-

Posts

1,312 -

Joined

-

Last visited

-

Days Won

14

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Adam H P15 D30

-

-

I responded late in your last post and stated the HEMI would increase the value but I don't think I would make the same claim with a V6. Kinda looses the coolness factor and it wouldn't solve the e-brake issue. Either way you are loosing the trans mounted e-brake unless you find a T.F. out of a motorhome. Put the HEMI in it and don't look back...

-

Run it... If done right it will increase the value of your truck...

-

Hate it. Why run something that every other hotrod has when there is access to a running HEMI? Kind of like following the herd of sheep over the cliff... Don't know why someone wouldn't drive a HEMI? They are not feeble in fact they are very robust. Best of all they are NOT a small block Chevy.

-

Come to the SF Bay Area and get my 49 Dodge rear axle. It has the drums you need and was apart 10 years ago for new brakes etc. FREE Adam

-

IFS verse cost and what i want in my toy ol Rufus

Adam H P15 D30 replied to garyanna2's topic in Mopar Flathead Truck Forum

Are you planning a clip job or a frame swap? I hope it isn't a frame swap but Installing a clip is a super involved job so don't underestimate it. Measure, measure, measure and don't hack it like most of the clip Jobs I've seen out there. In the end it should look like it was never cut and welded and be safe! i am a huge fan of clips for several reasons. 1. Better geometry and engineering. 2. You can keep the factory engineered ride height and get the stance you want without cutting coils and dropped spindles. 3. Most importantly it's not a Mustang 2! Dont forget to factor in the costs for the donor suspension rebuild. Couple of pictures of my clip job on my 47 -

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

I agree, one change at a time is really good advice. There are other things I'm going to change but only after I get it running and dialed in.- 90 replies

-

- 1

-

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

Turbulence is needed to avoid fuel puddling. I don't think you could get any engine with siamized ports to breathe very well, might as well keep it rough for the better drivability.- 90 replies

-

- 2

-

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

Put them on the Dodge- 90 replies

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

That article was a good read. I've thought about getting it coated but only after I am satasfied with it and maybe not even then. Never know, it may not perform the way I want it and I'll scrap it and start over???- 90 replies

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

Don, the last picture I saw of your Plymouth engine I think it had Carter carbs on it??? Did you ever try the Webers?- 90 replies

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

I did give it a quick thought. It is really not needed. It's going into a single 2.25 inch exhaust and that's more than enough for the amount of air these engines exhale. I didn't even put a balance tube behind my Hemi. Also, I'm not sure it would have the same benefit as a V8 with opposite cylinders firing 90 degrees of each other. I have never been a fan of crossovers.- 90 replies

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

Yeah, I got an Edmunds 2x2 for my Chrysler Hemi. Cost too much- 90 replies

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

I believe the "log" manifolds they are referring to are these. And yes they can have nasty street manners.- 90 replies

-

Man that sure is a pretty picture There really isn't any room to cut the exhaust spring seats on HEMI's is there?

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

I thought about that also. The steel I would have used for the runners was almost mirror like. An unintended benefit of using the EMT tubing it the inside of the tube is rough, almost like a casting. Adam- 90 replies

-

25" intake and exhuast port sizes needed

Adam H P15 D30 replied to Ajgkirkwood's topic in P15-D24 Forum

Funny, my 230's ports were all 1.25. I'll remeasure when I get back into town. The gaskets were larger and if I didn't have a freshly rebuilt engine I would have matched the portsto the gaskets also. The headers I used were the small primary tubed SBC headers, I think 1 5/8 and they were plenty big for my 230 Adam -

