-

Posts

784 -

Joined

-

Last visited

-

Days Won

16

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Loren

-

The Isky guy called tonight. They got the cam and decided they had a better profile than the Max #1. The Chrysler cam has a lot more lift than a Ford Flathead can tolerate so they found a grind that would utilize it. Cams with a lot of lift are a trade off to compression. You can't hog a lot off the head because sooner or later the valves will touch the head. The Chrysler's big advantage is it's long stroke small bore. You get a modern compression ratio with pretty good area around the valve for breathing. Flatheads have notoriously shrouded valves and that is why short stroke big bore overheads prevail now days. The long stroke makes for a slow turning engine but it has great gobs of torque and while horse power sells cars, torque moves weight. I am excited that one more piece is on the way.

-

Carrol Smith (Prepare to Win) has lots of hard earned data on the way you keep things together. I’ve used his thoughts on axles, splines and threads and happily never had a failure. Studs are rarely necked down as in the above, because they usually have cut threads. The necked down ones are usually rolled threads and rolled threads are 20% stronger. Think about that when you’re removing a stud using the double nut method. As a mechanic I hate studs, as an engineer I prefer them if done properly. Changed regularly, installed properly and properly designed studs are way better otherwise they are a pain. Studs have a memory. Anything evil done to them will be remembered.

-

On the Radio. I've looked into this and you can in fact change a radio from 6 volt to 12 volt. You have to change the vibrator of course. It is recommended that you stay with a mechanical version as they don't care about polarity. All the tubes have to be swapped out for 12 volt versions. Just change the first number in the part number to a "12" from a "6". The radio I want to convert is a MoPar 812 and there is one tube that doesn't have a 12 volt equivalent that I have found...yet, the 6C4. The bulbs for the dial. Finally the vibrator Transformer. To get back the clean sound of a brand new 1952 radio, you'll want to change all the old leaky capacitors as they deteriorate over time and maybe a new speaker. Of course unless you are a true gear head who loves pain, you can always send it out to the guys who do several each week.

-

I just removed the manifold studs on my 25 inch block. Most studs are "thru hole," where they go into the water jacket. Of course I broke some and they had a characteristic way of breaking. Every one that broke turned at least one full turn and sometimes two. That tells me they corroded on the ends and broke when the corroded part got tight in the hole. One could prevent that from happening again (if you care, as it is unlikely you'll be the one to overhaul it next time) by not screwing the studs all the way in. I ruled out shortening them or removing some of the threads as they plated and if you do that they will corrode quicker. My plan is to run a tap down each hole and carefully measure the depth with a caliper, writing down the measurement. Then when I install the studs I will "glue" them in with ARP Thread Sealant screwing them in only so far as the depth of the hole plus one thread. I used the Summit Racing online catalog to find the studs I needed. ARP doesn't make the size I needed but Dorman does. In boxes of ten, studs are 79 cents each. At that price I bought two boxes! ARP 12 point nuts and flat washers to finish things off. I am not bothering with brass nuts for this engine as I have Langdon's cast iron headers and I am making my own intake manifold. The split exhaust manifold should not be as troublesome as a full length one. It's my humble opinion that studs should not be reused unless you know their entire history. On a race car you keep log so you know how many times they've been loosened and tightened and you know they've always been torqued correctly. On a passenger car you know none of this.

-

53 Chrysler Spitfire engine in a 50 Meadowbrook

Loren replied to meadowbrook's topic in P15-D24 Forum

Back to the question of is it worth the effort to swap to a Chrysler engine. That’s kind of a personal judgement. My college 1949 Plymouth I was told would last forever if I drove it easy and never over 55 mph. I did as instructed and it never gave me a lick of trouble. But I always wondered what was the difference between a Plymouth 6 and a Chrysler 6 was. All the Chryslers in my family were driven at highway speeds or more (65 mph+) and never had any problems. The answer was, “Well the Chrysler was designed later and it has a larger displacement, plus it is the flagship brand with the founder’s name on it.” Of all the Chrysler products I’ve always liked the Plymouths and of all the Plymouths (I could afford) I liked the 1949-54 models especially the Suburbans and Business Coupes. So when I decided to finally restore my Suburban I wanted it to be the ultimate example. Still period correct, a 6 cylinder engine and drum brakes were absolute specs. Most folks look at a flathead 6 and they can’t tell a Plymouth from a Chrysler. When they see drum brakes the same thing applies. I could never put a V8 in my car. That would be an admission of a lack of imagination and skill. -

The good news is if you have to change steering columns you get much nicer looking shifter and turn signals. I would not adapt the push buttons, they are way out of place in a 1950, in my humble opinion. At the same time you might consider power steering. There's a Toyota unit the 1952-56 Ford F100 guys are using to good advantage.

