vintage6t

Members-

Posts

389 -

Joined

-

Last visited

-

Days Won

5

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by vintage6t

-

I believe my 50 Desoto has the same steering setup as your car. What I did for my mopar 383/727 combo was move the entire steering box towards the driver's side. That was accomplished by making spacer out of steel plate and inserting it between the vertical steering box frame mount and the steering box itself. Offhand I don't remember the exact thickness of the spacer but I think it was 1/2". It required longer mounting bolts as well. I measured the steering angles of the wheels lock to lock before and after inserting the spacer and there was negligible difference in terms of turning radius. As mentioned above, mini starters are shorter but wider due to their gear drive. I tried one with a clockable snout and it didn't have any advantage over the stock starter. After shifting the steering box, I just used the stock starter.

-

The first picture shows you have vacuum assisted shifting. That's what the large canister is on side of the transmission and the winged shift knob indicate. With the car not running that mechanism can sometimes make it difficult to move through the gears. With the car running and it working properly it will allow you to change gears with the flick of your finger. If you can't shift with the car running I'd look at the vacuum assist mechanism first to make sure its operating correctly. Vacuum from engine hooked up, no leaks and that the canister linkage is sucked in or out when you move the shift lever up or down. Might even disconnect it from the shift rods as a start.

-

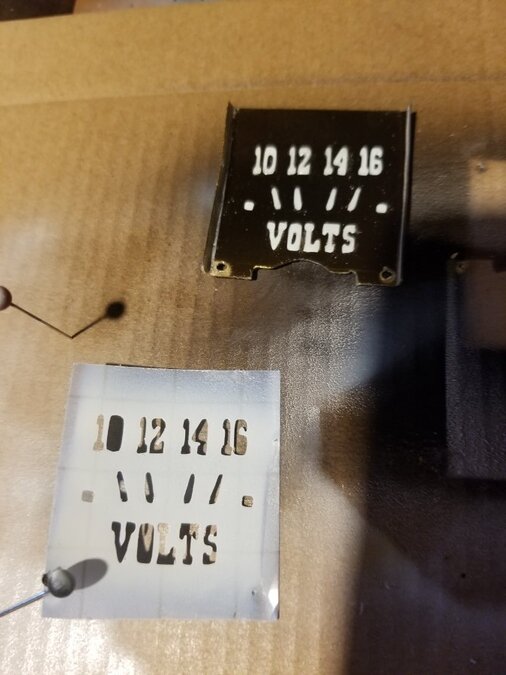

Picture is out of focus. However the small size of some of the gauge markings was definitely pushing the limits of the machine in terms of cutting resolution. I think the factory probably silk screened the original. In terms of trying to match, it is more about the result than the method. Spraying is easy, adding a luminescent coating on top to make the letters glow like the originals was a tedious task in hand painting and definitely effected the sharpness of the markings. Anyway for me results are acceptable. Here's another picture with a set of dirty old original gauges. The color looks off but it's really not when next to the NOS gauges that it will be grouped with. Sorry for high jacking this thread!

-

I actually don't own one. I borrowed one from a friend who uses it for crafting. Definitely can't justify the cost of new for a project or two but used ones come up for sale all the time. The work piece is held to the bed with a sticky mat. The Maker model will cut up to 2.4mm or 3/32". It will cut metal and leather with the correct tooling. I don't think cutting a gasket, even a thick one, is much of a problem.

-

Agree, very simple to cut out with a razor. If you want to get high-tech you can cut thecgaskey on a Cricut Maker machine. Search google to see people making gaskets on a Cricut. Either way I'd use regular automotive gasket material of the correct thickness. A bit off topic but here's a stencil I made on a Cricut for a custom gauge face.

-

Nothing personal. This forum gets about ten new posts a day, is clogging up the main board really a big concern? Also who's going to police when someone is a newbie and when they have sufficient knowledge to graduate to the main board, you? Maybe you should let the site moderator determine and enforce policy. If you don't like a post topic just don't post back to it and move on. You've posted to this one three times already, helping to keep it on top.

-

Agree, if you don't like a question just don't answer it. If the post is so "absurd" that no one answers then it will naturally sink to the bottom anyway. If it's a question asked many times before just post a link to the tech section that covers the topic or post where it was previously answered. Maybe add the search terms you used to find the previous post. Having said that one thing that you really can't teach someone is mechanical aptitude/common sense. That I agree can be a frustrating experience but then again just ignore the post if you're not inclined to even try.

-

Slight backfire and unable to preform under load

vintage6t replied to Jaybird's topic in P15-D24 Forum

Sounds like a bad ignition condenser. -

I was looking at the mp3 module you used. It looks like you're completely enclosing in an enclosure so no control of the tracks or volume? If you do want track/volume control you can make a remote control panel very easily. The panel can be exposed or hidden within reach. Just get four momentary contact single pole switches of your choice. Mount them in a panel of some sort. Solder a two conductor cable on each of the switches. One wire on each side of the switch. When your done you'll have four lengths of cable to run back to your module enclosure. Solder each cable to a corresponding control switch on your module. One wire on each side of the switch. Alternatively you can do the same with a single eight conductor cable. Just keep the internal wires sorted by how you solder them to the remote switches.

