-

Posts

784 -

Joined

-

Last visited

-

Days Won

16

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Loren

-

Some guys liked to use a light spring when lapping in the valves. It lifts them momentarily so they don't just go back and forth in the same spot. Could be the guy had to answer the phone or went to lunch and forgot it. That's the only thing I can think of.

-

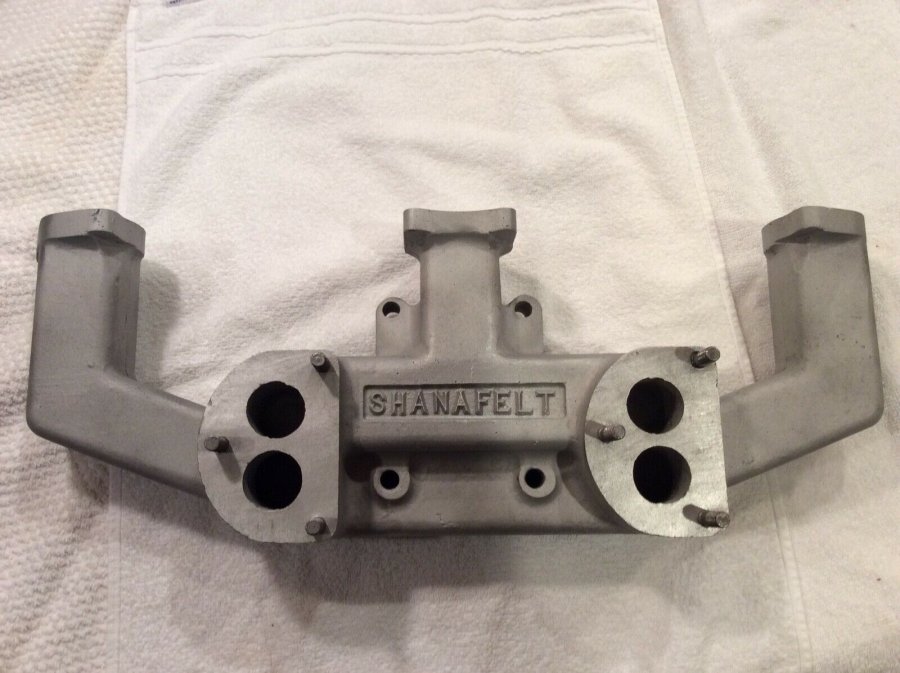

Hi Frank I really wanted that Shanafelt! I was going make a thin adapter plates so my Bendix-Stromberg WW carburetors would fit (they have a four bolt pattern). The Edmunds was mis-labeled as a Chevy manifold and not worth nearly as much as a Chrysler. Tom Langdon uses Offenhauser Chevy 216 manifolds modified to fit the Chrysler. He buys them for $300+ then re-works them. I am sure he has to get close to what I paid or more. His Weber/Motorcraft carburetors are then mounted on 2 to 1 adaptors like I will have to do with the Edmunds. Oh well I will get over it.

-

You can file this under "The one that got away!" Somebody snatched a prize away from me and I hope they appreciate it. They certainly paid for it! In an eBay auction I found this Portland, OR made manifold that fit two 97s! Just exactly what I was looking for. Anyway the price hovered at $255 till I did my usual bid pattern with 30 seconds left on the clock. The typical price for an Edmunds 2 x 1 manifold is around $600. Most start there. I figured using my personal proprietary algorithm that the premium vs unknown quantity vs activity vs fudge factor would be around $800 and bid it that way. It sold for $810. I'd like to know how far the other bidder was willing to go as I might have underestimated it's value. I did score a small consolation prize of a mis-labeled Edmunds 2 x 1 manifold an hour later for $412.77

-

I am liking my Forklift engine 265 more and more! I’ve come to dislike timing chains over the years. One thing I learned the hard way is that changing just the chain is only a temporary fix. If you want it to last you’ve got to change everything. Gears are by far the best way to go...with one exception. They should be all steel. Helical cut gears are silent and don’t vibrate like straight cut gears. The more you look at Mopar stuff the better you like it.