-

The Ford V8 was called for years the "85" which referred to it's HP. There was a V8-60 which was a shrunken 85 that replaced the Model B 4 cylinder. While the flathead Ford has its devotees it had a lot of faults which can be laid on Henry Ford himself's door step. One biographer quoted an internal study made after his death that said Ford Motor Co. hadn't made any money for 20 years and lost around 45 million or more! Nobody can say for sure because Henry didn't believe in keeping good books and there is one very good reason: ACCOUNTABILITY. Henry didn't take criticism well. For comparison the 1953 Ford had 239 cid from a 3.1875 x 3.750 bore and stroke yielding 110 bhp. The 1953 Mercury had 255 cid from 3.1875 x 4.00 bore and stroke yielding 125 hp. The Chrysler had 119 bhp from the same year. The V8 has 3 main bearings for 8 cylinders while the MoPar has 4 mains for 6 cylinders. You pays your money and takes your choice. I considered the Montana guys but they have not responded to my inquiry as yet. Ed Iskendarian himself paid a visit to me and my Dad Sept. 16, 2011. I'd been in the same place at the same time with him many times but this was the first time I actually got to talk to him. He's 98 years old and his life is pretty much the history of Hot Rodding. Isky's MAX # 1 is noted for being one of the better street cams for a V8.

-

I sourced mine from NAPA P/N 99186 The manufacturer is SKF (I think I recall Federal Mogul invented them and the metallurgy involved) The size range (if I read the box correctly is 1.866 to 1.872

-

Hi Frank, my logic works like this, a Flathead cam lobe profile and timing doesn't care how many cylinders you have. Long stroke, low RPM, high torque engine pretty much sums up both the V8 and the Chrysler. My objective is to get similar characteristics. However, digging a little deeper I find that the Chrysler Industrial 265 comes with much more valve lift stock than Isky's full race V8 cam! In the letter I packed with the cam I said I was open to suggestions, for it is true my level of knowledge pertaining to cams is limited to answering the right questions and then listening to what the experts have to say. I figure they know their business. Over the years I've come to realize there's not as much magic involved with camshafts as most people think. On one of the cars I raced, I would try a cam, figure out how to get the most out of it by driver technique (shift points) then report back to the cam grinder. I had a lot of cams ground before I had the "perfect one" for what I was doing. But what the hell? It's all about having fun isn't?

-

I am sending the cam off to Isky today. The engine came out of some large machine that needed a big engine driven hydraulic pump like a forklift. The hydraulic pump required a gear driven camshaft as it was driven off the cam gear. A gear driven cam turns the opposite direction than a chain driven cam. Chrysler making cams for both chain and gear drives enabled boat builders to have twin engine boats with counter rotating props. A gear drive cam assembled with a chain drive and a reverse turning starter would happily run backwards. An easy way to determine which way a cam turns is to look at cylinder number one’s exhaust lobe. The intake closely follows it. So looking on end if the exhaust lobe is to the top right and the intake is to the top left it is chain driven. A gear drive would be exhaust top left and intake top right. A fun factoid to impress your friends! Chrysler gear drive cams have the gear pressed on the cam and I am loath to remove it, so Isky gets the whole assembly. With the gear on it this is easily the heaviest cam I’ve ever handled! The presents of the hydraulic pump forced the relocation of the fuel pump (they moved the eccentric on the cam too) to the boss towards the flywheel and I am sure an upwards exhaust pipe. I asked for Isky’s Max #1 Flathead Ford V8 grind. Which should cause no dramatics as the V8 cam is gear driven too. After dealing with Flathead Fords there sure is a lot to like about this Chrysler! Like an extra 10 cubic inches over a Mercury.

-

One of the things I ponder every so often is the history that an object like a car has seen. My 1952 Suburban was built during the Korean war and it’s chrome plating suffered for it. The metal in the fenders is thinner than my 1949. In the time that passed since there has been momentous technological change. America of 1952 is not the same place as America of 2019, nor are the people the same. Bernie Sanders and Elizabeth Warren can talk openly about being Socialists where as in 1952 that conversation would have occurred in hushed whispers listened to by J. Edgar Hoover’s FBI. The cars go on with a certain immortally, being passed from one generation to another. You begin to realize you don’t own your car, you merely have stewardship of it. If you are a good steward it will last much longer than you can even imagine.

