-

Posts

825 -

Joined

-

Last visited

-

Days Won

17

Everything posted by Loren

-

eBay is kind of funny. Most of the sellers have a store online, but to make back the eBay fees they jackup the prices. So I shopping on eBay then go looking elsewhere for what I need. There are really no bargains on eBay. I learned from my 265 crank experience that automotive machine shops have a better pipeline than eBay. Go to your favorite machine shop and ask can they get you a crank and rods? You'd be surprised at what they can find. Before you click buy check to see what they sell the same item for on their website. Speedway Motors, Summit Racing et al, all sell on eBay and have considerably lower prices on their website, with discounts.

-

Also have a look at the post labeled "Rearend" I put a photo of where to look on the case for the ratio.

-

I’ve said my piece on this topic before so I’ll try not to be redundant. If you are determined to use a dual master cylinder, all you need to do is find one with the same size bore. If I were to do such a thing, I would not split the system front to rear. I’d split it diagonally one front wheel and one opposite rear wheel on the same circuit. A dual master cylinder just means you have two single circuits. Splitting it diagonally means more hard lines, connections and another rubber hose. More points of potential failure. Before a driver goes into panic mode with a brake problem, they ought to do some training. Go out and figure out what you have to do when you can’t use the brake pedal. As I said before I finished a race in a car with a seriously malfunctioning brake system. So how do you do that? Very carefully and with zero panic. You’re the driver, drive! I had an MG TD that had an intermittent issue where the pedal would go right to the floor and then a minute later all was well. Annoying but it did build character! I never wrecked it. My race car partner called me a few days after the race and told me he wanted to move the car and forgot I told him it had no brakes. The shop was on a pretty good hill and the only thing that stopped it (and him) from going down and hitting his house was a stack of tires. I think he was offended when I laughed at him.

-

-

I've got a couple (maybe two sets) of rear drums you can have....but I'd like to keep the hubs. If you don't need the hubs you're welcome to them. I also have a chart from I think it's Bendix of the measurements of the drums they make. I am pretty sure new ones without hubs are available. The trouble is the chart is metric.

-

I have two carriers that I've found the ratio stamped near the fill plug. A can of carb cleaner and a small wire brush revealed the ratio in about 3/16th numbers as 3.73.

-

A guy I knew had a Ford Pickup with a CAT 3208 diesel. He said it was a prototype Ford evaluated before going with International’s 6.9. While not an engine swap my Dad told a story about an unusual repair made during the war. A 1940 Ford that didn’t have the expected power was bought by a friend of his cheap in 1946. Upon engine disassembly a WOODEN PISTON was discovered! Apparently none were available so the wooden piston was substituted. Probably done on a used car lot.

-

The switch I bought from ebay came today so here’s a photo of it on the carburetor. It was sold as a Studebaker OD switch but honestly I don’t think it cares what it goes on. Studebaker of all the car companies really embraced OD and had the highest percentage installed. They also used this carburetor a lot. The switch was new and came in a box with a part number. I am sure that number will appear in somebody’s catalog.

-

How about a Model A Ford engine in a pinto?

-

Plymouth and Chrysler cars in general were the first mass market cars with hydraulic brakes. From the first Plymouth in 1929 until dual circuit brakes became mandatory in 1967 single circuit brakes did just fine. The argument against single circuit brakes is exactly the same as the one against hydraulic brakes in general made by Henry Ford. However, if you've ever driven a mechanical brake car that is out of adjustment you will willingly (and happily) drive a single circuit hydraulic braked car. I have never had a brake line fail by bursting. I have had to replace brake lines which de-laminated internally and caused fluid blockage. As it happened that was on a dual circuit system and it still wouldn't stop. I have raced a car with a dual circuit Master Cylinder, where the Master got fried by a broken exhaust pipe. It made for "interesting" braking performance to be sure...but I finished the race. The rarity of broken brake lines is more than made up for by the Plymouth parking brake system. That brake band will stop a car! So...you pays your money and you takes your choice. Simplicity vs complexity a good discussion. What causes a loss of brakes in a single circuit system is loss of fluid. If one checks the fluid once in a while and notices a fluid loss...problem solved. With a Master Cylinder under the floor board you're not as likely to do that. With my suggestion of a remote reservoir under the hood you'd be more likely to check it and you'd have a lot more fluid to lose. Taken one step further to add a level warning light satisfies safety and simplicity. In my mad mind such a system would actually be safer than a dual circuit master cylinder under the floor boards. But then it's my opinion.