-

Just to make light of the situation, I'll relate an experience of mine. I was working on a Model T when I noticed something funny. The two core plugs were not core plugs at all. They were Indian Head nickels! Somebody decades ago needed to replace the core plugs and wanted something that wouldn't rust and didn't want to make a special trip to the auto parts store. So they reached into their pocket and got a couple of nickels. I did not remove them as they were domed and now pretty worthless as coins. I did go and find a couple of new core plugs and they were the exact size of a nickel. I then made a note to myself never to buy core plugs for a Model T ever again when it was so much cheaper to use money to fill the hole.

-

That is one impressive gear set! On mine the crank gear has two threaded holes but the cam gear is solid with no holes at all. The cam should be here in the next few days (I hope).

-

For some of us, they haven't made a good Chevy (or at least one I'd own) since 1928! (last and best year of the four cylinder) I used to race SCORE off-road and the high point of my racing career (satisfaction wise) was catching Larry Schweikofer's '57 Chevy (powered by a 350 V8) on the highway between Ensenada and Valle de Trinadad in the Baja 500 in a SAAB 96 V4 (107 cid). I live in Northern Nevada now, one of the big events in Reno is "Hot August Nights" and I've never bothered to go. It seems that there is a "Check-off list" for Hot Rodding nowadays and SBC is the first box. Guys will spend $20,000 on paint and bodywork then put a Chevy crate engine in the car, which to me wastes all that work and money. Certain cars stick with you and you really don't care what other people think. I like my ole' Plymouth and I want it to be the best example of what a guy could have had in it's era. Canadian cars had 25 inch engines, Chryslers had 265 cid engines and you could get Overdrive from the dealer. So everything I want to do to my car is period correct, it just takes a work to get there.

-

Lol Reminds me of old life insurance ads where a piano is falling and one guy asks his friend, “Who's your insurance company?” You know something I don’t? Actually I’ve been trimming the number of projects I’ve taken on. Sad but true we can’t do them all. This car is intended to be a daily driver for my golden years and I’d like to wear it out before I hang up the keys.

-

Hi Frank, I have a long narrow tank made for bluing rifle barrels I am going to use to cool the cam. Put about two inches of shipping styrofoam packing material under the tank, then put about 5 or more pounds of dry ice in it. Drop the cam in and cover it with alcohol. As I recall that reduces the temp by about 125 degrees. The gear I'll heat another way I haven't determined yet...maybe a propane torch. All of this activity needs to be near my press if something goes wrong and I can't get it to seat. Putting the gear on the crankshaft is another job. I might have the machine shop do that. (one of those "I can't look" things) The last time I saw somebody put a gear on they heated it red hot with a torch. Not sure I want to see that. I was reading on the FB page a question about putting a blower on a 6 cylinder. Being familiar with this engine (and a Continental) I suggested the gear drive such as I have driven off the top of the cam gear where the hydraulic pump used to be. A guy could use a Graham/Kaiser (Continental) centrifugal blower. The cam gear train is super stout and should last forever silently even with the load of a blower. Only one problem, the cam turns backwards compared to the usual chain driven cam. You can tell which cam you have just by looking at it. The fuel pump lobe is at the rear (to make room for the hydraulic pump) and on the first cylinder the exhaust lobe leads the intake ( that tells you the direction it will turn).

-

My worry is "using up" a good block. I have two and one is sleeved and had .030 over bore pistons in it! Maybe I am being silly but I worked on two strokes and they would bore only as much as needed and only the cylinder that needed it. The cam grind I am getting may have a little less lift than the Forklift cam grind, so I am not worried about clearance. The Montana guys web site says there will be no more Edgy heads for "the foreseeable future" so I am not thinking about heads right now. The object next on my radar is fitting it to the 1952 Suburban engine bay.

