

Here is the ebay listing for the aluminum ties that I purchased. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The wood planks arrived as expected. I've opted to use Cyprus mainly due to availability and it is supposed to be have good resistance to the elements. The boards are 4/4 12" x 96" and surfaced one side so I have plenty of area to get the boards I need out of them. Also I got seven of them, just in case One of the decisions I have to make is do I want the surfaced side up or the sawn side up. I will be painting the wood and metal strips black.