-

James has a point. If you’ve ever experienced braking with a dual circuit system that has one side in failure mode it doesn’t give you much confidence. First of all a dual circuit Master Cylinder has both circuits in one cylinder bore. Meaning when the driver pushes on the pedal the first circuit pushes not only on it’s brake cylinders but also on the secondary cylinders. One being in line with other. A failure is evidenced by pedal movement thru the failed circuit then finally the good side. Lots of pedal travel with nothing happening. When you have a Master Cylinder that complicated lots of things can go wrong. There’s an old saying “Keep it simple”. The reason the Butch’s kit only works for automatics is that there is no provision for a clutch pedal which limits it’s use to engine/transmission swaps. The dual brake systems I’ve seen usually divide the system front and rear which is easiest to do. However, 80% of your braking power is on the front. A better system is the SAAB system (1964) of “Dual Diagonal” brakes where one front and the opposite rear are teamed on each circuit. Volvo went them one better by using both rear wheels and one front for each circuit but that’s way too complicated. If one were intent on improving the Plymouth brake system, it’s my humble opinion going to Desoto 11 inch brakes and finding a way to put a remote reservoir for the Master Cylinder under the hood would be the biggest improvement. You could get all Guru and put a level warning light on the dash for the brake fluid. Even if the system was beginning to fail you’d have plenty of warning with fluid loss being the indicator. Simple with little re-engineering involved.

-

Thanks for the photo! I saw a kit that had all of brackets to mount on the linkage, but they were mighty proud of it. Your linkage looks very robust! It seems the factory did it both ways, directly on the carburetor or on the linkage. Without a doubt either way is superior to "up through the floor board to the gas pedal." The carburetors I am going to use were from V8s (although the 1955-56 "Power Pack" used one). I've used the Bendix-Stromberg WW before and I always wondered why the throttle was so big and had so many "features". It seems they were built to accommodate Overdrive Kickdown Switches and Dash Pots for automatics. When tuning one, they use a lot of parts from the 48, 81 & 97 carburetors so parts are readily available. (things like jets and such) They are however much shorter than a 97 and another level of technology beyond them. To make them shorter Stromberg went from 3 stud mounting to 4 which means any application that has a 97 pattern needs an adaptor.

-

I gave an old Atwater-Kent distributor for a Model T to a friend of mine. (they were an accessory. Model Ts had a timer and vibrator coils originally) He grabbed my Dad and off they went to see Mr Harris. You know he went through his books and found a cap & rotor, a set of points & a condenser for that old thing! All the parts fit something else but they were exact replacements, he had to cross over several ignitions to get there though. I learned thirty years ago when I moved here you never know what you'll find around here.

-

I find myself in need of a carburetor mounted Overdrive Kick Down switch. I have a floor mounted switch but it is too long and the threaded portion is too big around for the hole in the bracket. It's always something isn't it?