-

Hi James, the ARP bolt shown in your photo is the "football shape" I was talking about. The idea with those is that most bolts use a straight cut across the rod for the head. This creates a stress point in the rod, so while the bolt doesn't fail, the rod does. The football shape is actually a radius. The cut for the bolt head is a matching radius and therefore creates no stress on the rod. Worrying about the bolts is wise. I read of analysis done by Ford which indicated that most rods can stand plenty of cycles, the failure point is the bolts and what causes them to fail is improper torque. Too tight or too loose...They have to be carefully torqued to achieve the longest life. Before I'd spend big money on rod bolts, I'd order custom rods. That way you know what they are made of and that they haven't been abused in their lifetime. CNC machinery has made manufacturing connecting rods so cheap, for some engines it's the best way to go. I am anticipating someone calling up SCAT and getting them to make 265 cranks and rods. SCAT makes Mercury cranks for Ford V8s and all sorts of flavors of Model A, T and B cranks and rods. Needless to say there are pages of SBC products in their catalog. Of course a Merc Flathead is 255 cid while a Chrysler is 265. I know a lot of Ford Flathead guys and it wouldn't take much trash talk to find out which has better performance.

-

I think item "C" is close to the football shape. I am not sure it would be appropriate for 265 rods. I have to think Federal Mogul knew what they were doing when they re-manufactured the rod (see photo in earlier post). On the facebook Plymouth Club page there was posted a link to a youtube video of dealer salesmen training for 1952. Pure propaganda! If you like your Plymouth it would put your teeth on edge. You could stop a Ford salesman in his tracks by comparing a 265 rod (or a Plymouth rod) to a Ford V8 rod. The bolts on the V8 rod are part of the rod they can't be removed or replaced. Also the web strength is much less. (I should post a comparative photo) Sleeving the rear cam bearing is an interesting idea. Model T Fords had a brass sleeve pushed into the rear of the block which was then line bored off the other cam bearings. (even brand new blocks from the factory had an un-finished rear cam bearing) It would not be a big deal to find an existing cam bearing to use then line bore the rear bearing bore to fit. Then you'd have a white metal bearing for all the cam bearings and it would be replaceable. (I am sure this was done back in the day) I think the Model T used brass because it was easily removed and it was easily reamed to size. If you think a Model T crank looks like a bent piece of baling wire you should see the cam. I heard a story that Ed Winfield calculated the twist of a T cam at the rpm he desire to run his engine, then ground progressively more advance into each lobe to compensate! Speaking of cams, I was thinking that I'd have Isky grind the gear driven cam. He has a well known grind for the Ford V8 that might do the job (Max-1). Any thoughts?

-

The cam bearings do not require 1/4 inch galleys to supply enough volume to lubricate them. In a Model T Ford there is no pressure as there is no oil pump, it's all splash. The cams in that engine are not much of a problem. Its the rods. In the 1960s and 70s NASCAR stock car racers figured out that too much oil volume was being sent to the cam bearings and that was starving the crankshaft bearings. Not only were the crank bearings starved but they found out they were having problems moving that oil back to the pan where the oil pump could pick it up again. Windage trays and baffles were designed to help but the one thing that worked were restrictors in the oil galley. A well known parts house which has a warehouse nearby me sells these items for many popular engines (Summit Racing). The oil pump is a positive displacement pump. Each turn puts out a known volume of oil. If you can "plug the leaks" that volume has to go somewhere either to the rods or out the pressure regulator by-pass. The pressure regulator keeps the pressure at the level the engineers decided is best. Unless of course the volume of oil pumped can't keep up the losses at places like the cam bearings. When you think about the path the oil has to go thru to get to the rods, it's a wonder they any oil at all. The oil has to go across the main bearing and find it's way into the crankshaft to be carried to the rod bearing. Too much clearance and a lot of oil will escape and get flung to the walls of the crank case doing no particular good. My guess is you could cut the diameter of the cam bearing oil galley in half and not hurt a thing. You might even go as small as .060 or .070 of an inch which is what the V8 guys use. In my garage I have a 5 hp air compressor which provides air to a bead blast cabinet inside and a sand blaster outside, plus air tools. When I am blasting the compressor runs constantly but it manages to keep the pressure at around 90 lbs. the max pressure is 175 and the motor starts at 125. The compressor pump puts out a fixed amount of air so the pressure goes up or down with the volume of air released through the blast nozzle and parasitic leaks. You can't have pressure without volume. Confine the volume and the pressure will rise. Yes I could set the max pressure to say 200 lbs and I could have the motor start at 150 lbs but I'd still be blasting at 90 lbs in a short time, because the volume has not been increased. Now if I got rid of any leaks or spin the pump faster, I'd have more usable volume and I'd be blasting at a higher pressure.