-

47 Plymouth - installing ignition lock cylinder

vintage6t replied to 46Chris's topic in P15-D24 Forum

The OP claims the cylinder won't turn at all. Not sure how he's going to push in the release pin if the cylinder can't be turned. -

47 Plymouth - installing ignition lock cylinder

vintage6t replied to 46Chris's topic in P15-D24 Forum

I suggested worst case drill out the key hole not the retaining pin. -

47 Plymouth - installing ignition lock cylinder

vintage6t replied to 46Chris's topic in P15-D24 Forum

You can try lubricating the cylinder tumbler with a dry graphite lubricant made for locks. Just squirt some in the key hole and work the key in and out. Dont use oil or any other wet lubricant though. Also you can't get the cylinder out of the housing without turning the key. There's a small pin you can see flush with the outer housing. Turn the key and you'll be able to push the pin in, releasing the cylinder from the housing. If you can't get the cylinder to turn with the key and you're going to replace it, then just drill the cylinder key hole out. That will release the tumblers and then you'll be able to turn the cylinder with a screwdriver. -

Also make sure your battery connections are good and fuel delivery/carb is working properly. As for battery connections, clean all connections well and make sure you have a 6v cable, at least 00 in size, and not a 12v cable. A 12v cable won't deliver the current you need to start.

-

Inspecting a '47 Deluxe sedan - Tow dolly transporting question

vintage6t replied to 46Chris's topic in P15-D24 Forum

And jack stands. Don't get under without them. -

Inspecting a '47 Deluxe sedan - Tow dolly transporting question

vintage6t replied to 46Chris's topic in P15-D24 Forum

Not sure of the laws there but here in CT you can only legally dolly a registered and insured vehicle. Otherwise all four wheels have to be off the ground, as in on a trailer or flatbed. If you pull the yoke of the driveshaft out of a transmission, as suggested above, isn't going to leak fluid out the back? In this case a moot point, won't the 47 just have a flange that the driveshaft bolts to and not a slide yoke? -

https://worcester.craigslist.org/pts/d/leicester-1940s-dodge-truck-pickup-bed/7674804455.html

-

I'm not sure I'd jump into rebuilding the starter yet. As mentioned above take the plugs out and see if it cranks faster. With plugs in and no fuel or spark it's going to crank slow. Also make sure you have the proper size 6 volt batter cable and not a 12 volt cable. A 12 volt cable is not going to carry enough current to the starter. Also make sure your engine is well grounded. As far as soaking the rings the longer you soak them the better. IMO overnight is probably the minimum amount of time. Everyone has thier own favorite soaking mixture. I like a mix of ATF, diesel and a bit of acetone. The idea of the acetone is it thins the mixture so it will flow into tight spaces but then it quickly evaporates. It's also a powerful solvent. After soaking and if you can get it started you may find the compression jumps up after running for a while.

-

In general I often find my local AutoZone stores have the parts I'm looking for in stock and at the best price. I always find the part # on thier website and bring them with me. While not always that knowledgable the counter help seems to always be helpful, even letting in the back room to look at hoses and such. I can even walk in and buy plasti-gauge of all things. Most every place else can get parts within a day or two. I find NAPA to be the most expensive by far and the store typically doesn't have what I need in stock. Not always but I've also found killer deals for things like master cylinders, starters and so on on Amazon. Prime free shipping and returns.

-

One thing that I don't think was mentioned is to use a filter with the temp tank. Just like a permanent tank it can introduce debris into the carb. resulting in running issues.

-

The collar probably is compressed on the nut side. You may be sorry of you do this but it may allow you to re-use the collar on a new tube: To get the collar off the old tube, carefully crush the old tube in until the collar will slide off. Once off the collar may not slide onto the new tube. If not put the new tube in the freezer for a few hours. Heat the collar with a torch and then quickly try to slide it onto the new tube. I say you may be sorry because if it doesn't work you won't have your old tube/collar stub to use.

-

I don't know for sure but I would think the jack either builds pressure or it doesn't. The fact that it only pumps up halfway might be an indication that there's air trapped somewhere in the system preventing the proper amount of fluid being added. Pump it up and it runs out of fluid halfway up. So why not pump it up, top off the fluid, see if it will pump up some more, cycle it up and down and see if it will bleed any trapped air? Yes, the worst case is too much fluid that overflows out the fill port when you release the pressure.

-

Again, just a guess. When it's half way up, add more fluid and see if it will start to go higher. It's possible it just needs more.

-

Just going from memory so I could be wrong. I don't think you need to put the plug back in. At least if it's the fill plug. That reservoir is not under pressure, similar to a brake master cylinder reservoir. Keep the plug out and raise and release the jack a bunch of times. You may get some fluid "splashing" out but that's okay, just top it off when done.

-

Parking brake with T5 transmission conversion

vintage6t replied to Theturtle's topic in P15-D24 Forum

The "parking brake" on my farm tractor is sort of what you describe. Press in the brake pedal and push down a lever to mechanically hold the pedal down. The tractor brakes are not hydraulic though, just mechanical linkage to the rear wheels. You could do some thing like this. Cable/pulley from your old parking lever to the back of your brake pedal. Pulling the parking lever out pulls the brake pedal down. The parking lever ratchet will hold the brakes on. You would also have to cut power to the brake lights so they would not be on in parking mode. -

Not mine but on my local craigslist. No year given and the price seems a bit high. https://hartford.craigslist.org/pts/d/south-windsor-full-set-of-vintage/7657914991.html