-

His name is Lester J. Harris. He is a resident of Northern Nevada and has about 2 warehouses full of old car parts the vast majority of which are brand new. He also has a 1938 Dodge so he speaks MoPar fluently. He bought a large part of his inventory when Mcquay-Norris auctioned off its inventory after a merger in 1969. You might find a couple of youtube interviews with him, so you get to see the man who will pick up the phone when you call. (775)267-2559

-

Great News! I have been in contact with the gentleman who has been selling the new Thickstun/Tattersfield Plymouth manifolds on eBay. He reports that Frank Boran the man who is making the Plymouth manifold we have much admired, is dusting off the patterns for the Chrysler/DeSoto manifold! He expects to have them in production later this year. He has placed my name on the list of potential buyers...so there is a list and if you might want one you really should get on the list. I'd go to eBay, search for Thickstun Intake Manifold find the new Plymouth manifolds and then contact seller to get on the list. If you're not sure about the Thickstun, then type in Offenhauser intake Manifold and see what they look like....you'll want the Thickstun believe me.

-

Some guys liked to use a light spring when lapping in the valves. It lifts them momentarily so they don't just go back and forth in the same spot. Could be the guy had to answer the phone or went to lunch and forgot it. That's the only thing I can think of.

-

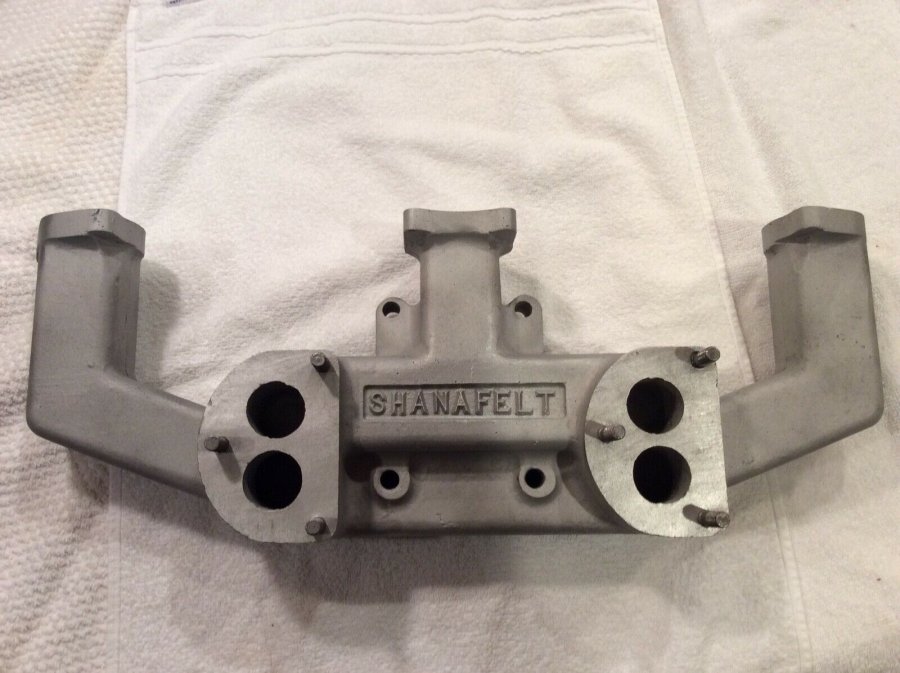

Hi Frank I really wanted that Shanafelt! I was going make a thin adapter plates so my Bendix-Stromberg WW carburetors would fit (they have a four bolt pattern). The Edmunds was mis-labeled as a Chevy manifold and not worth nearly as much as a Chrysler. Tom Langdon uses Offenhauser Chevy 216 manifolds modified to fit the Chrysler. He buys them for $300+ then re-works them. I am sure he has to get close to what I paid or more. His Weber/Motorcraft carburetors are then mounted on 2 to 1 adaptors like I will have to do with the Edmunds. Oh well I will get over it.

