vintage6t

Members-

Posts

356 -

Joined

-

Last visited

-

Days Won

5

vintage6t last won the day on December 30 2023

vintage6t had the most liked content!

Reputation

138 ExcellentProfile Information

-

Location

CT

-

My Project Cars

50 Desoto Convertible, 41 Plymouth Convertible

Converted

-

Location

CT

-

Interests

Classic cars

Recent Profile Visitors

2,817 profile views

-

In Portland, ME https://maine.craigslist.org/cto/d/south-portland-1951-plymouth-cambridge/7730673265.html

-

In Amesbury MA https://boston.craigslist.org/nos/cto/d/amesbury-1953-dodge-coronet/7725826150.html

-

In Cambridge, MA https://boston.craigslist.org/gbs/cto/d/cambridge-1949-chrysler-windsor/7732720331.html

-

On CL. https://baltimore.craigslist.org/pts/d/york-1949-desoto-desoto-desoto-only-805/7733339368.html Not sure the add is accurate as to numbers built. I found this info on another site: "The DeSoto DeLuxe (not Custom) Carry-All, introduced in mid-1949, used the regular trunk opening. DeSoto built 2,690 Carry-All sedans for 1949. Seat upholstery choices included all vinyl or broadcloth and vinyl. Chrysler would introduce its version of the Carry-All, the Traveler, in 1950. In July, 1949 DeSoto started production of the DeLuxe woody wagon – a 3-seat, 9 passenger affair with the third seat in the rear area of the wagon. 850 were built."

-

Had accident with my newly completed 52 Dodge Coronet

vintage6t replied to Marty C's topic in P15-D24 Forum

Sorry about your accident. Painful all around, but looks fixable. If you were trying to post an add, it cost $5. Maybe that's why it asked for a CC? -

If you just want the joy of cruising in a classic, and not the pain, cost and time of making something roadworthy then I'd sell it. Buy a finished car to enjoy and do minor tinkering on when needed. Sad to say but in the long run you'll come out ahead in every respect. Given that there is not a huge general interest in those old mopars, with a little patience and a lot of looking I'd but you'd find something different for a very good deal.

-

Looks decent for the price. https://www.facebook.com/marketplace/item/1123627562143507/?ref=category_feed&referral_code=undefined&referral_story_type=listing&tracking={"qid"%3A"-2522754316317032757"%2C"mf_story_key"%3A"7501326719912749"%2C"commerce_rank_obj"%3A"{\"target_id\"%3A7501326719912749%2C\"target_type\"%3A0%2C\"primary_position\"%3A6%2C\"ranking_signature\"%3A2616896740624196427%2C\"commerce_channel\"%3A504%2C\"value\"%3A0.00039975133397034%2C\"candidate_retrieval_source_map\"%3A{\"7501326719912749\"%3A111}}"%2C"ftmd_400706"%3A"111112l"}

-

The bushings are held in with a spring clip. The clip locates in a groove in the shaft I.D. and has "wings" that are positioned on the outer edge of the shaft. Squeeze the wings together to remove the clip. You can see one of the clip wings in the circled part of the attached picture.

-

Posted on the HAMB. https://www.jalopyjournal.com/forum/threads/1949-plymouth-doors.1310429/

-

Vintage Edmunds Speed Parts

vintage6t posted a topic in Ebay, Craigslist and External Site Referrals

On the HAMB. $2,200 yikes! https://www.jalopyjournal.com/forum/threads/chrysler-desoto-vintage-edmunds-engine-speed-parts.1256806/ -

Looks great as is. It depends on what aesthetic your going for but if wanted they can be made to look more like the original rubber. Spray on Plasti Dip or even a bed liner coating would probably hold up well in that location.

-

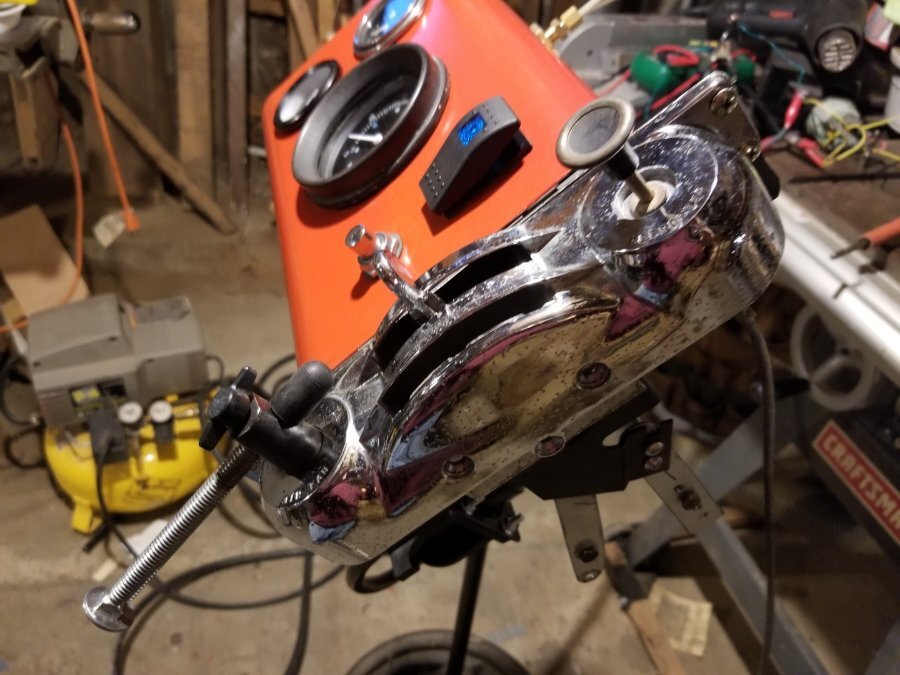

I decided to build a proper control panel for my engine run stand. I usually just connect various loose switches, gauges and wiring to the engine. I'm upgrading my stand so time to unclutter the control as well. The new control panel is made from scavenged parts. I gutted an old broken charge contoller from my RV for the gauge panel case and used existing gauges and switches for that. All external wiring connections are quick connect via a 7 blade trailer socket and cable. For the hand throttle I considered a bunch of solutions. Old bike hand brake levers, motorcycle throttles and so on. Nothing seemed satisfactory. Finally I came across an old heater control in my Mopar parts. Nice chrome housing, temperature slide lever used for the hand throttle and holes in the housing from defrost and heater controls for a choke cable and throttle lock. Perfect! I did have to extend the cable end of the temperature lever to get a long enough pull for full throttle operation but that was just a minor mod.

- 1 reply

-

- 1

-

-

IMO it adds complexity and therefore additional points of potential failure when you're out on the road. I'd add one more component. Either carry a jumper wire or permanently wire in a switch across the the relay power terminals. Jumper of proper gauge or switch of proper amp rating to carry full amp load for your car. Then If you have a failure in your new disconnect circuit while on the road just install the jumper or simply close the switch and you'll be able to drive on.

-

vintage6t started following 251 Broken Crankshaft / Noise on Rebuild

-

On the HAMB https://www.jalopyjournal.com/forum/threads/1956-dodge-boyertown-body-milk-truck-delivery-panel.1307998/