-

That’s it! Got anymore? While on the subject of oiling systems, I want to restrict the oil flow to the cam bearings. The galley to them is way bigger than they require and could be restricted to direct more oil to the mains and on to the rods. I seem to remember reading that some folks were drilling the crank passages a little bigger as well. Chryslers don’t have a reputation for lower end troubles but its hard to forget the lessons learned from NASCAR racing in the 1960s & 70s.

-

The current solution to the bolt head issue in other cars is a football shape. It wouldn't be to hard to re-machine the bolt head pocket for those. One other thing I discovered. Near the oil pressure regulator there is the "second chance" flow diverter valve. Full flow filters were a new thing at the time and the Chrysler engineers were worried about them plugging up. So they put in a fail safe device. Of course it didn't take too long before the filter makers put the by-pass valve in the filter. (along with anti-drain back valves) This renders the "second chance" flow diverter valves redundant. The 265 which had been rebuilt several times had an interesting variation. The steel plug for the valve had been replaced with a brass one. When I backed it out there was a long extension to it that went up into the passage blocking the flow. This was not a shade tree item. It was purpose manufactured. Either Chrysler made it or one of the aftermarket outfits and it was added during a rebuild. Automotive archeology.

-

I am going to have these rods "re-sized" and checked out by an automotive machine shop. I am certain they will know what to do. ARP (and others) make high quality rod bolts for just about everything. On one of my foreign car engines they even drilled out the holes and put bigger bolts in, so I am not worried.

-

The thought occured to me the other day that you could retain the “authentic appearance” of your car (and the function) by using a 12 volt generator. A 1956 12 volt generator could be found that would bolt right on and its regulator would fit in the same place with the same connections. My car a 1952 Suburban doesn’t have 5 networked computers, A/C and huge under hood heat loads from emissions equipment, so why do I need an alternator? The worst thing a generator ever did in my experience was caused by abuse. My Dad had a 1955 Ford (272 V8) that he use to rev up like a crazy person when he got on the freeway. Seated on the passenger side at night was always interesting as huge glowing red hot fire balls came over the top of the hood and headed right for my head! It turned out that the generator was being spin at well beyond its design limits and the solder was coming out of it in the globs I observed. One day it just stopped working. On the kitchen table he took a hammer and chisel and “Improved” all the connections on the armature. Then it was again off to the races! The fire balls never returned after that.

-

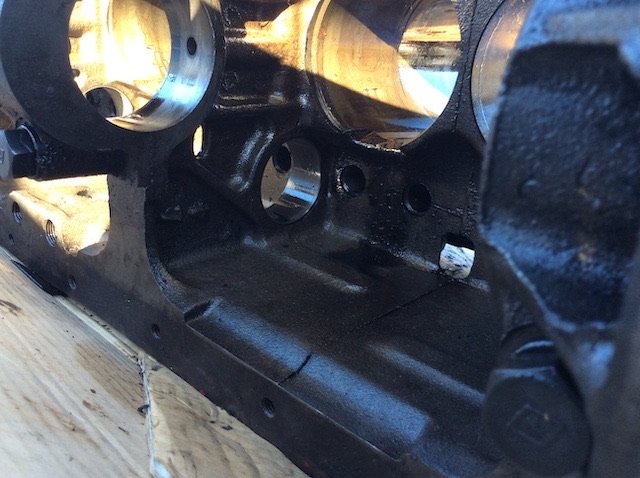

Okay here are photos of the connecting rod bolts and the shaved area to clear the inside of the crankcase with 237 & 265. Next the block notches in casting 1400229 & 1400229-1. Note the indent at the pan rail. Note this is the 1400229-1 block that had the 237 Crankshaft. The 265 is the same inside. The head casting numbers from the file found on this site are: 1120805, 1120806, 1120903, 1632430. I have one that is not listed but it's exactly the same as 1120805, it's number is 1532092.

-

These two blocks (the 265 & 237) have the notches. They are the full flow filter type as well. The casting numbers are the same except the 237 is newer and has a -1 after it. The 265 had a small serial number pad (but no number) and the 237 has a large one with the number on top in stead of the side. The rods have very different bolts. The recessed head on the 265 is to clear things. There is a substantial difference is the weight of the crankshaft. The 265 is much heavier. When you look at the 237 it looks plenty robust, but 265 looks like it came from a diesel. Without question the 25 inch engines are very strong.