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

Me too- 90 replies

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

still have about 8 inches to go before it hits the hood.- 90 replies

-

- 1

-

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

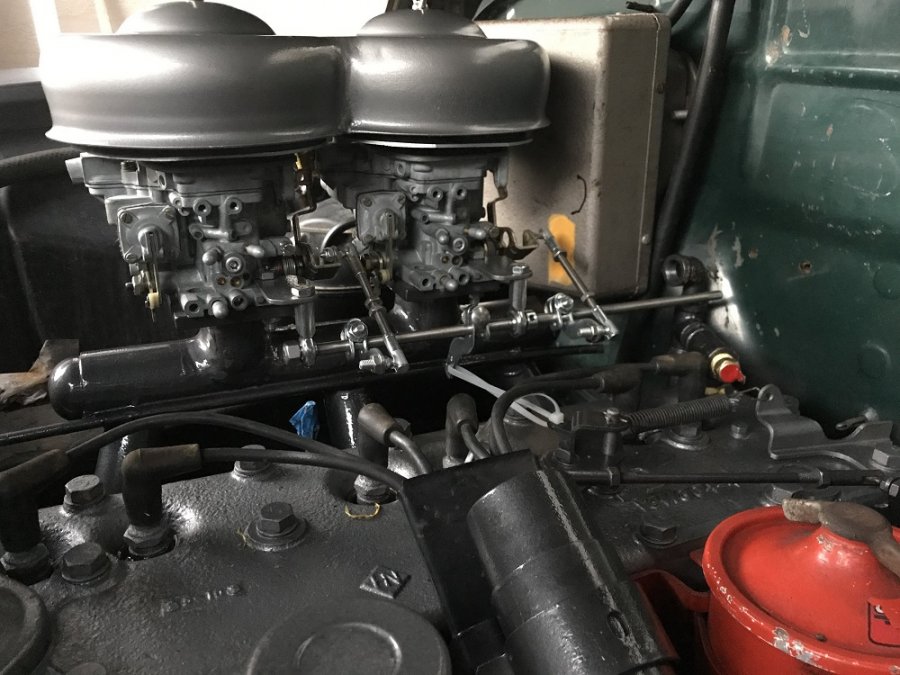

Don't forget to blend the intake holes on the flange to the runners. Wasn't sure how to cap the ends of the log part of the intake but I was sure I didn't want to just put flat plates on. Found front wheel bearing caps for a Volare fit nicely and add a little rounded touch to the project. Also added a hot water tube to the outside of the intake to keep it warm. Here is the 5th or so test fit after I painted it. You can see the choke hitting the heater box I also ordered Langdon's air cleaners and throttle linkage but do to me placing the carbs too close together they didn't fit, another mistake but after thinking it through I cut and welded the tops together and finish painted them the hammertone silver I painted the engine. The intake is painted a darker cast iron hammertone along with the breather tube for some contrast. The ugly heater valve is next. Added a new fuel line Next is the manifold and heater hose plumbing. Also, my PCV modification... Removing this spring is a must or you will have a super stiff throttle. I lifted this image from the net.. Finally installed with the throttle linkage, pedal feels nice and smooth. The red thing in my rear heater hose connection is my cooling fan switch. I ordered some hoses from NAPA and had to leave it here while I travel for work the next 2 weeks. Hopefully be running by the end of the year...- 90 replies

-

- 2

-

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

Intake time.... Couple of dilemmas here, my 49 has a heater box hanging on the firewall and I wanted to center the 2 carbs between the 3 intake ports as best as I could. Some careful measuring here but I did make a couple of boo boo's. First, I underestimated how bulky these Weber carbs were going to be so I goofed a little on the spacing. Second I mis-measured on the back carb and got too close to the heater box. The results were choke removal on both carbs to fit. Oh well, I live in CA so it will be fine... What to use for intake runners? I didn't want to use standard bends but I wanted a gradual bend from the intake log to the port, off to Home Depot I go. I found 90 degree bends in the EMT section that will fit the bill perfectly. Now to clear the heater box, remain symmetrical and be able to center the carbs between the ports I had to lean the outer intake runners toward the middle a little Adding the horizontal part of the intake Risers for the Weber carbs- 90 replies

-

- 4

-

-

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

I chose to finish the headers with a hand file. My OCD is showing... I didn't like the caps I welded over the removed 4th exhaust tubes so I made some covers. Warpage can be a problem so I had to bend it back a little. (pitfall)- 90 replies

-

- 4

-

-

Home Made Intake, Exhaust & Freshen-Up

Adam H P15 D30 replied to Adam H P15 D30's topic in P15-D24 Forum

Next would be to find a set of donor headers to cut up, in my case it was SBC headers. Cut, weld, modify and start tacking them to the flange. Best to get both tacked on and fit to the engine before final welding. I wanted to be able to clear the oil pump and fuel pump with room to spare. Finished welded the headers to the flange, ground and dressed the welds.- 90 replies

-

- 2

-

-

Hello group - Thought I would post some pictures of a project I've been working on with my 49 Dodge. Looking at some old spare parts I had hanging around the garage and decided to make use of some of them. Initially I was planning to make some headers for my 230 using an old set of SB Chevy Sanderson headers I've had for a while. Then I decided to make a header / intake combo with a Rochester 2bbl I had lying around. As all projects seem to go I decided multiple carbs was the way to go for better fuel distribution. Thinking through this further, I wanted to use Tom Langdon's Weber 32's as my carbs of choice. Hopefully I can share (remember) all the things I did correctly, pitfalls I encountered, and mistakes I made (there were a few). First was to cut a plate to act as a flange, I chose 3/8" steel. Note: Purchase a good holesaw for this and use a drill press.

- 90 replies

-

- 3

-

-

Yes, I installed the new exhaust and muffler when I still had the OE manifold. I just finished fabbing the new intake and exhaust so I haven't run it yet, I'll follow up in a few weeks when I get back on it. Maybe I'll do a thread with some of the build pictures?