47 dodge 1.5 ton

Members-

Posts

406 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 47 dodge 1.5 ton

-

There are several different style mechanical fuel pumps for these engines that you may want to look at. I have a set of his headers mounted on a 25” motor in a truck. The drops are entirely different from what you have. Both are closer to the oil pump. I didn’t feel there was adequate distance to the fuel pumps I tried so decided to go with an electric pump as well. On other point you may want to pay close attention to is the mounting flange thickness to the intake you are using. My intake was .159” thicker at the flange so I machined “step” washer tabs, a little larger for better contact. Also, check and make sure there is no contact to the intake /header that would allow a vacuum leak (minimal grinding was required for my application). I can’t be of much help to your final exhaust fitting but glad you can still use the heat shield.

-

Lug nut torque on 2 ton truck

47 dodge 1.5 ton replied to Dunkin's topic in Mopar Flathead Truck Forum

One item that I think worth mentioning on torque wrenches. I work in the large industrial pump industry and we use 1/2”,3/4”and 1” mechanical torque wrenches, over that are hydraulic. After working in quality the last several years and being involved with calibration, mechanical torque wrenches have a higher “failed” ratio out of almost 5000 tools that are calibrated in our system. Some go bad from just sitting in tool boxes due to poor storage. These are checked at 5 points of the range have an acceptable point tolerance of +\- 4% on a (6) month frequency. I just thought this is worth mentioning because I have seen some out 30% at a given point. Make sure they are stored per “manufacture”instructions. Common reasons for failure; being torqued past the “click” setting, used for backing off bolts, dropped, not backing off pressure when stored, moisture in storage. I also wanted to point out while on the subject that we have conducted several R&R’s using statistic analysis on torque bars, dewalt impacts and such. The mechanical torque wrench is the most accurate tool if in calibration for general use. Best regards, Kevin -

Replacement gauges for 1947 WC

47 dodge 1.5 ton replied to dgrinnan's topic in Mopar Flathead Truck Forum

Looks like a nice set, wish the speedometer was 80 mph though. I wonder how well that works in remote areas where my phone looses service? -

Don’t waste your money on the pre-made tubing, most likely will not fit anywhere clean. Recommend purchasing a roll as suggested by dodge4ya, a double bevel kit, tube cutter, and tube bender if you can’t barrow one.

-

Tip out windshield removal

47 dodge 1.5 ton replied to fireguyfire's topic in Mopar Flathead Truck Forum

I was able to put some pressure on the windshield enough while turning crank. Mine had a loose worm gear and rocking back and forth was enough to get out for replacement. I saved the old one but replaced with the billet aluminum one that DCM carries(better design IMO). I believe you will need to get that windshield out on an angle for removal. -

I believe vacuum sucks oil, mainly when going down hill. That’s what I have always been told.

-

When it comes to valves and seats, I like to remove the least amount of material necessary even if it cost time. I would lap and verify if the rust is removed, re-grind if needed. Please explain your thoughts on not lapping?

-

Plan to rebuild front end on my 1.5 ton soon. Have several options, remove springs and drag link from truck and do on shop floor or rebuild under fenders. Would like to hear from those that have worked on them. Are front hangers, hardware and spring pins available? I have not located kin pins/ bushings or cups to date. Napa said bring parts in and maybe match? This is the same people that can’t find parts that go back before 1960 so I am a little leary. Are there good methods to remove spring pins or will I most likely be cutting them out? Just trying to see my obstacles before I dive in. I have a torch, big hammers, a lathe (no press), and a lot of patience.

-

Yes, only needed (1) slot to match carb base, so believe I am good. Not using a governor, my goal is more towards the other way of the spectrum “make it breath”. Thanks for the clarity on the gaskets, I was trying to determine why the (4) slots were necessary.

-

Just wanted to reply that after pulling carbs down several times looking for issues in the idle delivery side and adjusting float level, I believe the root cause was too much fuel pressure. I started at 5 psi, have set at 3 PSI currently and am very pleased so far. I think 5 almost works but just a little too much for the needle valve on ethanol fuel. I currently have an electric pump with a regulator so the carbs saw 5 PSI at idle, not sure what a mechanical pump produced though. Again, this is just my thoughts currently and wanted relay what I have found. Thanks all, Kevin Ie… glass packs are Too loud!

-

Looking for a transmission (approximately 250#)to be picked up near Seattle Washington and be delivered within a few hours of Gettysburg Pa. Looking for any suggestions or any recommendations. Thank you, Kevin

-

No— it’s pretty clean—lol. I was driving about 20 miles from here last week with my “Dodge eyes on” and spotted this about 100 yards from the road in a hedge row. Turned around to get a better look and thought it might be a truck frame with a flathead—lol. Found a neighbor, got in touch with the owner for a better look. Turned out to be a Dodge 1.5 ton that may have a set of springs I could use. Now it’s home.