-

I really don't believe one needs to carry a spare coil. The failure rate of ignition coils is so small as to be unimportant. All the other ignition parts have significant failure rates, caps, rotors, wires, spark plugs all crap out more. Condensers got changed with points mostly out of insurance. I've changed more ignition switches than coils. The biggest reason I changed coils was corrosion. The one notable failure I can remember was one that exploded. It was mounted pointing down and it had leaked for years at the seam between the can and the insulator. One day the owner left the ignition on, it got hot and blew the end off sending hot tar everywhere. I think if you see some leakage I'd worry, if not then don't. A good exercise is to run the engine in a dark garage and watch for electrical "leakage" around the ignition parts. Caps, wires and even coils sometimes light up with leaks. What I would carry if you're concerned is a small can of WD40. It helped me finish a race after hitting a puddle once.

-

all good advice. I was taught about a hundred years ago that it was important to get the polarity right. If you got it backwards the coil would put out about 40% less spark, something in the intervening 99 years I haven't been able to confirm. It's true that point wear (erosion or pitting if you will) does increase with the wrong polarity and it's said you can tell by which way the points pit (or transfer material) if the polarity is wrong. The rule is the points are the ground for the circuit. If the car is positive ground then the positive side of the coil is connected to the points, if negative ground then the negative side of the coil goes to the points. Easy peasy. A little history: Charles "Boss" Kettering was the genius who invented what was known as the "Battery Coil Ignition" what we call the point type ignition. His company the Dayton Electric Company was bought out by Billy Durant's General Motors and merged with another company that made automotive electrical parts, Remy to become Delco-Remy. I am told by the really old-timers that Remy had a reputation for making rather inferior equipment, while Delco made excellent equipment. So Durant merged the strong with the weak. Billy Durant had a good eye for talent and hired Walter P. Chrysler to straighten out and save Buick. Durant however was such a flake he frustrated WPC till he quit. Kettering went on to invent the self-starter, the Tetra-Ethel-Lead fuel additive and improve the Winton 2 cycle diesel engine (Detroit Diesel, Cleveland Diesel and Electro-Motive-Diesel).

-

Finally this week some movement! Isky called to say they were going to grind the cam but they would have to press the gear off. It wouldn't fit in the cam grinder with it on. So I gave my permission. Should be interesting to get it back on. I am thinking I'll have to heat it but I will do some consultation first. Next the machine shop called. They were going to bore the block .030. I protested a little because it was a standard bore and there wasn't much of a ledge. So they will "creep" up on it. Of course hogging it out to a size you know it will clean up is the easy way to do it. Taking the bare minimum means you have to go back and re-bore cylinders if the last one doesn't clean up. They found a .030/.030 crank they'd rather sell than weld my crank. They are going to do the bake/blast cleaning of the heads (I sent two) and the block. It's going to be expensive but I think worth it. Estimated at $3,200. I've been cleaning out my garage to make space to build then install the engine. OMG! I've got a lot of crap! All the Plymouth parts are being gathered in one place and it's very exciting!

-

I recently finished overhauling a Gemmer (Ingersoll Machine in Canada) steering gear from a 1952-56 F100 and modified to fit a Model A Ford. They're basically the same design. The worm (mounted on the steering wheel shaft) is mounted in tapered roller bearings which are adjusted with gasket shims on the lower cover. If you put too much preload on the bearings the car steers with a lot of effort. Too little and there's slop in the steering. Assuming the steering gear was put together correctly then the top adjustment works very well to take up any wear in the gears. On a 60-70 year old car I would expect to see wear and a sector seal that's dry out and leaked. A good winter project might be to remove it and a have a look at things. I'd be curious to know if new gears and bearings are available. Cars in the early 1950s wandered a little and had big steering wheels to give the driver enough leverage to park them easily. Just watch an old movie and you'll see how much drivers moved the steering wheel normally.