-

You can file this under "The one that got away!" Somebody snatched a prize away from me and I hope they appreciate it. They certainly paid for it! In an eBay auction I found this Portland, OR made manifold that fit two 97s! Just exactly what I was looking for. Anyway the price hovered at $255 till I did my usual bid pattern with 30 seconds left on the clock. The typical price for an Edmunds 2 x 1 manifold is around $600. Most start there. I figured using my personal proprietary algorithm that the premium vs unknown quantity vs activity vs fudge factor would be around $800 and bid it that way. It sold for $810. I'd like to know how far the other bidder was willing to go as I might have underestimated it's value. I did score a small consolation prize of a mis-labeled Edmunds 2 x 1 manifold an hour later for $412.77

-

I am liking my Forklift engine 265 more and more! I’ve come to dislike timing chains over the years. One thing I learned the hard way is that changing just the chain is only a temporary fix. If you want it to last you’ve got to change everything. Gears are by far the best way to go...with one exception. They should be all steel. Helical cut gears are silent and don’t vibrate like straight cut gears. The more you look at Mopar stuff the better you like it.

-

Just to make light of the situation, I'll relate an experience of mine. I was working on a Model T when I noticed something funny. The two core plugs were not core plugs at all. They were Indian Head nickels! Somebody decades ago needed to replace the core plugs and wanted something that wouldn't rust and didn't want to make a special trip to the auto parts store. So they reached into their pocket and got a couple of nickels. I did not remove them as they were domed and now pretty worthless as coins. I did go and find a couple of new core plugs and they were the exact size of a nickel. I then made a note to myself never to buy core plugs for a Model T ever again when it was so much cheaper to use money to fill the hole.

-

That is one impressive gear set! On mine the crank gear has two threaded holes but the cam gear is solid with no holes at all. The cam should be here in the next few days (I hope).

-

For some of us, they haven't made a good Chevy (or at least one I'd own) since 1928! (last and best year of the four cylinder) I used to race SCORE off-road and the high point of my racing career (satisfaction wise) was catching Larry Schweikofer's '57 Chevy (powered by a 350 V8) on the highway between Ensenada and Valle de Trinadad in the Baja 500 in a SAAB 96 V4 (107 cid). I live in Northern Nevada now, one of the big events in Reno is "Hot August Nights" and I've never bothered to go. It seems that there is a "Check-off list" for Hot Rodding nowadays and SBC is the first box. Guys will spend $20,000 on paint and bodywork then put a Chevy crate engine in the car, which to me wastes all that work and money. Certain cars stick with you and you really don't care what other people think. I like my ole' Plymouth and I want it to be the best example of what a guy could have had in it's era. Canadian cars had 25 inch engines, Chryslers had 265 cid engines and you could get Overdrive from the dealer. So everything I want to do to my car is period correct, it just takes a work to get there.

-

Lol Reminds me of old life insurance ads where a piano is falling and one guy asks his friend, “Who's your insurance company?” You know something I don’t? Actually I’ve been trimming the number of projects I’ve taken on. Sad but true we can’t do them all. This car is intended to be a daily driver for my golden years and I’d like to wear it out before I hang up the keys.

-

Hi Frank, I have a long narrow tank made for bluing rifle barrels I am going to use to cool the cam. Put about two inches of shipping styrofoam packing material under the tank, then put about 5 or more pounds of dry ice in it. Drop the cam in and cover it with alcohol. As I recall that reduces the temp by about 125 degrees. The gear I'll heat another way I haven't determined yet...maybe a propane torch. All of this activity needs to be near my press if something goes wrong and I can't get it to seat. Putting the gear on the crankshaft is another job. I might have the machine shop do that. (one of those "I can't look" things) The last time I saw somebody put a gear on they heated it red hot with a torch. Not sure I want to see that. I was reading on the FB page a question about putting a blower on a 6 cylinder. Being familiar with this engine (and a Continental) I suggested the gear drive such as I have driven off the top of the cam gear where the hydraulic pump used to be. A guy could use a Graham/Kaiser (Continental) centrifugal blower. The cam gear train is super stout and should last forever silently even with the load of a blower. Only one problem, the cam turns backwards compared to the usual chain driven cam. You can tell which cam you have just by looking at it. The fuel pump lobe is at the rear (to make room for the hydraulic pump) and on the first cylinder the exhaust lobe leads the intake ( that tells you the direction it will turn).