-

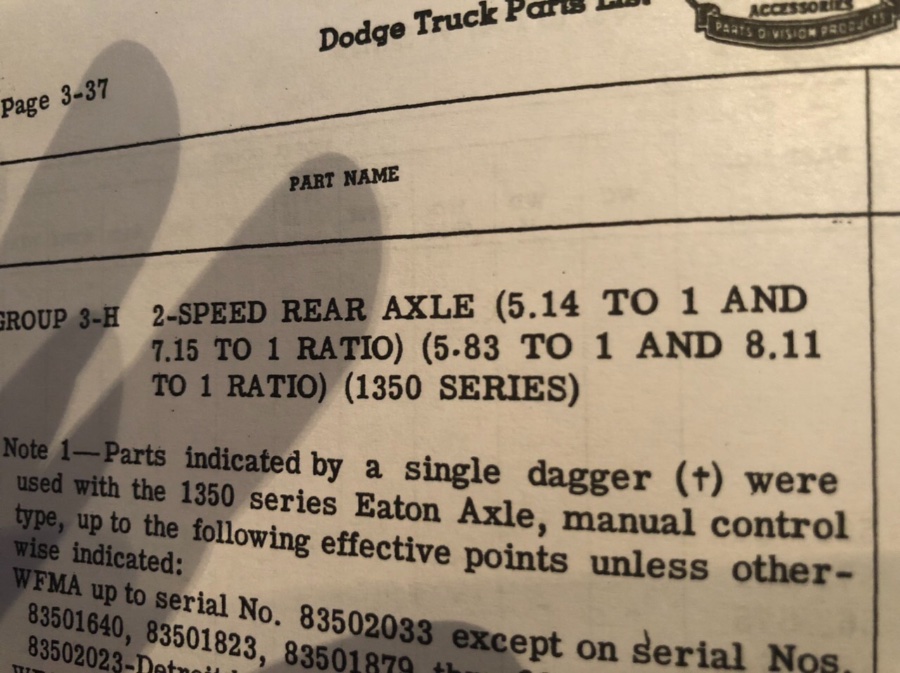

That’s sounds like a good comprehensive suggestion that I should be able to come up with a rod and lever. Would you think the brake assemblies could be swapped without compatibility issues? I just replaced everything on the single speed so shouldn’t be any issue getting back apart.

-

I have used a plumbing wrench like you use for a sink if not over tight.

-

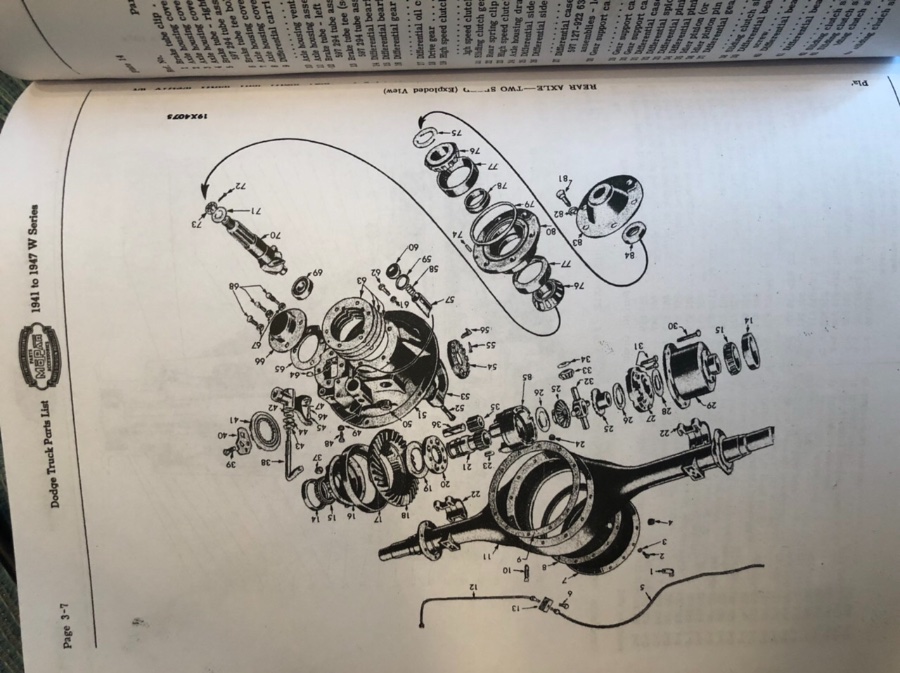

What is required to convert the Eaton 1350 2 speed rear to electric shift? I dragged home a ‘49 carcass over the weekend and has what’s left of a rear that I am thinking about saving. It is missing backing plates to brake drums and only has the shifting lever sticking out the top. I have a long shot thought that my backing plates & drums can be switched from my single speed ‘47? So my first thought if anyone has modified to electronic shift? I have a broke rear leaf spring that I was going to switch the set with and then started thinking about a little upgrade? Thanks, Kevin

-

Thank you, guess another item to be on the hunt for! Thanks again, Kevin

-

Now that I have seen several trucks without them that appear unmolested, were they optional on ‘47 trucks? Mine does not have them and I don’t see evidence of it ever having them. Just wanted to ask before I try to locate some good originals/aftermarket.