-

When I bought the 265 I also bought a 237. Today I got it apart and found that its is in beautiful shape. The crank is standard and the pistons have the DPCD stamp on the top. It has sodium cooled valves which I was surprised to see. Another thing that surprised me is that under the Brass Chrysler industrial tag I found that it was painted silver before it was painted Industrial red. The purist in my nature wondered if I should repeat this odd situation. When I get the 265 crank back its going in the 237 block with .010 over pistons. There's an old fellow nearby who has a pretty incredible warehouse full of NOS parts (for all cars). I am pretty certain he has most of the parts I need. When I get to talking to him I'll find out more.

-

The idea for this project started in my mind about 40 years ago. I finally decided it's now or never and I hate nevers. I acquired a 265 Chrysler Industrial engine that had once powered a Forklift of some kind. It must have been a big one too. I just got the thing taken apart and I have to tell you it is the most throughly worn out engine I think I've ever seen. It wasn't worn out once but several times! The bores are .060 overbore with sleeves! The crankshaft is .040 on the mains and .030 on the rods. The thrust flange on the rear main bearing was gone and each time the operator stepped on the clutch it pushed the crank forward till it ran on the main webs. It's just plain worn out. However, sometimes rebuilding something can make it better than brand new. Cranks can be welded up and re-ground. There is an outfit that makes equipment to weld cranks and they claim they can make them better than new with two different welding wires for the journals and the radiuses. Which is great if your journals are kind of soft in the first place. To bring my crank back to standard size and make all the strokes the same will cost around $1,500. Forklift engines get abused horribly but they do have an advantage. Because the have to drive a hydraulic pump they have a gear driven camshaft. Zero issues with sloppy cam chains. The fuel pump is moved to the rear of the engine to make room for the hydraulic pump and the camshaft turns backwards. I am hoping the gear will fit under the chain type front cover, it would be a shame to give up the gear drive. The 265 crank can be identified by the number 1400188 and the really deep groove in the center counter weight. A 237 crank has a very shallow groove and the number 870715. A 251 would be somewhere in between. In examining the design of this engine, I am impressed. These are very robust and well built. No wonder Chrysler sold them for everything that moved.

-

The 8 3/4 from the rear looks almost like the original. If you find a 1964 and earlier they even have tapered axles (or so I am told). The ratios available are numerous and there are limited slip differentials (Dana Power-lok being the most desirable). Unusual is the fact that they only have one differential design. If you need to change the ratio all you have to buy are the gears. Some axles have a cutoff point where the next ratio requires the purchase of a different differential. Strength wise they are very well engineered and rival the Ford 9 inch (or so an article in Hemmings says). The 8 3/4 is my plan "B" if my 3.73 stocker doesn't work out and I can't find a 3.54. To keep my car period correct (within 5 years) I am willing to paying up and I don't mind a little work. An 8 3/4 would be an admission to the difficulty of finding the right original part.

-

Also remember the area from the top of the piston to the top of the top ring is part of the area of the combustion chamber. When you bore a block you are in fact increasing the size of the combustion chamber. No matter how close the piston comes to the cylinder head and because of piston rock there has to be considerable clearance, which increases as the piston's diameter increases. Increases in cylinder bore can actually lower compression ratios in short stroke engines because of this. In long stroke engines there isn't enough area increase to make a measurable increase in CR. As a general rule hot rodders don't consider increases in cylinder volume for purposes of compression ratio from boring to be worth calculating. I know it is counter intuitive.

-

On compression ratios: Boring a block does nothing to increase a compression ratio and may even lower it. A bigger bore increases the area over the piston. Stroking a crank increases the CR dramatically. So if you have a short stroke engine with the same CR as a long stroke engine, then the head has a smaller chamber than than the long stroke. In that case you could get more CR using short stroke head. Just when you thought it was safe to go back in the water: Because of the way machinists re-grind cranks, you might find a 6 cylinder with 6 different strokes! Wear or dings say .010 deep would take .020 to clean up with the original stroke. The grinder machines on both sides of the journal. So the savy machinists adjust the centerline of that cylinder to clean the journal at .010. Personally I hate it but that’s standard practice. You can complain all you want but they are not going to listen to you. SO you can carefully adjust the volume of the chambers to make them all equal and still have the CRs all over the place because of the crankshafts strokes. Next is the camshaft: A stock docile cam will have much more pressure on a compression gauge than a hot cam. Because of that it will start easier too. Something to think about when you’re wedded to 6 volts. Automotive engineering is all about the compromises you are willing to make. Most of them have been made before you even see the car you plan to soup up. Flatheads, siamese intake ports are all the stuff we have to live with, don’t over think it.