-

Just my humble opinion but...you might wanted to remove the pressure regulator. A Plymouth 6 doesn't turn high enough RPM to cause a mechanical fuel pump to overwhelm the float. Those regulators have earned a reputation for problems. It is one of those things that just because something is available it doesn't mean it is useful. Like I said it's only an opinion.

-

Okay, this is how you tell how old it is: The center drawer is called the Bible drawer. It fitted “The Machinery Handbook” that was current when it was made. I think they are up to the twenty seventh or eight edition. My 22d edition I got in 1984 is about an inch too thick. My guess is late 1940s as you said. Gerstner was the last of the wood toolbox makers still in business. When a friend of mine died I sent his toolbox back to them and they restored it for his widow to use as a jewelry box. If you clean it up you’ll see how carefully they match the grain from side to the lid.....I think they use pieces cut from the same board.

-

I wish I had known about the factory Bendix-Stromberg WW 2 barrel factory setup years ago. I was using that carb on another car at the time and could not believe how well it worked. Chrysler used these WWs on some of their V8s as well. Some folks love the Stromberg 97, (so much so they are being reproduced). I went to a carburetor guy (years ago) who actually made 97s under license and he put me on to the WW. He said they were much better. I've talked to Tom Langdon about his Weber/Motorcraft progressive linkage carbs and he's pretty positive about them. Drivability is what he's concerned about and progressive linkage carbs almost guarantee you'll be happy. However, my experience with the WW makes me rather positive on them. So my plan is to go with his carbs (cause he's already worked out the kinks) then after I've had some experience with his setup try my WWs and see which I like better. (I think the bases are very close so its an easy swap) His point is that with progressive linkage carbs you are running on two of four barrels most of the time and when you put your foot in it you get all four. Where as two direct linkage two barrel carbs run on four barrels all the time. Obviously economy could suffer and there might be flat spots. In the race car the engine was so small fuel economy was never an issue and I never had a flat spot or hesitation. When we used a Weber the float would hang up (or something) and the engine would die from fuel starvation, a very embarrassing occurrence. If I had the factory 2 barrel I'd stay with it, even over a two carb manifold. If you want to play with the jets in the WW, the jet wrench and the main jets are the same as a 97 which means they are readily available. They made so many of them kits are available too. eBay has NIB carbs for sale as well for about half the price of a new 97. Just my humble opinion.

-

I love the shape of the Thickstun manifold for a Plymouth! I wish he made them for the Chrysler 25 inch block that would be epic! How long do you figure you'll have to wait for it? Oh and who do you call? A visit to NAPA with the part number I gave you will put them on the page with the long studs I am sure. The Dorman studs are nothing special just available and cheap. At that price you can change them each time you take the manifold off. Just be sure not to screw them in any farther than you have to. On my engine I figure I'll take an average thread depth then make a gauge to prevent the ends from rusting. Too many threads in the water jacket and the ends mushroom with rust and when you go to take them out they snap off. I hate when that happens! The next time I call Tom I'll ask him about the Thickstun Chevy 216 Manifold. I am sure he will have an opinion.

-

I got my studs from Summitracing.com but I am sure NAPA has them on hand. The Dorman box says 675-070 QTY:10 DBL END STUD They were as I said 79 cents each! When you talk to Tom Landon ask him about an intake manifold as well. In projects like this I go for the path of least resistance and I've almost talked myself into his dual carb 2x2 manifold. He takes an Offenhauser Chevy 216 manifold and cuts the flanges off and welds on the correct ones for the Chrysler. The carburetors are 2 barrel Weber/Motorcraft with progressive linkage. He supplies the 1 to 2 barrel adaptors fit them to the manifold. I am thinking the whole ball of wax would be about $1,000. Old Edmunds or Ellis manifolds have been going for $600 and up on eBay so this is not a bad deal at all. Besides you knew it's going to work as this guy knows what he's doing.