-

Flat bed (non tip) removal and weight

47 dodge 1.5 ton replied to ggdad1951's topic in Mopar Flathead Truck Forum

Did you keep the channels or decide to go another path? That’s a lot of bolts to cut. -

Flat bed (non tip) removal and weight

47 dodge 1.5 ton replied to ggdad1951's topic in Mopar Flathead Truck Forum

Looks like a good frame to work with. I don’t believe Dodge ever made a flatbed. All I have ever seen were aftermarket and possibly dealer sold. Even today, our beds are aftermarket unless it is a pickup bed. The one you picked up looks period correct. It also looks like it must have used wood beam runners. -

They were also popular in marine applications well up in the 70’s. I would think the salt water would have played hard on them but know they had multiple carb set ups as well.

-

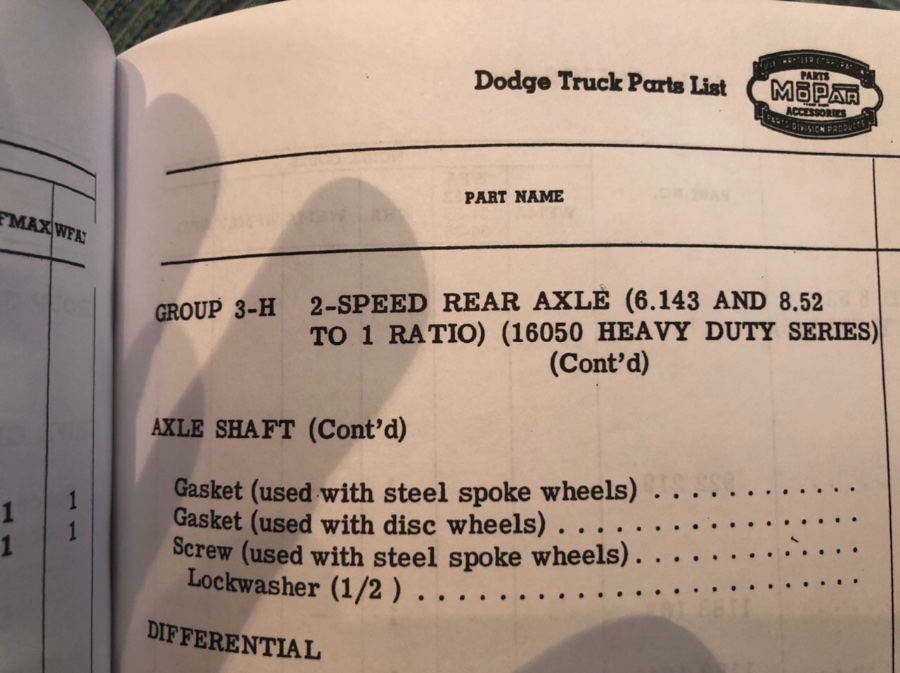

This is the heavy duty rear ratio. Without the serial number to the truck, it could have one of the two rears listed.

-

-

Welcome to the forum and nice truck. I have found the ratio on my non-two speed located on the drivers side, between to bolts (axle housing/gear housing assy), I believe about 3:00 position. I need to look back at some pictures I took. Now with that being said, the 48 2spd rear I have was in the same area but need to look at that again for certainty. I had to emory the paint because the stamps are not bold. I used a black light to read the numbers. i found a picture to give you the location but as you can see, not very visible.

-

-

To any folks that keep a record on where these engines can be easily obtained, the following pictures show my findings. The Massey Ferguson super 92 combine had (3) engine options, (1) being a Chrysler IND 265. I have reviewed (3) machines and all had the Chrysler 265 25”engine. The Smaller machine is of a Massey Harris special 80 which has a 23” 230 Chrysler IND engine. I have only reviewed (1) of these machines. These machines are mostly not in use anymore due to no cab and small capacity’s but generally low hours compared to other uses for these engines. Another point is they have been governed to low rpms. The engine is located behind the large front wheel and takes a few hours to pull(I am slow). They do not trailer well because the wheel base and header width so most likely will need driven to final destination.