-

Hi Ed, I like the looks of their self canceling turn signal! It would be easy to add a cruse control switch to the lever. The restoration of old tube radios is becoming a hobby with a wide following (speaking of table top radio). If one cruises the internet you find all sorts of good information. One site I found gave a primer on capacitors and why you need to change them. However, not all need to be changed. Also in the Mopar 812 there are seven different voltage specs for the capacitors. I found out why and that you could boil it down to three. Instead of 100, 200, 400 500, 1000 and 1600 volt capacitors, all you need are 630, 1000 and 1600 volt. The 630 volt are very common and it doesn't change the performance at all. Like most things electronic as time goes by things get cheaper, smaller and more durable. Some of the capacitors in this radio are of the most durable type and changing them would be counter-productive because other components were tuned to them. The cost for the capacitors you need to change is less than $7.00! I decided to change the capacitors myself and install a voltage reduction device. Not my first choice but it will work. When I get the capacitors I'll post some photos of the change out and which ones to change (there are 12).

-

Well I got the radio and it looks great. The facade is the wrong color of course and scratched. So... I pulled it apart and bead blasted the facade. Happily the scratches didn't go into the metal. I'll send it out for chrome plating next week. Next I called Bob's Radio and TV Service. Once we established what radio I had, we talked about 12 volt conversion. I think he wants to retire as he told me he wanted to pass on my radio. Now if I'd agree to changing over to a modern radio he'd do it. I don't want that and even if I would agree to that, I could certainly do it myself. So now I am looking for another place to convert and restore it. One of the issues is a replacement for the Vibrator Transformer. It steps up the voltage from 6 volts to 530 volts and is one of the key components required to convert to 12 volts. Sometimes one can salvage a 12 volt transformer from the 1956-58 era which will work but they are hard to find.

-

Besides a "Blind hole puller" you can use a big old tap. Just thread it in and then pull it out. Good for generator bushings too. Some guys get an old rusty tap and weld a big nut on the end so they can use a slap hammer or just lever it.

-

I actually found the Photofacts on this site and printed it. Then I went looking for data on vacuum tubes. I was able to find 12 volt versions for all of them accept one. The missing tube does not have a direct cross over but there is a 12 volt tube which has two elements exactly like the 6 volt version inside its envelope. You have to change the socket from 7 pin to 9 pin and use half its elements. The vibrator and the vibrator transformer need to be changed as well. Taking all that into consideration plus the fact I'd like some modern features like Bluetooth and SirrusXM satellite radio, I've decided to let an expert do the work. I mean I am no electronics genius but given enough time and money I know I could figure it out, but why when there are guys who do this everyday out there? The 7 button radio should be here Wednesday and then I'll find out more and report.

-

You are so right! On an old car (especially air cooled) uses about 12 pounds of air to every pound of fuel. And as you say a surprising amount of water is produced. Water from the humidity of the air plus the chemical reaction from combustion. The optimal fuel air ratio for combustion (with cat converters) is about 13.5 to 1 which is on the lean side for performance and way too lean for air cooled engines (a rich mixture displaces air which results in a cooler running engine). I don't know about you but I can not visualize 12 pounds of air! Gasoline is a different matter, 6.3 pounds per gallon. That fuel air ratio is pretty much the same at idle or highway speed. Now diesel works very differently. On a diesel you throttle the fuel not the air. A diesel at idle only needs enough fuel to tick the engine over. While a gasoline engine uses a 12 to 1 ratio at idle a diesel uses 144 to 1 ratio! So what does this have to do with Plymouths and radiators? Not much, I just got carried away. Although Chrysler experimented with diesel powered Plymouths and I know they had radiators. You know a 4bt Cummins will fit in anything that had a flathead 6.

-

The Radiator Shop is an old car owner's best friend! They can clean and repair a radiator with much less fuss than it's worth to DIY. From cleaning out old gas tanks to putting more efficient thicker cores in your radiator, it's good to know the best radiator shop. The Plymouths I've owned have all had honeycomb radiators, which seem to last forever. I would try to have one repaired by experts before replacing with something else. And if it was beyond repair, I'd find a used one before re-coring with the tube and fin type.